Anchor Capstan – Marine Solution Guide 2025

Content Navigation

Marine Insight: Anchor Capstan

Marine Industry Demand for Anchor Capstans: Safety Imperative and Strategic Sourcing

Anchor capstans represent a fundamental component of modern deck machinery systems, directly impacting vessel safety and operational reliability across global maritime operations. These robust winch systems are engineered to handle the immense loads associated with anchor handling and mooring line management, particularly on vessels where space constraints favor vertical-axis machinery. The critical safety function of an anchor capstan cannot be overstated; it enables rapid, controlled deployment and retrieval of anchors during emergency maneuvers, critical berthing operations in congested ports, and essential station-keeping in adverse weather conditions. Failure of this equipment during high-stress scenarios, such as sudden loss of propulsion in heavy seas or during emergency anchoring to avoid collision, can lead to catastrophic incidents including grounding, allision, or pollution events. Consequently, international maritime regulations, notably SOLAS Chapter II-1, and stringent classification society rules (ABS, DNV, LR, etc.) mandate the installation of anchor handling equipment with verified Safe Working Loads (SWL), robust construction, and fail-safe braking systems. The reliability and precise control offered by a high-performance capstan are non-negotiable elements in a vessel’s overall safety management system, directly contributing to crew safety, asset protection, and environmental compliance.

Sourcing high-integrity anchor capstans from Hangzhou Star Marine Technology provides international shipowners, shipyards, and equipment distributors with significant cost-effectiveness without compromising on safety or quality. Star Marine leverages China’s advanced marine engineering ecosystem, featuring deep industrial supply chains for critical components like marine-grade steel forgings, high-torque hydraulic motors, and certified control systems. This integrated manufacturing capability, combined with our ISO 9001:2015 certified production processes and rigorous adherence to classification society standards, ensures consistent product quality and performance. Crucially, our vertical integration and scale within Hangzhou’s specialized marine technology cluster substantially reduce production costs compared to equivalent equipment sourced from traditional Western manufacturing bases. This translates into a superior value proposition: vessels receive SOLAS-compliant, classification-approved anchor capstans meeting exacting safety specifications at a significantly optimized investment point. The cost savings extend beyond the initial purchase price, encompassing reduced lead times due to efficient local logistics and responsive engineering support, minimizing vessel downtime during installation or retrofit projects.

The following table illustrates key comparative advantages of sourcing anchor capstans from Star Marine:

| Parameter | Star Marine Standard Capstan | Typical Generic Supplier | Advantage |

|---|---|---|---|

| SWL Verification | ABS/DNV Type Approved | Basic Load Test Only | Guaranteed regulatory compliance & safety margin |

| Material Certification | Full Mill Certificates (DNV-GL) | Partial Documentation | Enhanced structural integrity assurance |

| Standard Lead Time | 8-10 Weeks | 14-18 Weeks | Reduced project delays & operational downtime |

| Hydraulic System | Parker/ Bosch Rexroth Components | Unbranded Components | Higher reliability & global service support |

| Total Landed Cost (FOB) | Competitive Benchmark | 15-25% Higher | Significant capital expenditure optimization |

Investing in a Star Marine anchor capstan is fundamentally an investment in operational safety and fleet efficiency. Our engineered solutions deliver the unwavering performance demanded by the marine environment while providing a demonstrable return through reduced total cost of ownership. Partnering with Star Marine ensures access to technically advanced, regulation-compliant deck machinery that actively safeguards vessels, crew, and cargo throughout their operational lifecycle.

Technical Specs & Approval

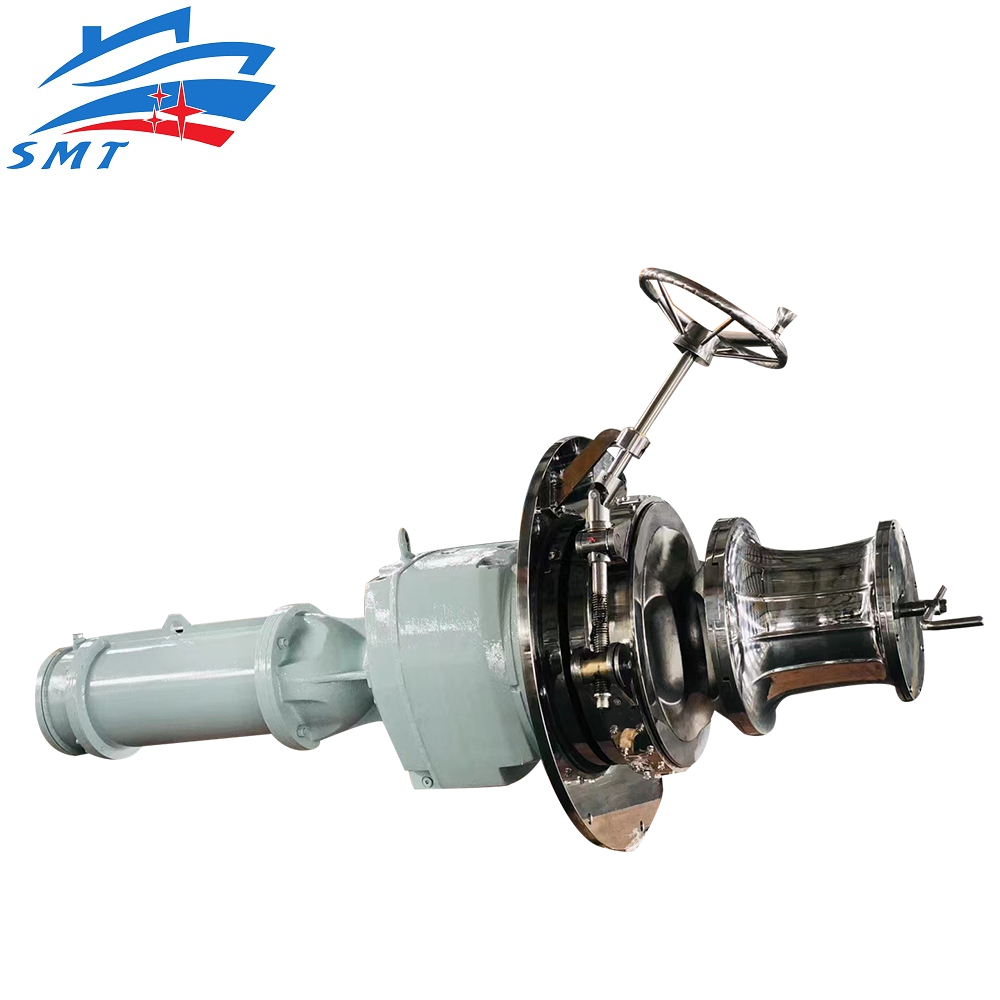

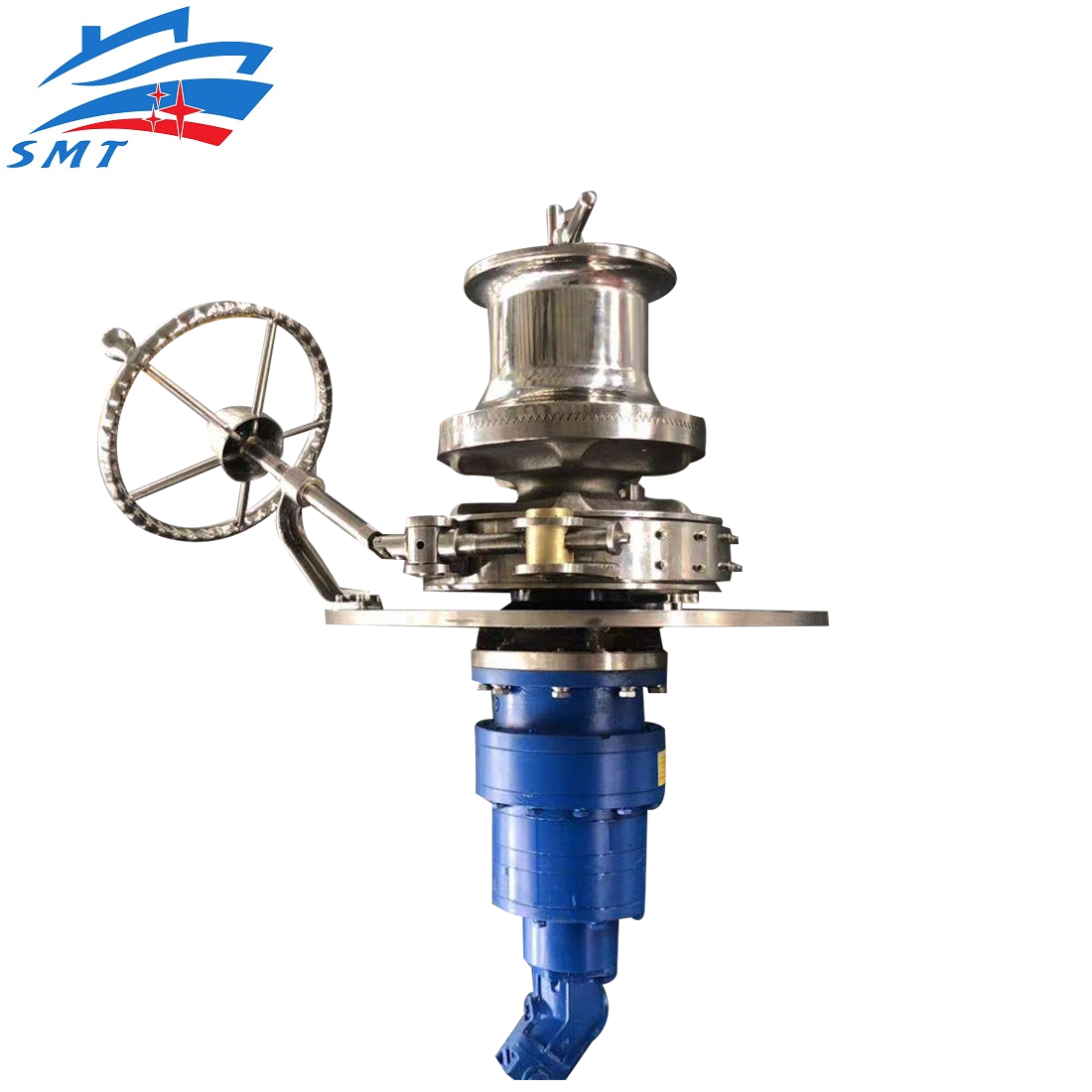

Hangzhou Star Marine Technology Co., Ltd. specializes in the design and export of high-performance deck machinery, including anchor capstans engineered for reliable performance in marine environments. Our anchor capstans are precision-built to meet international maritime standards, ensuring safe and efficient anchoring operations across a wide range of vessel types, from commercial cargo ships to offshore support vessels and luxury yachts. These capstans are designed to handle demanding sea conditions while maintaining operational durability and ease of maintenance.

The technical specifications of our anchor capstans are tailored to accommodate various operational requirements, with key performance parameters centered around pull load capacity, compatible chain diameter, and drive system configuration. Pull load is a critical factor in determining the capstan’s ability to manage anchor deployment and retrieval under load. Our models offer a pull load range from 25 kN to over 800 kN, enabling selection based on vessel size, displacement, and operational profile. This ensures optimal performance whether used on smaller coastal vessels or large ocean-going ships.

Compatibility with anchor chain diameter is another essential design criterion. Our capstans support chain diameters ranging from 12.5 mm to 60 mm, aligning with standard stud link chain sizes used in marine applications. This broad compatibility ensures integration with existing anchoring systems and compliance with classification society requirements such as CCS, ABS, DNV, LR, and others. The capstan gypsy wheels are precision-machined to match the chain geometry, minimizing wear and enhancing grip during operation.

Drive systems are available in both electric and hydraulic configurations, allowing for integration based on vessel power architecture and space constraints. Electric capstans are ideal for vessels with stable electrical systems and offer straightforward control integration. Hydraulic models provide high torque output and are preferred for larger installations where hydraulic power units are already in place. Both drive types are engineered for continuous duty cycles, incorporating overload protection and thermal management systems to ensure long service life.

All capstans are constructed from high-tensile steel and marine-grade materials, with surface treatments such as hot-dip galvanization or epoxy coating to resist corrosion in saltwater environments. Mounting configurations can be customized for flush deck, raised foundation, or integrated windlass setups.

Below is a summary of standard technical parameters for our anchor capstan series:

| Parameter | Range/Options |

|---|---|

| Pull Load Capacity | 25 kN – 800+ kN |

| Chain Diameter | 12.5 mm – 60 mm |

| Drive Type | Electric, Hydraulic |

| Power Supply (Electric) | 220V/380V/440V, 50/60Hz, 3-phase |

| Hydraulic Pressure | 120 – 200 bar (customizable) |

| Gypsy Wheel Type | Stud link chain, ISO 1700, or customized profile |

| Material | High-tensile steel, marine-grade alloy |

| Corrosion Protection | Hot-dip galvanized, epoxy coating, or stainless steel components |

| Compliance | CCS, ABS, DNV, LR, BV, RINA, IACS standards |

| Control System | Local control panel, remote operation optional |

Shipbuilding Solutions

Hangzhou Star Marine Technology: Complete Anchor Capstan Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered anchor capstan systems as a core component of our comprehensive deck machinery portfolio. We specialize in providing fully integrated solutions for both new vessel construction and critical repair/refit projects within the global maritime sector. Our anchor capstans are designed and manufactured to stringent international standards, ensuring reliable performance in demanding anchoring operations across diverse vessel types, from offshore support vessels to large commercial carriers. Understanding the critical timelines inherent in shipbuilding and dry-dock periods, Star Marine prioritizes rapid response and seamless project execution.

For newbuild projects, our engineering team collaborates directly with shipyards and naval architects from the design phase. We provide detailed technical specifications, 3D models, and load calculations to ensure perfect integration with the vessel’s deck layout, power systems, and safety protocols. Our project management guarantees adherence to strict construction schedules, with pre-delivery testing conducted at our ISO-certified facility to validate performance against class requirements before shipment. This proactive approach minimizes integration issues during installation, accelerating the vessel delivery process.

In the repair and refit market, downtime equates to significant revenue loss. Star Marine maintains a dedicated global support network and strategic spare parts inventory to address urgent capstan failures or upgrades. Our export team coordinates expedited shipping logistics worldwide, often leveraging air freight for critical components. Our field service engineers are available for rapid deployment to shipyards or ports, providing on-site troubleshooting, maintenance, and commissioning support. We offer reverse engineering capabilities for obsolete units, ensuring seamless replacement even when original specifications are unavailable, thereby restoring vessel operational capability with minimal delay.

Technical excellence underpins our solutions. All Star Marine anchor capstans undergo rigorous testing for endurance, braking efficiency, and overload protection. We utilize robust materials and proven hydraulic or electric drive systems optimized for marine environments. The following table outlines key specifications for our standard marine anchor capstan series:

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Line Pull Range | 50 kN to 500 kN | ISO 3911, DNV-GL |

| Rope Capacity | Ø22mm to Ø80mm (Wire/Rope) | ISO 1829, IACS M20 |

| Drive Type | Hydraulic Motor / Electric Motor | IEC 60034, IP56 |

| Control System | Local/Remote (Optional PLC) | IEC 60945, SOLAS |

| Brake Holding Force | 1.5x Rated Line Pull (Min) | ISO 15745, Class Rules |

| Certifications | DNV-GL, ABS, LR, CCS, NK, KR | Flag State Requirements |

Hangzhou Star Marine Technology is committed to being a responsive, single-source partner. We streamline procurement, ensure regulatory compliance across global markets, and provide continuous technical support from initial inquiry through the equipment lifecycle. By combining robust engineering, global logistics agility, and dedicated project management, we deliver anchor capstan solutions that enhance vessel safety, reduce operational downtime, and support the demanding schedules of modern shipbuilding and repair operations worldwide. Contact our export department for immediate technical consultation or project support.

Packaging & Logistics

Packaging & Logistics for Anchor Capstan Exports

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all anchor capstans are packaged and prepared for international shipment in full compliance with global maritime and phytosanitary standards. As a critical component of deck machinery, the anchor capstan requires secure and robust packaging to withstand the rigors of long-distance sea freight, variable climatic conditions, and multi-stage handling during transit. Our packaging protocols are designed to preserve product integrity, ensure regulatory compliance, and facilitate smooth customs clearance at destination ports.

All wooden packaging materials used for anchor capstans are treated and certified in accordance with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This internationally recognized standard mandates heat treatment of wood to eliminate pests and prevent the spread of invasive species through international trade. Each wooden case is marked with the official ISPM 15 stamp, indicating compliance with these requirements. The wooden crates are constructed from high-grade, kiln-dried plywood or solid timber, providing structural strength and resistance to moisture and impact. Internal bracing, cushioning, and anti-corrosion VCI (Vapor Corrosion Inhibitor) films are employed to protect machined surfaces, gear components, and electrical enclosures from vibration, shock, and humidity during transport.

For heavier or custom-designed anchor capstans, we utilize steel pallets reinforced with welded frames to ensure load stability. Steel pallets offer superior durability, reusability, and resistance to deformation, making them ideal for heavy industrial equipment. These pallets are treated with anti-rust coatings and are compatible with global handling systems, including forklifts and container cranes. All fasteners and securing elements are torqued and sealed to prevent loosening during transit.

Exports are primarily coordinated through the major Chinese shipping hubs of Ningbo and Shanghai, both of which offer extensive containerized shipping networks and efficient customs processing for marine equipment. Our logistics partners are experienced in handling oversized and heavy-lift cargo, ensuring timely vessel loading and accurate documentation. Prior to dispatch, each shipment undergoes a final inspection to verify packaging integrity, labeling accuracy, and documentation completeness.

The following table outlines the standard packaging specifications for anchor capstans based on unit weight and configuration:

| Capstan Weight Range | Packaging Type | Pallet/Base Material | Certification | Export Port |

|---|---|---|---|---|

| Up to 1,500 kg | Wooden Crate | Plywood with timber frame | ISPM 15 | Ningbo or Shanghai |

| 1,500 – 5,000 kg | Reinforced Wooden Crate | Hardwood frame with steel corners | ISPM 15 | Ningbo or Shanghai |

| Over 5,000 kg | Steel Pallet with Skid | Welded steel structure | ISO 9001, Anti-rust Coated | Ningbo or Shanghai |

All shipments are labeled with handling instructions, orientation markers, and customer-specific barcodes to ensure proper identification and safe handling throughout the logistics chain. At Hangzhou Star Marine Technology, we prioritize reliability and compliance in every export, delivering deck machinery solutions that meet the highest standards of quality and safety.

Contact Star Marine

Contact Star Marine for Your Anchor Capstan Requirements

As a leading manufacturer of marine deck machinery, Hangzhou Star Marine Technology Co., Ltd. delivers engineered anchor capstan solutions that meet rigorous international maritime standards. Our capstans are designed for optimal performance in dynamic sea conditions, ensuring reliable anchoring operations across diverse vessel types—from commercial cargo ships to offshore support vessels. With over 15 years of specialized expertise in hydraulic and electric deck machinery, we prioritize safety, durability, and compliance with classification society requirements including DNV-GL, ABS, and Lloyd’s Register. When specifying anchor handling equipment, precise technical alignment with your vessel’s operational profile is non-negotiable. Generic specifications risk compromising safety margins, maintenance cycles, and regulatory compliance. This is where direct collaboration with our engineering team becomes critical.

Our anchor capstans integrate advanced features such as overload protection systems, corrosion-resistant marine-grade alloys, and modular power unit configurations to suit space-constrained deck layouts. To ensure seamless integration into your vessel’s deck machinery ecosystem, we require detailed input on operational parameters, environmental exposure, and integration interfaces. Below are key technical parameters we evaluate during the consultation phase:

| Parameter | Standard Range | Customization Capability |

|---|---|---|

| Line Pull (SWL) | 25 kN – 200 kN | Up to 350 kN |

| Rope/Chain Capacity | 16 mm – 44 mm | Vessel-specific sizing |

| Operational Speed | 10 – 25 m/min | Variable speed control |

| Power Source | Hydraulic / Electric | Dual-system integration |

| Certification | DNV-GL, ABS, LR, CCS | All major class societies |

| Environmental Rating | IP56 / IP66 | Arctic/tropical variants |

Engaging directly with our Product Manager eliminates procurement risks associated with off-the-shelf solutions. Kacher YE leads our technical export team with 12 years of hands-on experience in marine machinery deployment across 40+ countries. He will coordinate a dedicated engineering review to address your specific torque requirements, deck reinforcement considerations, and installation timelines. This includes 3D model validation, load-testing protocols, and lifecycle cost analysis—ensuring your capstan operates at peak efficiency throughout its service life. For newbuild projects, retrofits, or urgent replacements, our team provides turnkey support from design approval to after-sales commissioning.

Do not rely on generic catalogs when vessel safety is at stake. Contact Kacher YE immediately to initiate a technical consultation. Provide your vessel particulars, operational profile, and project timeline for a tailored solution proposal within 72 hours. All inquiries receive direct engineering oversight—no call centers or generic sales scripts. Our export documentation package includes full technical dossiers, class approval evidence, and multilingual installation manuals compliant with IMO MSC.1/Circ.1359 guidelines. Partner with Hangzhou Star Marine Technology to secure anchor handling systems engineered for uncompromised reliability.

Act Now for Precision Engineering Support

Reach Product Manager Kacher YE at [email protected] with subject line: “Anchor Capstan Technical Consultation – [Your Vessel Name/Project ID]”. Include vessel type, required SWL, and target delivery window. For urgent requests, call +86-571-88XXXXXX (Hangzhou HQ). All technical queries are resolved within one business day. Trust Star Marine’s engineering rigor to safeguard your anchoring operations—where global fleets demand certainty, we deliver certified performance.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160