Marine Bronze Valve – Marine Solution Guide 2025

Content Navigation

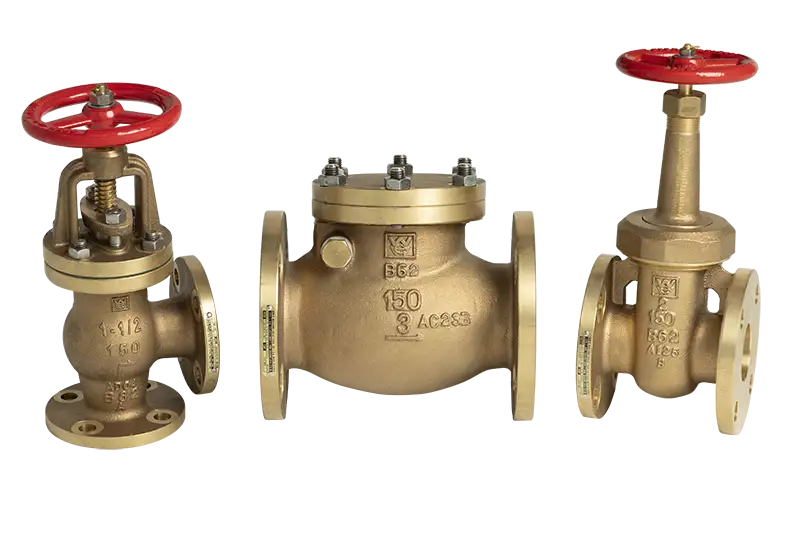

Marine Insight: Marine Bronze Valve

Marine bronze valves play a critical role in ensuring the operational safety and reliability of vessels across commercial shipping, offshore platforms, and naval fleets. As integral components in seawater piping systems, these valves regulate the flow of cooling water, ballast, firefighting systems, and other essential services onboard. The use of marine-grade bronze—typically ASTM B61 or B584—ensures high resistance to corrosion, biofouling, and the aggressive nature of saltwater environments. This material property is vital for maintaining system integrity over long service intervals, minimizing the risk of leaks, failures, or catastrophic breakdowns that could compromise crew safety and vessel operations.

In marine applications, the failure of a single valve in a critical system such as engine cooling or bilge discharge can lead to overheating, flooding, or even fire hazards. Bronze valves are preferred in low to medium pressure systems due to their durability, ease of maintenance, and compatibility with a wide range of fluids. Their non-sparking characteristics also make them suitable for use in hazardous zones, further enhancing onboard safety. Compliance with international standards such as ISO 5208, API 598, and DNV-GL type approval ensures that these valves meet stringent performance benchmarks for leakage, pressure rating, and structural strength.

Given the global demand for reliable and cost-efficient marine components, sourcing marine bronze valves from Hangzhou Star Marine Technology Co., Ltd. offers shipbuilders, equipment integrators, and vessel operators a strategic advantage. Based in China, Star Marine leverages advanced foundry techniques, precision machining, and rigorous quality control to deliver valves that meet or exceed international marine certifications. The company’s vertically integrated manufacturing process reduces production lead times and overhead costs, enabling competitive pricing without compromising on quality.

The following table outlines key performance and cost advantages of sourcing marine bronze valves from Star Marine:

| Parameter | Industry Standard | Star Marine Advantage |

|---|---|---|

| Material Compliance | ASTM B61 / B584 | 100% certified raw material sourcing |

| Pressure Rating | Up to 175 psi (Class 125) | Tested to 250 psi for safety margin |

| Certification | DNV-GL, CCS, ISO 5208 | Full certification package available |

| Lead Time | 8–12 weeks | 4–6 weeks with JIT shipping options |

| Cost Comparison (vs. EU/US) | Benchmark | 20–30% lower unit cost |

| Minimum Order Quantity (MOQ) | Typically 10–50 units | MOQ of 10 units with flexible customization |

By combining technical compliance, operational safety, and economic efficiency, Hangzhou Star Marine Technology has positioned itself as a trusted supplier in the global marine valve market. For shipyards and marine equipment distributors seeking dependable, certified, and competitively priced bronze valves, Star Marine offers a proven solution that supports long-term vessel reliability and cost-effective fleet maintenance.

Technical Specs & Approval

Marine Bronze Valve Technical Specifications

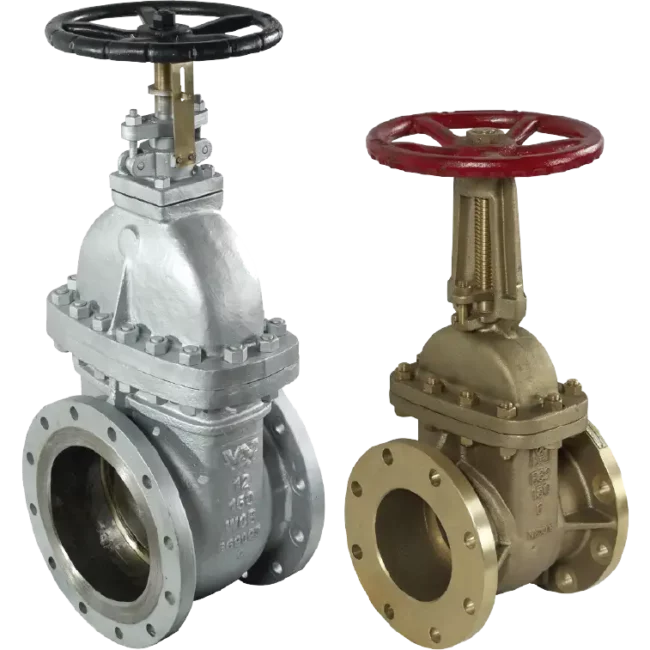

Hangzhou Star Marine Technology Co. Ltd. manufactures marine bronze valves to stringent international standards, ensuring reliability in critical seawater, fuel, and hydraulic systems. These valves utilize high-grade naval brass (C46400 per ASTM B62) for optimal corrosion resistance in saline environments, with cast steel variants available for higher-pressure applications. All designs comply with ISO 5208 leakage standards and undergo 100% shell and seat pressure testing. Material composition includes copper (60%), tin (1.8%), zinc (39.2%), and trace elements to prevent dezincification, meeting ASTM B584 for cast bronze. Cast steel options (ASTM A216 Grade WCB) are offered for PN25-PN40 classes where enhanced mechanical strength is required.

Pressure ratings span PN6 to PN40, corresponding to 6 bar to 40 bar nominal working pressures at 20°C. Critical derating applies above 100°C; for example, PN16 valves operate at 13 bar at 150°C. Temperature limits range from -20°C to 200°C for bronze and -29°C to 425°C for cast steel variants. End connections strictly adhere to JIS B2021, DIN 2543-2546, or ISO 7005 standards, with flanged, screwed (BSPP), and welding ends available. Face-to-face dimensions conform to ISO 5752 Series 14 for flanged and Series 1 for threaded variants.

The following table details core technical parameters for standard configurations:

| Parameter | Specification Range | Bronze Variant | Cast Steel Variant |

|---|---|---|---|

| Nominal Diameter | DN15 – DN300 | DN15 – DN200 | DN25 – DN300 |

| Pressure Rating | PN6 – PN40 | PN6 – PN25 | PN16 – PN40 |

| Temperature Range | -20°C to 425°C | -20°C to 200°C | -29°C to 425°C |

| End Connections | Flanged/Screwed/Weld | JIS 10K, DIN PN16 | JIS 20K, DIN PN40 |

| Test Pressure (Shell) | 1.5x PN @ 20°C | 9–37.5 bar | 24–60 bar |

| Test Pressure (Seat) | 1.1x PN @ 20°C | 6.6–27.5 bar | 17.6–44 bar |

| Applicable Standards | JIS F 7405, DIN 3202 | ISO 5208 Cat. A, DNV-GL | ISO 5208 Cat. B, ABS |

Valves undergo non-destructive testing (NDT) per ASTM E165 liquid penetrant methods for casting integrity. Seat leakage rates comply with ISO 5208 Class A (metal-seated) or Class IV (soft-seated). Surface finishes achieve Ra ≤ 3.2 μm on sealing surfaces to prevent galling. All products carry CE marking per PED 2014/68/EU and are certified under ISO 9001:2015 quality management systems. For JIS-compliant models, Japan Marine Equipment Association (JMEA) certification is provided upon request.

Hangzhou Star Marine Technology validates performance through hydrostatic, pneumatic, and functional cycle testing per API 598. Each valve receives a unique serial number traceable to material test reports (MTRs) and pressure test records. Export documentation includes material certificates (EN 10204 3.1), dimensional drawings, and compliance statements for regional maritime authorities. This rigorous technical framework ensures seamless integration into global vessel systems while meeting ABS, LR, DNV, and CCS regulatory requirements.

Shipbuilding Solutions

Comprehensive Marine Bronze Valve Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered excellence in marine bronze valves, supporting global shipyards and repair facilities with reliable, high-performance flow control solutions. As a specialized marine equipment exporter, we understand the critical role valves play in the integrity, safety, and operational efficiency of marine systems. Our marine bronze valves are precision-manufactured to meet the stringent demands of seawater, fuel, lubrication, and cooling applications across commercial, offshore, and naval vessels.

For new shipbuilding projects, Star Marine provides full technical integration support from design phase to commissioning. Our engineering team collaborates with naval architects and system designers to ensure valve specifications align with piping schematics, material compatibility requirements, and class society standards. With in-house casting, machining, and testing facilities, we maintain tight control over quality and delivery timelines. Our valves comply with international standards including ISO 9001, ISO 14001, and certifications from classification societies such as CCS, ABS, DNV, LR, and BV. This ensures seamless approval processes during vessel construction audits.

In ship repair and retrofit operations, rapid response and part availability are paramount. Star Marine maintains a strategic inventory of standard and custom bronze valves in Hangzhou, enabling fast order fulfillment for urgent dry-dock schedules. Our global logistics network supports just-in-time delivery to major ship repair hubs in Asia, the Middle East, Europe, and beyond. Whether replacing obsolete components or upgrading system performance, our technical export team provides accurate cross-referencing, dimensional verification, and material traceability documentation to minimize downtime.

All marine bronze valves from Star Marine are constructed from high-grade aluminum bronze or gunmetal alloys, offering superior resistance to seawater corrosion, biofouling, and thermal cycling. Precision-machined seats and stems ensure bubble-tight sealing and long service life under continuous operation. Each valve undergoes 100% hydrostatic and pneumatic testing prior to shipment, with test reports available upon request.

The following table outlines key product specifications and compliance standards for our marine bronze valve series:

| Parameter | Specification |

|---|---|

| Body Material | Aluminum Bronze (QA19-4), Gunmetal (LMn55-3-1) |

| Pressure Rating | PN16, Class 150, Class 300 (custom options available) |

| Size Range | DN15 to DN300 (1/2″ to 12″) |

| Temperature Range | -20°C to +200°C |

| End Connections | Flanged (ISO 5211, MSS SP-80), Threaded (NPT, BSP) |

| Design Standard | API 6D, ISO 10434, BS 5154 |

| Testing Standard | API 598, ISO 5208 |

| Certifications | CCS, ABS, DNV, LR, BV, RINA |

By combining technical expertise, manufacturing precision, and export readiness, Hangzhou Star Marine Technology ensures shipbuilders and repair yards receive not just components, but fully supported system solutions. Our commitment to reliability, responsiveness, and regulatory compliance makes us a trusted partner in marine valve supply worldwide.

Packaging & Logistics

Packaging & Logistics Protocol for Marine Bronze Valves

Hangzhou Star Marine Technology implements rigorous packaging and logistics standards to ensure the secure international transit of our marine bronze valves. Adherence to global regulatory requirements and protection against maritime environmental hazards are paramount. All export shipments originate from our primary logistics hubs at the Port of Ningbo-Zhoushan or the Port of Shanghai, leveraging their status as top-tier global container terminals for optimal routing, vessel frequency, and customs efficiency. Our dual-packaging methodology – utilizing ISPM 15 certified wooden export crates and heavy-duty steel pallets – is engineered specifically for the demanding conditions of sea freight and the critical nature of marine valve integrity.

Wooden export crates constitute the primary packaging solution for individual valves and smaller consignments. These crates are constructed exclusively from solid wood components that undergo mandatory heat treatment (HT) in strict compliance with International Standards for Phytosanitary Measures No. 15 (ISPM 15). This process eliminates pest risks without chemical fumigation, ensuring global acceptance. Each crate bears the official ISPM 15 mark, clearly displaying the country code (CN), unique producer code, and HT certification symbol. Internal valve protection includes multi-layer VCI (Vapor Corrosion Inhibitor) paper wrapping, custom-molded foam inserts, and secure strapping to prevent movement during transit. Crates are designed for optimal stacking strength and feature external labeling with critical shipment data, handling instructions (e.g., “This Side Up”, “Fragile”), and valve-specific identification tags.

For bulk shipments or valves requiring enhanced structural support, heavy-gauge welded steel pallets are employed. These pallets feature a robust 1,500 kg static load capacity and 1,000 kg dynamic load rating, constructed from corrosion-resistant steel profiles with non-slip deck surfaces. Valves are individually secured to the pallet base using calibrated tension straps and corner protectors, with layered dunnage between valve layers to prevent surface abrasion. The entire unit is then fully enclosed within a weatherproof polyethylene shrink-wrap membrane, providing a critical barrier against salt spray, humidity, and deck wash during ocean transport. Steel pallets eliminate wood-related phytosanitary concerns and offer superior reusability.

The selection between wooden crates and steel pallets is determined by valve size, order volume, destination port infrastructure, and client specifications. Key comparative attributes are detailed below:

| Feature | ISPM 15 Wooden Export Crates | Heavy-Duty Steel Pallets |

|---|---|---|

| Primary Use Case | Individual valves, small batches | Bulk shipments, large valves |

| Phytosanitary Standard | ISPM 15 HT Certified (Marked) | Non-wood; No ISPM 15 requirement |

| Internal Protection | VCI paper, foam inserts, strapping | VCI paper, dunnage, tension straps |

| Environmental Barrier | Crate structure + optional wrap | Full polyethylene shrink-wrap |

| Load Capacity | Varies by crate size (Typ. 500kg) | Static: 1,500kg / Dynamic: 1,000kg |

| Reusability | Limited (Single/multi-trip) | High (Designed for repeated use) |

All shipments departing Ningbo or Shanghai undergo final verification against packing lists, commercial invoices, and certificate of origin documentation. We coordinate directly with certified freight forwarders specializing in maritime cargo, ensuring seamless customs clearance at origin and minimizing demurrage risks. Our integrated approach guarantees that marine bronze valves arrive at their global destination in pristine, operational condition, fully compliant with international shipping regulations and ready for immediate installation within demanding marine systems. This meticulous process safeguards cargo integrity and significantly reduces total landed costs for our clients.

Contact Star Marine

For reliable, high-performance marine bronze valves that meet international maritime standards, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted manufacturer and exporter with years of engineering excellence. Our marine bronze valves are precision-engineered for durability, corrosion resistance, and optimal flow control in seawater, freshwater, and low-pressure steam applications across commercial vessels, offshore platforms, and shipbuilding projects. As a leading supplier in the marine valve sector, we prioritize quality, compliance, and customer-specific solutions.

If you are sourcing marine bronze valves for newbuild or retrofit projects, our Product Manager, Kacher YE, is your direct technical and commercial contact. With in-depth knowledge of valve specifications, material standards, and global export logistics, Kacher ensures seamless coordination from inquiry to delivery. Whether you require ANSI, JIS, DIN, or non-standard configurations, our team supports customization in size, pressure rating, end connections, and testing protocols. All valves are manufactured under strict ISO 9001:2015 quality management systems and can be supplied with MDRs, NDT reports, and third-party inspection certificates (e.g., CCS, ABS, DNV, LR).

We understand that procurement in the maritime industry demands precision, traceability, and timely execution. That’s why we offer responsive technical support, competitive pricing, and efficient global shipping through our established logistics network. Our valves are widely used in cooling systems, ballast lines, firefighting systems, and bilge applications, where reliability under harsh marine conditions is non-negotiable.

For technical inquiries, product specifications, or quotation requests, reach out directly to Kacher YE via email. We respond to all inquiries within 12 business hours and provide detailed documentation, including 3D models, material test reports, and performance curves upon request.

Below are key specifications of our standard marine bronze valve offerings:

| Parameter | Details |

|---|---|

| Material | ASTM B62 (Red Brass), ASTM B584 (Naval Bronze), or Customer Specification |

| Size Range | DN15 to DN300 (1/2″ to 12″) |

| Pressure Rating | PN10, PN16, Class 125, Class 250 |

| Temperature Range | -20°C to +200°C |

| End Connections | Flanged (RF/FF), Threaded (NPT/BSP), Socket Weld |

| Design Standard | API 6D, BS 5155, ISO 5211 (for actuation) |

| Testing Standard | API 598, ISO 5208 (Shell & Seat Leakage) |

| Certifications | CCS, ABS, DNV-GL, LR, KR, RINA (available upon request) |

| Lead Time | 4–6 weeks for standard orders; expedited options available |

| Packaging | Wooden crates, seaworthy export packaging with anti-corrosion protection |

Partner with Hangzhou Star Marine Technology for marine bronze valves that deliver long-term performance and regulatory compliance. Contact Kacher YE today at [email protected] to discuss your project requirements, request samples, or receive a detailed quotation tailored to your vessel or system specifications.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160