Self Closing Valve – Marine Solution Guide 2025

Content Navigation

Marine Insight: Self Closing Valve

Marine Industry Demand: Self-Closing Valves for Critical Vessel Safety

Self-closing valves represent a fundamental safety component mandated across modern commercial and naval vessels, directly addressing the paramount maritime concern of uncontrolled flooding and fluid release. These valves, primarily functioning as automatic non-return or emergency shutdown devices, are engineered to close rapidly upon loss of system pressure, pipe rupture, or fire detection, thereby isolating critical compartments and fluid systems. Their operational integrity is non-negotiable under international regulations, particularly SOLAS Chapter II-1, which stipulates stringent requirements for machinery space watertight integrity and fire safety systems. Failure of such valves during casualty scenarios—such as collision, grounding, or onboard fire—can escalate minor incidents into catastrophic losses of vessel or life. Consequently, global shipyards and fleet operators prioritize valves demonstrating proven reliability under extreme conditions, including high-cycle operation, exposure to seawater, fuel, lubricants, and rapid closure response times verified through rigorous hydrostatic and functional testing protocols.

Hangzhou Star Marine Technology delivers self-closing valves engineered explicitly to exceed these demanding maritime safety standards. Our manufacturing process integrates advanced CNC machining with stringent quality control aligned to ISO 9001:2015 and ISO 14001:2015 frameworks, ensuring dimensional precision and material consistency critical for leak-tight performance. Every valve undergoes 100% pressure testing at 1.5x maximum working pressure and functional verification per ISO 5208 leakage class A standards before shipment. This commitment to reliability is validated through type approvals from leading classification societies including DNV, LR, ABS, and CCS, providing global operators with immediate regulatory acceptance and reduced commissioning risk.

The following table outlines key performance specifications of Star Marine’s standard self-closing valve series compared to typical industry requirements:

| Parameter | Star Marine Standard Valve | Typical Industry Requirement | Compliance Advantage |

|---|---|---|---|

| Max Working Pressure | 16 bar | 10 bar | Higher safety margin for surges |

| Closure Time (Full) | ≤ 2 seconds | ≤ 5 seconds | Faster isolation during emergencies |

| Leakage Rate (Class) | ISO 5208 Class A | ISO 5208 Class D | Near-zero leakage critical zones |

| Material Standard | ASTM A216 WCB + NACE MR0175 | ASTM A216 WCB | Sour service compatibility |

| Certifications | DNV-GL, LR, ABS, CCS, CE | Varies by supplier | Global regulatory acceptance |

Sourcing self-closing valves from Hangzhou Star Marine Technology offers significant cost-effectiveness without compromising safety. Our vertically integrated manufacturing facility in Hangzhou leverages China’s robust maritime supply chain for raw materials and precision components, optimizing production costs. This structural advantage, combined with lean manufacturing practices, allows us to deliver valves with comprehensive classification society approvals at 15-25% below comparable European or Korean alternatives. Crucially, our cost efficiency extends beyond initial purchase price: reduced lead times (typically 4-6 weeks versus 12+ weeks for some competitors), minimized certification rework due to upfront regulatory alignment, and exceptional long-term reliability collectively lower the total cost of ownership. For global shipbuilders and operators facing intense cost pressures while navigating complex regulatory landscapes, Star Marine provides a demonstrably safer and more economical solution for this mission-critical safety equipment. Our valves are not merely components; they are engineered assurances of vessel survivability.

Technical Specs & Approval

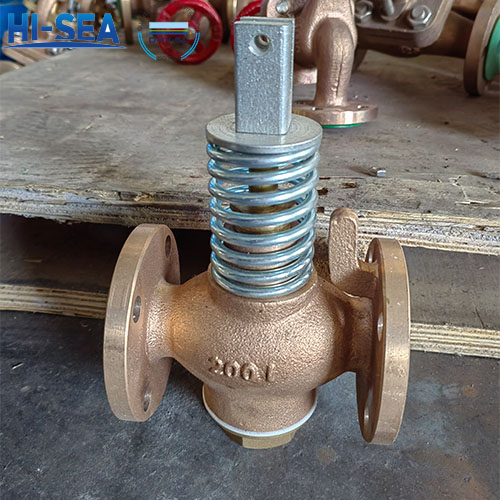

The self closing valve offered by Hangzhou Star Marine Technology Co., Ltd. is engineered to meet the rigorous demands of marine and offshore applications, ensuring reliable performance in critical fluid control systems. Designed for automatic closure upon actuation or failure condition, these valves are essential in bilge, ballast, cooling water, and firefighting systems where uncontrolled flow must be prevented. Constructed from high-grade materials including bronze and cast steel, the valves provide excellent corrosion resistance and mechanical strength, suitable for both seawater and freshwater environments.

Each self closing valve is precision manufactured to comply with international marine standards, including JIS and DIN, ensuring compatibility with global piping systems and certification requirements. The robust design incorporates a spring-assisted closing mechanism that ensures fail-safe operation, minimizing risk during power loss or system malfunction. The valve’s sealing integrity is maintained through the use of resilient EPDM or NBR seals, selected based on fluid compatibility and operating temperature range. All models feature a manual override function, allowing for local operation during maintenance or emergency scenarios.

The operating pressure range spans from PN6 to PN40, accommodating low to medium-high pressure systems commonly found in marine engineering. This wide pressure capability allows integration across various vessel types, from inland waterway craft to deep-sea cargo and passenger vessels. The valves are available in nominal diameters from DN25 to DN300, supporting flexibility in system design and retrofit applications. End connections are provided in flanged configurations as per JIS B2220 or DIN EN 1092-1 standards, ensuring secure and leak-tight installation.

Surface treatment includes epoxy coating or hot-dip galvanization for cast steel variants, enhancing protection against marine atmospheric and submersible conditions. All units undergo rigorous factory testing, including shell hydrostatic testing, seat leakage testing per ISO 5208, and functional cycle testing to guarantee long service life and operational reliability. Third-party certification from recognized classification societies such as CCS, LR, DNV, and ABS can be provided upon request, supporting compliance with SOLAS and other maritime safety regulations.

The following table outlines the key technical parameters of the self closing valve series:

| Parameter | Specification |

|---|---|

| Body Material | Bronze, Cast Steel (WCB) |

| Trim Material | Stainless Steel (SS316) |

| Seal Material | EPDM, NBR (options based on fluid compatibility) |

| Pressure Rating | PN6, PN10, PN16, PN25, PN40 |

| Temperature Range | -20°C to +120°C |

| Nominal Diameter (DN) | DN25 – DN300 |

| Standards Compliance | JIS B2220, DIN EN 1092-1, ISO 5208 |

| Design Type | Spring-return, fail-safe closed |

| Operation Mode | Pneumatic, Electric, or Manual with auto-close |

| End Connection | Flanged (JIS 10K/16K, DIN PN10/PN16/PN40) |

| Testing Standards | Shell Test: 1.5x PN, Seat Test: 1.1x PN, ISO 5208 |

| Coating (Cast Steel) | Epoxy paint or Hot-dip Galvanized |

| Certification Options | CCS, LR, DNV, ABS, BV, KR |

Hangzhou Star Marine Technology ensures all self closing valves are manufactured under ISO 9001-certified quality management systems, guaranteeing consistency, traceability, and performance in demanding marine environments.

Shipbuilding Solutions

Hangzhou Star Marine Technology: Complete Self-Closing Valve Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered self-closing valve solutions critical for vessel safety and operational continuity in both new construction and repair scenarios. Our valves are fundamental components within bilge, ballast, and firefighting systems, mandated by SOLAS for fail-safe operation to prevent uncontrolled flooding. We provide not merely components, but a fully integrated supply chain and technical support service designed to minimize project delays and vessel downtime. Understanding the stringent timelines of shipyards and the urgent nature of repairs, our operational model prioritizes rapid response without compromising on quality or regulatory compliance.

Our self-closing valves feature robust marine-grade bronze or stainless steel construction, engineered to withstand harsh seawater environments and cyclic operation. Key to their reliability is the integrated fail-safe mechanism, ensuring automatic closure upon loss of control signal or power, preventing backflow and maintaining compartment integrity. This critical function aligns precisely with International Maritime Organization (IMO) and classification society requirements for damage control systems. We supply valves with solenoid actuators compatible with standard vessel control voltages, featuring manual override functionality for emergency operation during maintenance or power failure. All products undergo rigorous factory testing per ISO 5208 for leakage class and API 598 for pressure integrity, providing documented assurance of performance before shipment.

Technical specifications for our standard marine self-closing valve offering are detailed below:

| Parameter | Specification Detail |

|---|---|

| Product Name | SMV-SC Series Solenoid Operated Self-Closing Valve |

| Compliance | SOLAS II-1/25, ISO 10434, DNVGL-ST-F101, ABS, LR, NK, CCS |

| Body Material | ASTM B61 Naval Brass or ASTM A351 CF8M Stainless Steel |

| Pressure Rating | PN16 / Class 150 (1.6 MPa / 232 psi) |

| Temperature Range | -20°C to +80°C (-4°F to +176°F) |

| Connection Type | Flanged (PN16 RF / ASME B16.1 Class 125/250) |

| Key Features | Fail-safe closure on signal loss, Manual override lever, IP67 rated solenoid, ISO 5208 Cat B leakage |

For newbuild projects, Hangzhou Star Marine integrates seamlessly with shipyard procurement schedules. We offer bulk order management, coordinated logistics to global shipyards, and dedicated technical liaison engineers to support installation and commissioning, ensuring valves meet the vessel’s specific system requirements. Our extensive inventory of standard sizes (DN25 to DN200) enables shipment within 72 hours of confirmed order, a critical advantage during critical path construction phases. In the repair and conversion sector, speed is paramount. We maintain a global network of authorized service partners and strategically located warehouses holding critical spares. Emergency orders for common self-closing valve models are processed and dispatched within 24 hours, supported by comprehensive technical documentation and remote troubleshooting assistance to expedite vessel return-to-service. This combination of certified product quality, deep maritime application knowledge, and an unwavering commitment to rapid fulfillment establishes Hangzhou Star Marine Technology as a trusted partner in marine safety and operational efficiency. We provide the complete solution, from specification through installation support, ensuring your vessel systems meet the highest safety standards with minimal disruption.

Packaging & Logistics

Packaging & Logistics for Self-Closing Valves – Hangzhou Star Marine Technology Co., Ltd.

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all self-closing valves are packaged to meet international maritime transport standards, safeguarding product integrity during global shipments. Our packaging methodology is designed to comply with stringent export regulations while providing optimal protection against mechanical stress, moisture, and environmental exposure during transit.

All self-closing valves are securely packed in custom-built wooden export cases that conform to ISPM 15 (International Standards for Phytosanitary Measures No. 15). This internationally recognized standard mandates that all wood packaging material used in international trade must be heat-treated and free from pests to prevent the spread of invasive species. Each wooden case is constructed from kiln-dried, solid timber and treated in accordance with ISPM 15 requirements, then clearly marked with the official IPPC (International Plant Protection Convention) stamp for customs verification. The interior of the case is lined with anti-corrosion paper and desiccant packs to prevent moisture ingress, which is critical for preserving the valve’s internal components, especially in high-humidity marine environments.

For larger valve models or bulk orders, we utilize heavy-duty steel pallets designed for secure stacking and compatibility with forklift handling. These pallets are powder-coated for corrosion resistance and fitted with reinforced edges to prevent deformation during loading and unloading. Each valve is firmly fastened to the pallet using industrial-grade straps and protective corner braces to minimize movement during transport. This method ensures stability during containerized shipping, particularly on long-haul ocean freight routes.

Our export operations are coordinated through the major international ports of Ningbo and Shanghai, both of which are among the busiest and most efficient container ports in the world. These strategic locations provide seamless access to global shipping networks, ensuring timely delivery to destinations across Europe, the Americas, Southeast Asia, and the Middle East. All shipments are accompanied by complete export documentation, including commercial invoices, packing lists, certificates of origin, and, when required, marine insurance and phytosanitary certificates.

We work closely with certified freight forwarders experienced in marine equipment logistics to ensure compliance with destination-specific import regulations. Our team manages all aspects of the export process, from inland transportation to final container stuffing and customs clearance at origin, minimizing delays and ensuring full supply chain transparency.

The following table summarizes our standard packaging and logistics specifications for self-closing valves:

| Parameter | Specification |

|---|---|

| Packaging Type | ISPM 15-compliant wooden cases or steel pallets |

| Case Material | Kiln-dried solid wood, heat-treated and stamped |

| Interior Protection | VCI anti-corrosion paper, desiccant packs |

| Pallet Type (if applicable) | Powder-coated steel, reinforced edges |

| Securing Method | Industrial strapping and corner protectors |

| Export Ports | Ningbo Port, Shanghai Port (China) |

| Documentation | Commercial invoice, packing list, CoO, ISPM 15 stamp, freight & insurance (if applicable) |

| Handling | Forklift-ready, stackable, seaworthy for container transport |

Hangzhou Star Marine Technology is committed to delivering marine valves that arrive at their destination in pristine condition, ready for immediate integration into vessel systems.

Contact Star Marine

Why Partner with Star Marine for Self-Closing Valves?

Selecting the correct self-closing valve is a critical decision impacting vessel safety, operational efficiency, and regulatory compliance. These valves are fundamental components within bilge, ballast, and firefighting systems, mandated by SOLAS and classification societies to automatically isolate pipelines upon fire detection or system failure, preventing catastrophic flooding or fire spread. Hangzhou Star Marine Technology Co., Ltd. specializes in the design, rigorous manufacturing, and global export of marine valves engineered specifically to meet and exceed these stringent international maritime requirements. Our self-closing valves undergo comprehensive pressure testing, fire resistance validation per ISO 10497, and material certification processes to ensure absolute reliability in the harshest marine environments. We understand the non-negotiable nature of performance for these safety-critical devices and embed quality control at every stage of production.

Our commitment extends beyond manufacturing to providing comprehensive export support tailored to the complexities of the global maritime supply chain. Star Marine navigates international shipping regulations, customs documentation, and Incoterms 2020 with precision, ensuring your valve procurement integrates seamlessly into your vessel construction or retrofit schedule. We maintain robust inventory of standard configurations while offering engineering flexibility for bespoke requirements, supported by detailed technical documentation compliant with ABS, DNV, LR, BV, and CCS standards. This combination of product integrity and export expertise minimizes project risk and delivery timelines.

Key technical specifications for our standard marine self-closing valve series are detailed below, reflecting our adherence to core industry benchmarks:

| Parameter | Specification Detail |

|---|---|

| Size Range (DN) | 25 to 200 |

| Pressure Class | PN16 / Class 150 (Custom up to PN40 / Class 300) |

| Body Material | ASTM B61 Bronze, ASTM A216 WCB, ASTM A351 CF8M SS |

| Disc/Stem Material | ASTM B148 Aluminum Bronze, ASTM A182 F316 SS |

| Temperature Range | -20°C to +200°C (Fire Safe Design per ISO 10497) |

| Seat Type | Metal-to-Metal (Fire Safe), PTFE (Standard) |

| Operation | Spring-Return Automatic Closure, Manual Override |

| Compliance | SOLAS II-2/4.2.3, ISO 5208 Cat. A, ISO 10497 |

Partnering with Star Marine means securing a supplier deeply embedded in maritime safety protocols. Our valves are not merely components; they are engineered safety barriers validated through independent third-party certification and decades of operational service across global fleets. We proactively engage with shipyards, owners, and classification surveyors to ensure our solutions align perfectly with project specifications and evolving regulatory landscapes.

Initiate Your Technical Consultation Today

For definitive technical validation, customized quotation, or urgent project support regarding Star Marine self-closing valves, direct engagement with our Product Management team is essential. Kacher YE, our dedicated Product Manager for Marine Valves, possesses in-depth expertise on application specifics, certification pathways, and export logistics for global maritime projects. Do not rely on generic inquiries; secure precise technical guidance tailored to your vessel’s requirements. Contact Kacher YE immediately via email at [email protected] to discuss your project scope, review certification documentation, or request a formal quotation. Provide your vessel particulars, required valve specifications, and target delivery timeline to expedite the process. Star Marine stands ready to ensure your self-closing valve solution meets the highest safety standards while integrating efficiently into your supply chain. Your vessel’s safety integrity demands this critical component be sourced without compromise – contact us now to commence the process.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160