Ships Oily Water Separator – Marine Solution Guide 2025

Content Navigation

Marine Insight: Ships Oily Water Separator

Marine Industry Demand: Ships Oily Water Separator

The oily water separator (OWS) represents a critical component in modern marine environmental compliance and vessel operational safety. Mandated globally under MARPOL Annex I Regulation 14 and subsequent IMO resolutions including MEPC.107(49), this equipment is non-negotiable for all vessels of 400 gross tons and above, as well as certain smaller vessels operating in sensitive waters. Its primary function—processing bilge water to ensure oil content in overboard discharges remains below the stringent 15 parts per million (ppm) threshold—is fundamental to preventing catastrophic marine pollution incidents. Non-compliance carries severe consequences including substantial port state control fines, operational detention, reputational damage, and potential criminal liability for crew and operators. Beyond regulatory adherence, a fully functional OWS directly safeguards vessel safety by mitigating risks associated with untreated bilge accumulation. Uncontrolled oil-water mixtures can compromise engine room stability, increase fire hazards near hot surfaces, and lead to hazardous slip conditions for crew. Reliability in harsh marine environments is therefore not merely an environmental requirement but a core operational safety imperative.

Hangzhou Star Marine Technology provides engineered OWS solutions that meet these demanding safety and regulatory requirements while delivering significant lifecycle cost advantages. Our systems undergo rigorous testing to achieve full certification from major classification societies including CCS, DNV, LR, and ABS, ensuring seamless integration with vessel safety management systems. Star Marine leverages China’s advanced marine manufacturing ecosystem to optimize production without compromising quality. Our vertically integrated supply chain and large-scale fabrication facilities in Hangzhou enable cost efficiencies unattainable by smaller regional manufacturers. Crucially, this cost-effectiveness extends beyond initial procurement. Star Marine OWS units feature robust 316L stainless steel construction, modular component design for simplified maintenance, and intelligent monitoring systems that minimize downtime and reduce long-term operational expenditure. We maintain a global network of certified service engineers and spare parts depots, ensuring rapid response times that prevent extended vessel off-hire periods—a critical factor in calculating true total cost of ownership.

Technical performance and reliability are validated through standardized parameters, as demonstrated below for our flagship OWS series:

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Flow Rate Range | 0.1 m³/h to 50 m³/h | IMO MEPC.107(49) |

| Maximum Discharge Oil Content | ≤ 15 ppm (alarmed & stopped at 15 ppm) | MARPOL Annex I Reg 14 |

| Operating Pressure | 0.2 – 0.6 MPa | ISO 10088 |

| Material Construction | 316L SS wetted parts | ABS Steel Vessel Rules |

| Power Supply | 220/380V AC 50/60Hz | IEC 60092-101 |

| Alarm & Control System | PLC with remote monitoring | IMO MSC/Circ.997 |

Sourcing from Hangzhou Star Marine Technology delivers a strategic balance of regulatory assurance, operational safety, and economic value. Our commitment to ISO 9001 quality management systems ensures every unit meets the exacting tolerances required for consistent ppm compliance under real-world operating conditions. For shipowners and managers navigating increasingly stringent environmental regulations and volatile operational costs, Star Marine provides a dependable partner whose OWS solutions protect both the marine environment and the vessel’s operational integrity throughout its service life. This combination of certified performance and optimized lifecycle economics makes Star Marine a prudent choice for global fleet compliance.

Technical Specs & Approval

The oily water separator (OWS) is a critical component in marine pollution prevention systems, designed to remove oil and hydrocarbons from bilge water to ensure compliance with international maritime regulations, including MARPOL Annex I. Hangzhou Star Marine Technology Co., Ltd. manufactures robust and efficient oily water separators tailored for commercial vessels, offshore platforms, and auxiliary marine equipment. These separators are engineered to deliver reliable performance under harsh marine conditions while maintaining minimal maintenance requirements and long service life.

Constructed using high-grade materials, our oily water separators are available in two primary configurations: aluminum alloy and carbon steel. The aluminum variant offers excellent corrosion resistance and reduced weight, making it ideal for high-speed craft and vessels where weight distribution is critical. The carbon steel version, treated with anti-corrosive coatings and primers, provides enhanced durability for prolonged exposure to saltwater environments and is suited for larger commercial and cargo vessels. Both material options are fabricated to meet stringent welding and structural standards, ensuring mechanical integrity and long-term operational safety.

Watertightness is a fundamental design criterion for all units. The separator housing is pressure-tested during manufacturing to verify leak integrity, and all flanged connections comply with ISO 10434 and ISO 7005 standards. Gaskets are fabricated from nitrile rubber (NBR) or EPDM, selected based on fluid compatibility and operating temperature. The system maintains a minimum IP56 rating for electrical components and control panels, protecting against dust ingress and water jets. The internal coalescer plates and filtration media are designed to achieve oil discharge concentrations of less than 15 ppm, meeting MEPC.107(49) performance standards.

Units are compact and modular, facilitating installation in confined engine room spaces. Standard dimensions are optimized for ease of integration with existing bilge systems, while custom configurations can be engineered upon request. All models include inlet and outlet flanges, sludge drain valves, and sampling points for regulatory inspections. The control system features automatic oil skimming, alarm indicators for high oil content, and optional remote monitoring via integrated digital interfaces.

Below are the standard technical parameters for our oily water separator series:

| Parameter | Value / Specification |

|---|---|

| Model Designation | OWS-0.5, OWS-1.0, OWS-2.0 |

| Flow Rate Capacity | 0.5 m³/h, 1.0 m³/h, 2.0 m³/h |

| Maximum Inlet Pressure | 0.6 MPa |

| Separation Efficiency | >99% (output oil content <15 ppm) |

| Material Options | Aluminum Alloy 5083 / Carbon Steel with Epoxy Coating |

| Design Temperature Range | 0°C to 70°C |

| Electrical Supply | 220V AC, 50Hz (custom voltages available) |

| Control System | PLC-based with touchscreen HMI |

| Housing Protection Rating | IP56 |

| Flange Standard | ISO 10434 (DIN/EN) |

| Overall Dimensions (L×W×H) | 1200×600×1100 mm (OWS-0.5), scalable per model |

| Weight (Dry) | 180 kg (Aluminum), 260 kg (Steel) – OWS-0.5 |

| Compliance Standards | MARPOL Annex I, MEPC.107(49), ISO 8799, SOLAS |

All units undergo factory acceptance testing (FAT), including hydrostatic testing, flow calibration, and simulated operational cycles. Documentation packages include material test certificates (MTC), performance test reports, and Declaration of Conformity. Hangzhou Star Marine Technology ensures each oily water separator meets global marine environmental standards and delivers consistent, trouble-free operation throughout its lifecycle.

Shipbuilding Solutions

Comprehensive Oily Water Separator Solutions for Global Vessel Operations

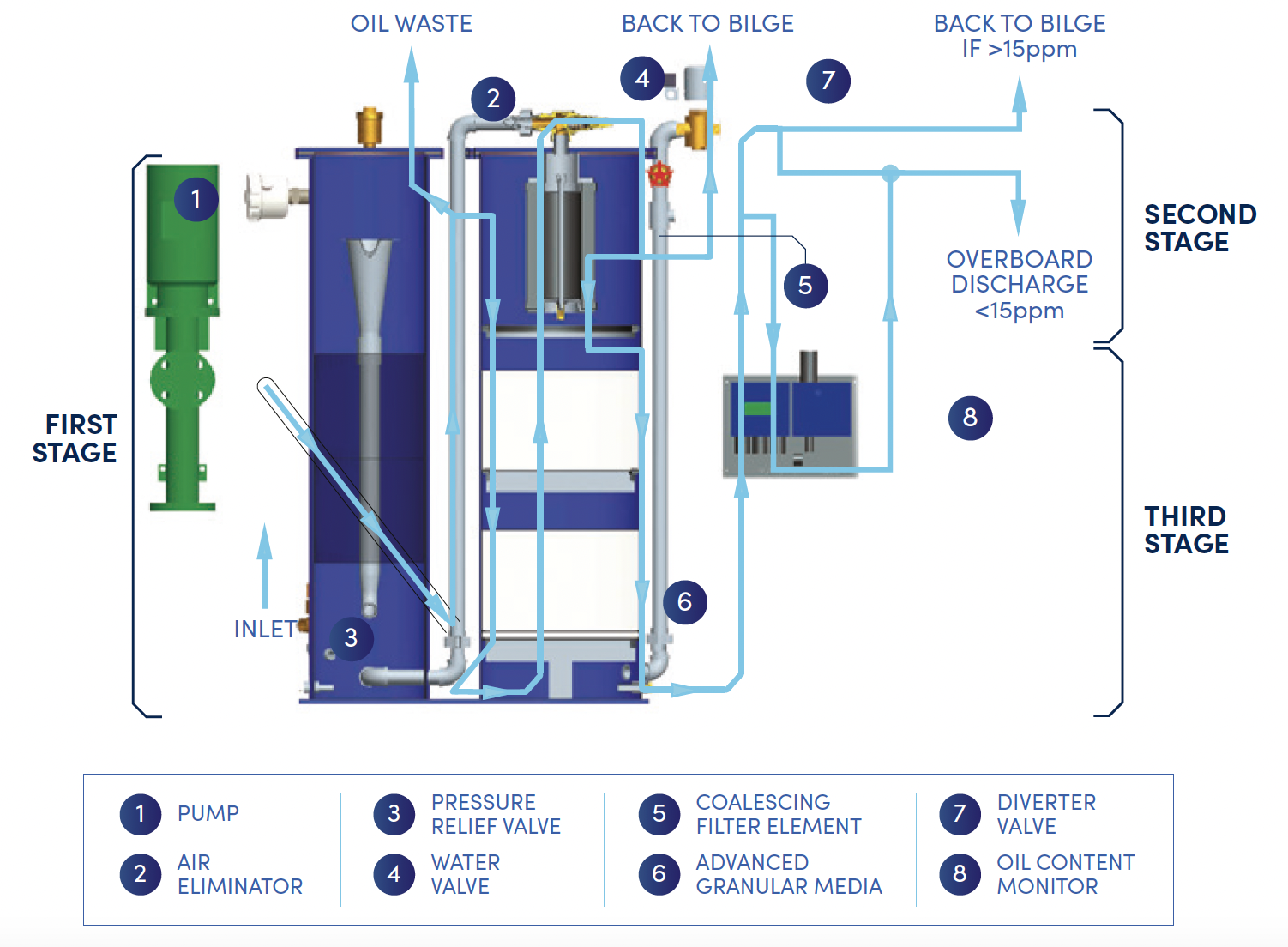

Hangzhou Star Marine Technology Co., Ltd. delivers engineered oily water separator (OWS) systems that ensure strict compliance with MARPOL Annex I and IMO MEPC.107(49) standards for both new vessel construction and critical repair scenarios. As an OEM with integrated design, manufacturing, and global service capabilities, we provide end-to-end solutions that minimize operational downtime while guaranteeing regulatory adherence. Our systems utilize advanced three-stage separation technology—gravity, coalescence, and ultrafiltration—to achieve effluent concentrations consistently below 15 ppm, with real-time monitoring via integrated 15-ppm alarms and automated bilge water management.

For newbuild projects, Star Marine collaborates directly with shipyards during the design phase to optimize OWS integration into vessel machinery spaces. We offer customizable skid-mounted or modular units compatible with diverse engine room layouts, ensuring seamless piping, electrical, and control system interfaces. All units undergo rigorous factory acceptance testing (FAT) per ISO 9001 protocols, including simulated operational load tests and third-party certification by major classification societies (DNV, ABS, LR, etc.). This proactive approach eliminates retrofitting delays and ensures immediate operational readiness upon vessel delivery.

In repair and retrofit contexts, our global service network guarantees rapid response to critical failures. With strategically located warehouses in Singapore, Rotterdam, and Houston, we maintain 24/7 availability of genuine spare parts—including coalescer cartridges, sensor modules, and control boards—for all legacy and current OWS models. Our certified marine engineers deploy within 24 hours to vessel locations worldwide, conducting on-site diagnostics, emergency repairs, or full system upgrades to meet evolving discharge regulations. This operational agility prevents extended port detention and costly non-compliance penalties.

The following table summarizes our differentiated service framework:

| Service Aspect | New Build Solution | Repair Solution |

|---|---|---|

| Integration Approach | Early-stage design collaboration with shipyards; FAT-certified pre-commissioning | Emergency mobilization; compatibility assessment for legacy systems |

| Response Time | Aligned with shipyard construction milestones | On-site engineering team deployment within 24 hours |

| Technical Support | Full documentation package (P&ID, 3D models, MARPOL compliance certificates) | Remote diagnostics; 24/7 technical hotline; spare parts logistics |

| Certification | Pre-delivery certification by client-specified classification society | Post-repair recertification with society surveyors |

Star Marine’s commitment extends beyond equipment supply. We provide comprehensive crew training on OWS operation and maintenance, digital logbook integration for discharge reporting, and lifecycle support through our global partner network. This holistic methodology ensures vessels maintain uninterrupted compliance while optimizing total cost of ownership. For shipyards and fleet operators facing stringent environmental mandates, our solutions deliver operational resilience without compromise. Contact our export team for immediate technical consultation or emergency service coordination.

Packaging & Logistics

Packaging & Logistics for Oily Water Separator Exports

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all marine oily water separators are packaged to meet international shipping standards, safeguarding product integrity during export. Our packaging protocols are designed to comply with global regulatory requirements, particularly ISPM 15 for wooden materials, and to withstand the rigors of maritime and overland transportation. Given that our primary export hubs are the ports of Ningbo and Shanghai—two of the busiest and most efficient container ports in the world—we coordinate packaging and logistics to optimize transit time and cost-efficiency.

All wooden packaging materials, including crates and cases used for oily water separator units, are constructed from fumigated and heat-treated timber in strict compliance with ISPM 15 regulations. This international standard, enforced by the International Plant Protection Convention (IPPC), prevents the spread of wood-borne pests across borders. Each wooden case is clearly stamped with the official IPPC mark, indicating compliance with phytosanitary requirements. These cases are engineered to provide structural support, shock absorption, and protection against moisture, ensuring that sensitive components such as control panels, pumps, and coalescer modules remain secure throughout transit.

For heavier models or containerized shipments, steel pallets are employed to enhance load stability and facilitate mechanical handling. Steel pallets offer superior durability compared to wood, particularly in high-humidity environments or long sea voyages. They are welded to exacting standards to support the full operational weight of the oily water separator, including ancillary piping and control cabinets. All steel surfaces are treated with anti-corrosion coatings to prevent rust during ocean transport.

Our logistics team coordinates directly with freight forwarders and shipping lines to ensure timely delivery from Ningbo or Shanghai ports. Both ports offer direct services to major global destinations, including Europe, the Middle East, Southeast Asia, and the Americas, with regular vessel schedules and advanced container tracking systems. We provide comprehensive shipping documentation, including packing lists, certificates of origin, and compliance certifications, to streamline customs clearance in the destination country.

The following table outlines the standard packaging configurations based on oily water separator model and shipping method:

| Model Type | Packaging Method | Dimensions (L×W×H) | Weight (kg) | Compliance Standard |

|---|---|---|---|---|

| Compact (1–5 m³/h) | ISPM 15 Wooden Case | 1800×1000×1600 mm | 450 | IPPC Certified |

| Standard (5–20 m³/h) | ISPM 15 Crate + Steel Base | 2500×1200×2000 mm | 980 | IPPC & ISO 9001 |

| Large (20–50 m³/h) | Steel Pallet + Bracing | 3500×1800×2500 mm | 2200 | Marine-Grade Coating |

All packaging is subject to internal quality inspection prior to dispatch, ensuring alignment with both customer specifications and international best practices in marine equipment logistics.

Contact Star Marine

Contact Star Marine for Expert Oily Water Separator Solutions

Hangzhou Star Marine Technology Co., Ltd. stands at the forefront of marine pollution prevention technology, delivering robust and compliant Oily Water Separator (OWS) systems essential for modern vessel operations worldwide. As global environmental regulations, particularly MARPOL Annex I and its stringent discharge standards, continue to evolve, selecting a reliable and technically proficient OWS supplier is not merely a procurement decision—it is a critical operational and compliance imperative. Our engineering team, with deep expertise in maritime fluid dynamics and separation science, designs systems that consistently achieve discharge concentrations well below the 15 ppm threshold, ensuring your vessel remains audit-ready and avoids costly port state control detentions or environmental penalties. We understand the operational pressures faced by shipowners and operators; our systems prioritize durability in harsh marine environments, minimal maintenance requirements, and seamless integration with existing vessel machinery control systems, directly contributing to reduced downtime and lifecycle costs.

Navigating the complexities of international OWS procurement requires a partner who combines certified manufacturing capability with comprehensive export proficiency. Star Marine holds all requisite international certifications, including IMO MEPC.107(49) type approval, and adheres strictly to ISO 9001 quality management standards throughout our production process. Our export department possesses extensive experience managing global shipments, ensuring smooth customs clearance, accurate documentation compliant with destination country requirements, and adherence to Incoterms® 2020. We provide complete technical support packages, including detailed installation manuals, operation and maintenance guides in multiple languages, and access to our global network of authorized service engineers for commissioning and critical support. Partnering with Star Marine means gaining a single point of accountability for the entire supply chain, from factory acceptance testing to final delivery at your shipyard or vessel location.

For tailored solutions addressing your specific vessel type, operational profile, or regulatory jurisdiction, direct engagement with our product management team is essential. Standard specifications provide a baseline, but optimal OWS performance is achieved through precise configuration. The table below outlines the core technical parameters of our flagship OWS series, demonstrating our commitment to exceeding baseline requirements:

| Parameter | Technical Specification | Compliance Standard |

|---|---|---|

| Maximum Treatment Capacity | 0.5 m³/h to 5.0 m³/h | IMO MEPC.107(49) |

| Discharge Standard | ≤ 5 ppm (Typical Operational) | MARPOL Annex I Reg 14 |

| Primary Separation Stage | Gravity + Coalescer Technology | IMO Resolution MEPC.60(33) |

| Secondary Polishing | Advanced Membrane Filtration | MEPC.107(49) Verified |

| Control System | PLC with Touchscreen HMI, Alarm Logging | IEC 60945 |

| Material of Construction | Marine-Grade SS316L, Duplex SS | DNVGL-SE-0153 |

| Certifications | IMO Type Approval, DNV, LR, ABS, CCS | Global Class Society认可 |

To initiate a technical consultation, request detailed quotation documentation, or discuss customization for newbuild or retrofit projects, contact our dedicated Product Manager for Pollution Prevention Equipment immediately. Kacher YE possesses in-depth knowledge of global market requirements and technical specifications for OWS systems across diverse vessel segments, from offshore support vessels to large commercial fleets. Provide your vessel particulars, operational requirements, and target delivery timeline to receive a precise technical proposal and commercial offer. Do not compromise on the critical component safeguarding your vessel’s environmental compliance and operational continuity. Reach out today to leverage Star Marine’s engineering excellence and export management proficiency.

Contact Product Manager Kacher YE directly at [email protected] for authoritative technical guidance and seamless export execution. Allow us to streamline your OWS procurement process and deliver a solution engineered for unwavering performance and regulatory adherence.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160