Marine Windlass – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Windlass

Marine Windlass: A Critical Component for Vessel Safety and Operational Efficiency

In the maritime industry, the marine windlass stands as a fundamental piece of deck machinery, directly influencing vessel safety, anchoring reliability, and overall operational efficiency. As vessels of all sizes—from commercial freighters to offshore support vessels and luxury yachts—depend on secure anchoring in dynamic marine environments, the windlass plays a pivotal role in deploying and retrieving anchor systems under high-load conditions. Its performance directly affects crew safety, vessel positioning, and the integrity of onboard anchoring equipment. A failure in windlass operation during adverse weather or in congested waters can lead to dangerous drifting scenarios, potential collisions, or grounding incidents, underscoring its critical importance in marine safety protocols.

The marine windlass must endure harsh saltwater environments, mechanical stress, and continuous cyclic loading. As such, it is engineered to meet stringent international standards, including those set by classification societies such as ABS, DNV, LR, and CCS. High tensile chain compatibility, efficient brake systems, robust gearboxes, and corrosion-resistant materials are essential design features. Modern windlasses also integrate hydraulic or electric drive systems that ensure smooth, controlled operation while minimizing maintenance requirements and maximizing service life.

Hangzhou Star Marine Technology Co., Ltd. specializes in the design and export of high-performance marine windlasses tailored to global market demands. With a focus on engineering excellence and compliance with international maritime regulations, Star Marine delivers reliable, durable, and efficient deck machinery solutions. Our windlasses are manufactured using precision machining techniques and undergo rigorous quality control testing, including load testing, salt spray resistance, and operational endurance checks, ensuring they meet the highest standards of safety and durability.

Sourcing marine windlasses from Star Marine Technology offers significant cost advantages without compromising on quality. China’s advanced manufacturing infrastructure, combined with our vertically integrated production processes, allows us to deliver competitively priced solutions. We maintain strict control over raw material sourcing, production timelines, and logistics, reducing overhead costs typically associated with intermediaries. This enables us to offer export clients high-value products with shorter lead times and flexible customization options.

The following table outlines key performance and economic advantages of Star Marine windlasses compared to industry averages:

| Feature | Star Marine Windlass | Industry Average |

|---|---|---|

| Material Quality | High-grade marine steel, electro-galvanized or stainless finishes | Standard carbon steel with basic coating |

| Brake Safety Factor | ≥3.5 | ≥2.5 |

| Compliance Standards | ABS, DNV, LR, CCS, ISO 9001 | Varies by supplier |

| Average Lead Time (Export) | 4–6 weeks | 8–12 weeks |

| Cost Efficiency (vs. EU/US) | 20–30% lower | Baseline |

| Customization Availability | Full (voltage, drive type, control) | Limited |

By combining technical reliability with economic efficiency, Hangzhou Star Marine Technology provides shipbuilders, shipowners, and marine equipment suppliers with a strategic advantage in global markets. Our commitment to safety, performance, and value makes Star Marine a trusted partner in marine deck machinery solutions.

Technical Specs & Approval

Marine Windlass Technical Specifications Guide

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures marine windlasses to stringent international maritime standards, ensuring reliability and safety for global vessel operations. Our deck machinery solutions undergo rigorous testing per ISO 3911 and DNV-ST-N001 requirements, with all models certified for SOLAS compliance where applicable. Critical technical parameters are engineered to match vessel size, operational profile, and environmental conditions, with particular emphasis on pull load capacity, chain compatibility, and drive system efficiency.

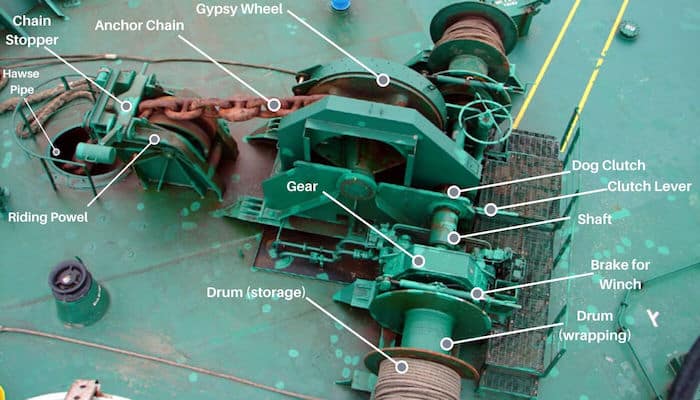

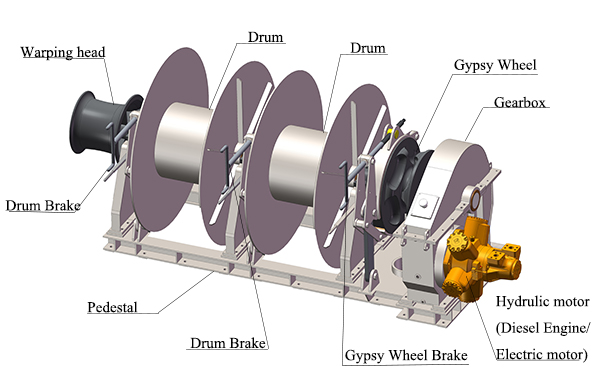

Pull load (kN) represents the maximum continuous hauling force the windlass can exert on the anchor chain, directly correlating to vessel displacement and sea state requirements. Our windlasses are rated for working loads ranging from 25 kN for small craft to 1,200 kN for large commercial vessels, incorporating a minimum 4.5:1 safety factor against breaking strength. Chain diameter compatibility spans 12.5 mm to 60 mm, accommodating Grade 2 and Grade 3 anchor chain per ISO 1704 standards. Precise gypsy wheel geometry ensures optimal chain engagement, minimizing wear and preventing derailment during heaving or veering operations. Drive systems are available in electric or hydraulic configurations, each optimized for specific power availability and duty cycles. Electric models utilize IP56-rated marine-duty motors with thermal overload protection, while hydraulic variants integrate with vessel hydraulic systems for high-torque, low-maintenance performance in demanding environments. All units feature fail-safe mechanical brakes meeting ISO 13779 braking torque requirements.

The following table details representative specifications across our standard product series:

| Model Series | Pull Load Range (kN) | Chain Diameter (mm) | Drive Type | Key Applications |

|---|---|---|---|---|

| STAR-WL-25 | 25–45 | 12.5–16 | Electric | Yachts, Small Commercial Vessels |

| STAR-WL-100 | 80–120 | 19–22.5 | Electric | Coastal Tugs, Fishing Vessels |

| STAR-WH-300 | 250–350 | 28–32 | Hydraulic | Offshore Support Vessels |

| STAR-WH-600 | 500–650 | 42–46 | Hydraulic | Medium Cargo Ships, Ro-Ro Vessels |

| STAR-WH-1200 | 1,000–1,200 | 52–60 | Hydraulic | Large Tankers, Container Ships |

Operational considerations include gypsy wheel material (stainless steel or hardened alloy), rope drum options for mixed anchor-rode systems, and integration with deck wash systems for chain cleaning. Environmental resilience is achieved through epoxy-polyamide coatings (min. 300μm DFT) and corrosion-resistant components suitable for tropical, arctic, and saline conditions. Electrical systems comply with IEC 60092-301, while hydraulic units adhere to ISO 4413 pressure integrity standards. All windlasses undergo factory acceptance testing at 1.5x working load to verify structural integrity and dynamic performance.

Hangzhou Star Marine Technology provides comprehensive technical documentation, including 3D CAD models, load curve analysis, and installation manuals aligned with ABS, LR, and CCS guidelines. Our engineering team collaborates with shipyards to ensure seamless integration with deck layouts, power systems, and control interfaces. For custom specifications exceeding standard parameters, we offer tailored design validation through FEA stress analysis and prototype sea trials. This commitment to precision engineering ensures optimal anchor handling performance across global maritime operations.

Shipbuilding Solutions

Comprehensive Windlass Solutions for Shipbuilding and Repair by Hangzhou Star Marine Technology

Hangzhou Star Marine Technology Co., Ltd. delivers integrated marine windlass systems engineered to meet the rigorous demands of modern shipbuilding and repair operations. As a specialized provider of deck machinery, we focus on delivering reliable, high-performance windlass solutions tailored to vessel specifications, operational profiles, and classification society requirements. Our expertise spans new vessel construction and retrofit or replacement projects in ship repair, ensuring seamless integration, regulatory compliance, and long-term operational efficiency.

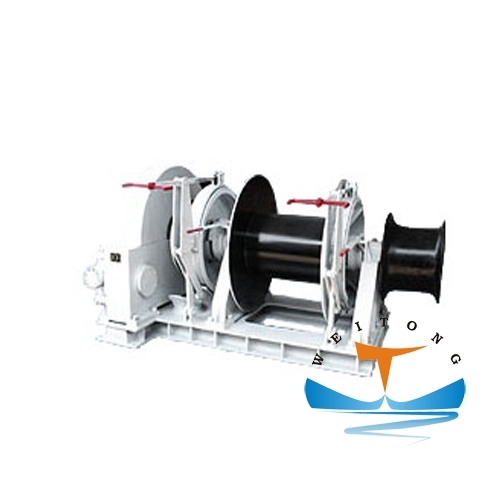

For new builds, Star Marine collaborates closely with shipyards and naval architects from the design phase through installation and commissioning. We offer full technical support, including load calculations, chain locker integration, deck reinforcement recommendations, and alignment with international standards such as ISO 3912, DNV, ABS, and CCS. Our windlasses are available in electric, electro-hydraulic, and hydraulic drive configurations, with customizable warping head arrangements, chain wheel sizes, and control systems. This ensures compatibility with a wide range of vessel types, including container carriers, offshore support vessels, fishing trawlers, and yachts.

In ship repair and retrofit scenarios, rapid response and precision are critical. Star Marine maintains an agile production and logistics network, enabling fast turnaround times for both standard and custom windlass units. Our engineering team conducts on-site assessments when required, facilitating accurate measurement, foundation evaluation, and compatibility checks with existing anchor handling systems. We also provide retrofit kits, chain stopper upgrades, and remote monitoring integration to modernize aging deck machinery fleets without full system replacement.

All Star Marine windlasses are manufactured using marine-grade materials, including spheroidal graphite iron chain wheels and corrosion-resistant housing, ensuring durability in harsh maritime environments. Our systems undergo rigorous factory acceptance testing, including dynamic load testing and endurance cycles, to validate performance prior to shipment.

To support global clients, we offer multilingual technical documentation, on-demand engineering consultation, and after-sales service coordination through our international partners.

The following table outlines key windlass models and their technical specifications:

| Model | Drive Type | Chain Size (mm) | Holding Load (kN) | Classification | Application |

|---|---|---|---|---|---|

| SM-WL-15 | Electro-hydraulic | 20–28 | 150 | DNV-GL, ABS, CCS | Coastal Vessels |

| SM-WL-30 | Hydraulic | 28–34 | 300 | LR, BV, NK | Offshore Supply |

| SM-WL-50 | Electric | 34–42 | 500 | ABS, DNV, RINA | Medium Cargo Ships |

| SM-WL-80 | Electro-hydraulic | 42–52 | 800 | All Major Classes | Large Commercial Vessels |

Hangzhou Star Marine Technology stands as a trusted partner in deck machinery solutions, combining engineering excellence with responsive service to support shipbuilders and repair yards worldwide.

Packaging & Logistics

Packaging & Logistics for Marine Windlass Exports

Hangzhou Star Marine Technology implements rigorously engineered packaging protocols for marine windlass exports, ensuring compliance with international maritime safety standards and preservation of equipment integrity during global transit. As critical deck machinery components subjected to extreme operational loads, windlasses demand packaging solutions that mitigate vibration, moisture ingress, and physical impact throughout multimodal transport cycles. Our standard methodology prioritizes ISPM 15-certified wooden export cases for primary windlass units and control systems, supplemented by reinforced steel pallets for ancillary components.

All wooden packaging materials undergo mandatory heat treatment per ISPM 15 regulations, eliminating pest transmission risks. Cases are constructed from kiln-dried, knot-free plywood with a minimum thickness of 18 mm, internally lined with VCI (Vapor Corrosion Inhibitor) paper to prevent salt-air-induced corrosion. Structural reinforcement includes galvanized steel corner posts and cross-bracing capable of withstanding 1.5 G acceleration forces during vessel motion. Each case incorporates integrated lashing points rated for 5-ton securement and features waterproof seals with desiccant packs to maintain <40% internal humidity. The ISPM 15 treatment stamp, bearing the IPPC logo, country code (CN), unique producer number, and HT (Heat Treated) certification, is visibly branded on all external surfaces.

For hydraulic power units, electrical control panels, and smaller spare parts, we utilize heavy-duty steel pallets with non-slip surfaces and welded perimeter frames. These pallets eliminate wood treatment requirements while providing superior stacking strength and forklift accessibility. All palletized loads are secured via strapping to pallet decks and enclosed in UV-stabilized polyethylene shrink wrap with humidity indicators.

Export shipments originate exclusively from the Port of Ningbo-Zhoushan or Port of Shanghai, leveraging their status as top-tier global hubs with direct liner services to all major maritime regions. Ningbo handles 90% of our containerized cargo due to its specialized heavy-lift berths capable of accommodating 24,000 TEU vessels, while Shanghai serves as a strategic alternative for urgent LCL (Less than Container Load) shipments requiring rapid consolidation. Both ports feature dedicated cold chain corridors and 24/7 customs clearance, minimizing dwell time. Critical documentation—including EUR.1 certificates for EU destinations, phytosanitary certificates for wooden packaging, and SOLAS VGM declarations—is processed electronically via China’s Single Window system to ensure seamless clearance.

The following table details our standard packaging specifications:

| Packaging Type | Construction Details | ISPM 15 Compliance | Typical Application |

|---|---|---|---|

| Wooden Export Case | 18mm plywood, steel corner posts, VCI lining, desiccants | Certified HT stamp | Main windlass unit, chain locker assemblies |

| Steel Pallet System | 25mm steel frame, non-slip deck, shrink-wrapped load | Not applicable | Hydraulic power units, control panels, spare parts kits |

All packaging designs undergo validation through ISTA 3A vibration testing and salt-spray exposure trials to simulate 60-day ocean voyages. This integrated approach ensures windlasses arrive at destination ports—whether Rotterdam, Singapore, or Houston—in operational condition, ready for immediate installation per ABS, DNV, or LR class requirements. We coordinate final-mile logistics through pre-vetted freight forwarders specializing in breakbulk deck machinery handling, guaranteeing adherence to project timelines and minimizing client supply chain risk.

Contact Star Marine

For marine operators, shipbuilders, and offshore project managers seeking reliable, high-performance deck machinery, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted global supplier of marine windlasses engineered to meet the rigorous demands of modern maritime operations. As a specialized manufacturer in the deck machinery category, we design and produce windlasses that deliver superior anchoring performance, durability in harsh marine environments, and compliance with international classification standards including DNV, ABS, CCS, and LR.

Our marine windlasses are built using advanced metallurgical processes, precision machining, and stringent quality control protocols to ensure long service life and minimal maintenance. Whether you require horizontal or vertical windlasses, electric, electro-hydraulic, or hydraulic drive configurations, or models tailored for commercial vessels, offshore support platforms, or luxury yachts, Star Marine provides customized solutions that align with your vessel’s technical and operational requirements.

To ensure seamless integration and optimal performance, our engineering team offers full technical support—from initial specification review and load analysis to installation guidance and after-sales service. We understand that every vessel has unique deck layouts, anchor handling needs, and regulatory requirements. That’s why we prioritize direct engagement with our clients to deliver windlass systems that are not only technically sound but also operationally efficient.

For project-specific inquiries, technical consultations, or product selection guidance, we encourage direct communication with our Product Manager, Kacher YE. With extensive experience in marine deck machinery and export logistics, Kacher serves as the primary technical liaison between our engineering department and international clients. He is well-equipped to assist with product specifications, customization options, certification documentation, and delivery timelines.

Below are key contact and company details to initiate your project discussion:

| Detail | Information |

|---|---|

| Company | Hangzhou Star Marine Technology Co., Ltd. |

| Product Category | Deck Machinery – Marine Windlasses |

| Product Manager | Kacher YE |

| [email protected] | |

| Language Support | English, Chinese, Basic Technical French |

| Lead Time (Standard Units) | 4–8 weeks (custom units vary) |

| Export Experience | Over 50 countries, including EU, Southeast Asia, Middle East, and North America |

| Certifications | ISO 9001:2015, DNV-GL, ABS, CCS, LR, CE |

We invite vessel designers, procurement officers, and marine equipment integrators to contact Kacher YE directly to discuss your windlass requirements. Whether you are retrofitting an existing vessel or specifying equipment for new construction, our team is prepared to support you with technical data sheets, 3D models, and performance calculations tailored to your project.

Partner with Hangzhou Star Marine Technology for engineered reliability, global compliance, and responsive service. Reach out today to ensure your anchoring system meets the highest standards of safety and performance at sea.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160