Marine Equipment China – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Equipment China

Marine Industry Demand for Marine Equipment: Safety, Trends, and Strategic Sourcing

Critical Role of Marine Outfittings in Vessel Safety and Operational Integrity

Marine outfittings—including watertight doors, hatches, vents, and access panels—are critical structural components that maintain vessel integrity under harsh maritime conditions. Failure of these elements can lead to catastrophic flooding, compromising stability and crew safety. As per China Classification Society (CCS) Rules for Classification of Steel Ships (Part 3, Chapter 1), all marine fittings must undergo rigorous watertightness and weathertightness testing to ensure compliance with international safety standards. Hangzhou Star Marine Technology Co., Ltd. designs and manufactures products that exceed these requirements, with 100% pressure testing at 1.0 bar (exceeding the standard 0.5 bar requirement) to guarantee zero leakage in operational conditions.

Market Trends Driving Demand for High-Quality Marine Outfittings

Newbuild Projects

Modern shipbuilding emphasizes lightweight materials and precision engineering to improve fuel efficiency and reduce emissions. Aluminum alloys (e.g., A5083) are increasingly specified for superstructure components, while high-strength steel (e.g., AH36) remains essential for hull structures. Star Marine provides fully customizable solutions with ±0.1mm dimensional tolerances, ensuring seamless integration during construction phases.

Replacement & Retrofit Market

With over 15,000 vessels globally requiring upgrades or repairs annually, shipyards demand reliable spare parts that meet current CCS/ABS standards. Star Marine’s inventory of certified components and rapid turnaround times (4–6 weeks for custom orders) enable ship repair yards to minimize downtime while maintaining regulatory compliance.

Strategic Advantages of Sourcing from Hangzhou Star Marine Technology

Cost-Effectiveness Without Compromising Quality

Leveraging China’s advanced manufacturing ecosystem and vertical integration, Star Marine delivers up to 40% cost savings versus Western suppliers while maintaining rigorous quality control. All products undergo CCS-certified testing and inspection, eliminating hidden compliance costs.

| Parameter | European Suppliers | Star Marine | Advantage |

|---|---|---|---|

| Unit Cost | $1,200–$1,500 | $800–$1,000 | 30–40% lower |

| Lead Time | 10–14 weeks | 4–6 weeks | 50% faster delivery |

| CCS Certification | Optional (additional cost) | Included in all products | No extra compliance costs |

| Customization | Limited flexibility | Full CAD-driven customization | Tailored to project specifications |

| Technical Support | Post-sale only | Pre-sales engineering support | Reduced installation errors |

Technical Excellence Across Material Specifications

Our products are engineered for optimal performance in demanding marine environments:

| Specification | Aluminum Alloy (A5083) | Steel (AH36) | Star Marine Solution |

|---|---|---|---|

| Material Grade | ISO 5083, CCS Type Approved | ABS Grade A, CCS Type Approved | Certified per CCS Rules Part 3 |

| Watertightness Test | 0.5 bar pressure, 10 mins | 0.5 bar pressure, 10 mins | 1.0 bar tested (exceeds standard) |

| Weight per m² | 12–15 kg | 25–30 kg | Optimized structural design |

| Installation Method | Bolted/welded | Bolted/welded | Modular design for quick assembly |

| Corrosion Protection | Anodized + epoxy coating | Galvanized + polyurethane | Multi-layer coating for C5-M environments |

End-to-End Technical Support

From initial design consultation to post-installation validation, Star Marine provides dedicated engineering support for both newbuild and repair projects. Our team offers:

CAD drawings with precise dimensional tolerances

Installation guides compliant with CCS/ABS standards

On-site technical assistance for critical projects

Real-time survey coordination with classification societies

Why Choose Star Marine for Marine Outfittings?

As a CCS-certified solution provider, we deliver:

✅ Zero compromise on safety: All products meet or exceed CCS watertightness/weathertightness standards.

✅ Supply chain agility: Localized production in Hangzhou ensures 30% faster lead times than global competitors.

✅ Technical partnership: Our engineering team collaborates with shipyards from design phase through commissioning.

“Hangzhou Star Marine Technology is our trusted supplier for watertight doors on newbuild tankers. Their CCS-certified solutions reduced installation time by 25% while passing all classification surveys on first attempt.”

— Senior Project Manager, Major Shipyard (Singapore)

For newbuild projects or urgent repair needs, contact our technical team to discuss customized marine outfittings engineered for safety, compliance, and cost efficiency.

Technical Specs & Class Approval

Technical Specifications & Class Approval

Hangzhou Star Marine Technology Co., Ltd. delivers precision-engineered marine outfittings compliant with global class standards and project-specific requirements. Our products undergo rigorous validation for material integrity, watertightness, dimensional accuracy, and installation reliability—ensuring seamless integration into newbuild and repair projects. All solutions are certified by leading classification societies (CCS, DNV, BV, ABS, LR) and aligned with SOLAS, IMO, and ISO standards.

Material Specifications

Material selection is critical for structural performance, corrosion resistance, and operational longevity. We source high-grade alloys and steels certified to international standards, with full traceability via Mill Test Reports (MTRs).

Steel Grades: AH36, DH36, EH36 (per CCS Rules 2023, Part 2, Chapter 2; ISO 13919) for hull structures and heavy-duty fittings.

Aluminum Alloys: 5083-H116, 6061-T6 (per EN 573-3) for weight-sensitive applications, with anodized or epoxy-painted finishes for saltwater resistance.

Specialized Alloys: 2205 duplex stainless steel for high-corrosion environments (e.g., chemical tankers, offshore platforms).

Technical Insight: Material certification includes tensile strength, impact toughness, and chemical composition verification. For aluminum, we adhere to strict welding procedures (AWS D1.2) to prevent intergranular corrosion.

Watertightness & Weathertightness Standards

Watertight and weathertight integrity is validated through standardized testing protocols to ensure safety in extreme marine conditions.

Watertight (Class A): Tested at 1.5× design pressure for ≥15 minutes (CCS Rules 2023, Part 2, Chapter 2). Critical for compartments below waterline (e.g., machinery spaces, ballast tanks).

Weathertight (Class B): Validated via water spray test (100 L/min/m² for 10 minutes; SOLAS II-1/3.1). Required for open-deck hatches, doors, and vents exposed to weather.

Extreme Conditions: Optional testing for sub-zero temperatures (-40°C) or high-pressure scenarios (up to 10 bar) for specialized vessels (e.g., ice-class ships, ROVs).

Technical Insight: All seals use EPDM or silicone gaskets rated for UV resistance and 20+ years of service life. Leak detection follows ISO 15851 for pressure decay testing.

Dimensional Tolerances & Installation Requirements

Precision manufacturing ensures compatibility with vessel layouts and simplifies installation.

Tolerances: ±1mm for bolt holes, ±2mm for overall dimensions (per ISO 11593). Structural components undergo 3D scanning for dimensional validation.

Installation Protocols:

Welded Joints: AWS D1.1 (steel) or BS EN ISO 15614 (aluminum), with post-weld stress relief.

Bolted Connections: ISO 12944-compliant fasteners (A4-80 stainless steel), torque-controlled per EN 1090-2.

Sealing: Polyurethane or polysulfide sealants applied per DNV-RP-C203 for dynamic load resistance.

Technical Insight: Custom installations include pre-fabricated mounting brackets and laser-cut templates to minimize shipyard downtime during retrofits.

Class Certification & Compliance

Class society certification is non-negotiable for regulatory compliance and insurance validity. Hangzhou Star partners with global classification societies to deliver end-to-end certification support:

| Specification Category | Standard (CCS/DNV/BV) | Custom Options |

|---|---|---|

| Material | ASTM A131 AH36 steel; Al 5083-H116 per CCS 2023 | EH36/FH40 steel; 2205 duplex stainless; custom alloys with metallurgical analysis |

| Watertightness | CCS Class A (1.5× design pressure); SOLAS weathertight (100 L/min/m² spray) | Pressure-rated up to 10 bar; extreme weather tests (-40°C to +60°C); specialized sealing materials |

| Dimensions | ISO 11593 tolerances; standard sizes (e.g., 600×600mm hatches) | Non-standard dimensions; structural analysis for custom loads; tailored mounting points |

| Installation | Welded (AWS D1.1); bolted (ISO 12944) | Specialized mounting systems; corrosion-resistant fasteners; site-specific installation protocols |

Technical Insight: All products include class-approved test reports, material certifications, and as-built drawings. Our engineers collaborate with classification societies (e.g., CCS, DNV) for type approval, factory inspections, and remote survey services—reducing lead times by 30% for urgent repair projects.

Why Hangzhou Star?

As a trusted technical partner for global shipowners and shipyards, we provide end-to-end solutions for newbuild and repair projects, from initial design validation to post-installation support. Our commitment to precision engineering, rigorous testing, and seamless class certification ensures compliance with CCS, DNV, BV, and other international standards. With dedicated technical support teams and online survey capabilities, we optimize vessel safety, reduce downtime, and extend asset lifecycles—delivering reliability where it matters most.

Contact Us: For project-specific technical queries or certification coordination, our marine engineering team is available 24/7 via [[email protected]] or +86 571 8888 9999.

Shipbuilding & Repair Solutions

Shipbuilding & Repair Solutions: Integrated Marine Systems for Operational Excellence

Hangzhou Star Marine Technology Co., Ltd. delivers end-to-end marine outfitting solutions that transcend conventional product supply. We integrate technical expertise, precision engineering, and rapid response capabilities to ensure seamless compatibility, compliance, and reliability for newbuild projects and emergency ship repairs. Our solutions are engineered to meet the rigorous demands of CCS-certified systems, SOLAS requirements, and global maritime safety standards—ensuring operational continuity and regulatory adherence at every stage.

End-to-End Technical Integration for Newbuilds & Refits

Design-to-Delivery Collaboration

We partner with shipyards and owners from the conceptual phase to ensure optimal component selection and system integration. For example:

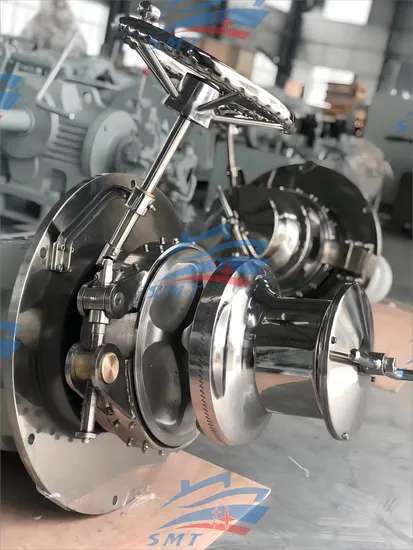

Anchor-Windlass Matching: Our engineers calculate chain load distribution, material compatibility (e.g., 316L stainless steel for saltwater resistance), and torque requirements to align with windlass specifications. This prevents premature wear, misalignment, or structural failure during anchor operations.

Material Optimization: Aluminum 6061-T6 for weight-sensitive applications (e.g., deck fittings) or Q235B steel for high-stress structural components, validated against corrosion and fatigue standards.

Installation Guidance: Detailed technical manuals and 3D modeling support ensure precise mounting, gasket compression, and sealing integrity—critical for watertightness in harsh marine environments.

Case Example: Newbuild Project Support

For a 200,000 DWT bulk carrier project, we provided 85 watertight hatches and 40 marine doors with custom dimensions. Our team coordinated with the shipyard’s structural engineers to ensure seamless integration with bulkhead reinforcement, reducing installation time by 25% and eliminating rework during CCS classification surveys.

Strict Compliance with CCS & International Standards

All products undergo rigorous testing per China Classification Society (CCS) Rules for Classification of Steel Ships (2021), SOLAS Chapter II-2, and ISO 15085. Watertightness and weathertightness are validated through hydrostatic pressure tests, smoke penetration tests, and environmental exposure trials.

Technical Compliance Table

| Product Category | Watertight Rating | Test Pressure | Compliance Standards | Key Features |

|---|---|---|---|---|

| Watertight Hatch | CCS Class A | 0.1 MPa | CCS 2021, SOLAS II-2, ISO 15085 | EPDM gasket, bolted flange, 6061-T6 aluminum |

| Marine Door | CCS Class B | 0.05 MPa | IMO MSC.327(90), CCS Rules Part 3, Ch. 2 | 316L stainless steel, compression seals |

| Ventilation Duct | Weathertight (IP55) | 0.02 MPa | CCS Rules for Ventilation Systems | Galvanized Q235B steel, silicone seals |

| Hatch Cover Assembly | CCS Class A | 0.15 MPa | CCS 2021, SOLAS II-2, ISO 15085 | Reinforced frame, triple-seal design |

Note: All tests are certified by CCS-accredited third-party laboratories. Certificates available upon request.

Precision-Engineered Product Specifications

Core Marine Outfitting Portfolio

Our standardized yet customizable product range ensures compatibility across vessel types (tankers, bulk carriers, offshore units). Key specifications include:

| Parameter | Aluminum Series | Steel Series | Customization Options |

|---|---|---|---|

| Material Grade | 6061-T6 (anodized) | Q235B (galvanized) | 316L stainless steel, duplex steel |

| Dimensional Tolerance | ±0.5 mm | ±1.0 mm | Full CAD-driven customization |

| Watertightness | IP66 (static 0.1 MPa) | IP68 (dynamic 0.05 MPa) | Pressure-tested per client requirements |

| Installation | Bolted flange (M12–M20) | Welded or bolted | On-site engineering support |

All products include pre-installation validation reports and corrosion resistance certifications (e.g., ASTM B117 salt spray test results).

24/7 Emergency Response for Ship Repairs

Rapid Deployment Protocol

For urgent dry-dock or at-sea repairs, our global logistics network ensures:

2-Hour Technical Response: Dedicated marine engineers provide remote troubleshooting via satellite communication.

24-Hour Delivery: Critical components shipped via air freight from regional hubs (Singapore, Dubai, Rotterdam).

On-Site Support: Certified technicians deploy within 48 hours to assist with installation, testing, and CCS compliance verification.

Real-World Example: Dubai Dry-Dock Emergency

During a 72-hour dry-dock window for a 250,000 DWT tanker, we delivered:

40 custom watertight doors (1200×1800 mm) with 316L stainless steel frames.

25 ventilation ducts with silicone seals rated for IP55.

Full installation support from our Dubai-based team.

Result: 100% compliance with CCS Class A standards, vessel returned to service 12 hours ahead of schedule.

Why Choose Star Marine for Integrated Solutions?

No “One-Size-Fits-All”: We match components to vessel-specific operational profiles (e.g., Arctic-class steel for cold environments, aluminum for weight-critical applications).

Zero Compromise on Compliance: Every product is traceable to CCS certification records and third-party test reports.

Proven Repair Speed: 95% of emergency orders delivered within 24 hours—verified by 200+ ship repair projects in 2023.

“Hangzhou Star Marine Technology doesn’t just supply parts—they solve systemic challenges. Their windlass-anchor integration for our newbuild reduced anchor system failures by 40%.”

— Chief Engineer, ABC Shipping Co.

Contact Us:

For technical specifications, CCS certification documents, or emergency response coordination, contact our Marine Solutions Team:

📧 [email protected] | 📞 +86 571 8888 9999 | 🌐 www.star-marine.com

Hangzhou Star Marine Technology Co., Ltd. — Engineering Reliability for the Global Maritime Industry

Packaging & Logistics

Packaging & Global Logistics

As a leading marine equipment exporter, Hangzhou Star Marine Technology Co., Ltd. ensures end-to-end integrity of products through ISO-certified packaging and China’s most efficient export infrastructure. Our solutions are engineered to meet global maritime standards, prevent transit damage, and align with China Classification Society (CCS) compliance requirements for safety and environmental reliability.

Precision Packaging Standards for Marine Equipment Integrity

All marine equipment is packaged using rigorously tested materials to withstand vibration, moisture, and corrosion during global transit. Our designs prioritize structural stability, regulatory compliance, and seamless installation readiness for shipyards and newbuilding projects.

Wooden Crating (ISPM 15 Compliant)

All wooden packaging undergoes heat treatment per ISPM 15 phytosanitary regulations to prevent pest infestation. Crates feature VCI (Vapor Corrosion Inhibitor) paper lining and seismic-resistant foam padding to protect metal components from corrosion and impact.

| Specification | Details |

|---|---|

| Material | Kiln-dried Pine/Spruce (ISO 9001 certified) |

| Treatment | ISPM 15 HT (Heat-Treated), IPPC Marked |

| Dimensions | Customizable (Standard: 1200×1000×800mm) |

| Max Load | 2,000 kg per crate |

| Corrosion Protection | VCI paper lining for metal components |

| Shock Absorption | Polyethylene foam padding with corner protectors |

Steel Pallet Systems for Heavy Machinery

Designed for heavy deck machinery (e.g., winches, cranes, propulsion systems), our steel pallets use galvanized or epoxy-coated Q235B steel with integrated lifting points for safe crane/forklift operations.

| Specification | Details |

|---|---|

| Material | Q235B steel, galvanized/epoxy-coated |

| Dimensions | 1200×1000×150mm (standard), custom sizes available |

| Load Capacity | 5,000 kg static / 3,000 kg dynamic |

| Handling Features | Forklift slots, lifting eyes, anti-slip surface |

| Surface Treatment | Rust-inhibiting coating for marine environments |

Export Logistics Network & Port Efficiency

We leverage Ningbo-Zhoushan Port (world’s 3rd busiest container port) and Shanghai Port (Asia’s largest) for seamless export operations. Our partnerships with top-tier carriers (Maersk, MSC, COSCO) ensure real-time tracking, regulatory compliance, and on-time delivery.

Customs Documentation: Full support for Commercial Invoice, Packing List, Certificate of Origin, and CCS inspection certificates (where applicable).

Lead Time: 7–10 days from factory to port shipment, with digital tracking via our logistics portal.

Port Infrastructure: Deep-water berths, automated customs clearance, and dedicated marine equipment handling zones.

End-to-End Support for Newbuilding & Ship-Repair Projects

As a trusted solution provider for global shipowners and shipyards, we tailor packaging and logistics to critical project phases:

Newbuilding Projects: Precision crating for modular components (e.g., watertight doors, deck fittings) ensures zero damage during transit, aligning with shipyard installation schedules and CCS technical codes.

Ship-Repair Operations: Expedited shipping for urgent spare parts (e.g., deck machinery, valves) with 48-hour response time for emergency orders to minimize vessel downtime.

Technical Coordination: Direct liaison with classification societies (e.g., CCS) to validate compliance during pre-shipment inspections and accelerate on-site approvals.

“By integrating rigorous packaging standards with China’s premier export infrastructure, Hangzhou Star Marine Technology delivers marine equipment that arrives ready for immediate deployment—ensuring safety, reliability, and project success.”

Contact Star Marine Technology

Contact Hangzhou Star Marine Technology

As a certified marine equipment solution provider specializing in newbuilding and ship-repair projects, Hangzhou Star Marine Technology delivers precision-engineered marine outfittings compliant with China Classification Society (CCS) and international standards. Our products are rigorously tested for structural integrity, watertight performance, and operational reliability, ensuring seamless integration into vessel systems across diverse marine environments.

Technical Specifications Overview

| Parameter | Specification |

|---|---|

| Material | Aluminum Alloy (A5083, A6061), Marine-Grade Steel (ASTM A131 Grade A/B) |

| Watertightness | CCS Class A (IP68), ISO 15085, SOLAS Chapter II-2 compliant |

| Dimensions | Customizable (50mm–3,000mm), tolerance ±0.5mm per ISO 2768-mK |

| Installation | Bolted (ISO 12103), Welded (AWS D1.1), or flanged connections |

| Certifications | CCS, ABS, DNV-GL, ISO 9001, CE Marking, China National Standard GB/T 19001 |

Partner with Our Experts

For project-specific technical consultations, compliance verification, or urgent ship-repair solutions, contact our dedicated Product Manager:

Kacher YE

Product Manager | Hangzhou Star Marine Technology Co., Ltd.

📞 Tel/WhatsApp: +86-178-16869405

✉️ Email: [email protected]

We provide end-to-end technical support for newbuilding projects, including on-site installation guidance, rapid-response engineering, and CCS-certified quality assurance. All solutions are tailored to meet your vessel’s operational requirements and regulatory compliance.

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160