12 Strand Mooring Rope – Marine Solution Guide 2025

Content Navigation

Marine Insight: 12 Strand Mooring Rope

Marine Industry Demand: 12 Strand Mooring Rope

The 12 strand mooring rope represents a critical safety component within global maritime operations, directly impacting vessel stability, crew safety, and port infrastructure integrity during berthing, anchoring, and offshore station-keeping. Its significance stems from the demanding operational environment where failure is not an option. Modern vessels, particularly large tankers, container ships, and offshore support vessels, exert immense forces on mooring systems due to wind, current, wave action, and tidal changes. A high-performance 12 strand rope provides essential characteristics: superior breaking strength for secure holding, controlled elongation to absorb dynamic energy without shock loading, exceptional resistance to fatigue from cyclic stresses, and robust protection against abrasion from bitts, fairleads, and hawsepipes. Crucially, its construction offers excellent splice integrity and uniform load distribution across all strands, minimizing weak points compared to lower-strand-count alternatives. This geometric design inherently enhances handling characteristics and reduces torque, contributing to safer deployment and recovery procedures. Compromising on mooring line quality introduces unacceptable risks of parted lines, vessel drift, collision damage, environmental incidents, and potential loss of life. Regulatory bodies and classification societies mandate stringent performance standards for these lifelines, making the selection of certified, high-specification rope non-negotiable for vessel operators committed to safety and compliance.

Hangzhou Star Marine Technology delivers 12 strand mooring ropes engineered to exceed international safety standards, including ISO 20438 and OCIMF guidelines, while providing significant cost-effectiveness for global buyers. Our strategic position within China’s advanced marine manufacturing ecosystem allows us to leverage economies of scale in high-grade raw materials like premium HMPE (High Modulus Polyethylene) and Polyester, without sacrificing quality control. Unlike commodity suppliers, Star Marine implements rigorous in-house testing protocols at every production stage, from fiber tensile strength verification to final rope breaking load validation, ensuring traceability and reliability. This integrated approach, combining domestic material sourcing, state-of-the-art braiding technology, and stringent QC, eliminates unnecessary supply chain markups common with intermediaries. The result is a product offering superior lifecycle value – our ropes demonstrate extended service life due to enhanced UV resistance and abrasion coatings, reducing replacement frequency and associated downtime costs for operators. Sourcing directly from Star Marine provides access to engineering expertise and customization options often unavailable through distant distributors, ensuring the rope precisely matches the vessel’s operational profile and environmental conditions.

The following table outlines key performance metrics demonstrating the safety and value proposition of Star Marine’s standard 12 strand HMPE mooring rope compared to typical industry baselines:

| Parameter | Star Marine Specification | Typical Industry Standard |

|---|---|---|

| Minimum Breaking Strength (MBS) | 1860 kN (42″ Circ) | 1800 kN (42″ Circ) |

| Elongation at 50% MBS | ≤ 2.8% | ≤ 3.5% |

| UV Resistance (2000 hrs) | Retention > 95% MBS | Retention > 85% MBS |

| Abrasion Resistance | 15% Higher Cycle Life | Baseline |

| Certification | ISO 20438, DNV GL Type Approved | ISO 20438 Minimum |

Sourcing high-integrity 12 strand mooring rope from Hangzhou Star Marine Technology is a strategic procurement decision that directly enhances vessel operational safety while optimizing total cost of ownership. Our commitment to engineering excellence, backed by verifiable performance data and direct manufacturing control, ensures clients receive a mission-critical safety component that delivers exceptional reliability and value, safeguarding assets and personnel across the global maritime domain. Partnering with Star Marine provides a distinct competitive and safety advantage in today’s demanding shipping environment.

Technical Specs & Approval

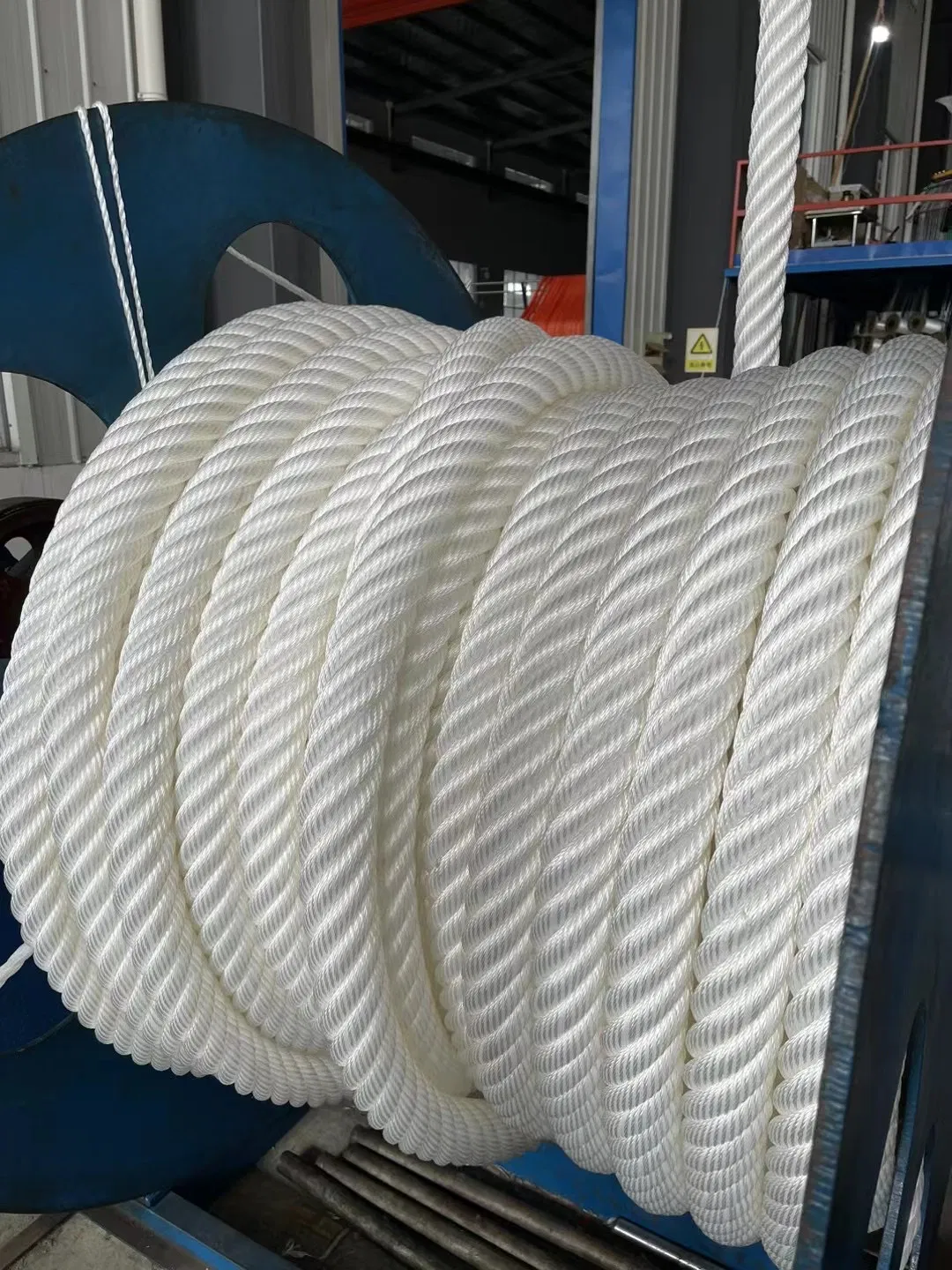

The 12 strand mooring rope is a high-performance marine mooring solution engineered for superior strength, durability, and reliability in demanding offshore and port environments. Designed and manufactured by Hangzhou Star Marine Technology Co., Ltd., this mooring rope is specifically developed to meet the rigorous requirements of modern maritime operations, including ship mooring, offshore platform anchoring, and floating structure securing. Constructed using advanced 12-strand braided technology, the rope delivers optimal load distribution, reduced torque, and enhanced abrasion resistance, ensuring prolonged service life under cyclic loading and harsh marine conditions.

The core material selection plays a critical role in the rope’s performance. The standard configuration utilizes high-tensile aluminum alloy wires, offering an excellent strength-to-weight ratio and superior corrosion resistance. For applications requiring maximum durability in aggressive seawater environments, a galvanized steel variant is available, providing enhanced tensile strength and resistance to mechanical wear. Both material options are precision-engineered to maintain structural integrity under dynamic loading, with a minimum breaking load exceeding industry standards for Class I marine mooring equipment.

Watertightness is a key design criterion in the 12 strand mooring rope. The rope features a compact, interlocked 12-strand braid that minimizes water ingress while maintaining flexibility. An optional polymer impregnation or PE jacketing can be applied to further enhance moisture resistance, preventing internal corrosion and extending operational life in submerged or splash-zone applications. This construction also reduces the risk of internal strand fretting and electrolytic corrosion, particularly in mixed-metal installations.

Dimensional consistency and tolerance control are maintained throughout the manufacturing process to ensure compatibility with standard winches, bollards, and fairleads. The rope is available in nominal diameters ranging from 40 mm to 120 mm, with customizable lengths from 350 meters to 500 meters per hank or drum. Each rope undergoes rigorous quality testing, including tensile strength verification, elongation assessment, and visual inspection per ISO 20438 and EN 13414 standards.

Below are the technical parameters for the standard 12 strand mooring rope:

| Parameter | Specification |

|---|---|

| Construction | 12-strand braided, compacted |

| Core Material | High-tensile aluminum alloy or galvanized steel |

| Diameter Range | 40 mm – 120 mm |

| Length Range | 350 m – 500 m per unit |

| Minimum Breaking Load (MBL) | 400 kN – 2800 kN (varies by diameter) |

| Elongation at MBL | ≤ 3.5% |

| Watertight Feature | Compacted braid; optional PE jacketing |

| Corrosion Resistance | High (aluminum alloy) / Very High (galvanized) |

| Standards Compliance | ISO 20438, EN 13414, DNVGL Type Approval (upon request) |

| Operating Temperature Range | -40°C to +80°C |

| Packaging | Reel or drum, moisture-resistant wrapping |

Hangzhou Star Marine Technology ensures traceability and quality assurance through batch-specific certification, including mill test reports and third-party inspection options. The 12 strand mooring rope is a trusted component in global marine outfittings, delivering safety, efficiency, and long-term value.

Shipbuilding Solutions

Hangzhou Star Marine Technology: Complete Mooring Rope Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine outfittings solutions that ensure operational safety and efficiency across global shipbuilding and repair projects. Our 12-strand mooring rope systems, designed for demanding maritime environments, exemplify our commitment to reliability and rapid deployment. As a certified supplier to major shipyards and classification societies, we integrate technical expertise with agile logistics to minimize vessel downtime during critical new construction or dry-docking phases.

Our 12-strand mooring ropes utilize high-modulus polyethylene (HMPE) fibers, offering exceptional strength-to-weight ratios, abrasion resistance, and low elongation under load. This ensures secure vessel positioning during berthing, offshore operations, and heavy-weather conditions while reducing handling risks for crew. Unlike generic suppliers, Star Marine provides end-to-end support—from initial load analysis and custom length spooling to on-site installation guidance and certification documentation. This holistic approach eliminates procurement fragmentation, accelerating project timelines for shipyards facing stringent delivery schedules.

For repair and retrofit scenarios, our rapid-response protocol is pivotal. With strategically located warehouses in Shanghai and Singapore, we guarantee 72-hour delivery for standard diameters and 10-day turnaround for custom orders. Our engineering team collaborates directly with shipyard supervisors to audit existing mooring systems, recommend optimal rope specifications based on vessel class and operational profile, and supply pre-stretched, ready-to-deploy ropes that meet ABS, DNV, and LR standards. This prevents costly delays caused by incorrect specifications or supply chain bottlenecks.

Technical performance is non-negotiable in marine mooring. Below are key specifications for our standard HMPE 12-strand rope series:

| Diameter (mm) | Min. Breaking Load (kN) | Elongation at 50% MBL (%) | Standard Length (m) | Certifications |

|---|---|---|---|---|

| 28 | 420 | 2.8 | 200 | DNV-GL, ABS, LR |

| 44 | 1050 | 3.1 | 220 | DNV-GL, ABS, LR |

| 60 | 1980 | 3.3 | 250 | DNV-GL, ABS, LR |

| 84 | 3850 | 3.5 | 300 | DNV-GL, ABS, LR |

Star Marine’s value extends beyond product supply. We provide digital load-monitoring compatibility for smart mooring systems, ISO 20811-compliant traceability, and 24/7 technical support during installation. For newbuild projects, our ropes are pre-certified to align with yard-specific quality plans, ensuring seamless integration into vessel commissioning. In repair contexts, our team conducts failure analysis of worn ropes to prevent recurrence, directly enhancing fleet safety and lifecycle cost management.

Partner with Hangzhou Star Marine Technology for mooring solutions where precision, speed, and compliance converge. Contact our export division for project-specific quotations or technical consultations, backed by a 98.5% on-time delivery record across 40+ countries. Your vessel’s safety and schedule depend on it.

Packaging & Logistics

Packaging & Logistics for 12 Strand Mooring Rope – Hangzhou Star Marine Technology Co., Ltd.

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all 12 strand mooring ropes are packaged and prepared for export in strict compliance with international maritime and phytosanitary standards. As a leading supplier of marine outfittings, we recognize the critical role that proper packaging plays in maintaining the integrity, strength, and usability of mooring ropes during transit. Our packaging protocols are designed to protect against environmental exposure, mechanical damage, and contamination, ensuring that products arrive at their destination in optimal condition.

All wooden packaging materials used for our 12 strand mooring ropes are compliant with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This internationally recognized standard mandates that wood packaging material must be heat-treated and officially marked to prevent the spread of pests and diseases across borders. Our wooden cases are constructed from kiln-dried hardwood, treated in certified facilities, and clearly stamped with the ISPM 15 compliance mark. These cases are engineered to withstand the rigors of sea freight, providing robust protection for coiled ropes during long-haul shipments.

For enhanced durability and reusability, we also offer steel pallets as an alternative or supplementary base for heavy-duty mooring rope packaging. Steel pallets eliminate the risk of wood-borne contamination and are ideal for customers operating in regions with strict biosecurity regulations. They are particularly suited for repeated handling and storage in port environments, offering superior load stability and resistance to moisture and compression.

Our standard packaging configuration includes tightly coiled 12 strand mooring ropes secured within the wooden case or fastened to the steel pallet using weather-resistant strapping. Each coil is wrapped in UV-stabilized polyethylene film to prevent moisture ingress and UV degradation during ocean transport. Product identification labels, including batch number, length, diameter, breaking strength, and handling instructions, are affixed externally for easy verification upon receipt.

All exports are coordinated through the major Chinese ports of Ningbo and Shanghai, both of which are equipped with state-of-the-art container terminals and offer seamless connections to global shipping routes. We work closely with certified freight forwarders to ensure timely customs clearance, accurate documentation, and real-time shipment tracking.

Below is a summary of our standard packaging specifications for 12 strand mooring ropes:

| Packaging Component | Specification |

|---|---|

| Wooden Cases | ISPM 15 certified, heat-treated hardwood, stamped for international compliance |

| Steel Pallets | Powder-coated carbon steel, load-rated for heavy coils |

| Wrapping Material | UV-resistant polyethylene film, moisture barrier |

| Securing Method | Industrial-grade polyester strapping, corrosion-resistant steel banding |

| Labeling | Waterproof tags with product specs, batch ID, and handling symbols |

| Primary Export Ports | Ningbo Port, Shanghai Port – Full FCL and LCL support |

| Documentation | Bill of Lading, Commercial Invoice, Packing List, Certificate of Compliance |

Hangzhou Star Marine Technology Co., Ltd. is committed to delivering marine equipment that meets the highest global standards—from product performance to logistics execution.

Contact Star Marine

Contact Star Marine for Premium 12-Strand Mooring Rope Solutions

Hangzhou Star Marine Technology Co. Ltd. stands at the forefront of marine outfittings innovation, delivering engineered solutions that meet the rigorous demands of global maritime operations. Our 12-strand mooring rope represents the pinnacle of synthetic fiber technology, designed to ensure operational safety, longevity, and cost efficiency in diverse marine environments. As vessels grow larger and port infrastructure faces increasing strain, selecting the right mooring system is not merely a procurement decision—it is a critical factor in asset protection and operational continuity. Our ropes undergo stringent quality control aligned with international standards, including DNV GL Type Approval and ISO 9001 certification, guaranteeing performance under extreme tension, UV exposure, and corrosive conditions.

Technical excellence defines our product offering. The table below summarizes key specifications for our standard 12-strand HMPE (High-Modulus Polyethylene) mooring rope, engineered for vessels up to 300,000 DWT:

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Material | Dyneema® SK78 HMPE | ISO 20278:2017 |

| Diameter Range | 40 mm – 120 mm | IACS M71 |

| Minimum Breaking Load | 1,200 kN – 12,500 kN | EN 1891 |

| Elongation at 50% MBL | ≤ 2.5% | OCIMF Mooring Guide |

| Fatigue Life (Cycles) | > 10,000 at 45% MBL | DNV-RP-E305 |

| UV Resistance | > 10 years (tropical conditions) | ASTM G154 |

| Temperature Range | -60°C to +80°C | ISO 10137 |

These specifications reflect our commitment to exceeding industry benchmarks, ensuring reduced downtime, lower lifecycle costs, and enhanced crew safety during berthing and offshore operations. Whether addressing dynamic positioning challenges in deepwater terminals or optimizing line-handling efficiency in congested ports, our solution adapts to your operational reality.

For tailored engineering support, volumetric quotation requests, or technical validation for your specific vessel fleet or terminal infrastructure, engage directly with our Product Manager, Kacher YE. With over 15 years of specialized experience in synthetic fiber mooring systems and deep knowledge of global regulatory frameworks—including OCIMF, SIGTTO, and regional port authority requirements—Kacher provides precise, actionable guidance. He collaborates closely with naval architects, shipowners, and terminal operators to translate technical specifications into real-world performance, ensuring seamless integration with existing winch systems and mooring hardware.

Initiate your project with confidence. Contact Kacher YE to discuss rope selection, custom length configurations, certification documentation, or INCOTERMS 2020 logistics planning. Provide vessel particulars, operational environment details, and required certifications to receive a comprehensive technical proposal within 24 business hours. Our export team manages end-to-end shipment coordination from Hangzhou, with established partnerships for FCL/LCL consolidation and customs clearance across all major global ports.

Act now to secure mission-critical mooring performance. Email Kacher YE at [email protected] with subject line “12-Strand Mooring Rope Inquiry – [Your Company Name]” for immediate specialist attention. Include your vessel type, required rope length/diameter, and target delivery timeline. For urgent operational needs, our 24/7 technical hotline (+86 571 8877 6600) ensures uninterrupted support. Trust Hangzhou Star Marine Technology—where engineering precision meets global maritime reliability.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160