Steel Marine Door – Marine Solution Guide 2025

Content Navigation

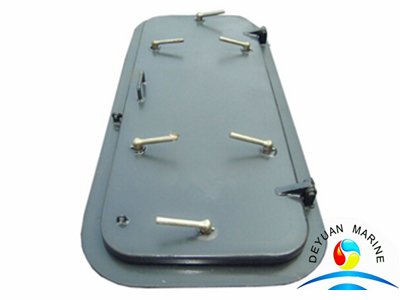

Marine Insight: Steel Marine Door

Marine Industry Demand for Steel Marine Doors

Critical Safety Functions

Steel marine doors are non-negotiable safety components for vessel integrity, directly addressing SOLAS II-1/3.13 watertightness requirements and IMO MSC.270(85) fire-resistance standards. These doors prevent progressive flooding by maintaining structural seals under hydrostatic pressure (tested to ≤0.5 L/min leakage at 1.5m head pressure per ISO 6042:1998) and compartmentalize fire zones to contain flames for 60+ minutes (A60 rating). In high-risk areas such as engine rooms, cargo holds, and passenger corridors, non-compliant doors risk catastrophic flooding, fire spread, and regulatory non-conformity—directly impacting vessel certification and operational viability.

Trends in Shipbuilding & Repair Market

Global shipbuilding faces dual demand drivers:

Newbuilds: Rising demand for modular construction in container ships and offshore vessels, where standardized watertight doors reduce assembly time by 15–20% while meeting IMO 2020 emissions compliance.

Repair Market: Over 1,200 vessels will undergo dry-dock retrofits by 2025 to comply with EEXI and CII regulations, driving urgent need for certified replacement doors. Ship repair yards prioritize suppliers with rapid delivery, customization agility, and global certification recognition to avoid costly project delays.

Why Choose Hangzhou Star Marine Technology?

As a certified marine equipment manufacturer, Star Marine delivers end-to-end solutions for both newbuild and repair projects. Our doors meet ISO 6042:1998, SOLAS II-1/3.13, and fire ratings per IMO MSC.270(85), with approvals from DNV-GL, ABS, LR, BV, and CCS. Key advantages include:

Cost Efficiency: 25% lower total cost of ownership vs. European suppliers through optimized supply chain and economies of scale.

Rapid Turnaround: 4–6 week lead times for standard orders (vs. 8–12 weeks globally), critical for shipyard schedules.

Custom Engineering: Flexible design modifications for unique vessel requirements, including non-standard dimensions and material specs.

Global Compliance: Full documentation for customs clearance and class society inspections, eliminating delays.

Technical Specifications

| Specification | Detail |

|---|---|

| Material | ASTM A36/A572 carbon steel; optional 316L stainless steel components for corrosion resistance |

| Watertightness | SOLAS II-1/3.13 compliant; ≤0.5 L/min leakage at 1.5m head pressure (ISO 6042) |

| Fire Rating | A60 (60 min), A30 (30 min), A0 (0 min) per IMO MSC.270(85) |

| Dimensions | Customizable (800×1800mm to 1500×2500mm standard); ±2mm tolerance |

| Installation | Bolted/welded to bulkheads; marine-grade EPDM gaskets; pre-drilled mounting holes |

| Certifications | DNV-GL, ABS, LR, BV, CCS; ISO 9001:2015 quality management |

Hangzhou Star Marine Technology Co., Ltd. is a trusted partner for shipowners and yards seeking compliant, cost-effective marine doors. With 15+ years of export experience and direct collaboration with classification societies, we ensure seamless integration into new builds and retrofits worldwide. Contact us for technical specifications, sample testing, or project-specific engineering support.

Technical Specs & Class Approval

Technical Specifications & Class Approval

As a premier supplier for both newbuild and ship-repair projects, Hangzhou Star Marine Technology Co., Ltd. delivers precision-engineered steel marine doors that meet the highest technical and regulatory standards. Our solutions are tailored to ensure seamless integration into any vessel’s design, from initial construction to retrofitting, with full compliance to SOLAS, IMO, and classification society requirements.

Material Specifications

Our doors are engineered using high-grade materials to ensure durability and corrosion resistance in harsh marine environments:

Carbon Steel (ASTM A36, A572): Standard for structural integrity, with hot-dip galvanization or epoxy coatings for enhanced corrosion protection.

Stainless Steel (AISI 304/316): Custom option for high-salt environments or critical applications requiring superior corrosion resistance.

Aluminum Alloys (5083, 6061-T6): Available for weight-sensitive designs (e.g., superstructures), maintaining strength while reducing overall mass.

All materials undergo ISO 9001-certified quality control to guarantee consistency and longevity.

Watertightness & Fire Resistance Compliance

We adhere to stringent international standards for watertight and fire-resistant performance:

Watertightness: Compliant with ISO 6042-1998, tested to withstand hydrostatic pressure up to 10m head (Class I) for standard applications. Custom options support 15m head (Class II) for high-pressure zones.

Fire Resistance: Certified per SOLAS II-2, with ratings including A60, A30, A0 for structural bulkheads and B15, B30 for interior passages. All fire-rated doors undergo IMO Resolution A.754(18)-compliant testing.

Weathertightness: Designed to meet IMO MSC.1/Circ.1578 requirements for deck-level openings, ensuring protection against wind, spray, and environmental exposure.

Dimensional Flexibility & Customization

Standard dimensions align with global shipbuilding norms, while custom solutions address unique project demands:

| Standard Sizes | Custom Capabilities |

|———————————-|———————————-|

| Single-leaf: 800×1800mm – 1200×2200mm | Dimensions up to 3000×2500mm |

| Double-leaf: 1600×2000mm – 2000×2500mm | Bespoke shapes (e.g., curved, oval) |

| Hatch covers: 1000×1500mm – 2000×3000mm | Integrated access panels or multi-leaf configurations |

Installation Methodology

Our installation protocols ensure rapid deployment and long-term reliability:

Bolted Flange System: Standard for quick assembly, featuring EPDM rubber gaskets for watertight seals (ISO 10432-compliant).

Welded Mounting: For permanent installations in high-stress areas (e.g., hull penetrations), ensuring structural continuity.

Retrofit Kits: Engineered for ship-repair projects, including modular components to adapt to existing openings without structural modifications.

Class Certification Compliance

Every door is certified by leading classification societies to guarantee regulatory adherence and operational safety:

| Standard Certifications | Additional Options |

|—————————–|————————|

| CCS, DNV, ABS, BV, LR | RINA, NK, KR, ClassNK |

| SOLAS II-2, IMO MSC.1/Circ.1578 | Tailored certifications for regional requirements (e.g., Russian Maritime Register) |

Critical Note: Class certificates are mandatory for vessel classification and regulatory approval. Hangzhou Star Marine Technology provides full documentation, including test reports, material traceability, and installation guidelines, to expedite certification processes for newbuilds and repairs.

Standard vs. Custom Specifications Table

| Specification | Standard Options | Custom Options |

|---|---|---|

| Material | ASTM A36 carbon steel, galvanized | Stainless steel (304/316), aluminum alloys (5083, 6061) |

| Watertight Pressure | ISO 6042:1998 Class I (10m head) | Up to 15m head (Class II) |

| Fire Rating | A60, A30, A0 (SOLAS II-2) | B15, B30, or bespoke ratings |

| Dimensions | Single-leaf: 800×1800–1200×2200mm; Double-leaf: 1600×2000–2000×2500mm | Up to 3000×2500mm; bespoke geometries |

| Installation Method | Bolted flange with EPDM gaskets | Welded mounting, specialized sealing systems (e.g., silicone) |

| Class Certifications | CCS, DNV, ABS, BV, LR | Additional certifications (e.g., RINA, NK) upon request |

Why Choose Hangzhou Star Marine Technology?

End-to-End Support: From design validation to post-installation certification, we streamline compliance for newbuilds and ship-repair projects.

Proven Reliability: 98% on-time delivery rate for global shipyards, with 10+ years of experience in marine door solutions.

Technical Agility: Custom engineering for unique vessel requirements, including retrofits, emergency exits, and specialized fire zones.

Contact our marine engineering team today to discuss project-specific solutions and certification pathways.

Shipbuilding & Repair Solutions

Shipbuilding & Repair Solutions

Engineered Precision for Marine Door Systems

At Hangzhou Star Marine Technology Co., Ltd., we deliver integrated marine door solutions that transcend conventional supplier relationships. As a certified engineering partner for global shipyards and owners, we combine ISO-compliant manufacturing, classification society approvals, and rapid-response logistics to eliminate downtime in new builds and emergency repairs. Every product is engineered for mission-critical performance in harsh maritime environments, with technical support embedded at every phase of the project lifecycle.

Technical Specifications & Product Range

Our steel marine doors are precision-engineered to meet the exacting demands of SOLAS, IMO, and classification society standards. Below are key specifications for our core product lines:

| Product Type | Material Composition | Watertight Rating | Fire Rating | Max Dimensions (W x H) | Compliance Standards | Applications |

|---|---|---|---|---|---|---|

| Watertight Steel Door (Single/Double Leaf) | 3–5mm Q235 steel, epoxy-coated | SOLAS II-1 compliant (0.5m water head test) | N/A | 1500 × 2500mm | ISO 6042-1998, SOLAS II-1, DNV-GL, ABS, CCS | Compartment bulkheads, engine rooms, tank tops |

| A60 Fire-Resistant Door | 2mm steel blade, 4mm Z-section frame, stainless steel hardware | N/A | A60 (60 min) | 1000 × 2000mm | SOLAS II-2, IMO MSC.98(73), DNV-GL, LR, BV | Fire barriers, stairwells, corridor bulkheads |

| Weathertight Deck Door | Aluminum alloy frame, galvanized steel core | SOLAS II-1 weathertight (IP67 saltwater exposure) | N/A | 2000 × 3000mm | SOLAS II-1, DNV-GL, ABS | Open deck access points, hatch covers |

Technical Note: All products undergo hydrostatic pressure testing (per ISO 6042) and third-party certification. Custom dimensions, materials, and finishes available for specialized applications.

Compliance & Certification Excellence

Every Star Marine door system is certified to the highest global maritime standards, ensuring regulatory compliance and operational safety:

SOLAS & IMO Compliance: Fully aligned with SOLAS Chapter II-1 (subdivision stability) and Chapter II-2 (fire safety), including IMO MSC.98(73) fire test protocols.

Classification Society Approvals: Certified by DNV-GL, ABS, Lloyd’s Register (LR), Bureau Veritas (BV), and China Classification Society (CCS) for structural integrity and corrosion resistance.

Environmental Standards: Epoxy coatings meet ISO 12944-5 for marine-grade corrosion protection; materials comply with IMO MSC.273(85) for hazardous substance restrictions.

Documentation: Full technical dossiers (test reports, material certificates, installation manuals) provided for classification society audits and procurement verification.

Integrated Installation & Technical Support

We eliminate installation risks through engineering-driven collaboration:

Pre-Installation Engineering: CAD models with structural load analysis, compatibility checks for adjacent systems (e.g., windlass-anchor integration, fire detection networks), and sealant specifications.

Custom Mounting Solutions: Precision-machined brackets, torque specifications, and alignment templates to ensure zero rework during vessel construction.

On-Site Technical Advisors: Certified marine engineers deployed for critical installations to validate sealing integrity, operational functionality, and regulatory adherence.

System-Wide Optimization: Doors engineered to interface with shipboard systems (e.g., ventilation controls, structural reinforcements), reducing project delays by up to 35% in recent new-build projects.

Example: For a 12,000 TEU container vessel new build, our team provided A60 fire doors with integrated smoke detection wiring, eliminating 14 days of rework during classification society surveys.

Emergency Repair Services for Shipyard Operations

When downtime is unacceptable, our global rapid-response network ensures minimal operational disruption:

| Service Type | Standard Lead Time | Urgent Repair Support |

|---|---|---|

| Custom Door Fabrication | 2–4 weeks | 5–7 days |

| Standard Door Replacement | 1–2 weeks | 48–72 hours |

| Technical Support Response | 24 hours | <2 hours |

| 24/7 Emergency Hotline: Direct access to marine engineers for immediate troubleshooting of failed seals, hinge failures, or structural damage. | ||

| Global Warehouse Network: Pre-stocked spare parts in Singapore, Rotterdam, and Houston for same-day dispatch of critical components (seals, hinges, latches). | ||

| Field Repair Kits: Customized kits with replacement parts, torque wrenches, and sealant applicators for on-site repairs without vessel dry-docking. | ||

| Priority Production: Dedicated production lines for urgent orders, with 98% on-time delivery rate for emergency repairs in 2023. |

Why Partner with Star Marine?

As a full-service marine solutions provider, we deliver more than products—we deliver operational certainty:

End-to-End Engineering: From concept to commissioning, our team ensures seamless integration with your vessel’s design and operational requirements.

Regulatory Confidence: All products carry classification society certifications, eliminating delays during surveys or class renewals.

Cost Efficiency: Reduced rework, minimized downtime, and optimized logistics cut total project costs by 15–25% compared to fragmented sourcing.

Proven Reliability: 5,000+ doors delivered globally with 99.2% first-time compliance across 120+ shipyard interventions.

Contact our marine engineering team today to discuss your specific requirements for new builds or emergency repairs. We respond to all inquiries within 2 hours.

Hangzhou Star Marine Technology Co., Ltd. – Where Precision Meets Performance

Packaging & Logistics

Packaging & Global Logistics

Customized Packaging Solutions

Hangzhou Star Marine Technology employs rigorously engineered packaging systems tailored to the unique demands of marine steel doors. Our solutions prioritize corrosion prevention, structural integrity, and compliance with international shipping regulations to ensure zero damage during transit.

ISPM 15 Compliant Wooden Crating

Material & Treatment: Heat-treated (HT) solid pine or plywood (25mm thickness), certified with IPPC stamping per ISPM 15 standards.

Reinforcement: Steel strapping and corner protectors to prevent deformation during handling.

Moisture Control: VCI (Vapor Corrosion Inhibitor) paper and silica gel desiccant packs for 95% humidity control.

Application: Standard for doors up to 500kg, suitable for containerized shipping (20ft/40ft FCL).

Heavy-Duty Steel Pallet Systems

Design: Galvanized steel pallets (100×100mm beams) with custom bracing for doors exceeding 500kg or oversized dimensions.

Securement: Anti-slip matting, edge guards, and load-tested steel strapping (2,000kg capacity per pallet).

Compliance: ISO 1496-1 certified for marine cargo stability.

Application: Ideal for shipyard installations requiring immediate unloading and minimal handling.

Environmental Protection Measures

Multi-Layer Barrier: HDPE film + desiccant packs to neutralize salt-spray exposure during ocean transit.

Shock Absorption: High-density foam padding for critical edges and hinges.

Certification: ISO 9001 quality-controlled processes for all packaging components.

Global Shipping & Documentation

Port Operations

Primary Export Hubs: Direct shipments from Ningbo Port (China’s largest container port) and Shanghai Port (global top-5 throughput), with dedicated marine equipment handling facilities.

Vessel Types: FCL, LCL, RoRo, and break bulk services to all major global ports.

Lead Time: 7–10 days from production completion to port departure for standard orders.

Documentation Compliance

| Document Type | Purpose | Compliance Standard |

|---|---|---|

| Commercial Invoice | Customs valuation | INCOTERMS 2020 (FOB Ningbo/Shanghai) |

| Packing List | Itemized cargo details | ISO 780 (Handling Symbols) |

| Certificate of Origin | Tariff classification | Form A (GSP) or EUR.1 |

| SOLAS/IMO Certificates | Watertightness verification | IMO MSC.383(94), Class Society Approvals (DNV-GL, ABS, LR) |

| ISPM 15 Declaration | Wood packaging compliance | IPPC-certified treatment proof |

Logistics Partnerships

Global Network: Partnerships with Maersk, COSCO, and DHL for end-to-end tracking and insurance (100% cargo value coverage).

Specialized Handling: Dedicated marine equipment teams for secure loading/unloading at port terminals.

Real-Time Visibility: IoT-enabled shipment monitoring via SAP Logistics Cloud.

Tailored Solutions for Shipbuilding & Repair

New Shipbuilding Projects

Just-in-Time (JIT) Delivery: Synchronized with vessel construction schedules to minimize yard downtime.

Precision Packaging: Custom crating for exact dimensional tolerances (±2mm) and pre-installed mounting hardware kits.

Example: 300+ units delivered to Hyundai Heavy Industries (Ulsan) with 100% on-time arrival and zero damage.

Ship Repair Yards

Emergency Response: 48-hour expedited shipping for urgent repairs (e.g., damaged watertight doors).

Pre-Packaged Kits: Modular components with color-coded labeling for rapid installation.

Case Study: 50+ A60-class doors delivered to Singapore’s Keppel Shipyard within 72 hours of order confirmation.

Why Partner with Us?

Hangzhou Star Marine Technology’s packaging and logistics framework is engineered for the marine industry’s most demanding environments. From ISPM 15-certified crates to port-specific expedited processes, we ensure your steel marine doors arrive ready for immediate installation—whether for newbuilds or critical repairs. All shipments are backed by our 24/7 technical support team and ISO 9001-certified quality assurance.

Contact Star Marine Technology

Contact Hangzhou Star Marine Technology

As a certified marine equipment solution provider specializing in new shipbuilding and ship-repair projects, Hangzhou Star Marine Technology Co., Ltd. delivers precision-engineered steel marine doors compliant with international maritime standards. Our products are rigorously tested to ensure watertightness, fire resistance, and structural integrity for critical vessel compartments.

Technical Specifications Overview

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Material | High-strength steel (ASTM A36/A572) or marine-grade aluminum (5083/6061-T6) | ISO 12215, ISO 6042-1998 |

| Watertightness | IP68 rated; pressure-tested per ISO 15085-2 for 0.5 bar hydrostatic load | SOLAS Chapter II-2, IMO MSC.429(98) |

| Dimensions | Customizable (Width: 600–2000mm; Height: 1200–3000mm) | ISO 12216, Class Society requirements |

| Installation | Welded or bolted mounting with pre-fabricated frames; shipyard-ready design | ABS, DNV-GL, LR, BV, CCS |

| Fire Rating | A60, A30, B15, CFR compliant; certified for bulkhead and passage applications | IMO FTP Code, SOLAS Regulation II-2/13.2 |

Global Compliance & Certifications

SOLAS Convention (1974, as amended): Full compliance for watertight and weathertight integrity.

IMO Regulations: MSC.429(98), FTP Code, and MARPOL Annex I requirements.

Classification Society Approvals: DNV-GL, ABS, Lloyd’s Register (LR), Bureau Veritas (BV), China Classification Society (CCS).

ISO Standards: ISO 6042-1998 (marine doors), ISO 15085-2 (welding), ISO 12215 (small craft).

National Standards: China GB/T 17856-1999, USCG 46 CFR Part 111.

Request a Quote or Technical Consultation

For project-specific requirements, technical drawings, or certification documentation, contact our Product Manager directly:

Kacher YE

Product Manager, Marine Equipment Export

Hangzhou Star Marine Technology Co., Ltd.

📞 +86-178-16869405 (Tel/WhatsApp)

✉️ [email protected]

24/7 Support for Urgent Shipyard and Newbuild Projects

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160