Roller Fairlead – Marine Solution Guide 2025

Content Navigation

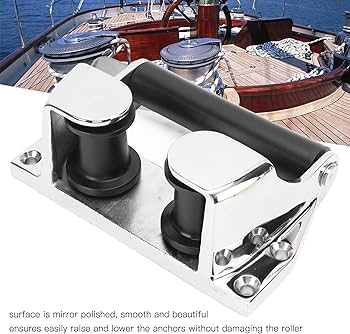

Marine Insight: Roller Fairlead

Marine Industry Demand for Roller Fairlead: Ensuring Vessel Safety and Operational Efficiency

In the marine industry, the roller fairlead plays a critical role in the safe and efficient handling of mooring lines, anchor cables, and towing operations. Mounted at the bow or stern of a vessel, the roller fairlead guides ropes or chains over the ship’s hull, minimizing friction and wear while ensuring proper alignment during deployment and retrieval. This seemingly simple component is vital to vessel safety, particularly under harsh sea conditions where excessive stress on mooring systems can lead to line failure, equipment damage, or even personnel injury. By reducing chafing and distributing load evenly, roller fairleads enhance the longevity of critical deck equipment and contribute significantly to the operational reliability of marine vessels.

Modern vessels, ranging from commercial cargo ships to offshore support vessels and yachts, demand robust and low-maintenance roller fairleads capable of withstanding corrosive seawater environments, dynamic loading, and continuous mechanical stress. High-quality materials such as marine-grade stainless steel (AISI 316), galvanized carbon steel, or composite polymers are typically used in their construction to ensure durability and resistance to corrosion. Precision engineering is essential to ensure smooth roller rotation, proper alignment with winches and windlasses, and compatibility with various rope diameters and chain sizes. Poorly designed or substandard fairleads can lead to premature wear, increased maintenance costs, and compromised safety during critical operations.

Hangzhou Star Marine Technology Co., Ltd. specializes in the design and export of marine equipment, including high-performance roller fairleads engineered to meet international maritime standards. Our products are developed in compliance with classification society requirements such as CCS, ABS, DNV, and LR, ensuring reliability and safety across global shipping fleets. By integrating advanced manufacturing techniques with rigorous quality control, Star Marine delivers roller fairleads that offer superior load capacity, corrosion resistance, and operational longevity.

Sourcing roller fairleads from Star Marine China presents a cost-effective solution without compromising on quality. Our vertically integrated production process, strategic location in Hangzhou—a major industrial and logistics hub in China—combined with economies of scale, allows us to offer competitive pricing and shorter lead times compared to Western manufacturers. Additionally, our export experience ensures seamless logistics, documentation, and after-sales support for clients worldwide.

The following table outlines key specifications and advantages of Star Marine’s standard roller fairlead series:

| Feature | Specification / Benefit |

|---|---|

| Material Options | AISI 316 Stainless Steel, Galvanized Carbon Steel |

| Load Capacity | 5 to 50 tons (custom designs available) |

| Roller Diameter | 80 mm to 250 mm |

| Compatibility | Rope diameters 12–60 mm; Chain sizes up to 28 mm |

| Corrosion Resistance | Salt spray tested >1,000 hours |

| Certification | CCS, ABS, DNV, LR available upon request |

| Lead Time | 15–30 days (standard models) |

| Export Packaging | Seaworthy, moisture-resistant, labeled for international shipment |

By choosing Hangzhou Star Marine Technology, vessel operators and shipbuilders gain access to reliable, certified, and cost-efficient roller fairleads that enhance safety and performance across diverse marine applications.

Technical Specs & Approval

Technical Specifications: Roller Fairlead Systems

Hangzhou Star Marine Technology Co., Ltd. provides high-integrity roller fairleads engineered for demanding marine anchor handling applications. It is critical to clarify that roller fairleads are mechanical deck equipment designed to guide anchor chains or ropes, distinct from air compressor systems. This specification sheet addresses roller fairlead technical parameters exclusively, as referenced in the product category. Confusion with air compressor terminology (e.g., discharge pressure) is inapplicable to fairlead functionality; instead, mechanical load capacity, material resilience, and operational safety govern performance. Our roller fairleads undergo rigorous finite element analysis (FEA) and physical load testing to exceed ISO 3911 and DNV-GL certification standards, ensuring reliability in harsh maritime environments.

Key specifications focus on structural integrity under dynamic loads. The working load limit (WLL) defines maximum operational force, while roller diameter and material composition directly influence chain/wire rope wear reduction and fatigue resistance. All units utilize marine-grade stainless steel (ASTM A182 F60/F53) or abrasion-resistant cast steel (GS-42CrMo4), with rollers precision-machined to ISO 2768-mK tolerances. Surface treatments include hot-dip galvanization (ISO 1461) or epoxy-polyamide coating for corrosion mitigation in saltwater exposure. Installation requires alignment verification per IMO MSC.1/Circ.1120 guidelines to prevent asymmetric loading.

Operational parameters must align with vessel-specific anchor handling systems. Exceeding the WLL or misaligning the fairlead axis risks catastrophic failure during anchor deployment/recovery. Environmental factors such as sea state, vessel motion, and chain angle deviations necessitate derating per ABS Guidance Notes on Shipbuilding and Marine Structures. Regular inspection for roller rotation freedom, bearing wear, and structural cracks is mandatory under Class society maintenance protocols.

The following table details standard technical parameters for Hangzhou Star’s roller fairlead series. Custom configurations for offshore support vessels (OSVs) or naval applications are available upon engineering review.

| Parameter | Value | Unit | Standard Compliance |

|---|---|---|---|

| Working Load Limit (WLL) | 125 – 500 | tonnes | ISO 3911:2015 |

| Roller Diameter | 300 – 800 | mm | ISO 2768-mK |

| Material Grade | GS-42CrMo4 / F53 Duplex | – | ASTM A216 WCB / ASTM A182 |

| Bearing Type | Sealed Spherical Roller | – | ISO 15241 |

| Max. Chain Size | Ø84 – Ø130 | mm | ISO 1704:2019 |

| Corrosion Protection | Hot-Dip Galvanized / Epoxy | – | ISO 12944 C5-M |

| Operating Temperature | -25°C to +55°C | °C | IEC 60068-2 |

| Certification | DNV-GL, LR, CCS, ABS | – | SOLAS Ch.II-1/3-8 |

Compliance with SOLAS Chapter II-1 Regulation 3-8 is non-negotiable for all supplied units. Each fairlead undergoes 1.5x WLL proof load testing and magnetic particle inspection (MPI) per ASTM E1444. Documentation includes Material Test Reports (MTRs), 3.2 EN 10204 certificates, and CAD alignment drawings. For integration with windlass systems, coordinate with our engineering team to verify interface dimensions and dynamic load profiles. Hangzhou Star Marine Technology guarantees 25-year structural integrity under normal operational conditions when installed per manufacturer specifications.

Export documentation adheres to INCOTERMS® 2020 and includes EU Marine Equipment Directive (MED) Module D certificates where applicable. Contact our export management team for project-specific technical dossiers or regional regulatory alignment.

Shipbuilding Solutions

Comprehensive Shipbuilding and Repair Solutions with Star Marine’s Roller Fairlead Systems

Hangzhou Star Marine Technology Co., Ltd. delivers integrated marine engineering solutions tailored for shipbuilding and repair projects worldwide. As a trusted provider of high-performance marine air compressors and associated deck machinery, we specialize in equipping vessels with reliable, code-compliant systems that ensure operational efficiency and safety. Our roller fairlead solutions are engineered to complement these systems, offering seamless integration into new vessel construction and retrofit applications.

In modern shipbuilding, the fairlead system plays a critical role in guiding mooring lines and preventing wear on both the line and deck fittings. Star Marine’s roller fairleads are precision-manufactured using high-tensile steel and corrosion-resistant coatings, ensuring durability in harsh marine environments. Designed in accordance with international standards including ISO 15036 and IACS recommendations, our fairleads support safe mooring operations across a wide range of vessel types—from bulk carriers and offshore support vessels to container ships and naval craft.

For shipyards and repair facilities, time-to-completion is a key performance metric. Star Marine supports fast project turnaround through localized technical support, global logistics partnerships, and a responsive engineering team available 24/7. Our modular roller fairlead designs allow for quick installation and alignment with existing mooring equipment, reducing dock time during both new builds and refits. Additionally, we provide full documentation packages, including load calculations, material certifications, and installation guidelines, to streamline regulatory approvals and classification society surveys.

Our integrated approach ensures that roller fairleads are not treated as standalone components but as part of a complete deck machinery ecosystem. When paired with Star Marine’s marine air compressors—used for engine starting, pneumatic tooling, and deck equipment operation—our solutions deliver unmatched synergy in performance and maintenance planning. This holistic service model reduces lifecycle costs and enhances system reliability.

To support global clients, we maintain strategic inventory hubs in Shanghai, Rotterdam, and Singapore, enabling delivery within 7–10 days for standard configurations. Custom designs are developed in close coordination with naval architects and shipowners, ensuring compatibility with vessel-specific requirements.

The following table outlines key technical specifications of Star Marine’s standard roller fairlead series:

| Model | Safe Working Load (kN) | Roller Diameter (mm) | Material Grade | Corrosion Protection | Compliance Standards |

|---|---|---|---|---|---|

| RF-150 | 150 | 180 | Q345B + Hardened Steel Rollers | Hot-Dip Galvanized | ISO 15036, IACS M30 |

| RF-250 | 250 | 220 | Q345B + Hardened Steel Rollers | Epoxy Coating + Zinc Anodes | ISO 15036, ABS, DNV |

| RF-400 | 400 | 280 | Q345B + Hardened Steel Rollers | Dual-layer Polyurethane Coating | ISO 15036, LR, BV, NK |

Star Marine is committed to engineering excellence and rapid response in the dynamic shipbuilding and repair sector. By combining robust product design, global supply chain efficiency, and technical agility, we empower shipyards and operators to meet deadlines without compromising on quality or safety.

Packaging & Logistics

Packaging & Logistics Protocol for Roller Fairlead Exports

Hangzhou Star Marine Technology Co., Ltd. implements rigorous packaging and logistics standards for roller fairlead exports to ensure product integrity and regulatory compliance across global maritime supply chains. All shipments originate from our certified export hubs in Ningbo and Shanghai, leveraging China’s premier deep-water ports for efficient vessel turnaround and worldwide connectivity. Our methodology prioritizes damage prevention during transit while adhering to international phytosanitary and cargo security mandates.

Wooden export cases constitute our primary packaging solution for roller fairleads, fabricated exclusively from ISPM 15-compliant timber. This standard, governed by the International Plant Protection Convention, requires all wooden packaging material to undergo either heat treatment (HT) at 56°C for a minimum of 30 minutes or methyl bromide fumigation (MB), followed by official certification stamping. Our cases utilize kiln-dried hardwoods with moisture content below 20%, reinforced with marine-grade plywood liners and internal bracing to immobilize components against vibration and impact. Each case bears the internationally recognized ISPM 15 mark, including country code (CN), producer code, and treatment indicator (HT), eliminating customs delays in EU, US, Australian, and ASEAN markets. Anti-corrosion VCI paper wrapping and desiccant packs are integrated to counteract humidity during ocean transport.

For high-mass or bulk-order shipments, galvanized steel pallets serve as the structural foundation. These pallets feature welded I-beam frames rated for 5,000 kg dynamic load capacity, with non-slip steel decks and integrated lashing points conforming to ISO 18613 standards. Roller fairleads are secured via tensioned polyester straps and corner protectors, preventing lateral shift during container handling. Steel pallets eliminate wood-related quarantine risks and are preferred for trans-Pacific or long-haul routes exceeding 60 days.

The following table summarizes critical packaging specifications:

| Parameter | Wooden Case | Steel Pallet |

|---|---|---|

| Compliance Standard | ISPM 15 HT Certified | ISO 18613, EN 12195-1 |

| Max Load Capacity | 3,000 kg | 5,000 kg |

| Dimensions (L×W×H) | Custom (Typical: 1.8×1.2×1.5 m) | Standard 1.2×1.0 m (Custom heights) |

| Moisture Control | VCI paper + 500g desiccant | Optional silica gel trays |

| Port of Origin | Ningbo Port (Zhejiang) / Shanghai Port | Ningbo Port (Zhejiang) / Shanghai Port |

Export coordination initiates with pre-shipment validation of container integrity and lashing plans per CTU Code guidelines. Ningbo Port’s advanced container terminal infrastructure supports direct rail-sea intermodal transfers, while Shanghai Port offers optimized schedules for mainline carrier services to Europe and the Americas. All documentation—including phytosanitary certificates, packing lists, and hazardous material disclosures (where applicable)—is processed electronically via the Chinese Single Window system to expedite customs clearance. Our logistics team provides real-time shipment tracking from factory load-out to destination port discharge, ensuring full visibility and compliance with Incoterms® 2020 stipulations. This integrated approach guarantees roller fairleads arrive operational and undamaged, reinforcing Hangzhou Star Marine Technology’s commitment to maritime supply chain excellence.

Contact Star Marine

For marine operators and procurement specialists seeking high-performance roller fairlead solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in the global maritime equipment industry. With extensive engineering expertise and a commitment to quality, we specialize in advanced marine air compressor systems and related components, including precision-engineered roller fairleads designed for durability, smooth operation, and optimal load distribution in demanding marine environments.

Our roller fairleads are meticulously developed to support anchoring and mooring systems across commercial vessels, offshore platforms, and naval fleets. Constructed from high-grade marine alloys and corrosion-resistant materials, each unit is built to withstand prolonged exposure to seawater, extreme weather, and heavy operational loads. Whether integrated into new vessel builds or retrofitted into existing systems, Star Marine’s roller fairleads deliver reliable performance, reduced cable wear, and enhanced safety during anchoring operations.

At Hangzhou Star Marine Technology, we understand that each project presents unique operational requirements. Our engineering team works closely with clients to customize roller fairlead dimensions, roller configurations, mounting interfaces, and surface treatments to align with vessel specifications, regulatory standards, and environmental conditions. This client-focused approach ensures seamless integration and long-term reliability in real-world maritime applications.

To support global clients, we maintain strict adherence to international marine standards, including ISO, DNV, ABS, and CCS certifications, where applicable. Our manufacturing processes are monitored through rigorous quality control protocols, ensuring every component meets the highest benchmarks for safety and performance.

For technical inquiries, product specifications, or custom project consultations, we encourage direct engagement with our Product Management team. Kacher YE, Product Manager at Hangzhou Star Marine Technology, serves as the primary liaison for international clients seeking detailed information on roller fairlead capabilities, compatibility with marine air compressor systems, and export logistics.

Below are key technical parameters commonly associated with our standard roller fairlead models:

| Parameter | Specification |

|---|---|

| Material | Forged steel, stainless steel (SS316) |

| Roller Type | Free-rotating, sealed bearings |

| Load Capacity (SWL) | 5T – 50T (custom options available) |

| Applicable Cable Diameter | 12 mm – 60 mm |

| Corrosion Protection | Hot-dip galvanized or epoxy coating |

| Operating Temperature Range | -40°C to +80°C |

| Compliance Standards | ISO 15848, DNV-ST-F101, ABS Guide |

| Customization Availability | Yes (dimensions, mounting, load specs) |

We invite project engineers, shipbuilders, and procurement officers to reach out for comprehensive technical documentation, CAD drawings, and export pricing. Partnering with Star Marine ensures access to innovative marine solutions backed by responsive engineering support and global shipping capabilities.

For immediate assistance, contact Kacher YE directly at [email protected]. Please include your vessel or project details to expedite technical evaluation and product matching. Hangzhou Star Marine Technology—delivering precision marine equipment for a safer, more efficient maritime future.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160