Marine Bilge Water Separator – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Bilge Water Separator

Marine Bilge Water Separator: Critical Safety Equipment and Strategic Sourcing Advantage

The marine bilge water separator represents a fundamental component of modern vessel safety and environmental compliance systems. Its primary function—removing oil from bilge water to levels permissible for overboard discharge—is not merely operational but a critical safety and regulatory imperative. Under MARPOL Annex I, discharging untreated bilge water exceeding 15 parts per million (ppm) oil content constitutes a serious violation, carrying significant fines, vessel detention, and potential criminal liability for the crew and owner. More critically, failure of this system risks catastrophic environmental incidents during routine operations or emergencies. Accumulated oil in bilges presents a severe fire hazard, while improper discharge can cause devastating pollution events, directly threatening crew safety, marine ecosystems, and the vessel’s operational license. Reliability in this equipment is non-negotiable; a malfunctioning separator compromises the vessel’s ability to manage routine operational waste safely, undermining core safety management systems mandated by the ISM Code.

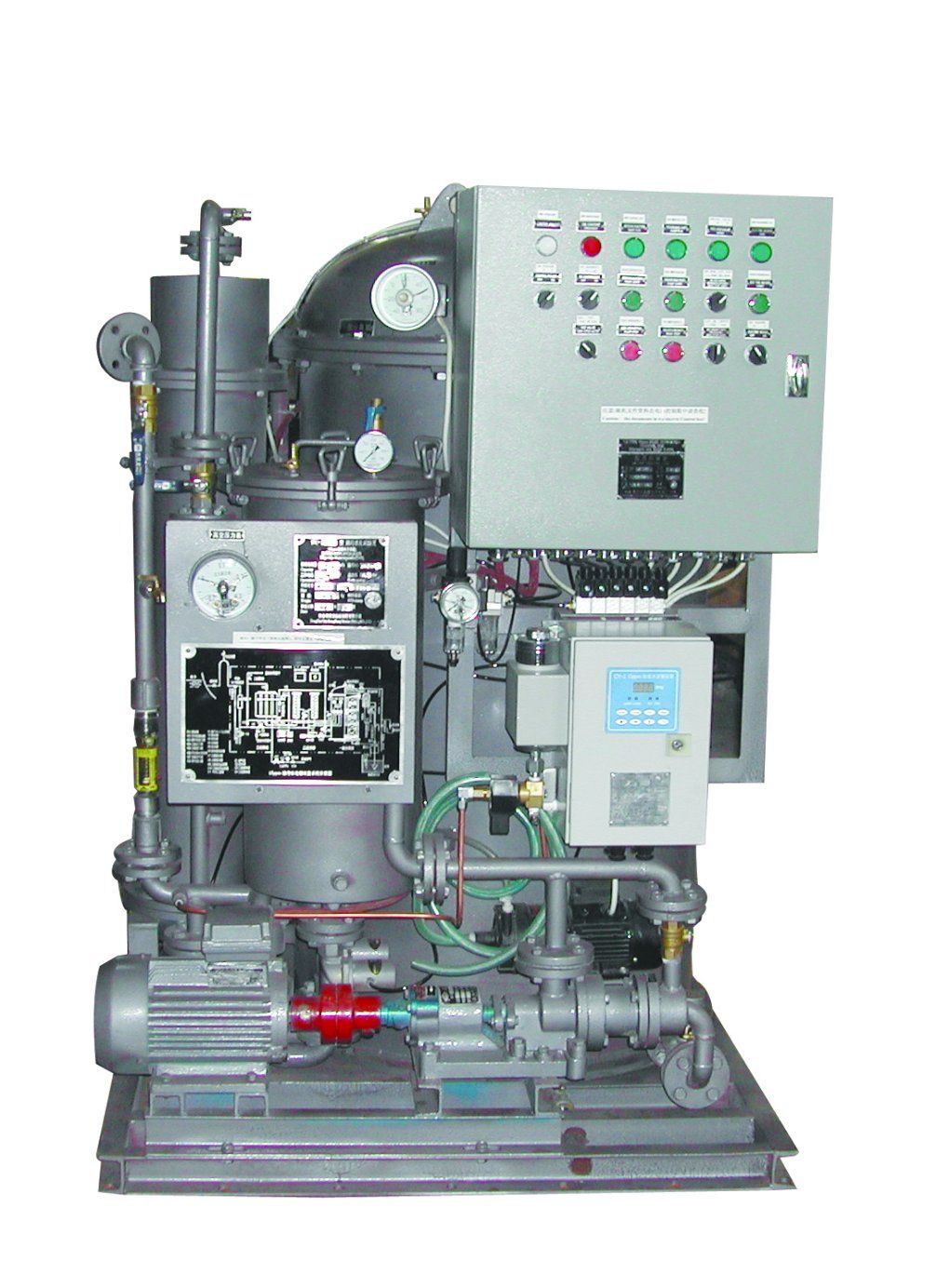

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures bilge water separators engineered specifically to meet these stringent safety demands. Our units incorporate robust coalescer technology, precise 15ppm oil content monitors with automatic overboard discharge shutdown, and fail-safe alarms, ensuring continuous compliance even under challenging sea conditions. Adherence to IMO MEPC.107(49) performance standards and full Type Approval certification are inherent to our production process, guaranteeing that every separator performs reliably when needed most. This technical rigor directly translates to enhanced vessel safety by eliminating preventable pollution risks and associated operational hazards.

Sourcing bilge water separators from Hangzhou Star Marine Technology offers shipowners and operators a significant strategic advantage through demonstrable cost-effectiveness without compromising on safety or compliance. Our integrated manufacturing facility in China, operating under strict ISO 9001 quality management protocols, enables optimized production costs. This efficiency stems from controlled supply chains, advanced CNC manufacturing capabilities, and economies of scale specific to the marine outfittings sector. Crucially, this cost structure does not equate to reduced quality; it reflects value engineering focused on delivering IMO-certified performance at a highly competitive total cost of ownership. Star Marine separators provide the essential safety function at a lower acquisition cost compared to many European or North American alternatives, while maintaining identical regulatory compliance and operational reliability. This represents a prudent investment, directly improving vessel operating economics while safeguarding against the far greater financial and reputational risks of non-compliance.

The following table outlines key specifications of our standard ST-BWS series separator, demonstrating the balance of performance, compliance, and value:

| Feature | Specification |

|---|---|

| Model Designation | ST-BWS-1000 |

| Rated Flow Rate | 1.0 m³/h |

| Discharge Standard | ≤ 15 ppm oil content (IMO MEPC.107(49)) |

| Separation Principle | Gravity & Coalescence |

| Alarm System | 15ppm Oil Content Monitor + High Level |

| Construction Material | Marine Grade SS316L Wetted Parts |

| Power Requirement | 220V AC, 50/60 Hz, 1.5 kW |

| Certifications | IMO Type Approved, CCS, DNV, LR, RINA |

Hangzhou Star Marine Technology delivers bilge water separation solutions where uncompromising safety compliance meets intelligent cost management. Our separators are proven assets in safeguarding vessels, crews, and the marine environment, providing shipowners with essential regulatory assurance and operational peace of mind at a sustainable investment level. We stand ready to support global fleets with reliable, certified equipment and dedicated export logistics.

Technical Specs & Approval

The marine bilge water separator is a critical component in onboard oily water treatment systems, ensuring compliance with international maritime regulations such as MARPOL Annex I. Hangzhou Star Marine Technology Co., Ltd. manufactures high-efficiency bilge water separators designed for durability, reliability, and optimal performance in marine environments. These separators are engineered to remove oil and suspended solids from bilge water, enabling safe discharge within permissible limits of 15 ppm oil content. Constructed using robust materials and precision engineering, our separators meet classification society standards including CCS, LR, DNV, ABS, and NK.

Material selection plays a pivotal role in the longevity and operational integrity of the bilge water separator. Our standard models are fabricated using either marine-grade aluminum alloy (Alu 5083/6061) or carbon steel with anti-corrosion coating, depending on the installation environment and customer requirements. Aluminum variants offer excellent corrosion resistance and reduced weight, ideal for high-speed craft and offshore support vessels. Steel constructions provide enhanced structural strength and are typically selected for larger commercial vessels and offshore platforms. All wetted parts, including internal piping, coalescer plates, and sensor housings, are made from stainless steel (SS316) or non-corrosive composite materials to resist degradation from prolonged exposure to hydrocarbons and seawater.

Watertightness is ensured through precision-machined flanged joints, EPDM or Viton gasketing, and rigorous factory pressure testing. Each unit undergoes a hydrostatic test at 1.5 times the maximum working pressure to verify seal integrity and structural soundness. The separator housing is designed to maintain watertight performance under dynamic vessel conditions, including vibration, pitch, and roll. The integrated 3-phase separation chamber utilizes gravity and coalescence principles to efficiently separate oil, water, and sludge without moving parts, minimizing maintenance needs.

Dimensions and footprint are optimized for compact engine room installations. Standard models range from 800 mm to 2,200 mm in length, with diameters between 300 mm and 600 mm, allowing integration into confined spaces. Weight varies based on material and capacity, with aluminum units averaging 30–40% lighter than their steel counterparts. Mounting provisions include adjustable steel skids or resilient rubber mounts to accommodate different foundation types and reduce transmission of operational vibration.

The following table outlines the technical parameters of standard bilge water separator models offered by Hangzhou Star Marine Technology:

| Parameter | Value / Specification |

|---|---|

| Model Type | Horizontal, Gravity-Coalescence Type |

| Material (Housing) | Alu 5083 / Carbon Steel with Epoxy Coating |

| Internal Components | SS316, PTFE, EPDM, or Composite |

| Design Pressure | 0.6 MPa (max) |

| Test Pressure | 0.9 MPa (hydrostatic) |

| Inlet/Outlet Connection | DN50 Flanged (ISO 6182-1) |

| Separation Efficiency | >99% (achieves <15 ppm oil in water) |

| Operating Temperature | 0°C to 70°C |

| Flow Rate Capacity | 0.5 m³/h to 5.0 m³/h (customizable) |

| Power Supply (for control unit) | 24 VDC / 220 VAC, 50/60 Hz |

| Overall Dimensions (L×W×H) | 800–2200 mm × 300–600 mm × 400–800 mm |

| Weight (approx.) | 80–320 kg (depends on material and capacity) |

| Compliance Standards | MARPOL Annex I, MEPC.107(49), ISO 10088, IMO Resolution |

All units are supplied with comprehensive documentation, including material test certificates, pressure test reports, and classification society type approval certificates. Custom configurations are available upon request to meet specific vessel requirements.

Shipbuilding Solutions

Complete Bilge Water Separation Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co. Ltd. delivers engineered bilge water separator systems that ensure strict compliance with MARPOL Annex I and IMO MEPC.107(49) standards. Our integrated approach addresses the critical need for reliable oily water treatment across new vessel construction and dry-dock repair projects. As a certified marine outfitter, we provide end-to-end support from design validation to commissioning, eliminating integration risks and accelerating project timelines. For shipyards, our systems are engineered for seamless compatibility with diverse vessel types, including tankers, offshore support vessels, and commercial fleets. We collaborate early in the design phase to optimize space allocation, piping interfaces, and electrical integration, preventing costly rework during outfitting.

In repair and retrofit scenarios, Star Marine minimizes vessel downtime through rapid assessment and modular replacement strategies. Our technical team conducts on-site audits to determine optimal separator sizing and configuration, leveraging legacy system data to ensure backward compatibility. All units undergo stringent factory acceptance testing (FAT) per ISO 8573 standards, with documentation fully aligned with class society requirements including DNV, LR, and CCS. This pre-validated approach reduces dry-dock periods by up to 30% compared to conventional procurement cycles.

Our export management framework guarantees responsive global delivery. A dedicated export coordination cell handles customs clearance, INCOTERMS 2020 compliance, and logistics for 85+ countries, with average shipment processing within 72 hours of order confirmation. For urgent repair projects, we maintain strategic regional hubs in Singapore, Rotterdam, and Houston stocking critical spares and compact separator units for 72-hour emergency deployment.

Technical Specifications

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Flow Rate | 0.5 m³/h to 5.0 m³/h | IMO MEPC.107(49) |

| Discharge Limit | ≤ 15 ppm oil content | MARPOL Annex I Reg 14 |

| Materials | 316L stainless steel, marine-grade composites | ISO 10088-3 |

| Power Supply | 220-440V AC, 50/60 Hz, 3-phase | IEC 60092-101 |

| Control System | PLC with touch-screen HMI, remote monitoring | IEC 60945 |

| Certifications | DNV-GL Type Approval, RINA, CCS | MEPC.107(49) Resolution |

Star Marine’s value extends beyond hardware. We provide comprehensive technical documentation in English, Chinese, and Spanish, including 3D CAD models for clash detection, and certified operator training programs accredited by the International Maritime Organization. Our post-installation support includes real-time troubleshooting via satellite-linked diagnostics and a 24/7 multilingual engineering desk. For shipbuilders, this integrated methodology ensures regulatory adherence without schedule overruns. For repair facilities, it translates to faster turnarounds and reduced operational liability. Partner with Hangzhou Star Marine Technology for bilge water separation solutions engineered for global maritime compliance and operational resilience.

Packaging & Logistics

Packaging & Logistics for Marine Bilge Water Separators – Hangzhou Star Marine Technology Co., Ltd.

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all marine bilge water separators are packaged to the highest international standards, guaranteeing safe and secure delivery to global destinations. As a leading supplier of marine outfittings, we recognize the critical importance of robust packaging in preserving equipment integrity during long-distance sea freight. Our packaging protocols are designed to meet stringent maritime shipping requirements, environmental regulations, and customs compliance across key international markets.

All bilge water separators are packaged using either export-grade wooden cases compliant with ISPM 15 standards or heavy-duty steel pallets, depending on the model, dimensions, and shipping route. ISPM 15 certification ensures that all wooden packaging materials are heat-treated and free from pests, meeting the International Standards for Phytosanitary Measures established by the International Plant Protection Convention (IPPC). This certification is mandatory for shipments to North America, the European Union, Australia, and many other regions. Each wooden case is constructed from durable, kiln-dried plywood or solid wood, reinforced with metal strapping and corner protectors to withstand stacking and rough handling.

For models requiring enhanced structural support or destined for extended transit times, we utilize steel pallets. These are particularly suited for large or heavy-duty bilge separation units, offering superior resistance to moisture, impact, and deformation. Steel pallets also facilitate easier handling via forklifts and cranes at ports and terminals, improving logistics efficiency. All units are internally lined with anti-corrosion VCI (Vapor Corrosion Inhibitor) paper and sealed in moisture-resistant plastic film to protect sensitive components from salt air, humidity, and condensation during ocean transport.

Our export operations are coordinated through the major international ports of Ningbo and Shanghai, two of the busiest and most efficient container hubs in the world. These ports provide direct access to global shipping lanes, ensuring timely consolidation, customs clearance, and onward delivery. We work closely with certified freight forwarders and logistics partners to manage documentation, including packing lists, certificates of origin, and phytosanitary certificates where required.

The following table outlines the standard packaging specifications based on unit type:

| Unit Type | Packaging Method | Dimensions (L×W×H) | Weight Range | Certification |

|---|---|---|---|---|

| Compact Bilge Separator (1–3 m³/h) | ISPM 15 Wooden Case | 1200×800×1000 mm | 150–300 kg | ISPM 15, IPPC Marked |

| Standard Bilge Separator (4–6 m³/h) | ISPM 15 Wooden Case or Steel Pallet | 1800×1000×1400 mm | 400–600 kg | ISPM 15 or Steel Certification |

| Heavy-Duty Bilge Separator (8–10 m³/h) | Steel Pallet with Bracing | 2200×1200×1600 mm | 800–1200 kg | Reinforced Steel, VCI Protected |

All packaging is clearly labeled with handling instructions, model and serial numbers, port of destination, and safety markings in accordance with IMDG and SOLAS regulations. This ensures seamless coordination throughout the supply chain, from factory dispatch to final delivery at the vessel or end-user facility.

Contact Star Marine

Contact Star Marine for Bilge Water Separator Solutions

Compliance with MARPOL Annex I regulations is non-negotiable for vessel operators globally. Failure to implement certified bilge water separation systems risks severe penalties, operational delays, and environmental liability. Hangzhou Star Marine Technology delivers engineered solutions meeting IMO MEPC.107(49) standards, ensuring your fleet operates within stringent international discharge limits. Our bilge water separators undergo rigorous third-party validation for reliability in demanding maritime environments, from offshore supply vessels to container ships. With decades of specialization in marine pollution prevention equipment, we prioritize technical precision over generic supply chain promises.

Star Marine’s separators integrate advanced coalescing technology, automated monitoring, and corrosion-resistant materials to maintain consistent 15 ppm discharge compliance. Below details critical specifications aligning with global regulatory frameworks:

| Parameter | Star Marine Standard | IMO MEPC.107(49) Requirement |

|---|---|---|

| Maximum Discharge Limit | ≤15 ppm oil content | ≤15 ppm oil content |

| Material Construction | ASTM A240 316L stainless steel | Corrosion-resistant materials |

| Alarm System | Dual-stage oil content monitor with visual/audible alarms | Oil content monitoring required |

| Flow Rate Range | 0.5–50 m³/h (customizable) | Matched to vessel’s bilge capacity |

| Certification | DNV-GL, LR, CCS, RINA Type Approval | Mandatory Type Approval |

Engaging our Product Manager, Kacher YE, initiates a technical consultation tailored to your operational profile. Unlike generic suppliers, we analyze vessel type, routing zones, and existing infrastructure to prescribe optimal separator integration. Kacher possesses direct oversight of engineering modifications, certification documentation, and export logistics—critical for navigating complex customs regimes in key markets like the EU, Southeast Asia, and the Americas. His expertise ensures seamless compliance with destination-specific regulations, including USCG Type Approval equivalents and EU Ship Recycling Regulation (SRR) documentation.

Initiate your project validation within 48 hours by contacting Kacher YE directly at [email protected]. Include your vessel specifications, target delivery timeline, and port of discharge for a prioritized response. Star Marine operates a dedicated export desk managing Incoterms® 2020 compliance, pre-shipment inspections, and multilingual technical manuals. We require no formal RFQ to commence preliminary engineering reviews—simply share your vessel’s IMO number or bilge pump capacity for a feasibility assessment.

All inquiries receive a structured technical dossier within one business day, including 3D installation schematics, Type Approval certificates, and lifecycle cost analysis. For urgent retrofits or regulatory audits, Kacher coordinates emergency response teams across our Hangzhou headquarters and regional hubs in Singapore and Rotterdam. Do not compromise environmental compliance on unverified equipment claims; Star Marine’s separators carry a 24-month performance warranty with global service network access.

Contact Kacher YE today to secure your bilge water separation solution. Responses are monitored during Hangzhou business hours (08:00–17:00 CST), with after-hours emergencies handled via +86-571-88XXXXXX. Your fleet’s regulatory integrity begins with engineered precision, not procurement convenience. Trust Star Marine—where maritime compliance meets uncompromised engineering.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160