Aluminum Windlass – Marine Solution Guide 2025

Content Navigation

Marine Insight: Aluminum Windlass

Marine Industry Demand: Aluminum Windlass Criticality and Sourcing Value

The aluminum windlass represents a fundamental component of modern deck machinery, directly impacting vessel safety and operational reliability. As the primary system responsible for controlled anchor deployment and retrieval, its performance is non-negotiable during critical anchoring maneuvers, especially in adverse weather or congested waters. A failure during anchor handling can lead to catastrophic consequences, including dragging anchors, collisions, groundings, and environmental damage. International maritime regulations, including SOLAS and classification society rules, mandate robust, fail-safe anchoring systems. Aluminum windlasses, engineered to stringent ISO 18295 and DNV-ST-N001 standards, provide the necessary mechanical strength, corrosion resistance, and operational consistency required for safe vessel operations across diverse global environments. Their reliability ensures crew confidence and minimizes the risk of incidents stemming from anchoring system malfunctions.

Aluminum construction offers significant advantages over traditional materials like cast iron or stainless steel in demanding marine applications. Its inherent corrosion resistance drastically reduces degradation from constant saltwater exposure, a primary cause of windlass failure in harsh conditions. This translates directly to enhanced safety through prolonged structural integrity and reduced risk of catastrophic component failure. Furthermore, the substantial weight savings of aluminum (approximately 60% lighter than cast iron equivalents) lowers the vessel’s center of gravity, improving overall stability – a critical safety factor, particularly for smaller craft and high-speed vessels where weight distribution is paramount. The reduced mass also eases installation and potential maintenance handling, contributing to safer onboard operations.

The lifecycle cost benefits of high-grade aluminum windlasses become evident when comparing long-term ownership against initial procurement price. The following table illustrates key comparative metrics:

| Material Property | Aluminum Alloy (Marine Grade) | Cast Iron | Stainless Steel (316) |

|---|---|---|---|

| Relative Weight | 1.0 (Baseline) | ~2.7x Heavier | ~3.0x Heavier |

| Saltwater Corrosion Resistance | Excellent (Passivated Surface) | Poor (Requires Coating) | Good (Susceptible to Pitting) |

| Typical Maintenance Frequency | Low (Infrequent Lubrication) | High (Painting, Rust Removal) | Moderate (Bearing Checks) |

| Estimated 10-Year Lifecycle Cost | Lowest | Highest | Moderate-High |

Hangzhou Star Marine Technology Co., Ltd. delivers exceptional value for global buyers seeking reliable, cost-effective aluminum windlass solutions. Our vertically integrated manufacturing facility in Hangzhou utilizes advanced CNC machining and robotic welding, ensuring precise tolerances and structural integrity that meet or exceed all major classification society requirements (DNV, LR, ABS, CCS). This rigorous quality control, coupled with economies of scale inherent in Chinese manufacturing, allows us to offer marine-grade aluminum windlasses at significantly lower total ownership costs than competitors in Europe or North America. Crucially, we achieve this cost advantage without compromising on material quality (using certified 5000/6000 series alloys) or safety-critical performance parameters. Our direct export model eliminates multi-tier distribution markups, providing international shipyards, vessel operators, and equipment distributors with access to ISO 9001-certified windlasses that guarantee operational safety while optimizing procurement expenditure. Partnering with Star Marine ensures vessels are equipped with a foundational safety component that delivers reliability, regulatory compliance, and demonstrable long-term economic efficiency.

Technical Specs & Approval

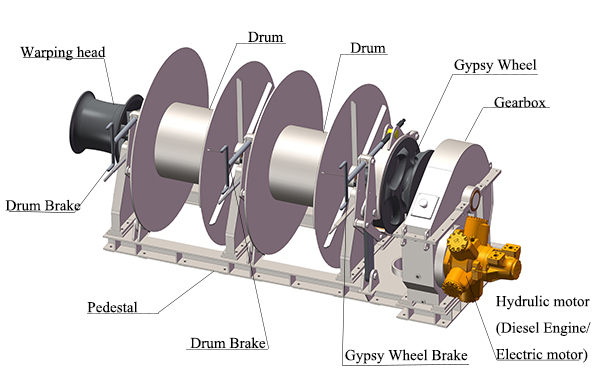

The aluminum windlass, engineered by Hangzhou Star Marine Technology Co., Ltd., represents a high-performance solution within the deck machinery category, specifically designed for reliable and efficient anchoring operations across a wide range of commercial and high-end recreational vessels. Constructed from marine-grade aluminum alloy, this windlass delivers an optimal balance between structural integrity and weight reduction, making it particularly suitable for vessels where weight distribution and corrosion resistance are critical. The design incorporates advanced surface treatments, including anodizing and protective coatings, to ensure long-term durability in aggressive maritime environments.

Performance specifications are tailored to meet international maritime standards, with a focus on operational safety, mechanical efficiency, and compatibility with various chain types and vessel configurations. The windlass is available in both electric and hydraulic drive configurations, allowing for integration into diverse onboard power systems. Electric models are equipped with high-torque, low-RPM motors featuring thermal overload protection and IP66-rated enclosures, ensuring reliable performance under continuous load. Hydraulic variants utilize compact, high-efficiency radial piston motors, compatible with standard marine hydraulic power units, offering smooth operation and exceptional power density.

A defining feature of this windlass is its broad compatibility with stud link anchor chains, supporting diameters ranging from 12.5 mm to 60 mm. This range enables deployment across vessels from mid-sized yachts to large commercial ships, with pull load capacities scaled accordingly. The gypsy wheels are precision-machined to ISO 1700 and DIN 766 standards, ensuring secure chain engagement and minimizing wear. All models incorporate a manual override option, allowing for emergency operation in the event of power failure.

The windlass is designed for direct flange mounting on anchor wells or foredeck foundations, with alignment and installation dimensions standardized for ease of integration. Optional accessories include chain stoppers, chain counters, remote control panels, and wash-down covers. All units undergo rigorous factory testing, including load testing at 1.5 times the rated pull load, dynamic braking verification, and leak testing for hydraulic models.

The following table outlines the core technical parameters for the aluminum windlass series:

| Parameter | Value/Range |

|---|---|

| Material | Marine-grade aluminum alloy (A7075-T6) |

| Finish | Hard anodized with anti-corrosion coating |

| Chain Diameter Compatibility | 12.5 mm – 60 mm |

| Pull Load Capacity | 25 kN – 350 kN (depending on model) |

| Drive Type | Electric or Hydraulic |

| Motor (Electric) | 24V/48V DC, IP66, thermal protection |

| Motor (Hydraulic) | Radial piston, max 250 bar pressure |

| Gypsy Standard | ISO 1700, DIN 766, NF E27-201 |

| Brake Type | Automatic mechanical band brake |

| Duty Cycle | Intermittent (30 min ON / 90 min OFF) |

| Ambient Operating Temp | -25°C to +55°C |

| Certifications | CE, ISO 9001, DNV-GL Type Approval (optional) |

Hangzhou Star Marine Technology ensures each unit is manufactured under strict quality control procedures, with full traceability of materials and components. Custom configurations are available upon request to meet specific vessel requirements or classification society standards.

Shipbuilding Solutions

Integrated Aluminum Windlass Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered aluminum windlass systems that address the critical demands of modern shipbuilding and vessel repair. Our expertise in lightweight, corrosion-resistant deck machinery ensures optimal performance for new construction projects and urgent retrofit scenarios. As a certified ISO 9001:2015 manufacturer, we integrate naval architecture requirements with rapid execution timelines, minimizing vessel downtime while meeting ABS, DNV-GL, and LR classification standards.

For newbuild programs, Star Marine collaborates directly with shipyard design teams during the early CAD phase. Our engineers validate structural interfaces, power specifications, and deck reinforcement requirements to ensure seamless integration. This proactive approach prevents costly redesigns and accelerates installation schedules. In repair contexts, our global service network provides 24-hour technical response for emergency windlass failures. We maintain strategic inventory hubs in Singapore, Rotterdam, and Houston, enabling same-vessel turnaround for critical components like gypsy wheels, motor assemblies, and control panels.

Our marine-grade 5083 aluminum windlasses offer a 40% weight reduction versus traditional steel units without compromising SWL capacity. This directly enhances vessel stability and fuel efficiency—key considerations for modern eco-design vessels. All models feature IP66-rated electrical systems and sacrificial anodes for extended service life in harsh marine environments.

Key Technical Specifications Comparison

| Model Series | Safe Working Load (SWL) | Chain Size Compatibility | Power Supply | Material Grade | Corrosion Protection |

|---|---|---|---|---|---|

| ST-AL75 | 7.5 Tons | 20-22mm | 24V DC | 5083-H116 | Anodized + Zinc Anodes |

| ST-AL12 | 12 Tons | 24-26mm | 110V AC/DC | 5083-H116 | Anodized + Zinc Anodes |

| ST-AL20 | 20 Tons | 28-30mm | 220V AC | 5083-H116 | Anodized + Zinc Anodes |

Star Marine’s end-to-end solution encompasses design validation, factory acceptance testing (FAT), on-site commissioning, and crew training. For repair projects, we deploy certified technicians within 72 hours globally to conduct root-cause analysis and implement permanent fixes. Our digital twin technology allows real-time performance monitoring post-installation, providing predictive maintenance alerts to prevent operational disruptions.

With a 15-year track record supplying windlasses to 300+ vessels—from offshore support vessels to luxury yachts—we understand the urgency of maritime operations. Contact our export team for project-specific quotations with 48-hour turnaround, including 3D model submissions and classification society documentation. Star Marine ensures your deck machinery investment delivers reliability from keel-laying through the vessel’s operational lifecycle.

Packaging & Logistics

Packaging & Logistics for Aluminum Windlasses – Export Guidelines

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all aluminum windlasses are packaged to meet international maritime transport standards, safeguarding product integrity during export. As part of our commitment to quality and reliability in deck machinery solutions, we utilize robust packaging methods specifically designed for heavy-duty marine equipment. Our standard packaging includes export-grade wooden cases compliant with ISPM 15 regulations and reinforced steel pallets for secure handling and transportation.

All wooden packaging materials used in the export of aluminum windlasses are treated in accordance with the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This globally recognized regulation mandates that wood packaging material must be heat-treated to eliminate pests and pathogens, then stamped with an official compliance mark. This certification is essential for customs clearance in most destination countries, particularly within the European Union, North America, Australia, and other major maritime markets. Our wooden cases are constructed from durable, kiln-dried hardwood or plywood, engineered to withstand stacking, moisture exposure, and mechanical stress during long-haul shipping.

For added structural support and ease of handling, each aluminum windlass is mounted on a steel pallet designed to distribute weight evenly and prevent deformation during transit. The steel pallets are welded to exacting standards, providing a stable base that is compatible with forklifts and container loading equipment. Components are securely fastened using high-tensile bolts and anti-vibration padding to minimize movement. Sensitive parts such as electric motors, control panels, and gear housings are additionally wrapped in moisture-resistant VCI (Vapor Corrosion Inhibitor) film to protect against salt air and humidity encountered at sea.

Each packaged unit is clearly labeled with essential shipping information, including product model, serial number, gross weight, handling instructions, and orientation markers. Hazard labels (if applicable) and barcodes for inventory tracking are also applied to streamline logistics operations at the destination port.

Exports are coordinated through China’s primary maritime hubs—Ningbo and Shanghai. Both ports offer world-class container handling facilities, direct liner services to global destinations, and efficient customs processing. We work exclusively with certified freight forwarders experienced in marine equipment logistics to ensure timely delivery and full documentation compliance.

Below is an overview of our standard packaging and shipping specifications:

| Parameter | Specification |

|---|---|

| Packaging Type | ISPM 15-compliant wooden case with steel pallet base |

| Wood Treatment | Heat-treated, stamped, and certified per ISPM 15 |

| Pallet Material | Mild steel, welded frame with anti-rust coating |

| Protection Layer | VCI film, foam padding, and moisture barrier |

| Labeling | Model, serial number, weight, handling symbols, destination markings |

| Export Ports | Ningbo Port, Shanghai Port (Yangshan Deep Water Port) |

| Container Compatibility | Standard 20’ and 40’ dry or high-cube containers |

| Handling Equipment Required | Forklift, crane, or pallet jack (rated for gross weight) |

We maintain strict quality control throughout the packaging process to ensure every aluminum windlass arrives at its destination in optimal condition, ready for installation and operation.

Contact Star Marine

Technical Consultation for Aluminum Windlass Integration

Selecting the correct aluminum windlass requires precise alignment with vessel specifications, operational environment, and regulatory standards. As a critical component of deck machinery, improper selection can lead to performance degradation, safety risks, or premature failure due to marine corrosion. Hangzhou Star Marine Technology prioritizes engineered solutions over off-the-shelf compromises, ensuring your windlass delivers decades of reliable service in saltwater conditions. Our aluminum windlasses utilize marine-grade 6061-T6 alloy, anodized for maximum corrosion resistance, and undergo rigorous salt spray testing per ISO 9227 standards. This commitment to material science and quality control is why global shipyards and superyacht builders specify Star Marine equipment.

Key technical parameters for our standard aluminum windlass series are summarized below. Note that all models support customization for chain size, voltage, control systems, and mounting configurations to meet project-specific demands.

| Specification | Value Range | Compliance Standard |

|---|---|---|

| Safe Working Load (SWL) | 500 kg – 3,000 kg | ISO 18294 |

| Chain Size Compatibility | 8 mm – 14 mm (ISO 4565) | DNVGL-SE-0192 |

| Operating Voltage | 12 V DC / 24 V DC / 110-240 V AC | IEC 60092-350 |

| Material | Anodized 6061-T6 Aluminum | ASTM B221 |

| Warranty | 24 months (commercial use) | ISO 9001:2015 certified |

For complex installations or vessels operating in extreme environments (e.g., polar expeditions or tropical salinity zones), direct engagement with our engineering team is essential. Kacher YE, Product Manager and Marine Equipment Engineer at Hangzhou Star Marine Technology, oversees all technical consultations and export coordination. With 12 years of experience in deck machinery design and ISO-compliant manufacturing processes, Kacher specializes in resolving integration challenges such as load distribution on aluminum foredecks, electromagnetic compatibility with navigation systems, and compliance with flag state regulations including SOLAS and LY3. His expertise ensures your windlass selection aligns with both operational requirements and international certification frameworks.

Initiate your project with a technical consultation to avoid costly redesigns or non-compliance penalties. Reach Kacher YE directly via email at [email protected] for prompt, engineering-focused support. Include your vessel’s length overall (LOA), displacement, intended operational profile, and applicable class society requirements to accelerate the solutioning process. For urgent export documentation requests—including CE declarations, material traceability reports, or CAD integration files—our Hangzhou headquarters provides dedicated multilingual export coordination within 24 business hours. All communications are handled under strict confidentiality per our ISO 27001-certified data protocols.

Do not risk vessel downtime or safety incidents through generic procurement channels. Partner with Star Marine’s engineering team from specification to sea trial. Contact Kacher YE today to receive a tailored technical proposal, including 3D mounting diagrams and performance validation data specific to your aluminum windlass requirements. Your vessel’s reliability begins with precision engineering—let us deliver it.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160