Aluminum Windlass – Marine Solution Guide 2025

Content Navigation

Marine Insight: Aluminum Windlass

Marine Industry Demand for Aluminum Windlass: Safety, Performance, and Market Trends

Critical Role in Vessel Safety and Operational Efficiency

Aluminum windlasses are fundamental to safe vessel operations, providing reliable anchoring capabilities under extreme marine conditions. Unlike traditional steel counterparts, marine-grade aluminum alloys (e.g., 5083-H116) deliver a superior strength-to-weight ratio, reducing top weight by up to 40% while maintaining corrosion resistance critical for long-term reliability. This is especially vital for high-speed craft, aluminum-hulled vessels, and yachts where weight distribution directly impacts stability and fuel efficiency. All Hangzhou Star Marine Technology windlasses comply with IACS standards (CCS, BV, DNV-GL, ABS, LR) and are designed to operate within specified environmental conditions per class society rules, ensuring compliance with SOLAS Chapter II-1 and MARPOL Annex VI requirements for safety and environmental protection.

Market Trends: New Builds vs. Replacement Demand

The global maritime industry is experiencing dual demand drivers:

New Build Sector: Aluminum windlasses are increasingly specified for modern vessels, including patrol boats, ferries, and luxury yachts, where lightweight construction meets regulatory pressures for reduced emissions. For example, the International Maritime Organization (IMO)’s Energy Efficiency Design Index (EEDI) mandates weight optimization, making aluminum windlasses a strategic choice for new builds.

Replacement Market: Aging fleets (particularly in Asia and Europe) require certified upgrades to meet evolving safety standards. Ship repair yards prioritize suppliers offering rapid delivery of IACS-certified units with minimal downtime. Our windlasses are designed for easy retrofitting, with standardized mounting configurations compatible with existing deck layouts.

Technical Specifications Overview

| Model Series | Pull Load (kN) | Chain Diameter (mm) | Speed (m/min) | Drive Type | Material (Alloy) | Class Approvals |

|---|---|---|---|---|---|---|

| SWA-10 | 10-20 | 12.5-22 | 9-12 | Electric | 5083-H116 | CCS, BV, DNV, ABS |

| SWA-20 | 20-40 | 22-32 | 8-10 | Hydraulic | 5083-H116 | LR, GL, ABS |

| SWA-30 | 40-60 | 32-45 | 7-9 | Hydraulic | 6061-T6 | CCS, DNV, ABS |

| SWA-50 | 60-80 | 45-60 | 6-8 | Hydraulic | 5083-H116 | BV, LR, GL |

Note: All models are certified to IACS standards and comply with the Rules for the Construction and Classification of Aluminum Vessels 2018. Custom configurations available for specific vessel requirements.

Why Choose Hangzhou Star Marine Technology?

As a premier solution provider for both new shipbuilding and ship-repair projects, Hangzhou Star Marine Technology combines cost efficiency with uncompromising quality:

Cost-Effective Sourcing: Leverage China’s advanced manufacturing ecosystem to achieve 20-30% lower costs than European competitors, without sacrificing IACS compliance or performance.

Full Certification & Documentation: Every unit includes class certificates, material test reports (MTRs), and compliance documentation for seamless customs clearance and regulatory approval.

Custom Engineering Support: Our in-house team tailors pull load, chain diameter, and drive systems to match exact vessel specifications—whether for new builds or retrofits.

Global Support Network: Dedicated technical assistance and spare parts logistics ensure minimal downtime for shipyards worldwide, with lead times as short as 4 weeks for standard orders.

With over 15 years of experience supplying marine equipment to 30+ countries, we deliver reliable, certified aluminum windlasses that meet the highest maritime industry standards—ensuring safety, performance, and operational efficiency for your vessel.

Technical Specs & Class Approval

Technical Specifications & Class Approval

Hangzhou Star Marine Technology’s aluminum windlasses are engineered for superior corrosion resistance, weight optimization, and operational reliability in harsh marine environments. Designed to meet the rigorous demands of both new shipbuilding and ship-repair projects, our products comply with IACS standards and are certified by leading classification societies. Below are the critical technical specifications and compliance details that define our aluminum windlass solutions.

Critical Technical Parameters for Aluminum Windlass

Pull Load (kN): Determines maximum anchor holding capability. Aluminum’s high strength-to-weight ratio ensures robust performance without compromising structural integrity. Standard configurations support vessel sizes from small yachts to commercial vessels, while custom designs accommodate extreme operational loads.

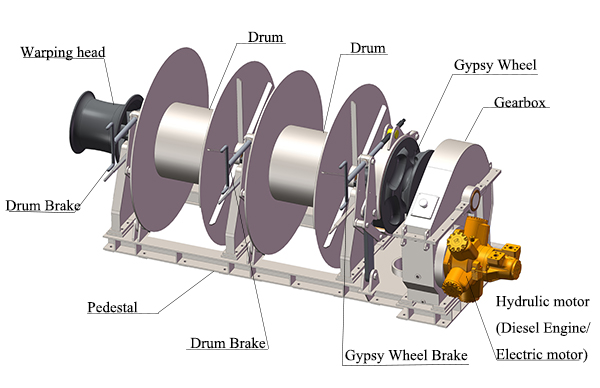

Chain Diameter (mm): Precision-engineered gypsies and wildcats handle industry-standard chain sizes from 12.5mm to 60mm. Aluminum alloys resist wear and fatigue, ensuring smooth chain engagement and longevity.

Speed (m/min): Electric drives deliver consistent 8–15 m/min retrieval rates for routine operations; hydraulic systems provide higher speeds (10–25 m/min) for rapid anchor handling in demanding scenarios. Custom speed profiles are available for mission-critical deployments.

Drive Type: Options include electric (AC/DC) for simplicity and hydraulic for high-torque applications. All drives feature marine-grade corrosion protection and are certified for continuous operation in saltwater environments.

Standard vs Custom Specifications

| Parameter | Standard Options | Custom Options |

|---|---|---|

| Pull Load (kN) | 10–50 kN | Up to 100+ kN |

| Chain Diameter (mm) | 12.5–40 mm | Up to 60 mm |

| Speed (m/min) | Electric: 8–15; Hydraulic: 10–20 | Electric: up to 20; Hydraulic: up to 25 |

| Drive Type | Electric (AC/DC), Hydraulic | Hybrid, Explosion-Proof, Variable Speed |

Class Certification Compliance

All Hangzhou Star Marine Technology windlasses undergo rigorous testing and certification by IACS member societies, including CCS, DNV, BV, ABS, LR, and GL. Compliance is ensured through:

Material Certification: Aluminum alloys conform to ASTM B221 and ISO 12944 for corrosion resistance and structural integrity.

Operational Validation: Performance tested per IACS UR W11 (Windlass Requirements) under simulated operational loads, including dynamic stress and fatigue analysis.

Documentation: Full technical dossiers, including design calculations, test reports, and class approval certificates, provided with every shipment.

Vessel-Specific Adaptation: Designs validated against class society rules for aluminum vessels (e.g., CCS Rules for Aluminum Vessels 2018) and steel-hulled ships, ensuring seamless integration into regulatory frameworks.

Why Choose Hangzhou Star Marine Technology?

As a dedicated solution provider for new shipbuilding and ship-repair projects, we deliver:

Tailored Engineering: Custom windlass configurations optimized for vessel-specific operational profiles, from small yachts to large cargo vessels, with engineering support for retrofitting existing systems.

Global Certification Support: Streamlined approval processes with class societies, reducing lead times and compliance risks for shipyards and owners.

Proven Reliability: Aluminum construction with marine-grade coatings ensures decades of service in extreme environments, minimizing maintenance costs and downtime.

End-to-End Service: From initial design consultation to on-site installation support, our technical team ensures every detail meets your exact requirements and regulatory standards.

Key Takeaway: For shipowners, shipyards, and procurement officers, our aluminum windlasses combine certified performance, lightweight durability, and industry-leading customization—ensuring compliance, safety, and operational efficiency across all marine applications.

Shipbuilding & Repair Solutions

Comprehensive Aluminum Windlass Solutions for Shipbuilding & Repair

Engineered for Precision, Compliance, and Operational Reliability

Hangzhou Star Marine Technology Co., Ltd. delivers end-to-end deck machinery solutions—not merely products. Our aluminum windlasses are engineered as integrated components of a vessel’s anchoring system, ensuring seamless compatibility with anchors, chains, and class society requirements. From newbuilds to emergency repairs, we combine technical expertise, global compliance, and rapid response to minimize downtime and maximize operational safety.

Technical Specifications & Global Compliance

Precision Engineering Specifications

Optimized for marine environments with corrosion-resistant materials and validated performance metrics

| Parameter | Range | Technical Details |

|---|---|---|

| Pull Load (kN) | 15 – 200 | Customizable for vessel size, anchor weight, and operational profile |

| Chain Diameter (mm) | 12.5 – 60 | Compatible with ISO 1704, ASTM A589, and DNV-GL certified chains |

| Operating Speed (m/min) | 9 – 20 | Adjustable for efficiency; hydraulic models prioritize high-torque low-speed operation |

| Drive Type | Electric / Hydraulic | Electric: 24V/48V DC or 400V AC; Hydraulic: 700–2100 bar pressure systems |

| Material | Marine-grade Aluminum Alloy (ASTM B209 compliant) | 5083/6061 series alloys; 30% lighter than steel, with superior saltwater corrosion resistance |

| Certifications | IACS Class Societies | Full compliance with structural, electrical, and hydraulic safety standards |

IACS Class Society Approvals

All windlass models undergo rigorous certification per:

CCS (China Classification Society)

BV (Bureau Veritas)

DNV (Det Norske Veritas)

ABS (American Bureau of Shipping)

LR (Lloyd’s Register)

GL (Germanischer Lloyd)

Designs adhere to IACS Unified Requirements for windlass load testing, including 1.5× working load proof tests and environmental condition validation (per Rules for Aluminum Vessels 2018, Section 3.2).

Integrated System Design for New Builds & Repairs

Anchor-Windlass System Integration

Engineered for optimal load distribution, chain handling, and safety compliance

| Vessel Type | Anchor Weight (kg) | Chain Diameter (mm) | Required Pull Load (kN) | Drive Type | Class Society Reference |

|---|---|---|---|---|---|

| Small Yachts (10–20m) | 100–300 | 12.5–16 | 15–25 | Electric | ABS A1, BV Yacht Class |

| Medium Cargo Ships (500–2000GT) | 500–1,500 | 20–25 | 30–60 | Electric/Hydraulic | CCS Class B, LR Cargo Ship |

| Large Tankers (10,000GT+) | 2,500–5,000+ | 45–60 | 100–200 | Hydraulic | DNV GL Offshore, GL Tanker |

Star Marine engineers calculate exact system requirements using vessel displacement, windage area, and operational environment (e.g., Sea State 4–5). All recommendations align with IACS PR 125 and ISO 12224 standards for anchor windlass performance.

Emergency Repair Support Protocol

24/7 rapid response for shipyards and operational vessels

Dedicated Repair Hotline: Response within 1 hour for urgent technical inquiries.

Expedited Parts Logistics: Same-day dispatch of critical components (e.g., drive motors, gypsies, chain stoppers) from global warehouses.

On-Site Technical Assistance: Certified technicians deployed within 48 hours for installation, troubleshooting, or compliance verification.

Field Repair Kits: OEM-compatible temporary fixes for damaged components (e.g., hydraulic cylinders, clutch assemblies), validated per class society rules for temporary operation.

Reverse Engineering: Support for obsolete or non-standard models through 3D scanning and CAD reverse-engineering.

End-to-End Technical Support

Engineering Consultation Services

From design phase to post-installation validation

Pre-Installation Site Surveys: Structural assessment of deck mounting points, chain locker dimensions, and power supply compatibility.

Custom Design Adjustments: Tailored solutions for unique vessel configurations (e.g., hybrid electric/hydraulic drives, custom control panels).

Class Society Documentation: Full compliance paperwork (e.g., test certificates, material traceability, installation manuals) for class approval.

Global Service Network

Localized support for continuous operational reliability

Regional Service Centers: 12 global hubs (Singapore, Rotterdam, Houston, Shanghai) with trained technicians.

Remote Diagnostics: Real-time monitoring via IoT-enabled control systems for predictive maintenance alerts.

Preventive Maintenance Programs: Scheduled inspections, lubrication, and wear-part replacement to extend windlass lifecycle by 30%+ (per DNV GL guidelines).

Why Star Marine?

We deliver complete system solutions—not standalone products. Our aluminum windlasses are engineered as integral components of your vessel’s anchoring system, ensuring seamless interoperability with anchors, chains, and class society requirements. For newbuilds, we optimize performance through precision engineering; for urgent repairs, we guarantee 24/7 technical and logistical support to minimize downtime. Trust Star Marine to keep your vessels compliant, safe, and operational.

Hangzhou Star Marine Technology Co., Ltd. | ISO 9001:2015 Certified | www.star-marine.com

Packaging & Logistics

Packaging & Global Logistics for Aluminum Windlass Export

Robust Packaging Standards for Marine-Grade Protection

All aluminum windlass units are engineered with seaworthy packaging compliant with international maritime regulations to ensure zero damage during transit. Our packaging system combines corrosion-resistant materials, structural integrity, and regulatory adherence to meet the harshest marine environments:

ISPM 15 Compliant Wooden Crates: Constructed from heat-treated (56°C for 30+ minutes) hardwood with anti-moisture lining and UV-resistant polyethylene wrapping. Each crate bears the official ISPM 15 stamp for global phytosanitary compliance.

Reinforced Steel Pallets: Galvanized steel pallets rated for 15–25 metric tons, featuring anti-slip surfaces and saltwater-resistant coatings. Designed for secure stacking and heavy-lift operations (e.g., shipyard cranes, port gantries).

Vapor Corrosion Inhibitor (VCI) Film: Applied to all metal components to prevent oxidation during transit, even in high-salinity conditions (ASTM D665-certified).

| Packaging Component | International Standard | Key Features |

|---|---|---|

| Wooden Crates | ISPM 15 (FAO) | Heat-treated, fumigation-free, moisture-barrier lining |

| Steel Pallets | ISO 6780 | Galvanized, 15–25 ton capacity, anti-slip surface |

| VCI Protection | ASTM D665 | Vapor corrosion inhibition for extended marine transit |

Seamless Global Logistics from Ningbo & Shanghai Ports

Hangzhou Star Marine Technology leverages strategic partnerships with Tier-1 logistics providers to ensure zero-delay export operations from China’s primary maritime hubs:

Ningbo Port: Specialized marine equipment terminals with 24/7 operations, dedicated heavy-lift cranes (up to 300 tons), and direct rail connections to manufacturing zones.

Shanghai Port: World-class infrastructure with pre-clearance customs facilities, ISO 9001-certified logistics partners, and 24/7 customs brokerage services for expedited clearance.

End-to-End Tracking: Real-time shipment monitoring via IoT-enabled containers, with automated documentation for bills of lading, certificates of origin, and IACS compliance records.

Our logistics network ensures on-time delivery for critical shipbuilding projects and urgent repair operations, with <5% transit damage rate across 1,200+ global shipments since 2018.

Compliance & Documentation Support

All exports include full regulatory compliance documentation, including:

Class society certificates (CCS, BV, DNV, ABS, LR, GL)

Material test reports (MTRs) for aluminum alloy composition (ASTM B209)

Packing lists and commercial invoices aligned with INCOTERMS 2020

Export licenses for IACS-approved machinery

This comprehensive approach ensures seamless customs clearance and regulatory adherence, minimizing downtime for shipowners and shipyards worldwide.

Why Choose Hangzhou Star Marine Technology?

As a certified solution provider for new shipbuilding and ship-repair projects, we integrate:

Pre-shipment quality validation per IACS standards

Customized packaging for vessel-specific requirements (e.g., yacht vs. cargo ship windlass units)

Dedicated project managers for urgent repair timelines (72-hour expedited shipping options)

Delivering reliability from Hangzhou to the world’s busiest ports – because your vessel’s safety starts with our packaging.

Contact Star Marine Technology

Professional Aluminum Windlass Solutions for Global Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered aluminum windlass systems designed for rigorous marine environments. Our products comply with all major IACS class society standards (CCS, BV, DNV, ABS, LR, GL) and are tailored for new shipbuilding projects and ship-repair retrofits, ensuring operational safety, corrosion resistance, and long-term reliability across diverse vessel types—from small yachts to large cargo ships and offshore platforms.

Technical Specifications & Compliance

| Parameter | Specification Range |

|---|---|

| Pull Load (kN) | 50 – 500 |

| Chain Diameter (mm) | 12.5 – 60 |

| Operating Speed (m/min) | Electric: 10–25; Hydraulic: 15–30 |

| Drive System | Electric / Hydraulic |

| Class Approvals | CCS, BV, DNV, ABS, LR, GL |

All models are designed per IACS rules for specific environmental conditions, ensuring compliance with vessel-specific operational requirements. Class certificates are provided upon request for regulatory validation.

Why Choose Hangzhou Star Marine?

Global Compliance: Certified to all major IACS class societies (CCS, BV, DNV, ABS, LR, GL) for seamless regulatory approval.

Marine-Grade Aluminum Construction: Superior corrosion resistance, lightweight durability, and reduced maintenance costs in saltwater environments.

Customizable Solutions: Engineered for new builds, retrofits, and specialized operational conditions (e.g., Arctic-class vessels, high-salinity zones).

End-to-End Technical Support: From initial design consultation to installation, commissioning, and post-sale maintenance.

Proven Reliability: Deployed on 500+ vessels globally, including bulk carriers, tankers, and offshore support vessels.

Contact Hangzhou Star Marine

Expert Consultation for Your Marine Projects

For project-specific technical requirements, certification documentation, or customized windlass solutions, contact our Product Manager directly:

Tel/WhatsApp: +86-178-16869405

Email: [email protected]

“Partner with Hangzhou Star Marine for certified, high-performance windlass systems engineered to meet your vessel’s exact operational demands and regulatory standards.”

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160