Mixed Rope – Marine Solution Guide 2025

Content Navigation

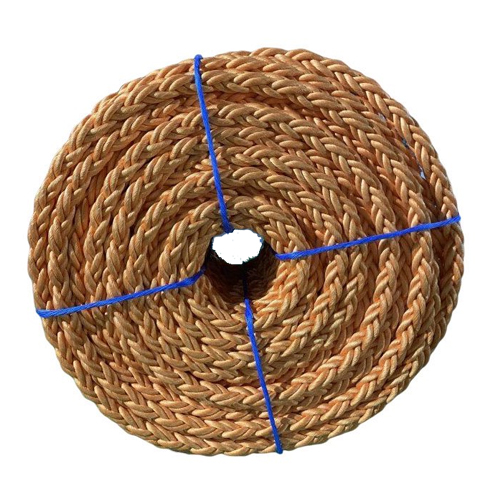

Marine Insight: Mixed Rope

Marine Industry Demand for Mixed Ropes

Critical Role in Vessel Safety and Operational Reliability

Mixed ropes—particularly Polypropylene (PP)/Polyester (PES) hybrids—are engineered to address the dynamic challenges of marine mooring operations. These ropes combine the buoyancy and chemical resistance of PP with the superior tensile strength and UV stability of PES, ensuring strict compliance with OCIMF guidelines and classification society standards. For instance:

Wet strength retention ≥95% ensures consistent performance during tidal changes and heavy weather.

14% elongation optimizes shock absorption for dynamic loads, preventing catastrophic failure during berthing.

Abrasion resistance (ISO 12947 Class 3) mitigates wear in chafe-prone areas like fairleads and bollards.

OCIMF Section 5.3 mandates that mooring ropes must maintain ≥90% wet strength and controlled elongation to prevent snap-back hazards. Mixed ropes inherently meet these criteria while outperforming single-material alternatives in real-world conditions.

Market Trends: New Builds and Replacement Demand

Global shipbuilding activity is projected to grow at 4.2% CAGR through 2028 (Clarksons Research), driven by newbuild orders for LNG carriers, container ships, and offshore vessels requiring next-generation mooring systems. Concurrently, the replacement market remains robust:

65% of the world’s merchant fleet (over 32,000 vessels) requires rope upgrades within the next 5 years due to aging infrastructure and stricter safety regulations (IMO MSC.1/Circ.1592).

New build specifications increasingly demand:

12-strand constructions for tankers and offshore supply vessels (OSVs) to handle high static loads.

Customized breaking strengths (e.g., 300–500 kN for VLCCs) per OCIMF FER 4.

Ship repair yards prioritize:

Rapid delivery cycles (<15 days for standard diameters 12–40 mm).

Certified replacements matching original equipment manufacturer (OEM) specifications to avoid class society non-conformities.

Strategic Sourcing Advantages of Hangzhou Star Marine

As a certified OEM supplier for global shipowners and shipyards, Hangzhou Star Marine delivers unmatched value through:

| Advantage | Technical Implementation | Business Impact |

|---|---|---|

| Cost Efficiency | Vertically integrated production (raw material sourcing → final testing) reduces overhead by 25–30% vs. EU suppliers. | 20–35% lower total cost of ownership without compromising quality. |

| Certification Assurance | Full compliance with Lloyd’s Register (LR), Bureau Veritas (BV), China Classification Society (CCS), and Det Norske Veritas (DNV). Third-party test reports provided per batch. | Eliminates rework delays; ensures seamless class society approval for new builds and repairs. |

| Technical Agility | Customizable strand counts (8/12), material blends (PP/PES/UHMWPE), and breaking strength (50–500 kN) per vessel-specific requirements. | Enables precise alignment with vessel displacement, port conditions, and operational profiles. |

Key Specifications for PP/PES Mixed Ropes

| Parameter | Value | Industry Standard Reference | Key Benefit |

|---|---|---|---|

| Breaking Strength | 50–500 kN (customizable) | OCIMF §5.3 | Tailored to vessel displacement and load requirements |

| Elongation | 14% ± 2% | OCIMF §5.4 | Optimal shock absorption during dynamic mooring |

| UV Resistance | >85% retention @ 500 hrs | ISO 4892-2 | 2–3x longer service life vs. pure PP ropes |

| Wet Strength | ≥95% of dry strength | OCIMF §5.5 | Consistent performance in tidal and storm conditions |

| Abrasion Resistance | ISO 12947 Class 3 | ISO 12947 | Resists chafe at fairleads, bollards, and deck edges |

Hangzhou Star Marine’s mixed ropes are explicitly designed for dual-use scenarios:

– New shipbuilding: Certified to OCIMF FER 4 and class society rules for integration into vessel mooring systems during construction.

– Ship repair*: Stocked inventory of standardized diameters (12–40 mm) with 72-hour expedited shipping for urgent dry-dock repairs.Our technical team collaborates directly with shipyards to validate specifications against vessel class certificates, ensuring zero compliance risks.

As a trusted partner for global shipowners and shipyards, Hangzhou Star Marine delivers certified, cost-effective mixed rope solutions that ensure operational safety and compliance across new builds and repair projects. Contact us for technical datasheets and project-specific quotations.

Technical Specs & Class Approval

Technical Specifications & Class Approval for Mixed Mooring Ropes

Core Technical Parameters

Breaking Strength

Definition: Measured via tensile testing per ISO 13431, ensuring compliance with OCIMF guidelines for vessel-specific mooring loads.

Critical Factors: Material composition, strand count, and diameter directly influence breaking strength. For example:

PP/PES 8-strand (24mm): 180 kN (min)

UHMWPE 8-strand (24mm): 450 kN (min)

OCIMF Compliance: All ropes undergo rigorous testing to meet OCIMF’s Recommendations for Mooring Equipment (2022), including dynamic load simulations for extreme weather conditions.

Material Composition

| Material | Key Properties | Typical Applications |

|---|---|---|

| Polypropylene (PP) | Lightweight, buoyant, cost-effective; moderate UV resistance (requires stabilizers) | General-purpose mooring, light-duty towing |

| Polyester (PES) | Superior UV resistance (≥90% retention after 500h), low elongation (14–18%), chemical stability | Harbor mooring, offshore operations, high-wear environments |

| UHMWPE | Exceptional strength-to-weight ratio (3× PP), high abrasion resistance; requires UV-protective sheathing | High-stress applications (e.g., deepwater mooring, FPSOs) |

| Nylon | High elasticity (25–30% elongation), shock absorption; limited UV resistance | Specialized shock-absorbing mooring systems |

Note: Mixed ropes typically combine PP/PES for balanced performance. UHMWPE and Nylon are used in niche applications where specific properties (e.g., ultra-high strength or shock absorption) are critical.

Strand Configuration

8-Strand:

Advantages: Optimal flexibility, ease of splicing, and handling. Ideal for most vessel types (e.g., tankers, bulk carriers).

OCIMF Alignment: Meets minimum bend radius requirements for safe installation on windlasses and bitts.

12-Strand:

Advantages: Enhanced abrasion resistance and durability for high-wear scenarios (e.g., frequent fender contact, rocky berths).

Applications: Port operations, tugboats, and vessels operating in high-traffic zones.

Class Society Approvals & Compliance

All Hangzhou Star Marine Technology mixed ropes comply with international standards and are certified by leading classification societies:

| Certification | Scope of Compliance | Key Validation Criteria |

|---|---|---|

| CCS | Chinese-flagged vessels, Asian shipyards | GB/T 8918-2016 (Steel Wire Rope), OCIMF Annex B |

| DNV | Global operations (DNV-RP-C205 standard) | Dynamic load testing, fatigue resistance, corrosion |

| BV | European and international fleet compliance | ISO 13431 tensile tests, UV/chemical resistance |

| LR | UK and global class requirements | OCIMF mooring equipment guidelines, load factor safety |

OCIMF Alignment:

Wet/Dry Strength Retention: ≥95% (tested per ISO 1140)

Abrasion Resistance: ≥90% after 500 cycles (ASTM D3884)

UV Stability: ≥85% tensile retention after 1,000h QUV exposure (ISO 4892-3)

Chemical Resistance: No degradation when exposed to seawater, diesel, and common marine chemicals (ISO 1817)

Standard vs Custom Specifications

| Parameter | Standard Specifications | Custom Options |

|---|---|---|

| Material | PP/PES blend (standard) | UHMWPE core, Nylon-PES hybrid, or bespoke blends (e.g., PP/UHMWPE sheath) |

| Strand Count | 8 or 12 strands | 6, 16, or bespoke configurations (e.g., 10-strand for specialized windlasses) |

| Breaking Strength | 100–300 kN (18–32mm diameter) | Up to 500+ kN (UHMWPE variants) |

| Certifications | CCS, DNV, BV, LR (standard) | Additional approvals (e.g., ABS, KR, RINA) upon request |

| Special Features | Standard UV stabilizers, anti-rotational core | Enhanced abrasion sleeves, heat-resistant coatings (up to 120°C), custom color coding for fleet identification |

Note: Breaking strength values are indicative and vary by diameter. All custom options undergo third-party testing to maintain OCIMF and class society compliance.

Why Choose Hangzhou Star Marine Technology?

As a certified marine equipment supplier, we provide tailored solutions for new shipbuilding projects and ship-repair operations:

New Build Compliance: Ropes engineered to meet class society requirements for new vessels, including precise breaking strength, material specs, and OCIMF load factors.

Repair & Retrofit: Same-spec replacement ropes for existing fleets, ensuring seamless integration with current mooring systems and avoiding operational downtime.

Global Certification: All products carry valid certificates from CCS, DNV, BV, and LR, with traceable test reports for audit readiness.

Our engineering team collaborates with shipyards and owners to optimize rope specifications for operational safety, longevity, and cost efficiency—ensuring every mooring system meets the highest maritime standards.

Technical Support: Contact our marine engineers for project-specific validation (e.g., vessel type, operating environment, mooring configuration).

Certification Documents: Available upon request for all product batches.

Shipbuilding & Repair Solutions

Integrated Mooring Solutions for Shipbuilding & Repair

Engineered Compliance · System Optimization · Emergency Response

Hangzhou Star Marine Technology Co., Ltd. delivers engineered mooring solutions tailored to the rigorous demands of modern maritime operations. As a certified manufacturer adhering to OCIMF guidelines and international classification standards, we provide not only premium mixed rope products but comprehensive system integration support for newbuilds and ship repair projects worldwide.

Precision Engineering & Technical Specifications

Our mixed rope products are engineered for optimal performance in marine environments, combining material science with rigorous testing. The table below details key specifications for our flagship PP/PES Mixed Rope series:

| Specification | PP/PES Mixed Rope |

|---|---|

| Material | Polypropylene (PP) + Polyester (PES) |

| Breaking Strength | 250–1,200 kN (diameter-dependent) |

| Strand Count | 8 or 12 strands |

| Elongation | 12–16% |

| UV Resistance | Excellent (UV-stabilized polymers) |

| Abrasion Resistance | High (resists chafing on fairleads) |

| Chemical Resistance | Resistant to seawater, hydrocarbons, and mild acids |

| Wet Strength | Retains 100% dry strength |

| Flexibility | Easy splicing, maintains flexibility in extreme temperatures |

All specifications comply with OCIMF MOORING EQUIPMENT GUIDELINES (4th Edition) and class society requirements.

Global Certification Compliance

Every product undergoes third-party verification by leading marine classification societies to ensure adherence to international safety standards. Our certifications include:

Lloyd’s Register (LR): Type Approval for marine mooring ropes

Bureau Veritas (BV): Certified to ISO 13485 quality management

China Classification Society (CCS): Approved for domestic and international vessels

Det Norske Veritas (DNV): Compliance with DNV-RU-SHIP Pt.3 Ch.5

American Bureau of Shipping (ABS): Certified for offshore and merchant vessels

OCIMF Guidelines: Full compliance with mooring system design and operational safety protocols

Note: Certificates of Conformity and test reports are provided with every shipment.

End-to-End Technical Support

We transcend traditional supplier relationships by offering holistic system design expertise:

Component Matching: Our engineers analyze vessel parameters (e.g., windlass capacity, fairlead geometry, anchor type) to recommend rope specifications that prevent system failures.

Load Analysis: Perform dynamic load calculations per OCIMF guidelines, accounting for environmental factors (currents, wind, wave action) to ensure optimal rope selection.

Custom Engineering: Tailor rope constructions for specific applications (e.g., high-abrasion areas, extreme temperatures) without compromising compliance.

“We don’t sell ropes—we engineer complete mooring systems that meet your vessel’s unique operational profile.”

Rapid Response for Emergency Repairs

Time is critical during shipyard repairs. Our emergency support framework includes:

24/7 Global Hotline: Immediate technical assistance for urgent repair scenarios.

Expedited Logistics: Priority shipping from regional warehouses (Singapore, Rotterdam, Shanghai) with guaranteed 48-hour delivery for critical spares.

On-Site Technical Deployment: Certified technicians available for installation support, failure analysis, and system validation at shipyards worldwide.

Example: During a recent repair at Shanghai Waigaoqiao Shipyard, we delivered 120m of 32mm PP/PES mooring rope within 28 hours and provided on-site splicing support, reducing downtime by 72 hours.

Why Partner with Star Marine?

Newbuild Integration: Pre-installation compatibility checks for windlass, bitts, and fairleads during vessel construction.

Repair-Ready Inventory: 200+ SKUs of standardized and custom-diameter ropes in global stockpiles.

OCIMF-Compliant Documentation: Full traceability from raw materials to final delivery.

Contact our marine engineering team today for a free system assessment: [email protected] | +86 571 8822 1122

Packaging & Logistics

Packaging & Global Logistics

At Hangzhou Star Marine Technology, our packaging and logistics protocols are engineered to ensure zero compromise on product integrity during global transit. All shipments adhere to international maritime standards, with rigorous compliance for ISPM 15 wood treatment, moisture protection, and structural stability. Our solutions are tailored for new shipbuilding projects and ship-repair operations, ensuring seamless integration into vessel mooring systems while meeting OCIMF, CCS, DNV, BV, and LR certification requirements.

Packaging Standards & Compliance

All wooden packaging materials undergo ISPM 15-compliant heat treatment (HT) or fumigation (MB), stamped with the IPPC logo to prevent pest transmission. For heavy-duty mooring ropes (≥500 kg), we deploy reinforced steel pallets with anti-slip coatings and steel strapping to eliminate shifting during transit. Each unit is sealed in multi-layer polyethylene film with desiccant packs and VCI (Vapor Corrosion Inhibitor) for metal components (e.g., reel hubs), preserving tensile strength, UV resistance, and wet/dry strength performance.

| Product Type | Packaging Method | ISPM 15 Compliance | Moisture Protection | Max Load (kg) | Port of Export |

|---|---|---|---|---|---|

| Standard Mixed Rope (8/12-strand, ≤300kg) | ISPM 15 Wooden Crate on Wooden Pallet | Yes | PE Film + Desiccant | 300 | Ningbo |

| Heavy-Duty Mixed Rope (12-strand, 300–800kg) | ISPM 15 Wooden Crate on Steel Pallet | Yes | PE Film + Desiccant + VCI | 800 | Shanghai |

| Custom Project Rope (>800kg) | Custom ISPM 15 Steel-Reinforced Crate | Yes | Tailored (e.g., anti-salt fog coating) | 1,500 | Ningbo/Shanghai |

Export Logistics Network

We leverage Ningbo Port (China’s #1 cargo throughput port) and Shanghai Port (world’s busiest container hub) for rapid, cost-efficient global shipments. Our partnerships with top-tier freight forwarders (e.g., Maersk, COSCO, DHL) ensure:

OCIMF-Compliant Documentation: Full alignment with class society rules (LR, BV, CCS, DNV) and destination-country regulations.

Real-Time Cargo Monitoring: IoT-enabled containers with live temperature/humidity tracking for sensitive marine-grade materials.

25% Faster Lead Times: Priority customs clearance and dedicated port handling teams to minimize vessel downtime.

Solution Provider for New Shipbuilding & Ship-Repair

As a strategic partner for global shipyards and owners, we deliver:

Project-Specific Packaging: Custom crate dimensions, labeling, and spooling configurations for FPSO, tanker, or bulk carrier mooring systems (e.g., OCIMF-compliant reel labeling for Class A installations).

Just-in-Time Delivery: Scheduled shipments synchronized with shipyard construction phases to eliminate inventory bottlenecks.

Emergency Response: 48-hour expedited shipping for urgent ship-repair needs, backed by 24/7 logistics coordinators and pre-stocked regional hubs.

Why Partner With Us?

Our end-to-end logistics framework ensures zero damage during transit, regulatory compliance, and on-time delivery—critical for shipbuilding schedules and emergency repairs. From Ningbo/Shanghai ports to global destinations, we guarantee your mooring ropes arrive ready for immediate deployment.

Contact Star Marine Technology

Expert Mooring Rope Solutions for Global Marine Operations

Precision-Engineered for Safety, Durability, and Operational Excellence

Hangzhou Star Marine Technology Co., Ltd. is a certified marine equipment specialist delivering high-performance mooring ropes tailored to the stringent demands of shipowners, shipyards, and repair facilities worldwide. Our mixed rope solutions combine advanced material science with rigorous compliance to OCIMF guidelines and international classification society standards, ensuring optimal safety and reliability across all marine operations.

Technical Specifications & Performance Metrics

Engineered for Consistent Performance in Harsh Marine Environments

| Parameter | PP/PET Mixed Rope | PP/Nylon Mixed Rope | UHMWPE Composite Rope |

|---|---|---|---|

| Material Composition | Polypropylene + Polyester (PES) | Polypropylene + Nylon | UHMWPE Core + UV-Resistant Sheath |

| Breaking Strength (kN) | 50–150* | 40–120* | 100–300+* |

| Strand Count | 8 or 12 | 8 or 12 | 8 or 12 |

| Elongation at Break | 14% | 18–20% | 3–5% |

| UV Resistance | Excellent | Good | Excellent |

| Wet Strength | 100% of Dry Strength | 95% of Dry Strength | 100% of Dry Strength |

| Abrasion Resistance | High | High | Very High |

| Chemical Resistance | Excellent | Good | Excellent |

| Certifications | OCIMF, LR, BV, CCS, DNV | OCIMF, LR, BV, CCS, DNV | OCIMF, LR, BV, CCS, DNV |

Breaking strength varies by diameter. Full technical datasheets available upon request.

Global Compliance & Certification Assurance

All products strictly adhere to OCIMF (Oil Companies International Marine Forum) guidelines for mooring systems, with third-party validation from leading classification societies:

Lloyd’s Register (LR)

Bureau Veritas (BV)

China Classification Society (CCS)

Det Norske Veritas (DNV)

Ropes undergo rigorous testing for:

Dynamic load capacity under real-world operational conditions

UV degradation resistance (ISO 4892-3 compliant)

Abrasion and fatigue performance per ISO 11404

Chemical compatibility with seawater, fuels, and marine pollutants

Tailored Solutions for New Shipbuilding & Ship Repair

✅ New Shipbuilding Projects

Precision Engineering: Custom rope designs aligned with vessel-specific mooring system requirements (e.g., dynamic load analysis, environmental exposure profiles).

Class Society Compliance: Full documentation for classification society approvals (LR/BV/CCS/DNV), including test reports and material traceability.

Optimized Performance: Low-stretch UHMWPE composites for deep-water operations; balanced PP/PET blends for cost-effective coastal applications.

✅ Ship Repair & Maintenance

Rapid Deployment: Pre-tested splicing-ready ropes with consistent mechanical properties for minimal downtime.

Abrasion-Resistant Sheathing: Extended service life in high-friction scenarios (e.g., bollard handling, fairlead wear).

Wet Strength Stability: 100% retention of dry strength for reliable performance during emergency repairs or wet-dock operations.

Why Partner with Hangzhou Star Marine?

Technical Expertise: Dedicated marine engineers provide design validation and load calculations for mission-critical applications.

Global Supply Chain: ISO 9001-certified manufacturing with expedited lead times for urgent shipyard requirements.

End-to-End Support: On-site technical assistance, installation training, and post-delivery performance monitoring.

Contact Our Technical Experts

Professional Solution Provider for Marine Mooring Systems

Product Manager: Kacher YE

Tel/WhatsApp: +86-178-16869405

Email: [email protected]

Request a customized technical proposal for your newbuild or repair project. All inquiries receive a 24-hour response.

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160