Marine Butterfly Valve – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Butterfly Valve

Marine Butterfly Valve: Critical Safety Component and Strategic Sourcing Advantage

Marine butterfly valves represent a fundamental safety component within modern vessel engineering, directly impacting operational integrity and crew protection. These valves serve as primary flow control devices across critical systems including ballast water management, firefighting networks, seawater cooling circuits, and bilge transfer lines. Their rapid quarter-turn operation enables swift isolation of fluid pathways during emergencies such as hull breaches or fire outbreaks, directly supporting compliance with SOLAS (Safety of Life at Sea) regulations and classification society rules (ABS, DNV, LR, etc.). A single valve failure in a ballast system could lead to catastrophic stability loss, while compromised firefighting valve performance may impede critical response efforts. Consequently, the reliability, pressure integrity, and corrosion resistance of marine butterfly valves are non-negotiable factors in vessel design and operation. Global shipyards and fleet operators increasingly prioritize valves manufactured to stringent ISO 5208 (leakage), API 609 (design), and EN 593 (performance) standards to mitigate systemic risks.

Sourcing high-performance marine butterfly valves from Hangzhou Star Marine Technology offers significant strategic and economic advantages without compromising safety. Our manufacturing facility in Hangzhou operates under a certified ISO 9001:2015 quality management system, with every valve undergoing 100% shell pressure testing per MSS SP-61 and seat leakage verification per API 598. Unlike generic industrial valve suppliers, Star Marine specializes exclusively in marine-grade components. We utilize ASTM A351 CF8M (SS316) and duplex stainless steel castings resistant to seawater corrosion, precision-machined sealing surfaces, and elastomer seats (EPDM, NBR, FKM) validated for marine environmental exposure. This focus ensures valves meet the demanding cycle life requirements of marine applications—typically 5,000+ cycles—where inferior alternatives often fail prematurely, triggering costly unscheduled dry-dock repairs.

The cost-effectiveness of partnering with Star Marine extends beyond initial procurement pricing. Our vertically integrated production process—from raw material sourcing to final testing—eliminates intermediary markups while maintaining rigorous quality control. The table below demonstrates key differentiators against standard offshore-spec valves:

| Parameter | Star Marine Standard Valve | Generic Offshore Valve | Impact on Vessel Operations |

|---|---|---|---|

| Body Material | ASTM A351 CF8M (SS316) | Cast Iron / Low-Grade SS | Eliminates seawater corrosion failures |

| Pressure Rating (PN) | PN16 / Class 150 | PN10 / Class 125 | Ensures safety margin in high-flow systems |

| Seat Leakage Test | API 598 Class VI | Class III-IV | Prevents system contamination & downtime |

| Certifications | DNV GL, CCS, ISO 5208 Cat 3 | Basic CE Mark | Guarantees regulatory acceptance |

| Lifecycle Cost (10-year) | 30% Lower | Baseline | Reduces dry-dock frequency & labor costs |

This technical superiority translates to demonstrable total cost of ownership reduction. Star Marine valves minimize through-life maintenance expenses by preventing leaks, avoiding system contamination, and eliminating premature replacement cycles. Our direct export model—including comprehensive technical documentation, MTCs (Material Test Certificates), and classification society survey coordination—streamlines procurement for international shipyards and owners. By selecting Hangzhou Star Marine Technology, operators secure valves that actively enhance vessel safety while optimizing capital expenditure. We invite technical teams to review our full product specifications and certification portfolio for integration into critical marine systems.

Technical Specs & Approval

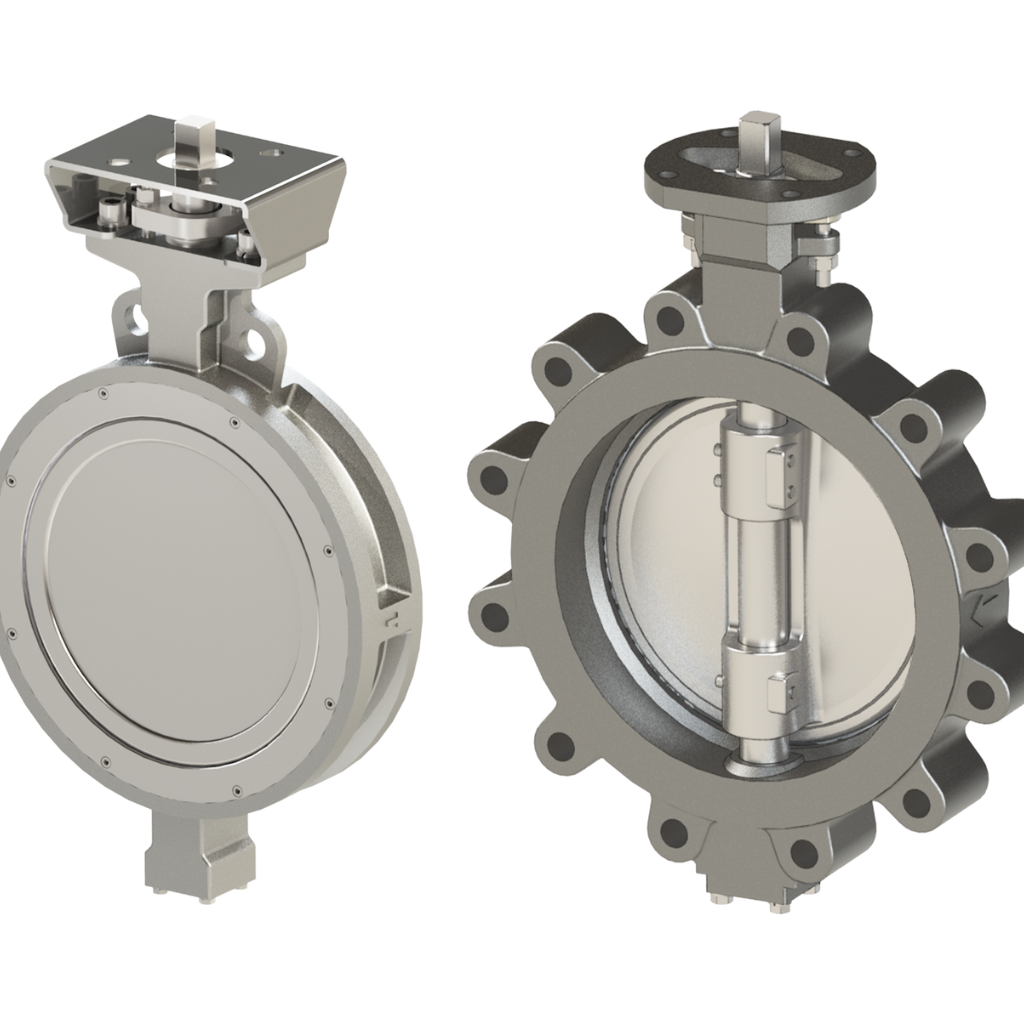

Hangzhou Star Marine Technology Co., Ltd. offers high-performance marine butterfly valves designed for reliable operation in demanding maritime environments. These valves are engineered to control the flow of seawater, freshwater, fuel, lubricating oil, and other non-corrosive fluids within shipboard piping systems. Constructed with durability and efficiency in mind, our marine butterfly valves provide excellent sealing performance, low operating torque, and long service life under continuous exposure to harsh marine conditions.

The core construction materials include bronze and cast steel, selected based on application requirements and system pressure. Bronze-bodied butterfly valves are ideal for low to medium pressure systems where corrosion resistance is critical, particularly in seawater cooling and freshwater distribution lines. These valves exhibit excellent resistance to biofouling and galvanic corrosion, ensuring stable performance over extended operational cycles. Cast steel variants are designed for higher pressure and temperature applications, commonly used in ballast, bilge, and firefighting systems. The robust casting process ensures structural integrity, while precision machining guarantees tight shut-off capabilities.

Our marine butterfly valves are available in pressure ratings from PN6 to PN40, accommodating a wide range of system demands. The PN6 and PN10 valves are typically deployed in low-pressure utility lines, whereas PN16 and PN25 models serve general-purpose applications such as cooling water and drainage systems. High-pressure variants rated at PN40 are suitable for critical systems requiring enhanced safety margins and mechanical strength. Each valve undergoes rigorous hydrostatic and pneumatic testing to verify pressure containment and sealing performance prior to shipment.

Compliance with international standards is a cornerstone of our product development. The valves are manufactured in accordance with JIS and DIN specifications, ensuring global interchangeability and acceptance across shipyards and classification societies. Design conformity to JIS F 4410 and DIN 3202 enables seamless integration into both Japanese and European vessel designs. Additionally, all valves can be supplied with certification from recognized marine classification bodies such as CCS, ABS, DNV, LR, and BV upon request.

The following table outlines the key technical parameters of our marine butterfly valve series:

| Parameter | Bronze Body Valves | Cast Steel Body Valves |

|---|---|---|

| Body Material | ASTM B62 Bronze | ASTM A216 WCB Cast Steel |

| Disc Material | Bronze or SS316 | SS316 or Duplex Stainless |

| Seat Material | EPDM or NBR | EPDM, NBR, or PTFE |

| Pressure Rating | PN6 – PN16 | PN10 – PN40 |

| Temperature Range | -20°C to +120°C | -20°C to +200°C |

| End Connection | Flanged (JIS 10K/20K, DIN) | Flanged (DIN PN10–PN40) |

| Operating Mechanism | Lever or Gear Operated | Gear Operated |

| Applicable Standards | JIS F 4410, DIN 3202 | JIS F 4410, DIN 3202 |

| Testing Standard | GB/T 13927 / ISO 5208 | GB/T 13927 / ISO 5208 |

All valves are designed for minimal maintenance, with replaceable seats and stem seals to extend service life. The compact design allows for space-saving installation in confined engine room areas. Hangzhou Star Marine Technology ensures consistent quality through ISO 9001-certified manufacturing processes and full traceability of materials.

Shipbuilding Solutions

Hangzhou Star Marine Technology: Complete Marine Butterfly Valve Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine butterfly valve solutions essential for efficient shipbuilding and critical repair operations worldwide. As a specialized marine equipment manufacturer and exporter, we understand the demanding operational environments and stringent regulatory requirements governing vessel systems. Our focus is on providing shipyards and repair facilities with a seamless, end-to-end supply chain for high-integrity butterfly valves, ensuring project timelines are met without compromising on safety or performance. We address the core need for reliability in vital systems such as ballast water management, seawater cooling, firemain, bilge, and ventilation, where valve failure carries significant operational and safety risks.

Our comprehensive solution begins with deep technical collaboration during the design phase for newbuilds, ensuring valve specifications align precisely with system requirements and class society rules. For urgent repair scenarios, our global inventory network and dedicated export logistics team enable rapid response, minimizing vessel downtime – a critical factor in the competitive repair market. We maintain significant stock of standard and commonly requested configurations, supported by a streamlined valve exchange program for immediate replacements during dry-docking.

Technical excellence underpins our offering. All Star Marine butterfly valves are manufactured to exacting marine standards, utilizing corrosion-resistant materials suitable for prolonged seawater exposure and rigorous duty cycles. Key specifications for our standard marine-grade butterfly valve series are detailed below:

| Parameter | Specification |

|---|---|

| Size Range | DN50 – DN1200 (2″ – 48″) |

| Pressure Class | PN10, PN16, Class 150 |

| Body Material | Ductile Iron (EN-GJS-500-7), CF8M (316SS), Duplex |

| Disc Material | CF8M (316SS), Duplex, Super Duplex |

| Seat Material | EPDM, NBR, FKM, PTFE Lined |

| End Connection | Lug, Wafer, Double Flanged |

| Certifications | DNV, ABS, LR, BV, CCS, RINA, ISO 9001, ISO 14001 |

Beyond supply, Star Marine provides full export documentation support, including Material Test Reports (MTRs), Certificates of Conformance (CoC), and class society certification paperwork, ensuring smooth customs clearance globally. Our experienced export management team proactively handles complex international shipping requirements, mitigating delays often encountered with marine equipment procurement. For shipyards managing tight newbuild schedules or repair facilities facing urgent valve failures, this integrated approach – combining technical expertise, robust inventory, rapid logistics, and uncomplicated export compliance – delivers the operational certainty required. Partner with Hangzhou Star Marine Technology for responsive, certified butterfly valve solutions that keep your projects and vessels moving forward. Contact our Export Department for immediate technical consultation and quotation support.

Packaging & Logistics

Packaging & Logistics for Marine Butterfly Valves

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all marine butterfly valves are packaged and prepared for international shipment in strict compliance with global maritime and export standards. Our packaging protocols are specifically engineered to protect equipment integrity during long-distance transportation, particularly under the demanding conditions associated with maritime logistics. Each valve undergoes a systematic packaging process designed to prevent mechanical damage, corrosion, and contamination throughout the supply chain.

All marine butterfly valves are securely packed in fumigation-free wooden cases that comply with ISPM 15 (International Standards for Phytosanitary Measures No. 15). These wooden crates are constructed from kiln-dried solid wood, treated to eliminate pests and pathogens, and officially stamped with the ISPM 15 certification mark. This ensures unrestricted entry into all major international markets, including the United States, European Union, Australia, and Japan. The internal structure of the wooden cases includes shock-absorbing corner protectors and cushioning materials such as foam inserts or anti-corrosion paper to safeguard flange surfaces, stem mechanisms, and actuator components.

For heavier-duty butterfly valves, particularly those exceeding 50 kg or with large diameters (DN300 and above), we utilize reinforced steel pallets in conjunction with wooden skids. Steel pallets provide superior load-bearing capacity and resistance to deformation during containerized shipping and port handling. They are powder-coated to resist rust and fitted with lifting points compatible with forklifts and crane slings. All palletized shipments are stretch-wrapped and secured with steel strapping to prevent shifting during transit.

Each package is clearly labeled with essential shipping information, including product identification, weight, handling instructions (e.g., “Fragile,” “Do Not Invert”), and orientation arrows. We also affix barcode labels for inventory tracking and customs documentation. Internal packaging includes desiccant packs to control humidity and vapor corrosion inhibitors (VCI) where applicable, especially for valves with internal brass or stainless steel components.

Our primary export hubs are the major seaports of Ningbo and Shanghai, both among the busiest and most efficient container ports in the world. These locations offer direct access to key global shipping lanes, ensuring timely and cost-effective delivery to destinations across Europe, the Americas, Southeast Asia, and the Middle East. All logistics operations are coordinated with certified freight forwarders experienced in marine equipment shipments, ensuring compliance with INCOTERMS, customs clearance, and marine insurance protocols.

The following table summarizes our standard packaging configurations based on valve size and weight:

| Valve Size (DN) | Weight Range (kg) | Packaging Type | Pallet Type | Compliance Standard |

|---|---|---|---|---|

| DN50 – DN200 | < 50 | ISPM 15 Wooden Case | Wooden Skid | ISPM 15, ISO 1496 |

| DN250 – DN350 | 50 – 150 | Reinforced Wooden Crate | Steel Pallet | ISPM 15, IEC 60068 |

| DN400 and above | > 150 | Heavy-Duty Crate with Frame | Steel Pallet + Skid | ISPM 15, MIL-STD-810 |

All shipments are scheduled and monitored through integrated logistics software to ensure on-time departure and real-time traceability. At Hangzhou Star Marine Technology, we recognize that proper packaging and seamless logistics are critical to customer satisfaction and project success in the marine industry.

Contact Star Marine

Contact Star Marine for Expert Marine Butterfly Valve Solutions

Hangzhou Star Marine Technology Co., Ltd. stands at the forefront of marine valve engineering, delivering SOLAS-compliant butterfly valves engineered for the harshest maritime environments. As your dedicated Export Manager and Marine Equipment Engineer, I emphasize that selecting the right valve partner transcends product specifications—it demands technical collaboration, regulatory assurance, and responsive global support. Our marine butterfly valves undergo rigorous testing per ISO 5208 (leakage), ISO 5752 (face-to-face dimensions), and DNV-GL Type Approval protocols, ensuring seamless integration into ballast, cooling, and firefighting systems across tankers, container vessels, and offshore platforms. When project timelines tighten or technical complexities arise, direct engagement with our product specialists becomes critical to mitigate risks and optimize system performance.

Do not navigate procurement challenges alone. Kacher YE, our Product Manager for Marine Valves, possesses 12 years of field experience in valve dynamics and international certification frameworks. He will guide you through material selection (e.g., ASTM A395 ductile iron for seawater resistance, super duplex for corrosive media), pressure class validation (PN10–PN40), and dimensional compliance with ISO 5211 actuator interfaces. Whether you require FEA stress analysis for high-torque applications or documentation for flag state approvals, his team provides actionable technical documentation within 24 hours—a commitment formalized in our export service level agreement. This responsiveness prevents costly delays during classification society surveys or sea trials.

The following table outlines our structured support pathway for international clients:

| Service Tier | Response Time | Scope of Support | Documentation Provided |

|---|---|---|---|

| Initial Technical Query | ≤ 4 business hours | Valve selection, material compatibility, pressure rating validation | Material certificates, dimensional drawings |

| Project-Specific Customization | ≤ 24 business hours | Actuator integration, non-standard flange adaptations | 3D models, FEA reports, DNV-GL compliance matrix |

| Urgent Operational Support | ≤ 2 business hours | Failure analysis, emergency replacement logistics | Root cause reports, expedited shipping manifests |

Initiate a technical dialogue today to secure valves that meet ABS, LR, and CCS requirements without compromising delivery schedules. Email Kacher YE directly at [email protected] with your vessel specifications, system pressure parameters, and target installation timeline. Include any classification society notes or port state control observations to accelerate our solution mapping. For time-sensitive tenders, reference your project ID in the subject line to trigger our priority export desk protocol.

Star Marine’s export division operates from Hangzhou with regional hubs in Rotterdam and Singapore, ensuring localized support for documentation, customs clearance, and after-sales service across 60+ maritime nations. We recognize that valve failure at sea carries operational and safety ramifications; thus, every inquiry receives engineered accountability—not transactional responses. Trust our ISO 9001:2015-certified processes to deliver valves that exceed IACS Unified Requirements for piping systems. Contact Kacher YE now to transform your procurement challenge into a certified, on-schedule installation. Your vessel’s integrity demands nothing less.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160