Shipboard Cable – Marine Solution Guide 2025

Content Navigation

Marine Insight: Shipboard Cable

Marine Industry Demand: Shipboard Cable Criticality and Sourcing Value

Shipboard cable systems represent a fundamental safety infrastructure within modern vessels, directly impacting crew survivability, operational continuity, and regulatory compliance. Unlike standard industrial cabling, marine-grade cables must withstand extreme environmental stresses including continuous vibration, high humidity, saltwater exposure, wide temperature fluctuations, and potential hydrocarbon contact. Crucially, their performance during fire scenarios is non-negotiable. SOLAS (Safety of Life at Sea) Chapter II-2 mandates stringent fire safety requirements, demanding cables maintain circuit integrity for specified durations under fire conditions to ensure critical systems like emergency lighting, fire detection, communication, and propulsion control remain operational. Failure in cable performance during such events can lead to catastrophic loss of life and vessel. Consequently, cables must exhibit exceptional flame retardancy, low smoke emission, zero halogen content (LSOH), and resistance to flame propagation to prevent toxic fume generation and facilitate safe evacuation and firefighting. The integrity of these systems is not merely operational; it is a primary life-saving barrier mandated by international maritime law.

Meeting these rigorous safety standards requires cables engineered with specialized materials and construction techniques. Star Marine Technology adheres strictly to IEC 60092-350 series standards, CCS, DNV, LR, ABS, and other major classification society requirements. Our cables undergo comprehensive testing for flame spread (IEC 60332-3), smoke density (IEC 61034), acid gas emission (IEC 60754), and circuit integrity under fire (IEC 60331). The table below illustrates key performance characteristics of our standard marine cable offerings:

| Cable Type | Flame Test Standard | Smoke Density (Max %) | Acid Gas Emission (Max %) | Operating Temp Range (°C) | Voltage Class (kV) |

|---|---|---|---|---|---|

| Power (LSOH) | IEC 60332-3 Cat A | 40 | 0.5 | -25 to +90 | 0.6/1.0 |

| Control (LSOH) | IEC 60332-3 Cat A | 40 | 0.5 | -25 to +90 | 0.3/0.5 |

| Instrumentation | IEC 60332-3 Cat B | 60 | 1.0 | -25 to +80 | 0.3/0.5 |

| Fire Survival (E30) | IEC 60331-21/23 | 40 | 0.5 | -25 to +90 | 0.6/1.0 |

Sourcing shipboard cable from Hangzhou Star Marine Technology delivers significant cost-effectiveness without compromising on safety or quality. Our vertically integrated manufacturing facility in Hangzhou enables strict process control from raw material selection through final testing, eliminating intermediary markups and ensuring consistent adherence to global standards. This integration, combined with optimized logistics from China’s premier maritime industrial hub, provides substantial cost advantages over European or North American alternatives while maintaining equivalent or superior certification coverage. Star Marine possesses extensive experience navigating complex international export regulations and classification society surveys, ensuring seamless documentation and customs clearance. Our dedicated export management team provides end-to-end support, from technical specification alignment and factory acceptance testing coordination to INCOTERMS 2020 compliance and shipment tracking. By choosing Star Marine, shipyards and operators secure certified, safety-critical cable systems at a competitive total landed cost, backed by responsive technical support and a proven commitment to maritime regulatory excellence. This combination of rigorous safety compliance, manufacturing efficiency, and export proficiency makes Star Marine a strategically valuable partner for global marine outfittings procurement.

Technical Specs & Approval

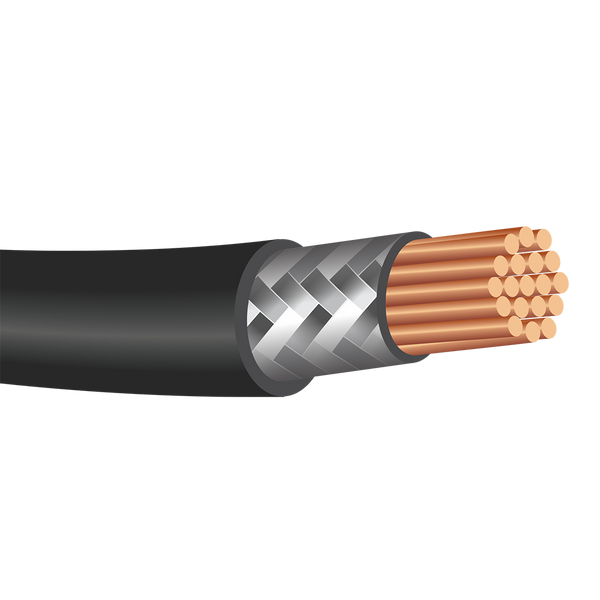

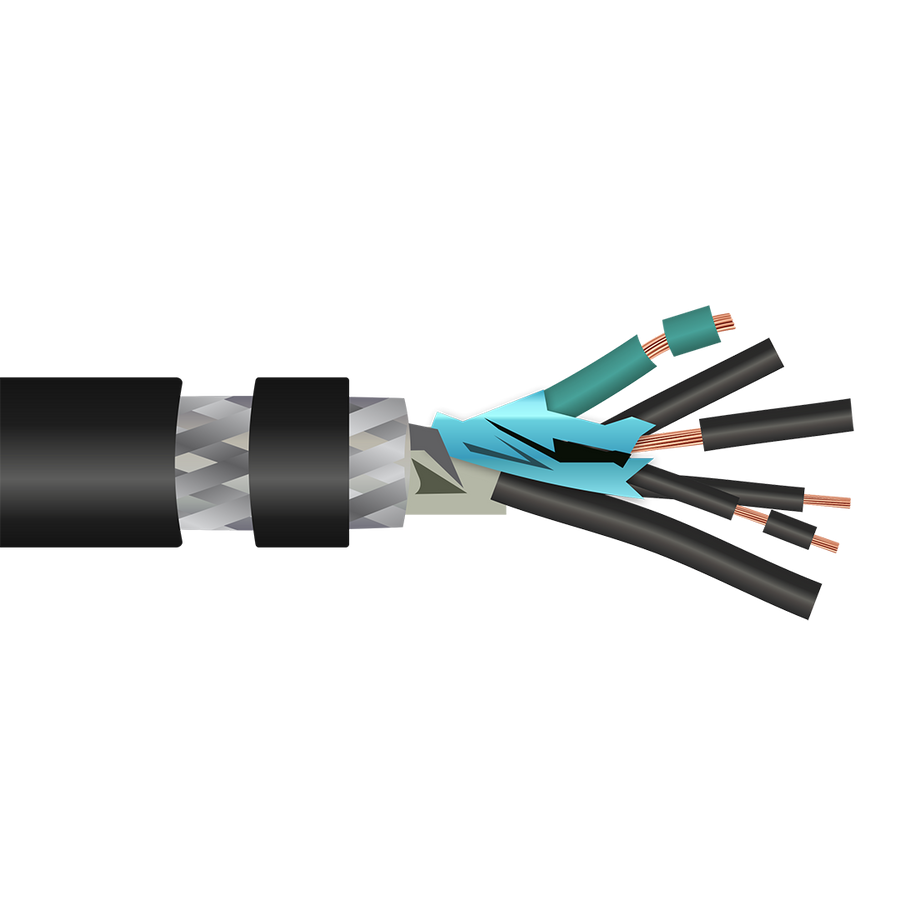

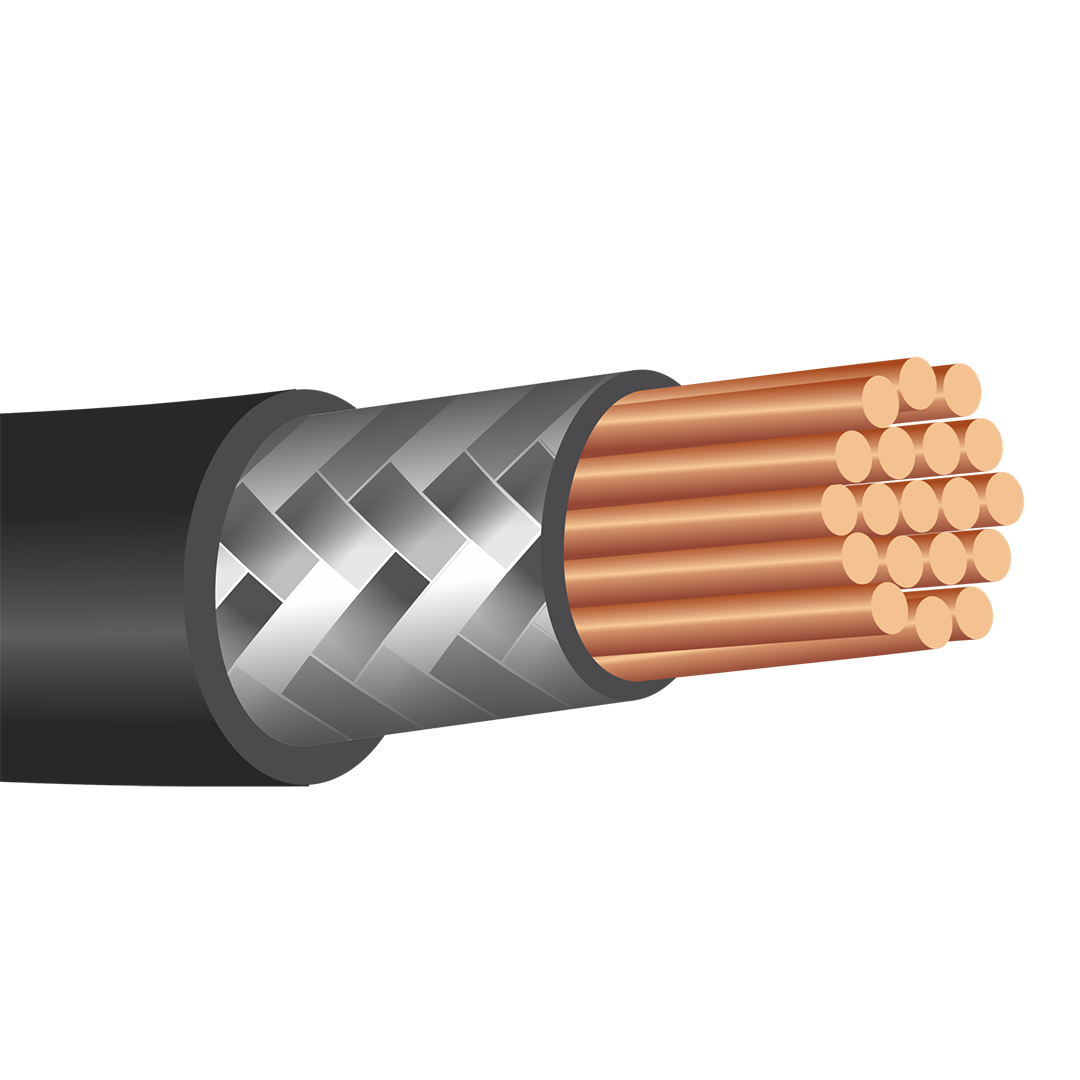

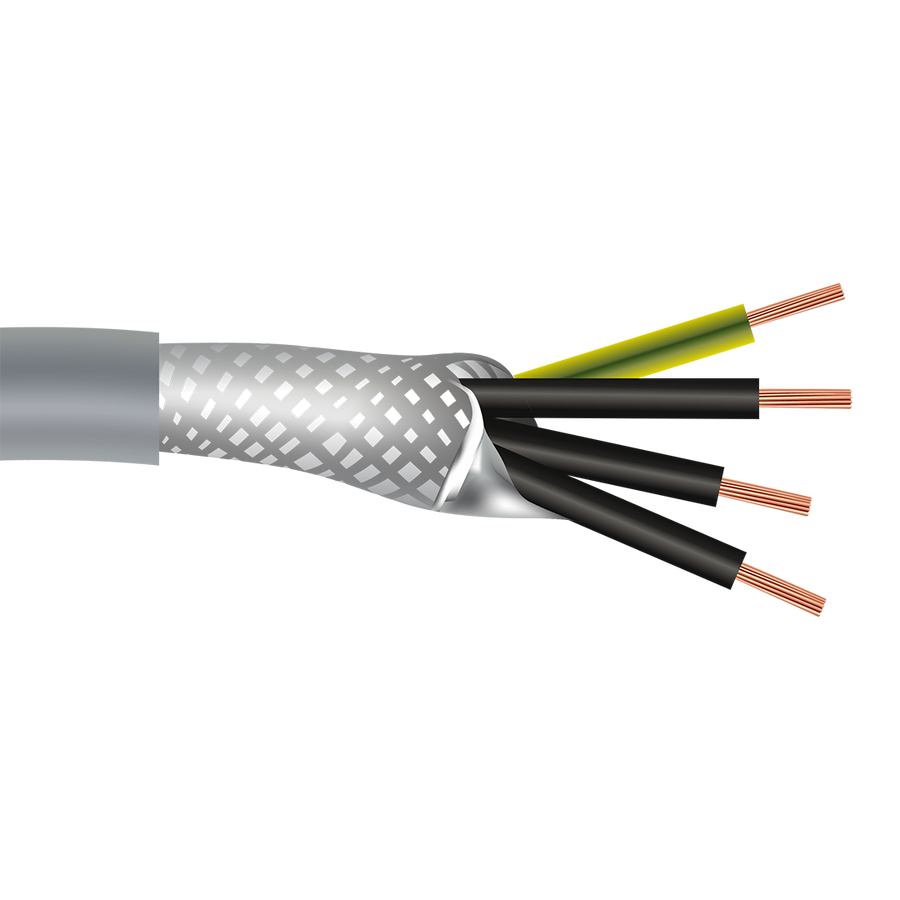

The shipboard cable systems supplied by Hangzhou Star Marine Technology Co., Ltd. are engineered to meet the rigorous demands of marine environments, ensuring reliable performance, structural integrity, and compliance with international maritime standards. These cables are integral components within shipboard electrical and control systems, facilitating power transmission, signal routing, and communication across various onboard zones. Designed for durability and safety, our cables are manufactured using high-grade materials and advanced insulation techniques to withstand mechanical stress, moisture exposure, temperature fluctuations, and chemical corrosion commonly encountered at sea.

Material selection is a critical factor in the performance of shipboard cables. Our standard offerings include aluminum (Alu) and steel armor variants, each selected based on the application requirements and installation environment. Aluminum-armored cables provide a lightweight solution with excellent corrosion resistance, ideal for upper decks and non-submerged zones. Steel-armored cables offer superior mechanical protection and are recommended for high-risk areas such as engine rooms, cargo holds, and zones with potential physical impact. Both materials are treated with anti-corrosive coatings to enhance longevity in saline and humid conditions.

Watertightness is achieved through precision extrusion of sheathing materials and robust layering techniques. The cables feature a multi-layer construction including conductor, insulation, metallic armor, and an outer thermoplastic or thermoset jacket. This design ensures IP68-rated protection, meaning the cable is dust-tight and capable of continuous submersion in water under pressure. The sealing performance is validated through hydrostatic testing in accordance with IEC 60092-370 and other relevant marine standards.

Dimensions are standardized to ensure compatibility with marine cable trays, conduits, and gland systems. Our cables are available in conductor cross-sectional areas ranging from 1.5 mm² to 240 mm², supporting current loads from low-signal applications to high-power distribution. The outer diameter varies accordingly, with precise tolerances maintained to ensure proper termination and gland compression. Flexibility and bend radius are optimized to facilitate installation in confined or complex routing paths.

All shipboard cables are certified to international marine regulations, including IMO A.657, IEC 60092-350 series, and ABS, DNV, LR, and CCS type approvals. Flame retardancy, low smoke emission, and zero halogen (LSZH) properties are standard in passenger vessel and enclosed-space applications to ensure safety during emergency conditions.

The following table outlines the key technical parameters of our standard shipboard cable range:

| Parameter | Specification |

|---|---|

| Conductor Material | Annealed tinned copper, class 2 stranded |

| Cross-Sectional Area Range | 1.5 mm² to 240 mm² |

| Insulation Material | EPR or XLPE (cross-linked polyethylene) |

| Armor Material | Aluminum wire braid or galvanized steel wire braid |

| Outer Sheath Material | PVC, PE, or LSZH (Low Smoke Zero Halogen) |

| Operating Voltage | Up to 1 kV AC (IEC 60502-1 compliant) |

| Temperature Range | -25°C to +90°C (short-term up to +130°C) |

| Bend Radius | Minimum 6× outer diameter |

| Watertight Rating | IP68 (submersible, long-term underwater operation) |

| Fire Performance | Flame retardant, low smoke, zero halogen (IEC 60332, IEC 61034, IEC 60754) |

| Approvals | CCS, ABS, DNV, LR, BV, RINA |

Hangzhou Star Marine Technology ensures full traceability and quality control throughout the production cycle, providing customers with reliable, certified solutions tailored to modern maritime electrical infrastructure.

Shipbuilding Solutions

Comprehensive Shipboard Cable Solutions for New Construction and Vessel Repair

Hangzhou Star Marine Technology Co. Ltd. delivers integrated shipboard cable systems engineered to meet the rigorous demands of modern maritime operations. As a specialized provider in marine outfittings under our Shipbuilding & Repair Solutions division, we address critical project timelines and technical complexities for both newbuilds and retrofit/refit programs. Our end-to-end approach ensures seamless integration from design specification to global delivery, minimizing vessel downtime and optimizing operational safety.

Shipyards and repair facilities face acute pressure to maintain schedules amid fluctuating supply chains. Star Marine mitigates these risks through strategic inventory management of certified marine cables compliant with IEC 60092-350/353/359 standards and ABS, DNV, LR, and CCS type approvals. Our engineering team collaborates directly with naval architects during early design phases to validate cable routing, termination requirements, and environmental resilience—preventing costly rework during installation. For urgent repair scenarios, our 24/7 export desk coordinates expedited shipments from Hangzhou or regional hubs, guaranteeing critical spares reach global ports within 72 hours of order confirmation.

Technical performance remains paramount in marine environments where moisture, vibration, and fire hazards threaten system integrity. All Star Marine cables feature flame-retardant XLPE or EPR insulation, tinned copper conductors, and optional steel wire armoring for mechanical protection. We supply full documentation packages including test certificates, traceability logs, and installation guidelines aligned with SOLAS Chapter II-2 fire safety regulations. This documentation rigor supports streamlined regulatory inspections and class society audits.

The following table outlines our core shipboard cable product specifications for common applications:

| Cable Type | Conductor Size Range | Insulation Material | Key Standards | Typical Application |

|---|---|---|---|---|

| Power Cable | 1.5–400 mm² | XLPE | IEC 60092-353 | Main propulsion, switchboards |

| Control Cable | 0.5–10 mm² | EPR | IEC 60092-376 | Automation systems, sensors |

| Instrumentation | 0.2–2.5 mm² | PE | IEC 60092-375 | Navigation, communication panels |

| Fire-Resistant | 1.5–95 mm² | MICA+XLPE | IEC 60092-359 | Emergency systems, evacuation routes |

| Armored Power | 4–300 mm² | LSZH | IEC 60092-350 | Deck machinery, high-abrasion zones |

Our export infrastructure leverages digital order tracking and dedicated maritime freight partnerships to ensure on-time delivery to any global shipyard. For repair projects, we provide technical field support via certified marine electricians who assist with cable fault diagnosis and replacement protocols. This operational agility reduces dry-dock periods by up to 30% compared to standard procurement cycles.

Star Marine’s commitment to technical excellence and rapid response establishes us as a trusted partner for shipbuilders and fleet operators. Contact our Export Management Team with project specifications to receive a tailored solution proposal within 24 business hours, backed by our ISO 9001-certified quality framework and 15-year industry track record.

Packaging & Logistics

Proper packaging and logistics are critical components in the successful export of shipboard cable, ensuring both product integrity and compliance with international maritime and phytosanitary regulations. At Hangzhou Star Marine Technology Co., Ltd., we adhere to stringent packaging standards specifically tailored for marine outfittings, with a focus on durability, moisture resistance, and safe handling during ocean freight. Our export operations are primarily coordinated through the major Chinese ports of Ningbo and Shanghai, offering efficient access to global shipping routes and reliable containerized transport solutions.

For the shipment of shipboard cable, we utilize two primary packaging systems: heat-treated wooden cases compliant with ISPM 15 standards and heavy-duty steel pallets. ISPM 15 (International Standards for Phytosanitary Measures No. 15) is a globally recognized regulation designed to prevent the spread of wood-borne pests through international trade. All wooden packaging materials, including crates and spools, undergo mandatory heat treatment and are officially marked with the ISPM 15 stamp, certifying compliance for entry into all major international markets, including the United States, European Union, Australia, and Canada.

Our wooden cases are constructed from durable, kiln-dried plywood or solid wood, engineered to withstand stacking, moisture exposure, and rough handling during transit. Cables are wound on robust wooden or composite reels, secured with protective end caps, and sealed within the crate to prevent contamination or mechanical damage. For customers requiring enhanced structural support or operating in high-moisture environments, we offer steel pallets as an alternative. These pallets provide superior load-bearing capacity and are ideal for long-distance shipments or projects involving offshore installations.

All packaging solutions are designed to meet or exceed IMO and IEC standards for marine equipment transport. Labels and handling instructions are clearly marked in accordance with international shipping protocols, including orientation arrows, weight indicators, and moisture-sensitive warnings. Our logistics team coordinates seamless inland transportation from our Hangzhou facility to the ports of Ningbo or Shanghai via bonded trucks, ensuring timely container stuffing and customs clearance. Both ports offer state-of-the-art container terminals, regular vessel schedules, and direct services to key maritime hubs worldwide.

The following table outlines the standard packaging and logistics specifications for our shipboard cable exports:

| Feature | Wooden Cases (ISPM 15) | Steel Pallets |

|---|---|---|

| Material | Heat-treated plywood or solid wood | Galvanized steel |

| Compliance | ISPM 15 certified | Non-wood, no phytosanitary treatment |

| Load Capacity | Up to 5,000 kg | Up to 8,000 kg |

| Protection Level | High (impact and moisture resistant) | Very high (corrosion-resistant) |

| Reusability | Limited | High |

| Export Port | Ningbo or Shanghai | Ningbo or Shanghai |

| Typical Transit Time (EU) | 28–35 days | 28–35 days |

| Typical Transit Time (USA) | 22–28 days | 22–28 days |

Hangzhou Star Marine Technology ensures that every export shipment of shipboard cable is packaged to the highest industry standards, minimizing risk and maximizing delivery reliability for our global clients.

Contact Star Marine

Contact Star Marine for Expert Shipboard Cable Solutions

Hangzhou Star Marine Technology Co. Ltd. stands as your dedicated partner for high-integrity marine outfittings, specializing in the critical domain of shipboard cable systems. Navigating the complexities of international maritime procurement demands a supplier with deep technical expertise, unwavering commitment to regulatory compliance, and responsive global logistics. Our shipboard cable portfolio is engineered and manufactured to meet the most stringent international standards, ensuring operational safety, longevity, and seamless integration across diverse vessel types and operational profiles. As your Export Manager and Marine Equipment Engineer, I emphasize that successful marine projects hinge on selecting cables that precisely match environmental conditions, electrical requirements, and classification society mandates. Generic solutions often lead to costly delays, rework, or non-compliance during surveys. Partnering directly with our technical team mitigates these risks from the specification phase through final delivery.

Engaging with our Product Manager, Kacher YE, provides immediate access to specialized knowledge crucial for your project’s success. Kacher possesses comprehensive oversight of our cable engineering, production processes, and global export documentation. He understands the nuanced differences between IEC 60092-350/351/353 series, IEEE 45, and specific classification society rules (DNV, LR, ABS, CCS, etc.), enabling precise product selection. Whether your requirement involves fire-resistant (IEC 60332-3 CAT A), low-smoke zero-halogen (LSZH), or specialized instrumentation cabling for dynamic applications, Kacher can guide you through optimal material choices and configuration options. This direct technical liaison ensures your inquiry receives an accurate, actionable response focused on solving your specific engineering challenge, not just fulfilling a basic quotation request. We recognize that export timelines and documentation accuracy are paramount; Kacher coordinates closely with our export department to guarantee smooth customs clearance and adherence to Incoterms® 2020.

The following table outlines core technical parameters defining our standard marine-grade shipboard cable offerings, reflecting the baseline quality and compliance you can expect. Custom specifications for unique project demands are a core strength of our engineering team.

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Conductor Material | Bare or Tinned Annealed Copper | IEC 60228 Class 2 |

| Insulation | Cross-Linked Polyethylene (XLPE) | IEC 60092-353 |

| Sheathing | LSZH Compound (Optional Armoring) | IEC 60092-359 |

| Voltage Rating | 0.6/1 kV, 1.8/3 kV, 3.6/6 kV | IEC 60502-1 |

| Temperature Range | -25°C to +90°C (Operating) | IEC 60092-350 |

| Fire Performance | Flame Retardant, Low Smoke Emission | IEC 60332-3 CAT A, IEC 60331 |

Initiate a technically grounded discussion for your next vessel build or refit project. Contact Kacher YE, our dedicated Product Manager for Marine Cabling Systems, directly via email at [email protected]. Clearly outline your vessel type, cable application (power, control, instrumentation, communication), required standards, and project timeline. Kacher commits to providing a detailed technical proposal, including certified test reports, dimensional drawings, and a firm export quotation within 48 business hours. Leverage Hangzhou Star Marine Technology’s engineering rigor and export proficiency to secure shipboard cabling that meets global maritime safety imperatives and project deadlines. We are prepared to support your success from initial inquiry through final onboard installation verification. Reach out today to ensure your electrical infrastructure foundation is built on certified marine-grade reliability.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160