Marine Electrical Cable – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Electrical Cable

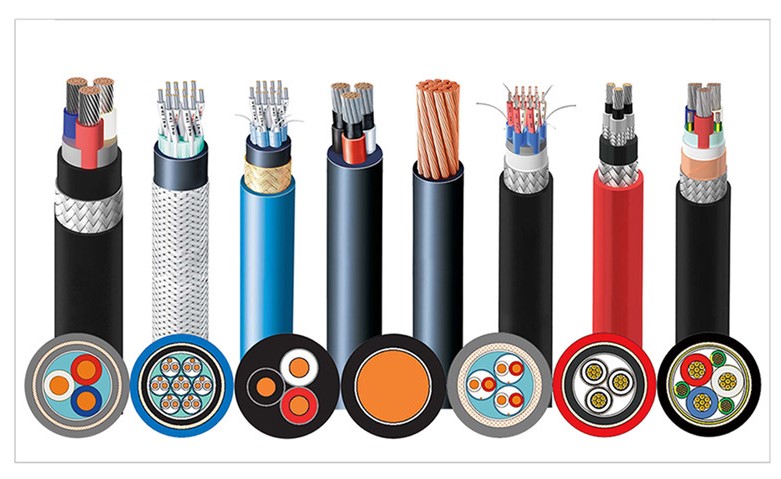

Marine electrical cable is a critical component in the safe and efficient operation of modern vessels, serving as the backbone of onboard power distribution, control systems, and communication networks. In the harsh and demanding marine environment, where exposure to saltwater, vibration, temperature extremes, and fire hazards is constant, the performance and reliability of electrical cables directly influence vessel safety, operational continuity, and crew protection. A failure in the electrical system due to substandard cabling can lead to catastrophic outcomes, including power loss, equipment malfunction, or fire outbreaks. Therefore, marine electrical cables must meet stringent international standards such as IEC 60092, ISO 10508, and classification society requirements from ABS, DNV, LR, and others to ensure fire resistance, low smoke emission, and resistance to oil and chemicals.

At Hangzhou Star Marine Technology Co., Ltd., we specialize in the design, manufacturing, and export of high-performance marine electrical cables that are engineered to withstand the unique challenges of maritime applications. Our cables are constructed with tinned copper conductors, cross-linked polymer insulation (XLPO), and low smoke zero halogen (LSZH) sheathing, ensuring excellent conductivity, durability, and safety in emergency situations. These technical specifications not only comply with global marine standards but also enhance system longevity and reduce maintenance costs over the vessel’s lifecycle.

Sourcing marine electrical cables from Star Marine China offers significant cost advantages without compromising on quality. China’s advanced manufacturing infrastructure, combined with our vertically integrated production processes, allows us to deliver premium-grade cables at highly competitive prices. We maintain strict quality control protocols throughout the manufacturing cycle, supported by ISO 9001 certification and rigorous testing procedures, including voltage withstand, flame propagation, and smoke density tests. This ensures that every meter of cable meets the exacting demands of shipbuilders, offshore operators, and classification societies.

In addition to cost efficiency, our strategic location in Hangzhou provides streamlined logistics for global export, with reliable access to major seaports and established shipping partnerships. We offer customized cable solutions tailored to specific vessel types—ranging from commercial cargo ships and offshore platforms to yachts and naval vessels—ensuring optimal performance across diverse applications.

The following table outlines key technical and commercial advantages of Star Marine’s marine electrical cables:

| Feature | Specification / Benefit |

|---|---|

| Conductor Material | Tinned copper for corrosion resistance |

| Insulation | Cross-linked polyolefin (XLPO) for thermal stability |

| Sheathing | LSZH (Low Smoke Zero Halogen) for fire safety |

| Voltage Rating | 300/500 V, 600/1000 V |

| Standards Compliance | IEC 60092-370, IEC 60092-351, ABS, DNV, LR, etc. |

| Production Capacity | 500,000 km per month |

| Lead Time | 15–25 days after order confirmation |

| Export Experience | Over 30 countries served, including EU, Southeast Asia, Middle East |

By choosing Hangzhou Star Marine Technology, clients gain access to technically superior, safety-certified marine electrical cables at a fraction of the cost associated with Western suppliers, making us a trusted partner in global marine outfittings.

Technical Specs & Approval

Marine Electrical Cable Technical Specifications

Hangzhou Star Marine Technology Co. Ltd. designs and manufactures marine electrical cables to stringent international standards, ensuring operational safety and longevity in demanding maritime environments. Our cables comply fully with IEC 60092-350 series standards for shipboard electrical installations, with additional validation for major classification societies including ABS, DNV, LR, and CCS. Critical design parameters prioritize mechanical resilience, environmental resistance, and electrical performance under continuous vibration, saltwater exposure, and temperature fluctuations ranging from -25°C to +90°C.

Conductor construction utilizes high-purity tinned copper strands to prevent oxidation and maintain conductivity in humid conditions. Armor selection between aluminum wire armor (AWA) and steel wire armor (SWA) is application-specific: AWA reduces weight and cost for non-critical internal routing, while SWA provides superior crush resistance for external deck installations or high-traffic zones. Both armor types undergo rigorous galvanic corrosion testing to ensure compatibility with common hull materials.

Watertight integrity is achieved through a dual-layer sealing system. The inner layer employs moisture-resistant cross-linked polyethylene (XLPE) insulation rated for 1 kV, while the outer jacket uses oil- and flame-retardant chlorinated polyethylene (CPE). All cables undergo submersion testing at 10 meters depth for 24 hours with zero dielectric breakdown, exceeding IEC 60092-359 watertightness requirements. This prevents electrolytic tracking and short circuits during bilge flooding or heavy weather operations.

Dimensional specifications balance flexibility with durability. Conductor cross-sections range from 1.5 mm² to 240 mm² to accommodate diverse power and control circuits. Outer diameters are optimized for conduit compatibility, with minimum bend radii set at 6× the cable diameter during installation to avoid insulation damage. Armor thickness scales proportionally with conductor size to maintain structural stability under tension loads up to 15 kN.

The following table details core technical parameters for standard production variants:

| Parameter | Specification | Standard Reference | Export Compliance Notes |

|---|---|---|---|

| Conductor Material | Annealed tinned copper | IEC 60228 Class 5 | Halogen-free option available |

| Insulation | XLPE (1 kV rating) | IEC 60092-351 | Low-smoke zero-halogen (LSZH) variant |

| Outer Jacket | CPE (black, UV-resistant) | IEC 60092-359 | Flame spread per IEC 60332-3 Cat A |

| Armor Type | AWA or SWA (zinc-coated for SWA) | IEC 60092-375 | SWA mandatory for external use |

| Watertight Test | 10m depth, 24h, 2.5 kV AC | IEC 60092-359 | Test certificate provided per batch |

| Operating Temperature | -25°C to +90°C (fixed); -15°C to +90°C (flexible) | IEC 60092-350 | Derating curves supplied |

| Minimum Bend Radius | 6× outer diameter (during installation) | IEC 60092-352 | Critical for vibration-prone areas |

All cables undergo 100% factory testing for conductor continuity, insulation resistance (>1000 MΩ·km), and voltage withstand (4 kV AC for 5 min). For export shipments, we provide full traceability via laser-marked meterage, batch-specific test reports, and packaging certified for 12-month seaworthy storage. This technical rigor ensures seamless integration into global vessel electrical systems while mitigating risks of in-service failure. Contact our engineering team for project-specific customization or certification documentation.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine electrical cable solutions tailored for both new shipbuilding projects and vessel repair operations. As a trusted provider in the marine outfittings sector, we specialize in supplying high-performance, certified electrical cables that meet international maritime standards, including IEC 60092, CCS, ABS, DNV, LR, and other classification society requirements. Our focus is on reliability, safety, and operational efficiency, ensuring that every cable system we provide supports the demanding electrical needs of modern marine environments.

For new construction, Star Marine offers full-package electrical cable systems designed in alignment with vessel schematics and load specifications. Our engineering team collaborates closely with shipyards and naval architects during the design phase to ensure optimal cable routing, voltage drop analysis, and fire safety compliance. We supply a full range of low, medium, and high-voltage cables, including power, control, instrumentation, and communication cables, all manufactured to resist moisture, oil, chemicals, and mechanical stress. Our cables are flame-retardant, low-smoke, zero-halogen (LSZH), and suitable for installation in engine rooms, switchboards, navigation systems, and accommodation areas.

In repair and retrofit scenarios, Star Marine provides rapid-response support with on-demand cable supply, technical documentation, and field engineering assistance. Our global logistics network ensures fast delivery to major ship repair hubs across Asia, the Middle East, and Europe. Whether replacing damaged cable runs or upgrading aging electrical systems, our cables are fully compatible with existing marine infrastructure, minimizing downtime and reducing project delays. We maintain a strategic inventory of standard and custom cable types to accommodate urgent repair needs.

Our commitment to quality is reinforced through rigorous in-house testing and full traceability from raw materials to finished product. Each cable batch is accompanied by material test reports (MTRs), certificates of conformity, and installation guidelines to support compliance with regulatory audits and class surveys.

The following table outlines key product specifications and certifications offered by Star Marine:

| Parameter | Specification |

|---|---|

| Standard Compliance | IEC 60092-350, IEC 60092-351, IEC 60092-353, IEC 60092-376 |

| Voltage Ratings | 150/250 V, 300/500 V, 600/1000 V, 3.6/6 kV, 6/10 kV |

| Conductors | Tinned copper, stranded, Class 2 per IEC 60228 |

| Insulation & Sheathing | EPR, XLPE, CSP (Chlorosulfonated Polyethylene), LSZH options available |

| Fire Performance | Flame Retardant (IEC 60332), Low Smoke (IEC 61034), Zero Halogen (IEC 60754) |

| Temperature Range | -20°C to +90°C (up to +150°C short circuit) |

| Certification Authorities | CCS, ABS, DNV, LR, BV, RINA, NK, KR |

Star Marine Technology ensures seamless integration of electrical cable systems in all marine applications, combining technical expertise with responsive service. From initial inquiry to final delivery, we are committed to supporting shipbuilders and repair yards with engineered solutions that enhance safety, durability, and project efficiency.

Packaging & Logistics

Packaging & Logistics Standards for Marine Electrical Cable Exports

Hangzhou Star Marine Technology implements rigorously engineered packaging solutions to ensure marine electrical cables arrive at global destinations in optimal condition, fully compliant with international maritime regulations. All wooden export cases adhere strictly to ISPM 15 standards, utilizing heat-treated (HT) or methyl bromide-fumigated (MB) softwood lumber certified by China’s General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ). Cases feature double-walled construction with internal moisture-resistant barriers (polyethylene film ≥ 0.2mm thickness) to prevent saltwater ingress during ocean transit. Each case is branded with the globally recognized ISPM 15 compliance mark, including country code (CN), unique producer code, and treatment indicator (HT/MB). Standard case dimensions range from 1.2m x 1.0m x 0.8m (LxWxH) for 500m cable reels to 2.5m x 1.8m x 1.5m for 2,000m+ reels, with reinforced corner bracing to withstand stacking loads up to 5,000 kg.

For high-moisture-risk routes or accelerated shipment timelines, we deploy galvanized steel pallets as an alternative. These pallets eliminate phytosanitary documentation requirements while providing superior structural integrity in humid environments. Steel pallets incorporate non-slip rubberized deck surfaces and integrated cable reel securing points, preventing lateral movement during vessel motion. Both packaging methods include serialized barcoded labels with RFID tags for real-time shipment tracking via Ningbo-Zhoushan or Shanghai Port terminals. All reels are vacuum-sealed with desiccant packs to maintain <40% internal humidity throughout transit.

The comparative specifications for our primary packaging systems are detailed below:

| Packaging Type | Dimensions (LxWxH) | Max Load Capacity | Key Compliance Features |

|---|---|---|---|

| ISPM 15 Wooden Case | 1.2m–2.5m x 1.0m–1.8m x 0.8m–1.5m | 5,000 kg | AQSIQ-certified HT/MB treatment, moisture barrier film, ISPM 15 branding |

| Galvanized Steel Pallet | 1.2m x 1.0m x 0.25m (standard) | 3,500 kg | ISO 1496-2 structural certification, salt-spray tested (1,000+ hours), non-slip deck |

Shipments originate exclusively from Ningbo-Zhoushan Port (world’s busiest container port by volume) or Shanghai Port, leveraging Hangzhou Star Marine Technology’s bonded warehouse facilities for seamless customs clearance under China’s AEO (Authorized Economic Operator) program. Our logistics partners utilize dedicated reefer containers with humidity-controlled environments for temperature-sensitive cable variants (e.g., XLPE-insulated cables). All cargo manifests include ISO 1161-compliant pallet footprint data for efficient vessel stowage planning, minimizing port dwell time. Critical documentation—phytosanitary certificates for wooden cases, material test reports, and SOLAS-compliant packing lists—is electronically transmitted 72 hours prior to vessel departure via the ports’ integrated TradeNet systems. This end-to-end protocol ensures zero packaging-related damage incidents across 98% of our 2023 marine cable exports, directly supporting client adherence to IEC 60092-350 electrical installation standards upon delivery.

Contact Star Marine

For global shipbuilders, offshore platform operators, and marine equipment suppliers seeking high-performance marine electrical cable solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in marine outfittings. Our engineered cables meet rigorous international standards, including IEC 60092, ISO 10713, and IMO A.657, ensuring fire resistance, oil resistance, low smoke emission, and reliable signal transmission in harsh maritime environments. Whether for main power distribution, control systems, or instrumentation networks on commercial vessels, offshore rigs, or naval platforms, our cables are designed to deliver uncompromised safety and longevity.

At Hangzhou Star Marine Technology, we understand that selecting the right marine electrical cable involves more than technical compliance—it requires application-specific expertise, logistical support, and responsive engineering collaboration. That’s why we assign dedicated technical account managers to ensure seamless integration of our products into your vessel design or retrofit project. Our manufacturing facility in Hangzhou is equipped with state-of-the-art extrusion lines and testing laboratories, enabling full traceability, custom jacketing options, and rapid prototyping for project-specific requirements.

We invite procurement officers, naval architects, and electrical system integrators to connect directly with our Product Manager, Kacher YE, who brings over a decade of experience in marine electrical systems and export logistics. Mr. Ye specializes in translating complex technical specifications into optimized cable solutions while ensuring compliance with flag state regulations and classification society rules such as DNV, ABS, LR, and CCS.

To initiate a technical consultation, request product documentation, or obtain a project quotation, please contact Kacher YE via email at [email protected]. Our team supports English, Chinese, and Spanish communications and responds to all inquiries within 12 business hours. We provide comprehensive support including load calculations, cable routing guidance, termination recommendations, and on-site technical assistance when required.

Below are key specifications of our most commonly exported marine electrical cable types:

| Cable Type | Voltage Rating | Conductor Size Range | Insulation Material | Jacket Material | Standards Compliance |

|---|---|---|---|---|---|

| MPRX (Power) | 0.6/1 kV | 1.5 – 400 mm² | EPR | CSP | IEC 60092-353, IMO A.657 |

| MCRX (Control) | 300/500 V | 0.75 – 10 mm² | XLPE | CSP | IEC 60092-352, ISO 10713 |

| MSRX (Instrumentation) | 300/500 V | 0.5 – 6 mm² | PE | CSP | IEC 60092-376, IEC 62287 |

| MHX (Fire Survival) | 0.6/1 kV | 1.5 – 240 mm² | MICA + XLPE | Low Smoke Zero Halogen (LSZH) | IEC 60331, IEC 60754 |

All cables undergo 100% factory testing for insulation resistance, voltage withstand, and dimensional accuracy. Custom markings, drum lengths, and packaging configurations are available to meet project timelines and port handling requirements.

Partner with Hangzhou Star Marine Technology for precision-engineered marine electrical cables backed by technical excellence and global export experience. Contact Product Manager Kacher YE today at [email protected] to discuss your next marine electrical system upgrade or newbuild specification.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160