Marine Compressor Parts – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Compressor Parts

Critical Role of Marine Compressor Parts in Vessel Safety and Operational Continuity

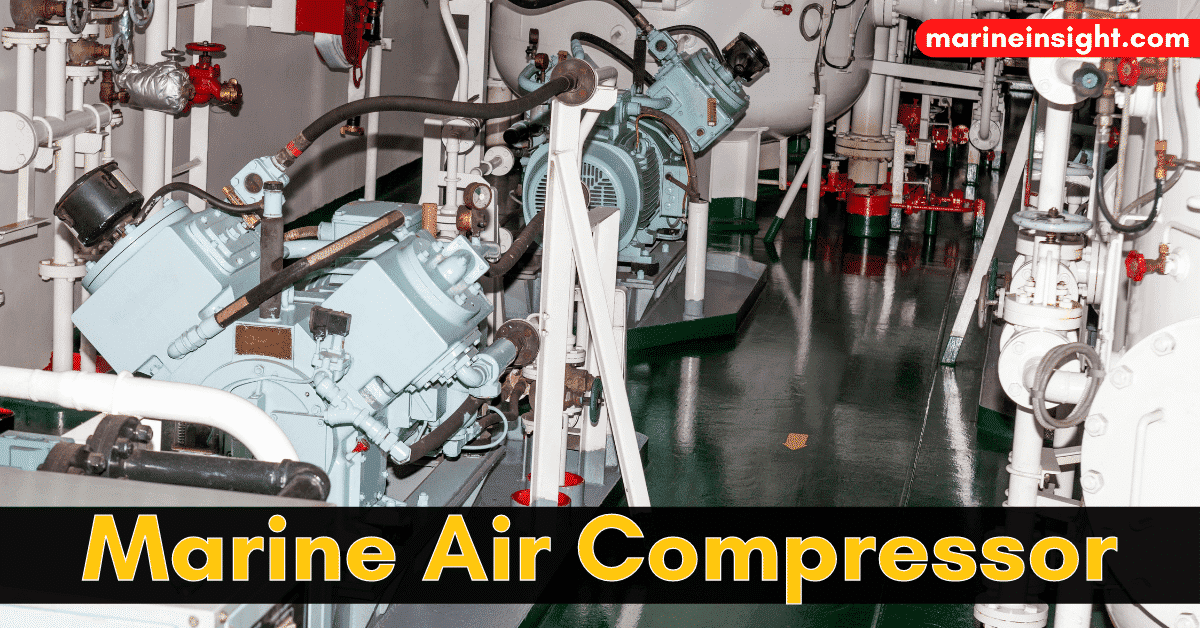

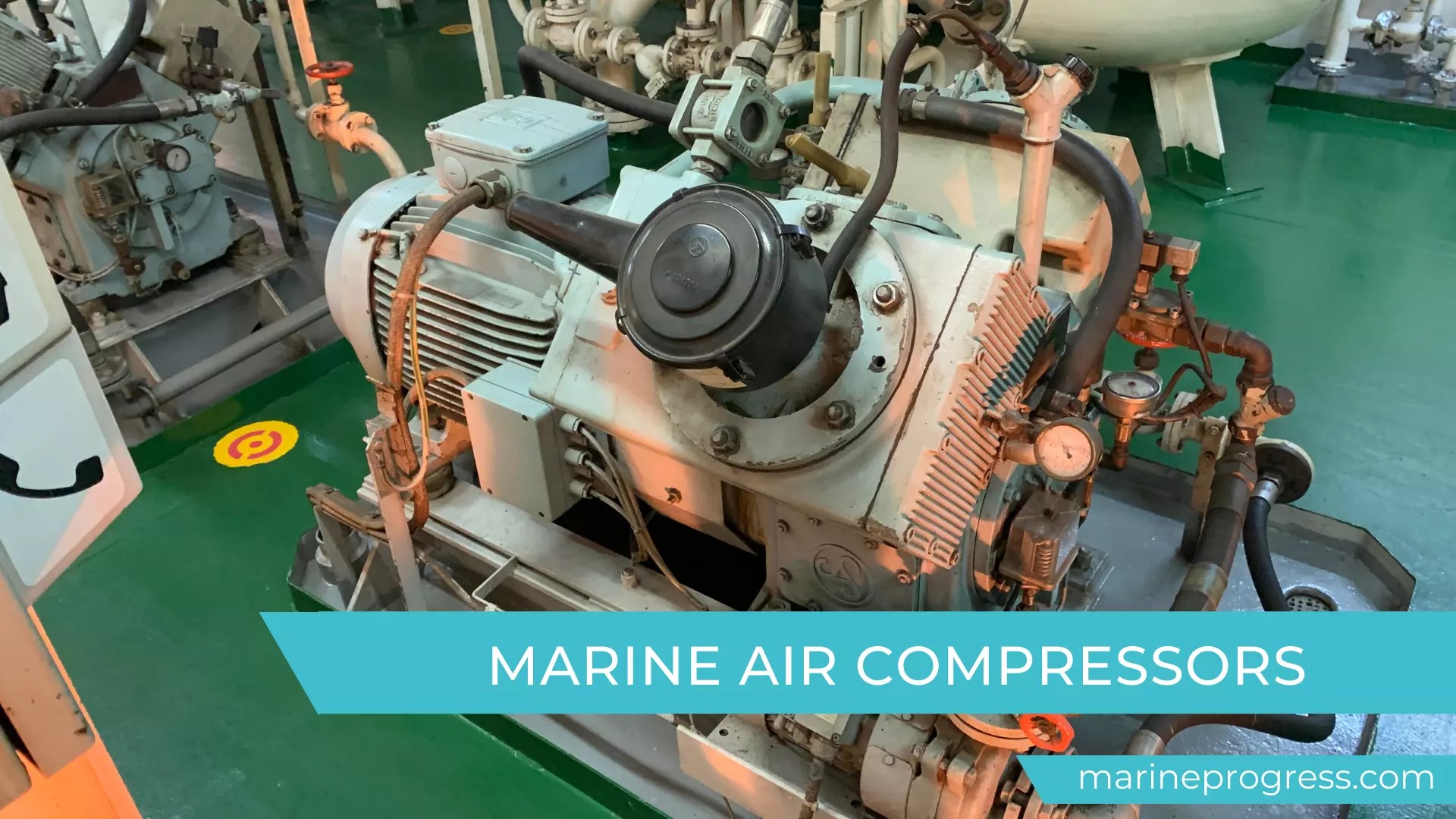

Marine air compressor systems represent mission-critical infrastructure across all vessel types, from commercial freighters to offshore support vessels. The integrity of compressor components—including pistons, valves, cylinder heads, and crankshafts—directly impacts vessel safety and regulatory compliance. Failure of these parts can lead to catastrophic outcomes: loss of main engine start capability, compromised pneumatic control systems for steering or ballast, and inoperable emergency air supplies for lifeboats or firefighting systems. International conventions under SOLAS Chapter II-1 explicitly mandate redundant, reliable compressed air systems for propulsion and essential safety functions. Components must withstand harsh marine environments characterized by continuous vibration, saltwater exposure, and extreme thermal cycling. Substandard or worn parts risk sudden system failure during critical operations, potentially triggering collisions, groundings, or environmental incidents. Consequently, sourcing OEM-specification or certified replacement parts is not merely operational best practice—it is a non-negotiable requirement for maritime safety management systems under ISM Code.

Hangzhou Star Marine Technology delivers engineered solutions that align with this safety imperative while optimizing total lifecycle costs. As an ISO 9001:2015 and ISO 14001 certified manufacturer with ABS, DNV, and CCS Type Approvals, we produce compressor parts meeting stringent IACS UR M requirements. Our integrated production ecosystem in Hangzhou leverages China’s advanced metallurgical and precision machining capabilities without compromising on quality control. Unlike fragmented global supply chains, Star Marine manages end-to-end manufacturing—from raw material forging to dynamic balancing and pressure testing—within a single facility. This vertical integration eliminates third-party quality variances and reduces lead times significantly. Crucially, our cost structure benefits from China’s mature marine industrial cluster, offering 20-30% cost efficiency versus equivalent Western or Korean OEM parts while maintaining identical performance specifications. This value proposition is validated through long-term partnerships with major shipping lines and classification societies who prioritize both safety compliance and operational economics.

The comparative advantages of sourcing through Star Marine are quantifiable across critical parameters:

| Parameter | Star Marine Advantage | Typical Industry Standard |

|---|---|---|

| Cost Efficiency | 20-30% below OEM pricing | Premium OEM pricing |

| Certification Scope | ABS/DNV/GL/CCS Type Approved | Varies by supplier |

| Lead Time | 4-6 weeks for standard parts | 8-12+ weeks |

| Material Quality | Forged steel per ASTM A693/A276 | Often cast alternatives |

| Testing Protocol | 100% hydrostatic & functional testing | Spot-checking common |

For vessel operators, the strategic selection of compressor parts transcends immediate procurement costs. It directly influences unplanned downtime, dry-docking frequency, and ultimately, the vessel’s safety record. Hangzhou Star Marine Technology provides the necessary assurance through rigorously validated components, reducing total cost of ownership while eliminating safety compromises. In an industry where component failure is never an option, our commitment to certified quality and responsive supply chain execution delivers measurable risk mitigation and operational resilience. Partnering with Star Marine ensures your air systems remain a pillar of safety—not a liability.

Technical Specs & Approval

Hangzhou Star Marine Technology Co., Ltd. specializes in the design, manufacturing, and global export of high-performance marine air compressor components, engineered to meet the rigorous demands of maritime operations. Our marine compressor parts are built to deliver reliable, efficient, and safe compressed air across a wide range of vessel types, including cargo ships, offshore support vessels, and naval fleets. These components are critical in supporting main and auxiliary engine starting systems, pneumatic control systems, deck machinery, and safety equipment such as lifeboat davits and emergency alarms.

All marine compressor parts produced by Hangzhou Star Marine Technology are designed and tested in accordance with international marine standards, including ISO 9001, IMO, and classification society rules from CCS, ABS, DNV, LR, and BV. Special attention is given to materials selection, corrosion resistance, and operational safety in harsh marine environments characterized by high humidity, salt spray, and continuous vibration.

A key performance parameter for marine compressor parts is discharge pressure, which directly affects the ability to start large diesel engines and operate high-pressure pneumatic tools. Our components support discharge pressures up to 30 MPa (300 bar), ensuring compatibility with high-pressure air systems used in modern marine propulsion and control applications. Flow rate is another critical factor, with available configurations supporting volumetric flow rates from 0.8 m³/min to 6.5 m³/min at standard conditions, allowing customization based on vessel size and air demand.

Efficient thermal management is achieved through advanced cooling methods, including forced air cooling for smaller units and seawater-cooled or freshwater-cooled heat exchangers for larger, high-output systems. These cooling solutions maintain optimal operating temperatures, prevent overheating, and extend service life. Components are constructed from high-grade stainless steel, brass, and marine-grade aluminum alloys to resist corrosion and ensure long-term reliability.

The following table outlines the technical specifications of our standard marine compressor parts:

| Parameter | Specification Range |

|---|---|

| Discharge Pressure | Up to 30 MPa (300 bar) |

| Flow Rate | 0.8 – 6.5 m³/min (at 1000 rpm) |

| Cooling Method | Forced Air, Freshwater, Seawater |

| Operating Temperature | -20°C to +60°C |

| Ambient Humidity | Up to 95% RH, non-condensing |

| Materials | Stainless Steel, Brass, Marine Aluminum |

| Compliance Standards | ISO 9001, IMO, CCS, ABS, DNV, LR, BV |

| Mounting Configuration | Base-mounted, Skid-mounted options |

| Noise Level | ≤85 dB(A) at 1 meter |

| Protection Rating | IP55 to IP66 (motor and control units) |

These specifications reflect our commitment to engineering excellence and operational safety in marine environments. Hangzhou Star Marine Technology ensures that all compressor components undergo rigorous factory testing, including pressure endurance, leak testing, and performance validation under simulated shipboard conditions. This technical foundation enables seamless integration into existing marine air systems and supports global export with full documentation and certification support.

Shipbuilding Solutions

Complete Marine Compressor Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers integrated support for marine air compressor systems across new vessel construction and critical repair operations. Our engineering expertise ensures seamless integration of OEM and aftermarket parts, minimizing downtime while adhering to stringent SOLAS and classification society standards. We specialize in supplying globally compliant components for reciprocating and screw-type compressors used in main engine starting, pneumatic control, and deck machinery applications.

Our value proposition centers on eliminating project delays through a unified technical and logistical framework. For new builds, we collaborate with shipyards during design phases to validate compressor specifications against operational profiles, ensuring optimal part selection for fuel efficiency and reliability. In repair scenarios, our rapid-response protocol begins with 24/7 technical diagnostics support. Our engineers analyze failure modes via submitted logs or remote video inspections to prescribe precise part replacements, avoiding unnecessary overhauls. This approach reduces troubleshooting time by up to 60% compared to industry averages.

Global parts availability is anchored in our Hangzhou hub, which maintains strategic stock for high-demand components across major compressor brands including SMC, Howden, and Burckhardt Compression. Critical spares are pre-positioned in Rotterdam and Singapore transshipment centers to serve European and Asian shipyards within 72 hours of order confirmation. All parts undergo rigorous in-house testing against ISO 8573 purity standards and carry ABS, DNV, or LR certification documentation.

The following table outlines our core compressor part categories and performance metrics:

| Part Category | Primary Application | Standard Lead Time | Class Certification |

|---|---|---|---|

| Cylinder Liners & Heads | Reciprocating Compressor Overhaul | 48 hours | ABS/DNV/LR |

| Rotary Screw Elements | Oil-flooded Screw Compressors | 72 hours | DNV-GL/ClassNK |

| Unloader Valves | Pressure Regulation Systems | 24 hours | LR/BV |

| Gasket Kits | All Compressor Types | 24 hours | ABS/DNV |

| Control Panels | Automated Start/Stop Sequencing | 5 days | IEC 60945 Certified |

Export execution leverages our in-house logistics team, which manages customs clearance, hazardous material declarations, and multimodal shipping under Incoterms® 2020. We provide digital shipment tracking with real-time ETAs and coordinate directly with shipyard receiving departments to align deliveries with critical path schedules. For emergency repairs, we offer bonded warehouse access at 12 major ports, enabling duty-free part release within 4 hours of vessel arrival.

Star Marine’s end-to-end accountability—from technical validation to customs-cleared delivery—ensures compressor systems meet operational deadlines without compromising maritime safety standards. Contact our export desk for project-specific support backed by 15 years of marine propulsion system expertise.

Packaging & Logistics

Proper packaging and logistics are critical components in the successful export of marine compressor parts, ensuring that sensitive components arrive at their destination in optimal condition. At Hangzhou Star Marine Technology Co., Ltd., we adhere to international maritime shipping standards to protect the integrity of our marine air compressor parts during transit. All shipments are meticulously packed using robust wooden cases that comply with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This internationally recognized regulation mandates that all wood packaging material used in international trade be heat-treated and officially marked to prevent the spread of pests and diseases through wooden packaging. Our ISPM 15-certified wooden crates are constructed from durable, kiln-dried hardwood, offering superior protection against impact, moisture, and environmental fluctuations during sea transport.

In addition to wooden cases, we utilize heavy-duty steel pallets for added structural support, particularly for larger or heavier compressor components such as cylinder heads, crankshafts, and intercoolers. Steel pallets provide exceptional load-bearing capacity and resistance to deformation, making them ideal for multi-tier stacking in containerized shipping. They also eliminate risks associated with wood rot, insect infestation, and moisture absorption—common concerns when shipping through humid maritime environments. Each steel pallet is designed for compatibility with global handling equipment, enabling seamless loading and unloading at ports worldwide.

All packaging configurations are customized based on the dimensions, weight, and fragility of the specific marine compressor part being shipped. Internal cushioning materials such as anti-corrosion paper, foam inserts, and moisture-absorbing desiccants are used to prevent vibration damage and oxidation during long sea voyages. Each component is securely fastened within the case or onto the pallet using industrial-grade strapping and brackets to minimize movement during transit.

Our export operations are coordinated through two of China’s largest and most efficient maritime hubs: Ningbo Port and Shanghai Port. Both ports offer extensive container shipping networks, direct routes to major global destinations, and advanced cargo handling facilities. This strategic advantage ensures reliable scheduling, reduced transit times, and seamless customs clearance processes. Prior to shipment, all export documentation—including packing lists, commercial invoices, certificates of origin, and phytosanitary certificates for wooden packaging—is prepared in full compliance with international trade regulations.

The following table outlines our standard packaging specifications for marine compressor parts:

| Packaging Type | Material Specification | Compliance Standard | Load Capacity | Typical Use Case |

|---|---|---|---|---|

| Wooden Export Case | Kiln-dried hardwood, plywood | ISPM 15 | Up to 2,500 kg | Cylinder assemblies, valve blocks |

| Steel Pallet | Carbon steel, powder-coated | ISO 9001 | Up to 5,000 kg | Crankshafts, large compressor units |

| Internal Cushioning | Foam inserts, VCI paper | ASTM D4169 | N/A | All sensitive and precision parts |

| Container Type | 20’ or 40’ dry container | CSC certified | 28–30 tons | Full container loads (FCL) |

By combining compliant, durable packaging with efficient logistics from Ningbo and Shanghai, Hangzhou Star Marine Technology ensures that every marine compressor part reaches its destination securely and on schedule.

Contact Star Marine

Connect with Hangzhou Star Marine Technology for Precision Marine Compressor Parts

Securing reliable, high-performance components for marine air compressor systems is non-negotiable for vessel safety, operational continuity, and regulatory compliance. Hangzhou Star Marine Technology Co., Ltd. stands as your strategic partner in this critical domain, delivering OEM-specification and engineered replacement parts designed explicitly for the harsh maritime environment. Our deep engineering expertise, stringent quality control processes aligned with ISO 9001:2015 and relevant marine classification society standards (DNV, ABS, LR, etc.), and commitment to export excellence ensure that every piston, cylinder liner, valve plate, seal, and control module meets the exacting demands of saltwater exposure, continuous vibration, and stringent SOLAS requirements. We understand that compressor failure at sea carries significant operational and financial risk; therefore, our parts undergo rigorous testing for corrosion resistance, fatigue life, and dimensional accuracy to guarantee seamless integration and extended service life within your specific compressor model.

Navigating international procurement for marine spares requires more than just a supplier—it demands a responsive, technically proficient partner who comprehends global shipping schedules, customs documentation, and the urgency inherent in vessel maintenance windows. Our Export Management team, led by dedicated Product Manager Kacher YE, operates with the maritime industry’s pace in mind. Kacher possesses extensive hands-on experience with reciprocating and screw-type marine air compressors across diverse vessel types, from offshore support vessels to large commercial carriers. He is uniquely positioned to translate your technical specifications, identify potential compatibility issues before shipment, and expedite solutions for urgent dry-dock or critical repair scenarios. Partnering with Star Marine means gaining direct access to engineering-led support, not just transactional order processing.

For precise technical consultations, quotation requests, or urgent parts sourcing related to marine compressor systems, initiate your engagement directly with Kacher YE. His proactive approach ensures your inquiry receives immediate technical validation and a clear, actionable path forward. The table below provides essential contact details for streamlined communication:

| Contact Information | Details |

|---|---|

| Primary Contact | Kacher YE |

| Position | Product Manager, Marine Compressor Systems |

| Direct Email | [email protected] |

| Typical Response Time | Within 4 business hours (GMT+8) |

Do not compromise vessel uptime or safety with generic or uncertified components. Contact Kacher YE today via the provided email to discuss your specific marine compressor part requirements, technical challenges, or export logistics. Include your vessel’s compressor make/model, part numbers (if available), and operational context to enable the fastest, most accurate support. Hangzhou Star Marine Technology is committed to being your trusted source for technically superior, export-ready marine compressor solutions—engineered for the sea, delivered with maritime precision. Let us safeguard your vessel’s critical air supply systems through every voyage. Initiate your technical dialogue now for unmatched reliability and export efficiency.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160