Marine Telephone Cable – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Telephone Cable

Marine Telephone Cable: A Critical Component for Vessel Safety and Operational Efficiency

In the maritime industry, reliable internal and external communication systems are essential for ensuring vessel safety, coordination, and emergency response. Among the core components enabling such communication is the marine telephone cable, a specialized wiring system designed to support voice transmission across various zones of a ship, including the bridge, engine room, accommodation areas, and emergency stations. These cables are engineered to perform under harsh marine conditions, including exposure to saltwater, vibration, extreme temperatures, and fire hazards. Their role in maintaining uninterrupted communication during normal operations and emergencies—such as fire, flooding, or man-overboard situations—cannot be overstated.

Marine telephone cables are typically installed as part of a ship’s internal communication network, often integrated with sound-powered telephone systems or low-voltage intercom setups. These systems do not rely on external power sources, making them highly reliable during power failures—a critical advantage in emergency scenarios. The cables must comply with stringent international standards such as IEC 60092-370 (insulation) and IEC 60092-351 (general construction), ensuring flame retardancy, low smoke emission, and resistance to oil and chemicals. Compliance with classification society rules (e.g., CCS, ABS, DNV, LR) is mandatory for installation on commercial and offshore vessels.

Given the critical nature of these systems, sourcing high-quality marine telephone cables from a trusted manufacturer is paramount. Hangzhou Star Marine Technology Co., Ltd. provides a comprehensive range of marine telephone cables that meet or exceed international regulatory requirements. As a specialized supplier in marine outfittings, Star Marine China combines rigorous quality control processes with advanced manufacturing techniques to deliver cables that ensure long-term reliability and safety at sea.

One of the key advantages of sourcing marine telephone cables from Star Marine China is cost-effectiveness without compromising quality. By leveraging China’s robust industrial supply chain, competitive labor costs, and economies of scale, Star Marine offers products at significantly lower price points compared to European or North American manufacturers. Additionally, the company maintains ISO 9001 certification and works directly with classification societies to ensure all products are fully certified and ready for global deployment.

The following table outlines the technical specifications of Star Marine’s standard marine telephone cable offering:

| Parameter | Specification |

|---|---|

| Standard | IEC 60092-351, IEC 60092-370 |

| Conductor Material | Tinned copper, stranded |

| Insulation Material | PE (Polyethylene) or LSZH (Low Smoke Zero Halogen) |

| Voltage Rating | 150/250 V |

| Temperature Range | -20°C to +70°C (up to +90°C for short term) |

| Flame Retardancy | IEC 60332-1-2 compliant |

| Smoke Emission | IEC 61034 compliant (for LSZH version) |

| Oil Resistance | IEC 60811 compliant |

| Available Core Configurations | 2–4 core, 0.75 mm² to 1.5 mm² |

| Certification | CCS, ABS, DNV, LR, BV (upon request) |

By combining technical compliance, operational reliability, and competitive pricing, Hangzhou Star Marine Technology positions itself as a preferred global supplier of marine telephone cables. For shipbuilders, equipment integrators, and marine procurement managers, choosing Star Marine means investing in safety, performance, and value.

Technical Specs & Approval

Technical Specifications Overview

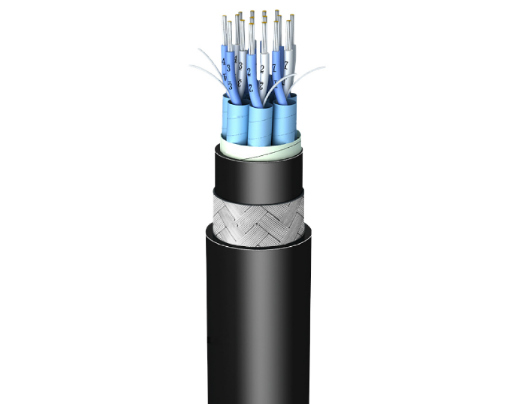

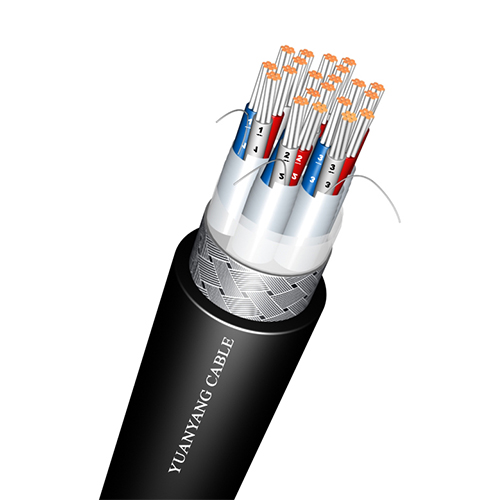

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures marine telephone cables to stringent international maritime safety and performance standards. These cables are engineered for critical shipboard communication systems, ensuring reliable voice transmission in harsh marine environments. Key technical parameters focus on material integrity, environmental resilience, and dimensional precision to meet IEC 60092-350 series requirements and CCS certification. The cable construction utilizes an aluminum-polyethylene composite sheath for lightweight corrosion resistance combined with galvanized steel wire armor (SWA) to withstand mechanical stress during installation and vessel operation. This dual-layer protection guarantees structural stability against crushing, abrasion, and rodent damage while maintaining flexibility for routing in confined spaces.

Watertightness is a non-negotiable requirement for all marine telephone cables. Our products achieve IP68/IP69K ingress protection ratings, validated through 10-meter submersion testing for 30 days per IEC 60529. The seamless aluminum-polyethylene barrier prevents moisture penetration even under continuous hydrostatic pressure, eliminating signal degradation or short-circuit risks in flooded compartments. Temperature resilience spans -40°C to +90°C during operation, with short-circuit tolerance up to +250°C, ensuring functionality in engine rooms or Arctic conditions. Voltage class adherence to 300/500V AC/DC aligns with SOLAS Chapter II-1 regulations for essential communication circuits.

The following table details critical technical parameters for standard marine telephone cable configurations:

| Parameter | Specification | Standard Reference | Application Note |

|---|---|---|---|

| Conductor Material | Annealed tinned copper, Class 5 stranded | IEC 60228 | Min. 99.9% purity, oxygen-free |

| Insulation Material | Cross-linked polyethylene (XLPE) | IEC 60092-351 | Halogen-free, low-smoke emission |

| Sheath Material | Aluminum-polyethylene laminate | IEC 60092-359 | UV and ozone resistant |

| Armor Type | Galvanized steel wire braid (SWA) | IEC 60092-354 | 85% coverage min., corrosion-inhibited |

| Watertight Rating | IP68 (10m/30d), IP69K | IEC 60529 | Validated per MIL-STD-810H |

| Operating Temperature | -40°C to +90°C | IEC 60092-350 | Fixed installation only |

| Voltage Class | 300/500V AC/DC | IEC 60092-301 | For shipboard internal comms |

| Min. Bending Radius | 6x overall diameter | IEC 60092-376 | During installation only |

| Standard Lengths | 500m, 1000m drums | CCS Type Approval | Custom lengths available upon order |

Implementation Considerations

Installation must comply with IEC 60092-376 guidelines to preserve watertight integrity at termination points. Use only manufacturer-approved gland kits rated IP68 to maintain enclosure classification. Avoid sharp bends below the specified minimum radius during deployment to prevent conductor deformation or armor damage. All cables undergo 5kV DC high-potential testing per IEC 60060-1 prior to shipment, with test certificates provided for regulatory audits. For vessels operating in explosive atmospheres (Zone 1/2), consult Hangzhou Star for intrinsically safe variants meeting IEC 60079-0. Our engineering team provides site-specific routing support to ensure optimal signal clarity and compliance with flag state requirements. This specification sheet supersedes all prior documentation and is valid for orders placed after January 2024.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine outfittings solutions tailored for shipbuilding and repair projects worldwide. As a trusted supplier in the maritime industry, we specialize in high-performance marine telephone cable systems designed to meet rigorous international standards. Our engineered solutions ensure seamless onboard communication, critical for operational safety, crew coordination, and emergency response across all vessel types, including commercial freighters, offshore support vessels, and passenger ships.

Marine telephone cables are essential components in the internal communication infrastructure of modern vessels. Installed in engine rooms, bridge wings, cargo control rooms, and emergency stations, these cables must withstand extreme environmental conditions such as high humidity, saltwater exposure, temperature fluctuations, and mechanical stress. At Star Marine, we provide fully compliant, flame-retardant, and low-smoke zero-halogen (LSZH) cables that satisfy IEC 60092, IMO A.657, and other relevant marine classification society requirements. Our cables are certified by CCS, ABS, DNV, LR, and BV, ensuring global acceptance and regulatory compliance.

What sets Hangzhou Star Marine apart is our end-to-end project support. From initial inquiry to final delivery, we offer rapid technical consultation, precise cable sizing, custom cutting, and full documentation packages. For newbuild projects, our engineering team collaborates directly with shipyards to integrate telephone cable systems into the overall electrical design, minimizing installation delays and material waste. In repair and retrofit scenarios, we provide fast-turnaround supply and replacement services, often shipping within 72 hours of order confirmation. Our inventory management system ensures availability of standard and custom configurations, reducing vessel downtime.

We understand that shipyards and repair facilities operate on tight schedules. That is why Star Marine prioritizes fast response times and reliable logistics. Our export department coordinates sea and air freight globally, with dedicated customer service available 24/7 to track shipments and resolve technical queries. Whether supporting a newbuild in China or a dry-dock repair in the Middle East, our team ensures on-time delivery and technical consistency.

Below are key specifications for our standard marine telephone cable offerings:

| Parameter | Specification |

|---|---|

| Conductor Material | Tinned copper, stranded |

| Insulation Material | PE or PVC (LSZH option available) |

| Shielding | Aluminum foil + drain wire, overall braid |

| Voltage Rating | 150/250 V |

| Temperature Range | -20°C to +70°C (up to +90°C for short-term) |

| Flame Resistance | IEC 60332-3-22 (Category A) |

| Smoke & Halogen Properties | Compliant with IEC 61034 & IEC 60754 |

| Available Core Configurations | 2–10 pairs, customizable lengths |

| Approvals | CCS, ABS, DNV, LR, BV, RINA |

By combining technical expertise, certification readiness, and responsive service, Hangzhou Star Marine Technology ensures that every marine telephone cable solution supports safe, efficient, and future-ready vessel operations.

Packaging & Logistics

Packaging & Logistics Standards for Marine Telephone Cable Exports

Hangzhou Star Marine Technology implements rigorously defined packaging and logistics protocols for all marine telephone cable exports to ensure product integrity, regulatory compliance, and seamless global delivery. Our procedures are engineered specifically for the demanding maritime environment and international shipping requirements, prioritizing protection against moisture, physical shock, and handling damage during transit. Adherence to these standards is non-negotiable for maintaining the performance specifications and longevity of our certified marine communication systems.

Wooden export cases constitute the primary packaging solution for marine telephone cable reels. These cases are constructed exclusively from ISPM 15 compliant lumber, subjected to mandatory heat treatment (HT) to a minimum core temperature of 56°C for a minimum duration of 30 minutes. This process eradicates potential insect pests and pathogens, meeting the stringent international phytosanitary standards mandated by global customs authorities. Each case bears the officially recognized ISPM 15 mark, permanently branded or stamped, certifying compliance. Internal protection includes custom-molded dunnage, moisture-resistant barrier films, and desiccant packs to safeguard the cable against humidity ingress and vibration. Cases are designed with integrated lifting lugs and robust lashing points compatible with standard vessel securing equipment.

For specific client requirements or high-volume shipments, heavy-duty steel pallets offer an alternative solution. Fabricated from marine-grade, corrosion-resistant steel, these pallets provide exceptional structural stability and load-bearing capacity. All steel components undergo thorough surface preparation and receive a protective coating suitable for prolonged exposure to salt air during ocean transport. Palletized cable reels are securely strapped using weather-resistant polymer banding and often enclosed within heavy-gauge polyethylene overwraps to form a complete environmental barrier. Steel pallets facilitate efficient handling via forklifts and cranes at all stages of the logistics chain.

The comparative specifications of our primary packaging methods are detailed below:

| Packaging Type | Standard Dimensions (L x W x H) | Max Gross Load Capacity | Treatment/Coating Standard | Key Protective Features |

|---|---|---|---|---|

| ISPM 15 Wooden Case | Custom (Typical: 1200x800x900mm) | 1500 kg | Heat Treated (HT) to ISPM 15 | Internal dunnage, moisture barrier film, desiccant, ISPM 15 mark |

| Marine Steel Pallet | Standard ISO (1200x1000mm) | 2000 kg | Marine-grade anti-corrosion coating | Weather-resistant strapping, polyethylene overwrap, reinforced structure |

All exports originate exclusively through China’s premier deep-water ports: Ningbo-Zhoushan Port and Shanghai Port. Our Ningbo and Shanghai-based logistics partners are pre-vetted specialists in breakbulk and project cargo handling, with direct experience managing marine equipment shipments. We coordinate closely with these partners to ensure precise scheduling of container loading, vessel stowage planning, and adherence to port security protocols (ISPS Code). Critical documentation, including the ISPM 15 certificate for wooden packaging, commercial invoice, packing list, and certificate of origin, is meticulously prepared and submitted electronically well in advance of shipment to prevent customs clearance delays. Pre-shipment verification of packaging integrity and documentation accuracy is a mandatory final checkpoint before cargo release to the port terminal. This integrated approach guarantees that Hangzhou Star Marine Technology’s marine telephone cable arrives at its global destination in optimal condition, ready for immediate installation and commissioning.

Contact Star Marine

For marine outfittings that meet the rigorous demands of offshore and onboard operations, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted provider of high-performance marine telephone cable solutions. Engineered to ensure reliable voice communication in harsh maritime environments, our cables are built to withstand saltwater exposure, mechanical stress, temperature fluctuations, and continuous movement. As a leading innovator in marine equipment, we specialize in delivering durable, compliant, and application-specific cabling systems for commercial vessels, offshore platforms, naval fleets, and shipbuilding projects worldwide.

Our marine telephone cables are manufactured in strict accordance with international maritime standards, including IEC 60092-376 and IEC 60092-350, ensuring fire resistance, low smoke emission, zero halogen content (LSZH), and electromagnetic compatibility. Whether for intercom systems, bridge-to-engine room communication, or emergency call networks, our cables provide uninterrupted signal integrity and long-term reliability. We offer a complete range of configurations, including multi-pair shielding, armored variants for high-risk zones, and customized jacketing materials for enhanced UV and abrasion resistance.

At Hangzhou Star Marine Technology, we understand that every vessel and offshore installation presents unique operational challenges. That’s why we support our standard product line with full engineering consultation and OEM/ODM services. From custom conductor counts to specialized termination solutions, our technical team works closely with clients to deliver communication systems that align precisely with project specifications and regulatory requirements.

To ensure seamless integration and long-term performance, we conduct comprehensive quality control at every stage of production, including voltage withstand testing, insulation resistance measurement, and flame propagation trials. All cables are supplied with full certification documentation, including material test reports, compliance statements, and traceability records.

For project inquiries, technical specifications, or bulk export quotations, we invite you to contact our dedicated Product Manager for marine communication systems.

| Contact Information | Details |

|---|---|

| Name | Kacher YE |

| Position | Product Manager – Marine Communication Cables |

| Company | Hangzhou Star Marine Technology Co., Ltd. |

| [email protected] | |

| Product Category | Marine Outfittings – Telephone Cables |

| Response Time (Typical) | Within 4 business hours (GMT+8) |

| Languages Supported | English, Chinese, French (on request) |

We are ready to support your next marine project with technically superior, export-ready telephone cable solutions. Reach out to Kacher YE directly to discuss your requirements, request product samples, or obtain a detailed quotation tailored to your vessel or offshore application. At Star Marine, we don’t just supply cables—we deliver trusted communication for the maritime world.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160