Marine Check Valve – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Check Valve

Marine Check Valve: Critical Safety Component and Strategic Sourcing Advantage

Marine check valves represent a fundamental safety component within vessel engineering systems, mandated by international regulations including SOLAS for critical applications. Their primary function—preventing reverse flow of fluids or gases—is non-negotiable for operational integrity and crew safety. In bilge systems, failure of a check valve can lead to catastrophic flooding if seawater backflows through drainage lines during hull breaches or pump failure. Similarly, within fire main systems, these valves ensure unidirectional water flow to firefighting outlets, preventing pressure loss that could render suppression efforts ineffective during emergencies. Engine cooling circuits also rely on check valves to maintain coolant directionality; reversal could cause overheating, engine seizure, or even fire. The consequences of valve failure extend beyond immediate safety hazards to include environmental pollution risks from uncontrolled discharge and significant financial losses due to downtime and repairs. Consequently, maritime classification societies (DNV, LR, ABS, CCS) enforce stringent performance and material standards, requiring valves to withstand cyclic pressure surges, corrosion from seawater, and maintain sealing integrity under extreme conditions. Selecting valves that consistently meet or exceed these standards is not merely a procurement decision but a direct investment in vessel seaworthiness and regulatory compliance.

Sourcing high-performance marine check valves from Hangzhou Star Marine Technology offers shipyards, operators, and repair facilities a compelling strategic advantage through demonstrable cost-effectiveness without compromising on safety or quality. Our integrated manufacturing approach leverages China’s efficient production ecosystem while adhering strictly to Western engineering specifications and quality control protocols. Unlike suppliers who may cut corners on materials or testing to reduce costs, Star Marine utilizes certified marine-grade alloys (ASTM A351 CF8M, CF3M) and subjects every valve to rigorous hydrostatic and pneumatic testing at 1.5x working pressure, alongside mandatory non-destructive examination per ISO 5208 leakage Class VI standards. This ensures absolute reliability while optimizing the total cost of ownership. The table below illustrates the tangible value proposition compared to alternative sourcing regions:

| Parameter | Hangzhou Star Marine (China) | European Supplier | US Supplier | Cost Advantage vs. West |

|---|---|---|---|---|

| Avg. Lead Time | 4-6 Weeks | 8-12 Weeks | 10-14 Weeks | 30-40% Faster Delivery |

| FOB Price (DNV-GL 4″ BW) | $1,200 | $1,700 | $1,850 | 29-35% Lower Cost |

| Material Certification | Full MTRs + CCS/DNV Reports | Standard MTRs | Standard MTRs | Enhanced Traceability |

| Standard Testing | Hydro + Pneumatic + NDT | Hydro Only | Hydro Only | Superior Quality Gate |

This efficiency stems from Star Marine’s vertically integrated facility in Hangzhou, which controls the entire production chain from raw material sourcing to final certification, eliminating intermediary markups. Crucially, our valves carry full Type Approval from major classification societies including DNV-GL and CCS, ensuring immediate acceptance during vessel surveys. The combination of accelerated delivery cycles, significant cost reduction, and uncompromised adherence to maritime safety standards makes Star Marine the optimal partner for global marine procurement. Investing in our check valves directly mitigates operational risk while optimizing capital expenditure—a critical consideration in the competitive maritime sector.

Technical Specs & Approval

Hangzhou Star Marine Technology Co., Ltd. provides high-performance marine check valves engineered for reliable operation in demanding maritime environments. These valves are critical components in shipboard piping systems, designed to prevent backflow and ensure unidirectional fluid movement in applications such as cooling water systems, ballast lines, fuel transfer, and firefighting systems. Constructed to meet international marine standards, our check valves deliver durability, leak-tight sealing, and long service life under variable pressure and temperature conditions.

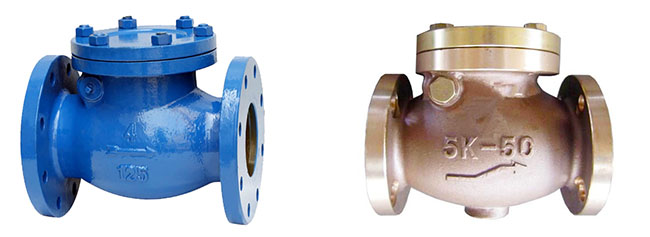

The marine check valves offered by Hangzhou Star Marine Technology are available in two primary body materials: bronze and cast steel. Bronze valves are ideal for seawater and freshwater applications due to their excellent corrosion resistance and are commonly used in low to medium-pressure systems. Cast steel variants are suited for high-pressure and high-temperature environments, making them suitable for steam lines, boiler feed systems, and heavy-duty industrial marine applications. Both materials are sourced to meet stringent material certifications and are tested for chemical composition and mechanical properties in accordance with international standards.

Our check valves are designed and manufactured in compliance with JIS (Japanese Industrial Standards) and DIN (Deutsches Institut für Normung) specifications, ensuring global interchangeability and compatibility with standard marine piping systems. These standards govern dimensional accuracy, pressure ratings, flange connections, and performance testing protocols. All valves undergo rigorous hydrostatic and pneumatic testing prior to shipment to verify structural integrity and sealing performance.

The valves are available in pressure classes ranging from PN6 to PN40, allowing selection based on system requirements. PN6 valves are suitable for low-pressure auxiliary systems, while PN40 models are engineered for critical high-pressure applications. End connections are typically flanged to facilitate secure installation and easy maintenance. The internal design features a hinged disc mechanism that opens under forward flow and closes automatically when flow reverses or stops, minimizing water hammer effects and enhancing system protection.

Below is a summary of the key technical parameters for our marine check valve product line:

| Parameter | Bronze Check Valve | Cast Steel Check Valve |

|---|---|---|

| Body Material | ASTM B62 Bronze | ASTM A216 WCB Cast Steel |

| Disc Material | Bronze or Stainless Steel | Stainless Steel |

| Seat Material | Bronze or Nitrile Rubber | Stainless Steel |

| Pressure Rating | PN6 to PN16 | PN10 to PN40 |

| Temperature Range | -20°C to +200°C | -20°C to +425°C |

| Standards Compliance | JIS K 5150, DIN 3352 | JIS K 5150, DIN 3352 |

| Connection Type | Flanged (JIS 10K, 16K, DIN PN10–PN40) | Flanged (JIS 10K–20K, DIN PN10–PN40) |

| Size Range (DN) | DN15 to DN300 | DN50 to DN400 |

| Test Standard | API 598, ISO 5208 | API 598, ISO 5208 |

| Application | Seawater, freshwater, oil | Steam, high-pressure water, oil |

All marine check valves are certified by recognized classification societies upon request, including CCS, ABS, DNV, and LR, ensuring compliance with global marine safety and quality requirements. Hangzhou Star Marine Technology supports OEM/ODM services and provides comprehensive technical documentation for seamless integration into vessel systems.

Shipbuilding Solutions

Star Marine Complete Solution for Marine Check Valve Integration in Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine check valve solutions essential for fluid control integrity across new vessel construction and critical repair projects. Our focus extends beyond component supply; we provide integrated technical support, rapid logistics, and certification compliance to minimize project delays and ensure operational reliability from keel-laying through vessel service life. For shipyards and repair facilities, this translates to reduced downtime and assured system performance under demanding maritime conditions.

During new build phases, Star Marine collaborates closely with naval architects and piping system designers. We supply DNV-GL, LR, ABS, and CCS certified check valves meeting stringent IMO and SOLAS requirements for seawater, fuel oil, lubricating oil, and ballast systems. Our engineering team facilitates seamless integration by providing detailed 3D model data, material test reports (MTRs), and pressure testing documentation upfront, preventing costly design clashes or rework during installation. Standard lead times for common sizes (DN15-DN600) are maintained at 4-6 weeks, with expedited manufacturing options available for critical path items, ensuring valves arrive synchronized with the shipyard’s block assembly schedule.

For vessel repair and retrofit operations, where time equates directly to lost revenue, Star Marine’s global response network is pivotal. We maintain strategic inventory hubs in Shanghai, Singapore, and Rotterdam stocking high-demand check valve types and materials (bronze, cast iron, ductile iron, stainless steel). Our 24/7 technical support desk provides immediate troubleshooting guidance, while dedicated export managers coordinate same-day dispatch for urgent spares requests. This rapid deployment capability, often achieving port delivery within 72 hours globally for standard items, significantly curtails dry-dock periods and operational interruptions.

Technical specifications for our core marine check valve range are detailed below, reflecting adherence to international marine standards:

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Pressure Rating | PN10, PN16, PN25, Class 150, Class 300 | ISO 5208, API 598 |

| Temperature Range | -20°C to +200°C (standard materials) | ISO 10434 |

| Seat Seal | EPDM, NBR, Viton, Metal-to-Metal | DNVGL-SCP-ST-001 |

| Body Material | ASTM A126 Class B, ASTM A216 WCB, CF8M | ISO 4136 |

| Testing | Shell Test: 1.5x PS, Seat Test: 1.1x PS | ISO 5208 Cat B |

Star Marine’s value proposition lies in combining certified product quality with responsive project execution. We proactively manage documentation for customs clearance and port acceptance, including Certificate of Origin and Material Traceability Reports, eliminating bureaucratic delays. Whether supporting a new container vessel’s propulsion system installation or replacing a failed check valve during an emergency offshore repair, our integrated approach ensures fluid systems operate safely and efficiently. Partner with Hangzhou Star Marine Technology for dependable check valve solutions where timing and technical precision define project success. Contact our export team for immediate project support.

Packaging & Logistics

Packaging & Logistics for Marine Check Valves – Hangzhou Star Marine Technology Co., Ltd.

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all marine check valves are packaged and prepared for export in full compliance with international maritime shipping standards and regulatory requirements. Our packaging protocols are designed to protect product integrity during long-distance sea freight, while also meeting phytosanitary and customs regulations across global markets. We utilize two primary packaging systems: ISPM 15-certified wooden cases and reinforced steel pallets, selected based on valve size, weight, and destination requirements.

For smaller to medium-sized check valves, we use wooden export crates that are fully compliant with the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This certification ensures that all wooden packaging materials have undergone approved heat treatment to eliminate pests and pathogens, preventing the spread of invasive species through international trade. Each wooden case is constructed from durable, kiln-dried hardwood or plywood, with internal bracing and cushioning to prevent movement during transit. The valves are individually wrapped in anti-corrosion VCI (Vapor Corrosion Inhibitor) paper and secured within the crate using custom-fit foam inserts or wooden blocks. The exterior of each case is clearly labeled with handling instructions, product details, batch numbers, and destination information to facilitate efficient customs clearance and logistics tracking.

For larger, heavy-duty check valves—typically those exceeding 50 kg or with flanged ends—we deploy steel pallets with additional structural reinforcement. These pallets are fabricated from galvanized or powder-coated steel to resist corrosion during ocean transport. Valves are securely fastened using industrial-grade straps or bolted fixtures, ensuring zero displacement during vessel movement or port handling. The steel pallet system is especially recommended for shipments to regions with strict environmental regulations or where wooden packaging is restricted.

All export shipments originate from the major Chinese port hubs of Ningbo and Shanghai, both of which offer direct container services to North America, Europe, Southeast Asia, the Middle East, and Africa. We coordinate with certified freight forwarders to ensure timely container loading, proper stowage, and full documentation compliance, including packing lists, certificates of origin, and phytosanitary certificates where applicable.

Below is a summary of our standard packaging configurations:

| Valve Size Range | Packaging Type | Material Specification | Weight Capacity | Compliance Standard |

|---|---|---|---|---|

| DN15 – DN150 | Wooden Export Case | Kiln-dried plywood, ISPM 15 | Up to 100 kg | ISPM 15, IMO Safe Goods |

| DN150 – DN600 | Steel Pallet with Frame | Galvanized steel, anti-rust | Up to 2,000 kg | IEC, ISO 1496-1 |

| Special Orders | Custom Crating | Mixed (steel/wood composite) | Variable | Client-specific standards |

Our packaging strategy reflects our commitment to product safety, regulatory compliance, and operational efficiency in global marine equipment logistics.

Contact Star Marine

Initiate Your Marine Check Valve Procurement with Engineering Precision

For mission-critical marine check valve solutions that ensure system integrity and regulatory compliance across global voyages, Hangzhou Star Marine Technology stands as your definitive engineering partner. Our valves are engineered to withstand the harshest maritime environments—from deep-sea pressure fluctuations to corrosive saltwater exposure—while adhering strictly to SOLAS, ISO 5208, and class society standards (DNV, ABS, LR, NK, KR). As an ISO 9001-certified manufacturer with 15 years of specialized marine valve production, we integrate advanced metallurgy, rigorous non-destructive testing (NDT), and lifecycle validation into every component. This technical rigor translates to reduced downtime, extended service life, and unwavering safety for propulsion, ballast, and firefighting systems.

Our marine check valves are not merely components but engineered safeguards for your vessel’s operational continuity. Below outlines core technical specifications reflecting our commitment to maritime excellence:

| Parameter | Specification Detail | Compliance Standard |

|---|---|---|

| Material Configuration | ASTM A216 WCB, CF8M; Duplex 2205; Super Duplex 2507 | ASTM A743 / A995 |

| Pressure Rating | Class 150 to 2500 (ASME B16.34) | EN 1092-1 / ISO 5208 |

| Size Range | DN15 to DN600 (½” to 24″) | ISO 5752 / API 600 |

| Seat Leakage | Zero leakage at 110% of design pressure | ISO 5208 Class A |

| Testing Protocol | Hydrostatic, pneumatic, ultrasonic (UT) inspection | API 598 / MSS SP-61 |

These specifications underscore our capacity to deliver valves that exceed operational demands while aligning with your vessel’s classification requirements. Whether retrofitting legacy systems or integrating into newbuild projects, our engineering team collaborates directly with naval architects and shipyard procurement officers to ensure seamless compatibility. We maintain strategic partnerships with global logistics providers to guarantee timely delivery to major shipbuilding hubs—including Shanghai, Singapore, Rotterdam, and Houston—without compromising on customs documentation or export control adherence.

To secure valves that embody reliability under extreme conditions, direct technical dialogue with our Product Management team is essential. Generic procurement channels cannot address the nuanced engineering variables inherent in marine applications. Kacher YE, our dedicated Product Manager for Marine Valves, possesses unparalleled expertise in valve dynamics, material science, and international regulatory frameworks. With over a decade of field experience resolving complex valve failures and optimizing system performance, Kacher ensures your procurement process is grounded in engineering pragmatism—not transactional convenience.

Contact Kacher YE immediately to advance your project. Initiate a technical consultation by emailing [email protected] with your vessel specifications, operational parameters, and class society requirements. Include reference codes (e.g., STC-700 Series for high-flow duplex check valves) to expedite your quotation. Kacher will provide a comprehensive technical dossier, 3D CAD models for integration validation, and a tailored delivery schedule within 48 business hours. For urgent operational support, reference your vessel’s IMO number and port location to prioritize response.

Hangzhou Star Marine Technology operates at the intersection of maritime safety and precision engineering. Trust our valves to safeguard your vessel’s critical fluid systems—and trust Kacher YE to navigate the technical complexities of your procurement. Your next voyage demands components engineered without compromise. Reach out today to establish a partnership built on technical excellence and export execution.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160