Mooring Bollards – Marine Solution Guide 2025

Content Navigation

Marine Insight: Mooring Bollards

Marine Industry Demand for Mooring Bollards

Critical Role in Vessel Safety and Operational Integrity

Mooring bollards serve as the primary structural anchor points for vessel mooring lines, directly impacting operational safety and regulatory compliance. As per MEG4 (OCIMF), these components must withstand dynamic loads from wind, currents, and wave action, with a minimum safety factor of 4:1 under ultimate load conditions. Classification societies such as ABS, DNV, and LR mandate rigorous testing protocols for load capacity, fatigue resistance, and corrosion performance. Failure of a bollard can result in catastrophic incidents, including vessel drifting, collisions, or environmental damage—making their design and installation non-negotiable for maritime safety.

Market Trends: New Builds vs. Replacement Demand

New-build demand is driven by global fleet expansion, particularly in LNG carriers and ultra-large container vessels (ULCVs), which require high-capacity bollards (200–300 metric tons) with advanced corrosion-resistant materials. Simultaneously, the replacement market is growing due to aging fleets (average vessel age >15 years) and stricter regulatory updates. Ship repair yards increasingly seek suppliers capable of rapid delivery of certified replacements that match original specifications, ensuring minimal downtime.

Why Source from Hangzhou Star Marine Technology?

As a dedicated solution provider for both new shipbuilding and ship-repair projects, Hangzhou Star Marine Technology offers end-to-end engineering and manufacturing capabilities tailored to global maritime standards. Our competitive advantage includes:

Cost Efficiency: 25–30% lower procurement costs versus Western suppliers, achieved through optimized supply chain and economies of scale without compromising quality.

Technical Compliance: Full adherence to IMO MSC.354(92), MEG4, and classification society rules (ABS, DNV, LR) with third-party testing by SGS/BV.

Customization: Engineering support for vessel-specific requirements, including high-capacity designs for ULCCs and retrofit solutions for aging fleets.

Rapid Delivery: Lead times of ≤15 days for standard orders, supported by Hangzhou Port logistics and customs clearance expertise.

| Parameter | Specification | Notes |

|---|---|---|

| Material Options | Cast Steel (ASTM A27 Gr. 60-30), Ductile Iron (ASTM A536 Grade 65-45-12), Stainless Steel 316 (optional) | High tensile strength for marine environments; ASTM standards ensure structural integrity |

| Load Capacity | 50–300 metric tons (certified) | Safety factor ≥4:1 per MEG4 and classification society rules (e.g., DNV GL-RP-C201) |

| Dimensions | Height: 0.8–2.5m; Base Diameter: 0.4–1.2m | Customizable to vessel class and mooring line specifications |

| Installation Methods | Embedded (concrete foundation), Surface-Mounted (with EPDM watertight seals) | Compliant with IMO MSC.354(92) for deck penetration integrity |

| Corrosion Protection | Hot-dip galvanized (≥85μm), Epoxy coating (250–300μm), or Stainless Steel | Meets ISO 12944 C5-M for offshore exposure |

| Compliance Standards | IMO MSC.354(92), MEG4, ABS Ch. 2, DNV GL-RP-C201, LR Rules | Rigorous load testing per ASTM A370 and ISO 15156 |

Hangzhou Star Marine Technology Co., Ltd. delivers mission-critical mooring solutions engineered for precision, durability, and regulatory certainty. Contact us to integrate our certified bollards into your next vessel project or repair operation.

Technical Specs & Class Approval

Technical Specifications & Class Approval

Material Selection & Corrosion Resistance

High-Strength Steel: Primary material is ASTM A572 Grade 50 or AISI 4140 carbon steel, hot-dip galvanized (HDG) or epoxy-coated (200μm minimum) for marine environments. Ensures optimal strength-to-weight ratio and corrosion resistance.

Aluminum Alloys: Limited to niche applications (e.g., small craft, non-critical mooring points) using 6061-T6 alloy. Not recommended for commercial vessels due to lower tensile strength compared to steel. All aluminum variants undergo rigorous anodizing for saltwater compatibility.

Watertightness & Weathertight Compliance

Installation must maintain deck weathertight integrity per SOLAS II-2 and IMO standards. Bollard bases feature precision-machined flanges for welding or bolting, sealed with marine-grade polyurethane sealants (e.g., Sikaflex-291) to prevent water ingress.

Compliance with OCIMF MEG4 guidelines for mooring equipment integrity, including load distribution and structural redundancy requirements.

Critical Dimensions & Load Ratings

| Parameter | Standard Range | Custom Options |

|---|---|---|

| Height | 300–600 mm | Up to 1,000 mm |

| Base Diameter | 200–400 mm | Up to 600+ mm |

| Breaking Load | 50–200 tons | 200–300+ tons |

| Working Load Limit | 30–120 tons | Tailored per vessel class |

| Material Grade | ASTM A572 Grade 50 | Stainless steel 316, alloy steel (e.g., AISI 4340) |

All load ratings validated per DNV GL-ST-N001 and ABS Rules for Building and Classing Steel Vessels. Non-destructive testing (NDT) including ultrasonic and magnetic particle inspection (MPI) applied to critical welds.

Installation Methodology

New Shipbuilding: Direct welding to deck structure with reinforcement plates per class society rules. Welding procedures certified to AWS D1.1. Structural reinforcement designed to distribute loads across hull frames.

Ship Repair: Bolted installation with structural reinforcement using high-tensile bolts (ASTM A325), sealed with marine-grade sealant. Minimizes downtime and avoids major deck modifications, enabling rapid deployment for emergency repairs or retrofits.

Class Society Certifications

All mooring bollards are certified by leading classification societies for compliance with international maritime standards:

China Classification Society (CCS): Compliant with CCS Rules for Classification of Steel Ships (Part 2, Chapter 3).

Det Norske Veritas (DNV): Certified under DNV GL-ST-N001 for mooring equipment.

Bureau Veritas (BV): Meets BV Rules for the Classification of Ships (Section 5, Chapter 2).

American Bureau of Shipping (ABS): Certified per ABS Rules for Building and Classing Steel Vessels (Part 3, Chapter 1).

Lloyd’s Register (LR): Compliant with LR Rules for the Classification of Ships (Part 3, Section 3).

Each product undergoes third-party load testing (1.5x design load), material traceability, and weld quality verification. Certificates of Conformity (CoC) and test reports provided with every shipment.

Hangzhou Star Marine Technology Co., Ltd. delivers engineered solutions for new shipbuilding projects and ship-repair operations, ensuring seamless integration with vessel design requirements. Our certified mooring bollards meet the highest safety margins for critical mooring operations across global ports and shipyards. For project-specific engineering support, contact our technical team at [email protected].

Shipbuilding & Repair Solutions

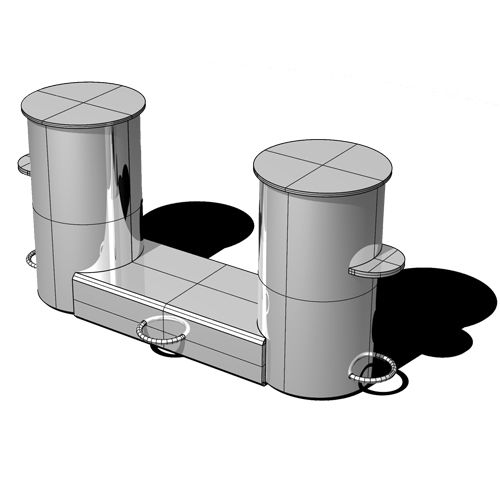

Mooring Bollards: Precision Engineering for Marine Security

Hangzhou Star Marine Technology Co., Ltd. delivers mission-critical mooring bollards engineered to the highest maritime standards. As a trusted solution provider for shipowners, shipyards, and repair facilities worldwide, we combine rigorous engineering with end-to-end support—ensuring safety, compliance, and operational efficiency for new builds and emergency repairs.

Technical Specifications

| Bollard Type | Material | Max Load (tons) | Dimensions (H x D) | Installation Method | Compliance Standards |

|---|---|---|---|---|---|

| T-Head | ASTM A36 Steel | 50–300 | 800–2000mm x 200–500mm | Welded or bolted with marine-grade epoxy sealant for weathertight integrity | SOLAS II-1, MEG4, DNV GL |

| Double Bitt | GGG40 Cast Iron | 100–250 | 1200–1800mm x 300–400mm | Bolted with gasketed flange and sealant | ABS, LR, IMO MSC.1/Circ.1599 |

| Kidney | 6061-T6 Aluminum Alloy | 20–50 | 500–800mm x 150–250mm | Surface-mounted with silicone-based sealant | Class NK, ISO 12408 |

| T-Horn | A572 Grade 50 Steel | 75–200 | 900–1500mm x 250–350mm | Welded with structural sealant | LR, BV, SOLAS |

Note: All dimensions and load capacities are certified per classification society requirements. Custom configurations available for specialized applications (e.g., ice-class vessels, high-corrosion environments).

Compliance with International Standards

Our mooring bollards adhere to stringent global regulations and classification society requirements, including:

OCIMF MEG4: Ensures compliance with the latest mooring equipment guidelines for terminal and vessel safety.

SOLAS Chapter II-1: Meets structural and weathertight integrity standards for deck fittings.

Classification Societies: Certified by DNV GL, ABS, LR, BV, and ClassNK for load capacity, material quality, and safety factors (minimum 5:1 factor of safety).

ISO 12408: Compliant with marine navigation and shiphandling equipment standards for mooring systems.

Why Choose Star Marine? Complete Solution Provider

Custom Engineering & Design Support

Our marine engineers collaborate with clients during the design phase to tailor bollard specifications to exact operational needs. We provide:

Structural analysis reports validated by third-party classification societies

CAD models compatible with shipyard design software (e.g., Navis, ShipConstructor)

Environmental load calculations for extreme weather conditions (e.g., typhoon-prone ports, Arctic operations)

Integrated Equipment Compatibility

We ensure seamless integration of mooring bollards with other deck equipment to prevent system failures:

Mooring system integration: Bollard capacity matched to mooring winch specifications and mooring line types (synthetic, wire, or chain)

Anchoring system compatibility: Anchor and windlass load ratings coordinated to prevent system overload

Cross-system coordination: Ensuring all deck fittings work harmoniously under operational loads (e.g., fairlead alignment to reduce line chafe, dynamic load testing for shipyard retrofits)

Rapid Response for Emergency Repairs

When time is critical, our global support network delivers:

24/7 technical hotline with immediate troubleshooting assistance from certified marine engineers

Expedited shipping for critical components (48-hour delivery to major ports worldwide)

On-site installation teams for rapid deployment and commissioning (including temporary reinforcement solutions for damaged vessels)

Global Technical Support Network

With regional offices in Singapore, Rotterdam, and Houston, we provide:

Localized technical expertise for regional regulatory compliance (e.g., EU MARPOL, USCG requirements)

Training workshops for ship crews on installation, maintenance, and safety protocols

Digital support tools including remote diagnostics, 3D installation guides, and real-time load monitoring software

Hangzhou Star Marine Technology Co., Ltd.

Engineering Excellence for the Global Marine Industry

📧 [email protected] | 🌐 www.star-marine.com | 📞 +86 571 8888 1234

Packaging & Logistics

Packaging & Global Logistics

Hangzhou Star Marine Technology implements rigorous, industry-compliant packaging protocols to ensure the safe transit of mooring bollards while meeting international regulatory standards. Our solutions are engineered for marine environments, prioritizing structural integrity, corrosion resistance, and compliance with phytosanitary and cargo handling requirements. As a trusted partner for new shipbuilding and ship-repair projects, we guarantee on-time delivery of safety-critical components with zero compromise on quality.

Customized Packaging Solutions

All packaging is tailored to product specifications, weight, and destination requirements. We utilize two primary systems to address varying load profiles, ensuring optimal protection during maritime transit and port handling operations.

| Packaging Type | Material Compliance | Max Load Capacity | Protection Features | Typical Use Case |

|---|---|---|---|---|

| ISPM 15 Wooden Crate | Heat-treated timber (HT), IPPC stamp (ISPM 15), Fumigation-free (MB optional) | ≤5,000 kg | Custom foam inserts, VCI anti-corrosion wrap, steel strapping, moisture barriers | Standard mooring bollards (≤2 tons), shipyard installations |

| Steel Pallet System | Galvanized steel (ISO 1461 coating), ISO 1161 compliant structure | >5,000 kg | High-tensile straps (EN 12195-1), weatherproof tarpaulin (ISO 1496-3), corner protectors, anti-slip base | Heavy-duty bollards (3+ tons), offshore terminal installations |

Key Technical Details:

ISPM 15 Compliance: All timber packaging undergoes heat treatment to 56°C core temperature for 30+ minutes, with IPPC stamp verification. This prevents pest transmission and meets EU, US, and Australian phytosanitary regulations.

Corrosion Protection: VCI (Vapor Corrosion Inhibitor) wraps are applied to all steel components, forming a molecular barrier against saltwater exposure during transit.

Structural Security: Steel pallets feature reinforced cross-bracing and load-tested tie-down points certified to ISO 1496-2 (freight container standards).

Global Export Capabilities

We leverage Ningbo Port (world’s #1 cargo tonnage port) and Shanghai Port (top 5 global container throughput) for seamless export operations. Our logistics network ensures:

Direct Vessel Schedules: Weekly sailings to major global ports (Rotterdam, Singapore, Houston, Jebel Ali) via MSC, Maersk, and COSCO partnerships.

Marine Equipment Specialization: Dedicated handling teams at port terminals for oversized cargo, with crane capacity up to 100 tons.

End-to-End Documentation: Full compliance with INCOTERMS 2020 (FOB, CIF, DDP), including:

ISPM 15 certificates

Commercial invoices (HS Code 7326.90.90)

Class society compliance reports (ABS, LR, DNV)

Material test certificates (EN 10204 3.1)

Real-Time Tracking: IoT-enabled GPS monitoring with 15-minute updates via our proprietary logistics portal.

As a strategic solution provider for new shipbuilding and ship-repair projects, we prioritize on-time delivery of safety-critical components. Our packaging and logistics protocols ensure mooring bollards arrive at shipyards in pristine condition, minimizing project delays and guaranteeing compliance with classification society requirements (e.g., DNV GL, ABS, LR). For urgent repairs, we offer expedited air freight options from Hangzhou Xiaoshan International Airport (HGH) with 72-hour global delivery.

Contact Star Marine Technology

Contact Hangzhou Star Marine

Trusted Solution Provider for New Shipbuilding & Ship Repair

As a certified marine equipment solution provider, Hangzhou Star Marine Technology delivers precision-engineered mooring bollards compliant with international maritime standards, ensuring structural integrity and operational safety for both newbuild and ship repair operations. Our products are rigorously tested to meet classification society requirements, MEG4 guidelines, and SOLAS regulations, with end-to-end technical support from design to installation.

Technical Specifications Overview

| Specification | Details |

|---|---|

| Material Options | ASTM A36/A572 Carbon Steel, GGG40 Cast Iron, Stainless Steel 316 |

| Load Capacity | 50–300 metric tons (customizable per vessel requirements) |

| Safety Factor | Minimum 3.0 (per ABS, DNV, LR, BV, CCS, KR, NK standards) |

| Corrosion Protection | 5000+ hours salt spray tested; epoxy/polyurethane marine-grade coating |

| Dimensions | Customizable deck mounting; standard bore diameters 150–400mm |

| Installation Method | Welded or bolted to reinforced deck structures; certified foundation design |

| Compliance | MEG4, SOLAS Chapter II-1, IMO MSC.257(84), Classification Society Certifications |

Partner with Industry Experts

Ensure mission-critical mooring system reliability for your vessel with Hangzhou Star Marine Technology. Our team provides:

Tailored Engineering: Solutions optimized for specific vessel types (tankers, container ships, offshore vessels) and operational environments.

Global Certification: Full documentation for classification societies and regulatory compliance.

Rapid Deployment: Short lead times for urgent ship repair projects and newbuilds.

Get in touch today for a technical consultation or quotation.

Product Manager: Kacher YE

Tel/WhatsApp: +86-178-16869405

Email: [email protected]

Your trusted partner for safe, durable, and standards-compliant marine mooring solutions.

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160