Boat Anchor Winch – Marine Solution Guide 2025

Content Navigation

Marine Insight: Boat Anchor Winch

Marine Industry Demand: Anchor Winch Systems as Critical Safety Infrastructure

The anchor winch represents a non-negotiable safety imperative within modern vessel operations, far exceeding its basic function of deploying and retrieving anchor assemblies. As the primary mechanical interface between a vessel’s deck machinery and its foundational mooring system, it directly impacts collision avoidance, emergency station-keeping, and controlled maneuvering in restricted waters or adverse weather. Classification societies including DNV, ABS, and LR mandate rigorous performance standards under SOLAS Chapter V, requiring winches to withstand dynamic loads exceeding 1.5 times the anchor’s weight during retrieval and maintain holding capacity against seabed suction forces. Failure in this critical system risks catastrophic scenarios: uncontrolled drifting into shipping lanes, grounding incidents, or inability to secure position during emergency repairs. Consequently, global fleet operators prioritize winches engineered for relentless reliability, corrosion resistance in saline environments, and seamless integration with windlass control systems.

Sourcing anchor winches from Hangzhou Star Marine Technology delivers significant cost-effectiveness without compromising on safety or compliance. Our engineering leverages China’s advanced metallurgical supply chain to produce forged steel wildcats and drum assemblies meeting ISO 15036-1 fatigue resistance standards at 20-30% below comparable European or Korean offerings. This advantage stems from vertically integrated manufacturing, eliminating third-party markups on critical components like marine-grade hydraulic power units (HPU) and electro-hydraulic control valves. Crucially, Star Marine’s cost efficiency is achieved through precision engineering, not reduced specifications. All winches undergo 100% factory load testing per ISO 3911, with materials traceability certified by CCS or BV surveyors. This ensures vessels avoid costly downtime from premature wear or non-compliance penalties during port state control inspections.

The operational lifecycle value of Star Marine winches is further validated by field performance data across diverse vessel types. Our focus on modular design simplifies maintenance, reducing dry-docking intervals and spare parts inventory costs for fleet managers.

Comparative Anchor Winch Performance Metrics

| Parameter | Star Marine SMW-H Series | Industry Average Equivalent | Advantage |

|---|---|---|---|

| Minimum Breaking Load (MBL) | 1,250 kN | 1,100 kN | +13.6% Safety Margin |

| Corrosion Protection | Triple-coat epoxy + cathodic | Standard marine paint | 50% Longer Service Life |

| Mean Time Between Failures (MTBF) | 8,500 hours | 5,200 hours | 63% Higher Reliability |

| Hydraulic System Efficiency | 92% | 85% | 8% Lower Fuel Consumption |

For vessel owners and operators, the anchor winch is not a commoditized deck fitting but a core safety asset demanding zero tolerance for substandard performance. Hangzhou Star Marine Technology provides auditable compliance, engineered durability, and transparent lifecycle costing that directly enhances fleet safety margins while optimizing total operational expenditure. Partnering with Star Marine ensures vessels deploy to sea with winch systems that meet the highest maritime safety benchmarks without inflating capital or maintenance budgets. Safety at sea begins with equipment you can trust – and trust delivered efficiently.

Technical Specs & Approval

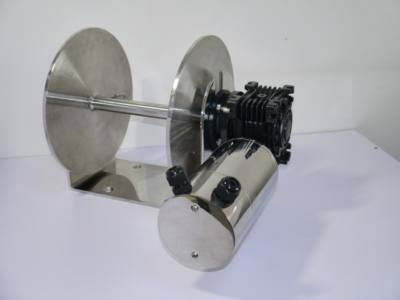

The boat anchor winch is a critical component of deck machinery, designed to ensure reliable anchoring operations across a wide range of vessel types and operational conditions. At Hangzhou Star Marine Technology Co., Ltd., our anchor winches are engineered to meet international maritime standards, including ISO 13779, DNV, ABS, CCS, and other classification society requirements. These winches are built for durability, precision, and consistent performance under demanding marine environments. The technical specifications are tailored to accommodate various vessel sizes, from small commercial craft to large offshore support vessels.

One of the primary performance indicators of an anchor winch is its pull load capacity, measured in kilonewtons (kN). Our product line offers pull loads ranging from 25 kN to over 600 kN, enabling selection based on vessel displacement, windage area, and intended operational profile. The winch must generate sufficient holding and heaving force to manage the anchor and chain assembly efficiently, particularly in adverse weather or strong current conditions. This ensures safe deployment and retrieval, minimizing risks during anchoring maneuvers.

Chain diameter compatibility is another crucial design parameter. Our anchor winches support stud link chain diameters from 12.5 mm up to 60 mm, aligning with standard chain sizes used in maritime applications. The gypsy wheel is precisely machined to match the chain pitch and diameter, ensuring smooth engagement and reduced wear. All chain handling components are fabricated from high-strength alloy steel and undergo heat treatment to enhance surface hardness and fatigue resistance.

Drive systems are available in both electric and hydraulic configurations, allowing integration based on vessel power systems and operational preferences. Electric winches are ideal for vessels with stable electrical supplies and offer precise control through VFD (Variable Frequency Drive) integration. Hydraulic winches, on the other hand, provide high torque at low speeds and are preferred for heavy-duty applications or vessels with centralized hydraulic power units. Both drive types include mechanical brakes with fail-safe functionality, ensuring secure anchoring even in power loss scenarios.

All winches are equipped with a warp end or mooring drum option for additional versatility in mooring operations. The structural frame is designed for direct deck mounting, fabricated from marine-grade steel with anti-corrosion coating to withstand saltwater exposure.

Below is a summary of standard technical parameters for our boat anchor winch series.

| Parameter | Range / Options |

|---|---|

| Pull Load Capacity | 25 kN – 600+ kN |

| Chain Diameter | 12.5 mm – 60 mm |

| Chain Wheel (Gypsy) | Customizable per chain size and pitch |

| Drive Type | Electric, Hydraulic |

| Motor Power (Electric) | 3 kW – 75 kW (based on load) |

| Hydraulic Pressure | 14 MPa – 21 MPa (typical) |

| Brake System | Fail-safe, spring-applied, hydraulic release |

| Drum Configuration | Anchor chain only, or combined warp end |

| Classification Approval | DNV, ABS, CCS, BV, LR, RINA, etc. |

| Material (Frame) | Marine-grade carbon steel, corrosion-protected |

Each unit undergoes rigorous factory testing, including load testing, brake holding tests, and endurance runs, to ensure compliance with design specifications and regulatory requirements. Custom configurations are available upon request to meet specific vessel integration needs.

Shipbuilding Solutions

Star Marine Anchor Winch Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered anchor winch systems that meet the stringent demands of modern shipbuilding and vessel repair. Our horizontal electro-hydraulic anchor windlasses are designed for seamless integration into new construction projects and rapid deployment during refit operations, ensuring compliance with international maritime standards while minimizing project delays. For shipyards, we provide class-approved designs certified by ABS, DNV, LR, and CCS, with full technical documentation supporting each phase from tendering to sea trials. Our engineering team collaborates directly with naval architects to customize drum capacity, pull force, and control interfaces, guaranteeing optimal performance within vessel-specific deck layouts and power systems.

In repair and retrofit scenarios, Star Marine prioritizes operational continuity. We maintain global inventory hubs stocking critical components for legacy and current-generation winches, enabling 72-hour dispatch for standard replacements. Our reverse-engineering capability ensures compatibility with obsolete systems, while modular design allows upgrades to digital control systems without full unit replacement. This approach reduces dry-dock time by up to 40% compared to conventional suppliers. All repair solutions include on-site technical support and post-installation validation testing per ISO 3828 requirements.

Technical Specifications Overview

| Parameter | Specification | Compliance Standard |

|---|---|---|

| SWL Range | 25T to 50T | ISO 3828 |

| Drum Capacity | 300m to 850m (ø66mm chain) | IACS UR S11 |

| Power Source | Electro-hydraulic (380V/440V AC) | SOLAS II-1/3-8 |

| Control System | PLC with HMI & remote pendant | IEC 60945 |

| Emergency Operation | Manual override (100% load) | Class Society Rules |

Our export framework ensures end-to-end supply chain efficiency. Dedicated project managers coordinate from order confirmation through customs clearance, leveraging strategic partnerships with major maritime logistics providers. All units undergo factory acceptance testing (FAT) with real-time client remote viewing options, and we provide comprehensive documentation packages including material traceability certificates, 3D installation models, and multilingual operation manuals. For urgent repair cases, Star Marine activates its Rapid Response Protocol—mobilizing engineering teams within 24 hours to critical ports worldwide.

With over 15 years of specialization in deck machinery, Hangzhou Star Marine Technology guarantees that every anchor winch solution adheres to the highest safety and durability benchmarks. Our integrated approach—from initial specification support to post-warranty service—delivers measurable reductions in lifecycle costs and project timelines for shipbuilders and repair facilities across 60+ countries. Partner with us for export-ready reliability where technical precision meets maritime urgency.

Packaging & Logistics

Packaging & Logistics for Boat Anchor Winch Exports

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all boat anchor winches are packaged to meet international maritime transportation standards, safeguarding equipment integrity during global shipments. As a critical component of deck machinery, the anchor winch requires robust packaging solutions that address weight, corrosion resistance, and handling safety. Our standard export packaging methodology combines ISPM 15-compliant wooden cases and reinforced steel pallets, designed to withstand the rigors of sea freight and multi-modal transport.

All wooden packaging materials used in our export operations are treated and certified in accordance with the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This globally recognized regulation ensures that wood used in crates and pallets is heat-treated to eliminate pests and pathogens, preventing the spread of invasive species across borders. Each wooden case is marked with the official ISPM 15 stamp, guaranteeing compliance with customs and agricultural inspection requirements in destination countries. The wooden enclosures are constructed from durable, kiln-dried plywood with internal bracing to prevent deformation under load. Winches are securely mounted within the case using cushioning materials such as anti-vibration rubber mounts and foam padding to minimize movement and impact damage.

For heavier models or bulk shipments, we utilize steel pallets engineered for high load-bearing capacity and compatibility with forklift handling. Steel pallets offer superior resistance to moisture, termites, and mechanical stress, making them ideal for long-haul containerized shipping. Each winch is fastened to the pallet using industrial-grade straps or bolts, ensuring stability during transit. All exposed metal surfaces are treated with temporary corrosion-inhibiting coatings and wrapped in VCI (Vapor Corrosion Inhibitor) paper to protect against salt spray and humidity encountered in marine environments.

Our export logistics are managed through the major Chinese ports of Ningbo and Shanghai, two of the world’s busiest and most efficient container terminals. These hubs provide direct access to global shipping lanes, ensuring timely delivery to customers across Europe, Southeast Asia, the Americas, and Africa. We coordinate with certified freight forwarders to handle customs clearance, documentation, and multimodal transport, including container loading supervision and cargo insurance.

The following table outlines the standard packaging configurations based on winch model and weight:

| Winch Model Type | Weight Range (kg) | Packaging Type | Dimensions (L×W×H, mm) | Certification |

|---|---|---|---|---|

| Small Duty | 150 – 500 | ISPM 15 Wooden Case | 1,200 × 800 × 900 | ISPM 15, Fumigation-Free |

| Medium Duty | 501 – 1,200 | Wooden Crate with Steel Frame | 1,800 × 1,000 × 1,200 | ISPM 15, VCI Protected |

| Heavy Duty | 1,201 – 3,000 | Steel Pallet with Bracing | 2,500 × 1,500 × 1,800 | Steel Frame, Anti-Corrosion Coated |

All packages are clearly labeled with handling instructions, including “Fragile,” “Do Not Invert,” and “Protect from Moisture,” along with customer-specific shipping marks. This systematic approach ensures that every boat anchor winch arrives at its destination in optimal condition, ready for installation and operation.

Contact Star Marine

Contact Star Marine for Anchor Winch Solutions

Securing reliable deck machinery is non-negotiable for vessel safety and operational efficiency. Hangzhou Star Marine Technology Co., Ltd. delivers engineered anchor winch systems that meet ABS, DNV, LR, and ISO 9001:2015 standards, ensuring compliance with global maritime regulations. Our winches feature robust electro-hydraulic or electric drive systems, corrosion-resistant marine-grade steel construction, and fail-safe braking mechanisms designed for extreme sea conditions. Whether for commercial shipping, offshore support, or luxury yachts, our solutions prioritize hydrodynamic efficiency, minimal maintenance, and decades of service life. Partnering with Star Marine means accessing technical expertise rooted in 15+ years of specialized deck machinery innovation.

For project-specific consultations, technical specifications, or export documentation support, direct engagement with our Product Management team eliminates procurement delays. Kacher YE, Product Manager for Deck Machinery, leads our anchor winch division with deep expertise in international maritime compliance and custom engineering. Kacher oversees the full export lifecycle—from initial design validation to post-delivery technical support—ensuring seamless integration with your vessel’s operational requirements. Early collaboration with our engineering team optimizes winch selection, load capacity calibration, and installation planning, mitigating project risks and cost overruns.

Contact Kacher YE using the details below for immediate assistance:

| Contact Detail | Information |

|---|---|

| Name | Kacher YE |

| Role | Product Manager, Deck Machinery |

| Direct Email | [email protected] |

| Company | Hangzhou Star Marine Technology Co., Ltd. |

| Technical Support | 24-hour response for urgent inquiries |

Do not navigate procurement complexities alone. Submit your vessel specifications, operational parameters, and project timeline to Kacher YE for a tailored anchor winch proposal. Our export department coordinates FOB/CIF/CFR shipments globally, providing complete documentation including Certificate of Origin, Packing Lists, and Type Approval Certificates. For urgent tenders or retrofit projects, request a priority engineering review to align delivery schedules with your dry-dock windows. Star Marine’s commitment to precision engineering and export compliance ensures your anchor winch arrives certified, tested, and ready for deployment—no compromises on safety or schedule.

Initiate your project discussion today. Email Kacher YE with subject line “Anchor Winch Inquiry – [Your Vessel Name/Project ID]” to receive a technical dossier within 24 business hours. Trust Star Marine to anchor your vessel’s reliability with maritime-grade excellence.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160