Marine Oil Water Separator – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Oil Water Separator

Marine Oil Water Separator: A Critical Component for Vessel Safety and Environmental Compliance

In the modern maritime industry, the safe and efficient operation of vessels is directly linked to compliance with stringent environmental regulations and the integrity of onboard systems. Among the most essential pieces of marine equipment is the marine oil water separator (OWS), a system designed to remove oil and other hydrocarbons from bilge water before discharge overboard. This equipment plays a pivotal role in preventing marine pollution, ensuring adherence to international standards such as MARPOL Annex I, and maintaining the operational safety of ships.

Oil-contaminated bilge water is an inevitable byproduct of engine room operations. If discharged untreated, it poses severe risks to marine ecosystems and can result in heavy fines, port state detentions, and reputational damage for shipowners. The marine oil water separator mitigates these risks by reducing oil content in bilge water to levels below 15 parts per million (ppm), the threshold permitted under international law. Advanced systems incorporate oil content monitors (OCM), automatic shut-off mechanisms, and alarm functions to ensure continuous compliance and prevent accidental discharges.

Beyond regulatory compliance, the reliability of an oil water separator directly impacts vessel safety. Malfunctioning or poorly maintained separators can lead to backpressure in bilge systems, overflow incidents, or even fire hazards due to oil accumulation. Therefore, selecting a high-performance, durable, and easy-to-maintain OWS is not merely a regulatory necessity but a fundamental aspect of safe ship operation.

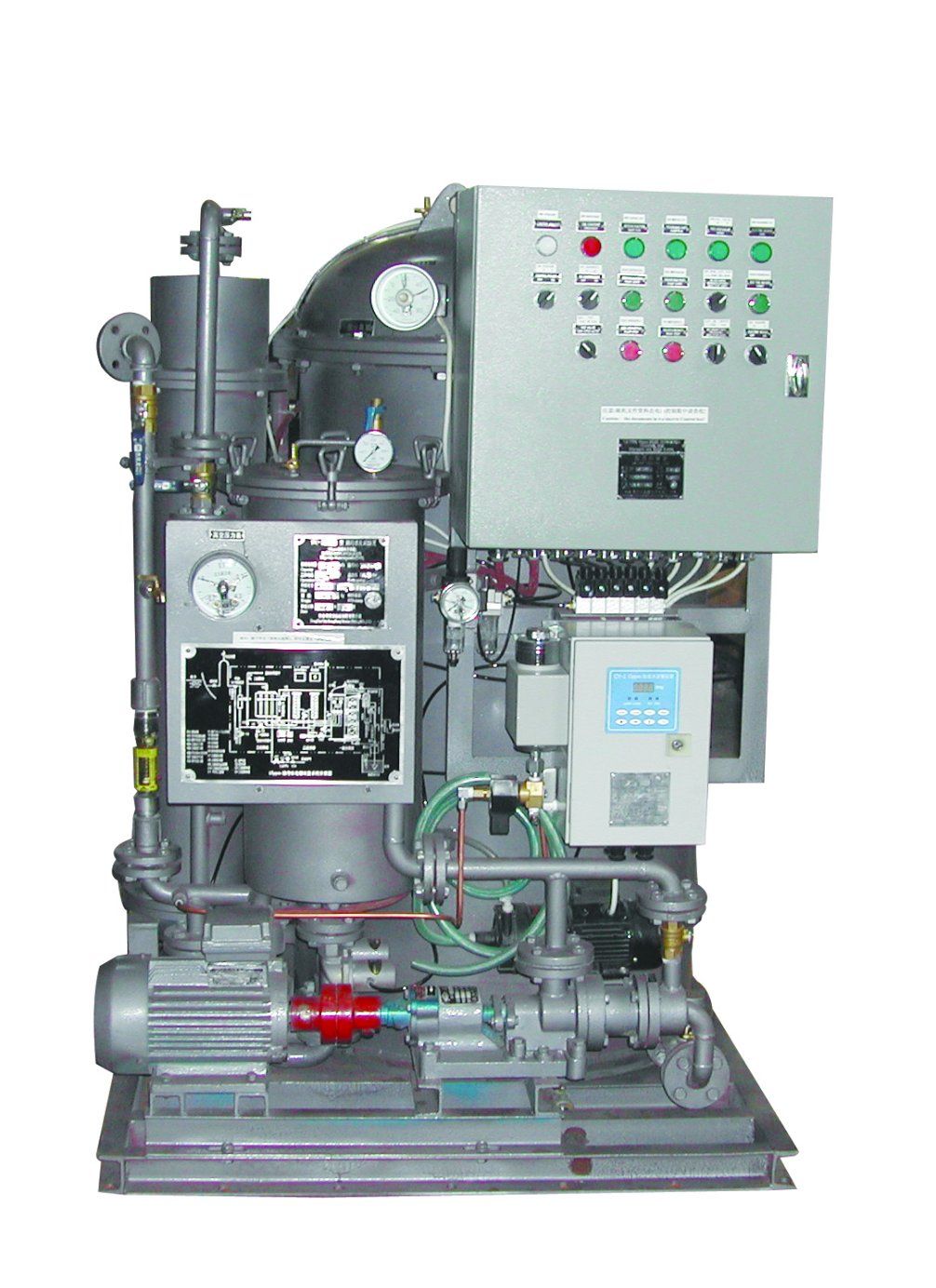

Hangzhou Star Marine Technology Co., Ltd. specializes in the design and export of marine outfittings, including a full range of marine oil water separators engineered to meet international standards. Our systems are built with corrosion-resistant materials, optimized for compact installation, and equipped with intelligent monitoring features to ensure long-term reliability under harsh marine conditions.

Sourcing marine oil water separators from Star Marine China offers significant cost advantages without compromising quality. Leveraging China’s advanced manufacturing infrastructure, economies of scale, and efficient supply chain logistics, we deliver high-performance systems at competitive price points. Our in-house R&D team ensures continuous innovation, while our ISO and CCS certifications validate our commitment to quality and safety.

Below is a comparison of standard specifications for Star Marine’s oil water separator models:

| Model | Flow Rate (L/H) | Max Oil Content (ppm) | Compliance Standard | Material | Certifications |

|---|---|---|---|---|---|

| SMS-05 | 500 | ≤15 | MARPOL Annex I | Stainless Steel 316 | CCS, ISO 9001 |

| SMS-10 | 1,000 | ≤15 | MARPOL Annex I | Stainless Steel 316 | CCS, ISO 9001 |

| SMS-20 | 2,000 | ≤15 | MARPOL Annex I | Stainless Steel 316 + Coating | CCS, ISO 9001, RINA |

By combining technical excellence, regulatory compliance, and cost-effective manufacturing, Hangzhou Star Marine Technology provides shipbuilders, operators, and marine suppliers with a trusted solution for one of the most critical systems onboard any vessel.

Technical Specs & Approval

Technical Specifications

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures marine oil water separators (OWS) compliant with MARPOL Annex I and MEPC.107(49) standards for global vessel operations. Our systems ensure bilge water discharge meets stringent 15 ppm oil content limits, integrating advanced coalescence and monitoring technology. All units undergo rigorous factory acceptance testing per ISO 9001:2015 protocols to guarantee reliability in harsh marine environments.

Material selection prioritizes corrosion resistance and structural integrity. Aluminum alloy variants (5083/5086 grade) are ideal for lightweight applications in coastal or tropical zones, offering superior resistance to saltwater degradation. Carbon steel models (ASTM A36 with epoxy coating) provide robust performance for deep-sea or Arctic operations, featuring reinforced framing to withstand extreme vibration and thermal cycling. Both configurations maintain IP66-rated watertight integrity across all flange connections and access points, validated through 0.5 MPa hydrostatic testing.

Operational parameters include automatic oil-sludge discharge cycles, continuous 3-phase monitoring via integrated 4-20mA sensors, and redundant high-oil-content alarms. Units support flow rates from 0.5 to 5.0 m³/h with <5-second response time to contamination spikes. Temperature tolerance spans -20°C to +70°C, accommodating engine room conditions. Electrical interfaces comply with IEC 60945 for marine EMC safety.

Key technical parameters are summarized below:

| Parameter | Specification |

|---|---|

| Material Options | Marine-grade aluminum alloy or epoxy-coated carbon steel |

| Dimensions (L×W×H) | 850×600×1200 mm (Standard) ±5% tolerance |

| Flow Rate Range | 0.5–5.0 m³/h (adjustable per IMO guidelines) |

| Separation Efficiency | ≤15 ppm oil content in effluent (MEPC.107 certified) |

| Pressure Rating | 0.6 MPa max operating pressure |

| Temperature Range | -20°C to +70°C (ambient) |

| Certifications | MEPC.107(49), ISO 9001:2015, DNV-GL Type Approval |

Installation flexibility is achieved through modular skid-mounted designs with ISO-standard mounting feet and ISO 10208-compliant flange interfaces (DN50 inlet/outlet). Weight varies by material: aluminum units average 220 kg, while steel variants weigh approximately 380 kg. All separators include integrated sight glasses, manual sampling ports, and CE-marked control panels with remote alarm relay outputs.

Hangzhou Star provides comprehensive technical support for integration, including 3D CAD models for space planning and commissioning supervision by certified marine engineers. Our separators require minimal maintenance due to self-cleaning hydrocyclone stages and accessible service points, reducing vessel downtime. Every unit ships with a full test dossier, including material traceability certificates and performance validation reports for port state control inspections. Quality assurance remains our cornerstone for sustainable maritime operations.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine oil water separator solutions tailored for shipbuilding and vessel repair projects worldwide. As a specialized provider in marine outfittings, we integrate engineering expertise, regulatory compliance, and rapid project execution to support shipyards and maritime operators during new construction and retrofitting operations. Our systems are designed to meet international discharge standards, including MEPC.107(49) and IMO Resolution MEPC.1/Circ.834/Rev.3, ensuring full compliance with MARPOL Annex I requirements.

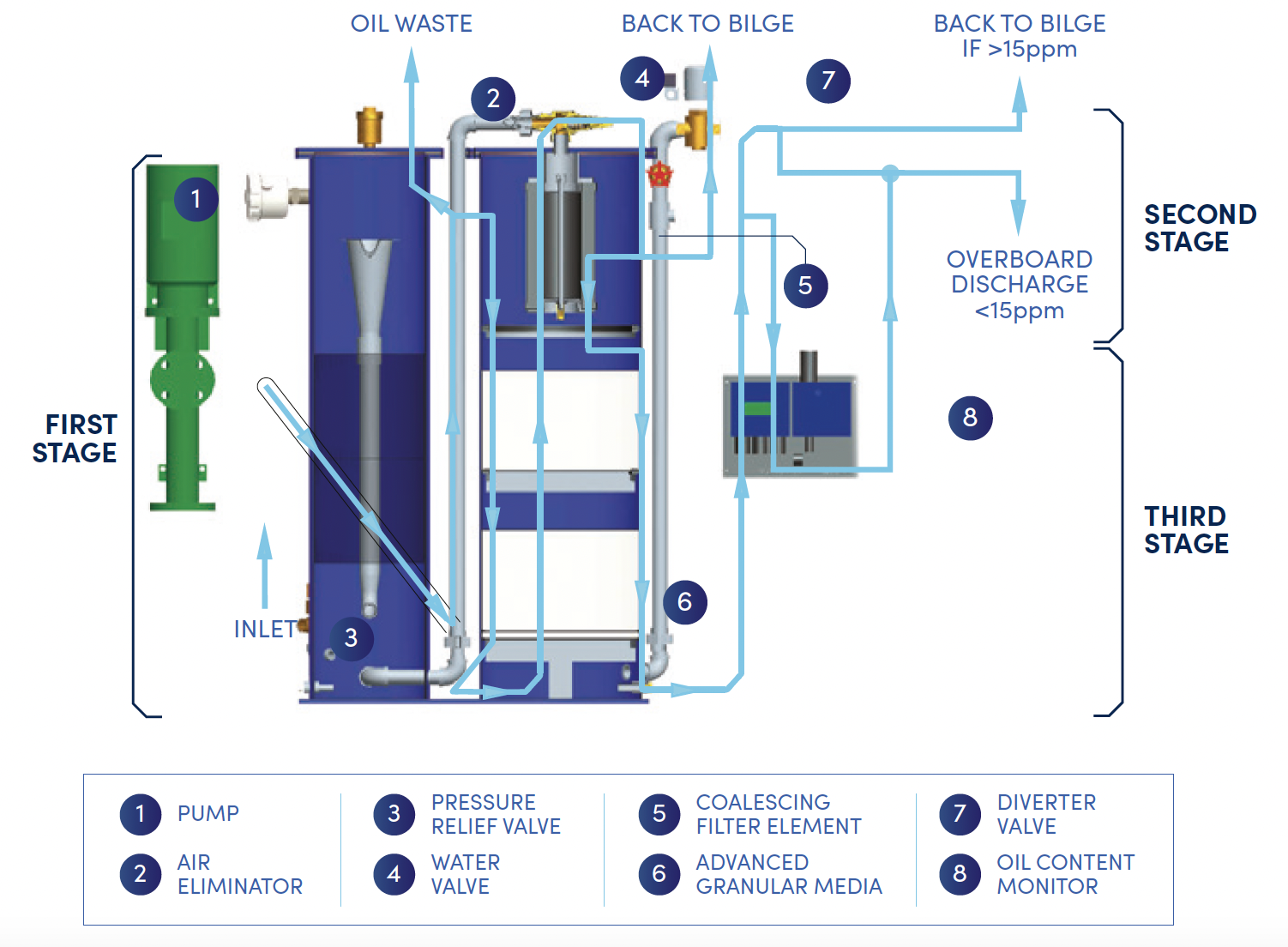

Our oil water separators are engineered for efficient operation across diverse marine environments, from offshore support vessels to bulk carriers and container ships. Utilizing advanced three-stage separation technology—gravity, coalescing, and final polishing with ultrafiltration or membrane systems—our units consistently achieve effluent oil content below 15 ppm, with many configurations capable of reaching 5 ppm. This performance is critical for vessels operating in sensitive or zero-discharge zones, where environmental regulations are strictly enforced.

For new shipbuilding projects, Hangzhou Star Marine provides full integration support from design to commissioning. Our technical team collaborates directly with naval architects and classification societies to ensure compatibility with onboard systems, space constraints, and load specifications. We offer customized footprint designs, material selections (including marine-grade stainless steel and corrosion-resistant coatings), and control system interfaces compatible with centralized monitoring platforms. All units are supplied with detailed installation manuals, P&ID diagrams, and factory acceptance test (FACT) reports.

In repair and retrofit applications, we prioritize fast turnaround and operational continuity. Our global service network enables prompt assessment, spare part delivery, and on-site technical support. We maintain a stock of standard and upgraded models, allowing for quick replacement or capacity expansion. Additionally, our team conducts performance audits of existing systems, identifying inefficiencies and recommending upgrades to meet current environmental standards.

All Star Marine oil water separators are certified by major classification societies, including CCS, LR, DNV, ABS, and NK. We also support clients with documentation packages required for IOPP certification and port state control inspections.

Below is an overview of our standard product specifications:

| Parameter | Specification |

|---|---|

| Flow Rate Range | 0.5 – 50 m³/h |

| Inlet Oil Content | Up to 5,000 ppm |

| Outlet Oil Content | ≤15 ppm (standard), ≤5 ppm (optional) |

| Design Pressure | 0.6 MPa max |

| Materials | Carbon steel (coated), SS316, duplex options |

| Electrical Supply | 380V/440V, 50/60Hz, customizable |

| Control System | PLC with touchscreen HMI, alarm logging |

| Certifications | MEPC.107(49), ISO 9001, DNV, LR, ABS, NK, CCS |

With a commitment to quality, compliance, and rapid response, Hangzhou Star Marine Technology ensures reliable, future-ready oily water separation solutions for the global maritime industry.

Packaging & Logistics

Packaging & Logistics for Marine Oil Water Separator Exports

Hangzhou Star Marine Technology implements rigorous packaging protocols for marine oil water separators (OWS) to ensure integrity during global transit. Our methodology aligns with IMO MSC.1/Circ.1394 guidelines for machinery handling and adheres strictly to international phytosanitary standards. All OWS units undergo pre-shipment preservation using vapor corrosion inhibitors (VCI) and desiccants before enclosure in custom-engineered export packaging. This dual-layer protection mitigates moisture ingress and vibration damage inherent in maritime supply chains.

Wooden export cases form the primary containment system for OWS assemblies. These cases utilize 18mm thick, kiln-dried plywood compliant with ISPM 15 regulations, bearing the official HT (Heat Treatment) stamp and IPPC certification mark. Internal framing incorporates marine-grade plywood cross-bracing at critical stress points, while external surfaces receive a water-resistant sealant coating. Each crate is dimensioned to accommodate the OWS unit’s footprint plus 150mm clearance on all sides for shock-absorbing polyethylene foam inserts. Corner protectors and steel strapping (19mm width, 3,500 kg tensile strength) secure the assembly, with lifting lugs welded to the base frame for crane operations.

Where applicable, heavy-duty steel pallets serve as the foundational transport platform. Constructed from 3mm galvanized steel with non-slip decks, these pallets support static loads up to 5,000 kg and integrate seamlessly with ISO container corner castings. Palletized units feature welded tie-down points compatible with lashing bridges, eliminating the need for wooden dunnage that could attract pests. All steel components undergo zinc-rich primer coating to withstand salt-laden air during ocean transit.

Shipments originate exclusively from China’s premier maritime hubs: Ningbo-Zhoushan Port (world’s busiest container port) and Shanghai Port. Both facilities offer direct access to major global trade lanes with dedicated roll-on/roll-off (RoRo) and container berths. Our logistics partners maintain C-TPAT certification and utilize GPS-tracked reefers for temperature-sensitive components. Pre-shipment documentation includes ISPM 15 certificates, non-wood packaging declarations, and detailed stowage plans compliant with CSS Code Annex 13.

The following table summarizes critical packaging specifications:

| Parameter | Wooden Case Specification | Steel Pallet Specification |

|---|---|---|

| Material | ISPM 15 Certified Plywood (18mm) | Galvanized Steel (3mm) |

| Treatment | HT 56°C min. 30 min. (IPPC Marked) | Zinc-Rich Primer Coating |

| Max. Payload | 3,800 kg | 5,000 kg |

| Internal Dimensions | Custom (+150mm clearance buffer) | 1,200 x 1,000 mm (ISO Standard) |

| Port Handling Priority | Ningbo (RoRo Direct Loading) | Shanghai (Containerized) |

Hangzhou Star assumes end-to-end responsibility for packaging validation through simulated ISTA 3A testing. Units are staged at Ningbo/Shanghai bonded warehouses 72 hours prior to vessel loading, with real-time humidity monitoring throughout storage. This integrated approach ensures OWS systems arrive at destination ports—fully operational and regulatory-compliant—reinforcing our commitment to maritime operational excellence.

Contact Star Marine

For international buyers and maritime partners seeking reliable, high-performance marine oil water separator systems, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted manufacturer and exporter in the marine outfittings sector. Our engineered solutions are designed to meet stringent international regulations, including MEPC.107(49) and MARPOL Annex I, ensuring compliance, operational efficiency, and environmental protection across commercial, offshore, and naval vessel applications.

At the heart of our export service is direct access to technical expertise and responsive project coordination. We understand that selecting the right oil water separator involves evaluating system capacity, automation level, discharge monitoring integration, and compatibility with existing onboard systems. To ensure precise alignment with your operational requirements, we encourage direct consultation with our dedicated Product Manager, Kacher YE. With extensive experience in marine pollution prevention systems and global project execution, Mr. Ye provides tailored support from initial specification review to after-sales service planning.

Our marine oil water separators are built with advanced coalescing plate technology, integrated 15 ppm bilge alarms, and optional PLC-controlled operation for seamless integration into modern engine room automation systems. We offer a range of standard models from 0.25 m³/h to 5.0 m³/h, with customized configurations available to meet specific vessel designs or flag state requirements. All units undergo rigorous factory testing and are supplied with full certification, including Type Approval documents from recognized classification societies.

To initiate a technical discussion or request a quotation, please contact Kacher YE directly via email at [email protected]. In your inquiry, include vessel type, required flow rate, applicable regulations, and any integration preferences to expedite the proposal process. Our team operates in multiple time zones and responds to all inquiries within 24 business hours.

The following table outlines key specifications of our standard marine oil water separator series:

| Model | Flow Rate (m³/h) | Inlet Oil Content | Outlet Standard | Dimensions (L×W×H, mm) | Weight (kg) | Certifications |

|---|---|---|---|---|---|---|

| SMS-OWS-0.25 | 0.25 | ≤20,000 ppm | ≤15 ppm | 1,200×800×1,600 | 280 | CCS, EC, RINA, ABS |

| SMS-OWS-0.5 | 0.5 | ≤20,000 ppm | ≤15 ppm | 1,400×900×1,800 | 360 | CCS, EC, DNV, LR |

| SMS-OWS-1.0 | 1.0 | ≤20,000 ppm | ≤15 ppm | 1,600×1,000×2,000 | 450 | CCS, EC, NK, BV |

| SMS-OWS-2.5 | 2.5 | ≤20,000 ppm | ≤15 ppm | 2,000×1,200×2,200 | 680 | CCS, EC, ABS, DNV |

| SMS-OWS-5.0 | 5.0 | ≤20,000 ppm | ≤15 ppm | 2,500×1,500×2,500 | 1,100 | CCS, EC, LR, BV |

All models support remote monitoring options and alarm interface integration. Custom voltages, materials, and control panels are available upon request.

Partner with Hangzhou Star Marine Technology for technically sound, regulation-compliant oil water separation solutions backed by professional export support. Contact Kacher YE today to discuss your project requirements and receive a detailed technical proposal.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160