Carbon Steel Windlass – Marine Solution Guide 2025

Content Navigation

Marine Insight: Carbon Steel Windlass

Marine Industry Demand: Carbon Steel Windlass Criticality and Sourcing Value

The carbon steel windlass represents a fundamental component of vessel deck machinery, directly impacting operational safety and mission readiness across global maritime operations. As the primary system for deploying, retrieving, and securing a vessel’s anchor, its structural integrity and reliable performance under extreme dynamic loads are non-negotiable. During critical anchoring maneuvers, particularly in adverse weather or emergency situations, the windlass must withstand immense tensile forces generated by the anchor chain and vessel motion. Failure of this system can result in catastrophic loss of anchoring capability, leading to drifting, collisions, grounding, or inability to maintain position during essential operations like offshore support or emergency sheltering. International regulations, including SOLAS requirements for anchor handling equipment and adherence to ISO 15089 standards for windlass design and testing, mandate robust construction capable of exceeding the Safe Working Load (SWL) by significant safety factors. Carbon steel, specifically marine-grade low-alloy variants, provides the essential combination of high tensile strength, exceptional fatigue resistance, and proven weldability required for these demanding applications, forming the backbone of reliable anchoring systems worldwide.

Material selection directly influences both safety margins and lifecycle economics. While stainless steel alternatives exist for specific corrosive environments, carbon steel remains the dominant, optimal choice for the majority of commercial and offshore vessel applications due to its superior strength-to-cost ratio and established repairability. The inherent strength of properly specified carbon steel allows for designs that meet or exceed all classification society requirements (DNV, LR, ABS, CCS, etc.) for structural components like wildcats, chainwheels, and foundation frames, without the prohibitive cost escalation associated with large-scale stainless steel fabrication. Crucially, modern, multi-stage corrosion protection systems – including high-performance epoxy primers, intermediate coats, and polyurethane topcoats applied to stringent surface preparation standards (ISO 8501-1 Sa 2.5) – effectively mitigate corrosion risks, ensuring long service life even in harsh marine atmospheres when maintained per manufacturer guidelines.

Sourcing carbon steel windlasses from Hangzhou Star Marine Technology delivers significant cost-effectiveness without compromising on safety or quality. Our integrated manufacturing ecosystem in China leverages economies of scale in raw material procurement and precision fabrication, while maintaining rigorous adherence to international marine standards. We utilize domestically sourced, certified marine-grade carbon steel (e.g., ASTM A131 Grade AH36/DH36) processed through controlled foundry and machining workflows, eliminating unnecessary import markups on base materials. This strategic advantage, combined with our lean production methodologies and deep expertise in marine deck machinery, allows us to offer windlasses with identical performance specifications and certification profiles as competitors at substantially lower total landed costs. The table below illustrates the key comparative advantages.

| Parameter | Carbon Steel Windlass (Standard Marine) | Stainless Steel Alternative | Star Marine Advantage |

|---|---|---|---|

| Base Material Cost | Low | Very High (3-4x Carbon) | Optimized domestic sourcing & procurement |

| Tensile Strength | High (490-620 MPa typical) | Moderate (500-620 MPa) | Meets/exceeds all class requirements |

| Corrosion Resistance | Requires robust coating system | Inherent | Advanced multi-layer coating application |

| Fabrication Cost | Moderate | High | Efficient Chinese manufacturing ecosystem |

| Lifecycle Value | Excellent (with proper maintenance) | Good | Optimal balance of safety, durability, cost |

Hangzhou Star Marine Technology ensures every carbon steel windlass undergoes comprehensive testing, including hydraulic pressure tests, dynamic load testing per ISO 15089, and full non-destructive examination (NDE) of critical welds. Our commitment to ISO 9001 quality management and direct collaboration with major classification societies guarantees equipment that meets the highest safety benchmarks. For vessel operators and shipyards seeking reliable, certified anchoring solutions that deliver maximum safety assurance within constrained budgets, Star Marine provides the proven, cost-effective carbon steel windlass solution demanded by the global maritime industry.

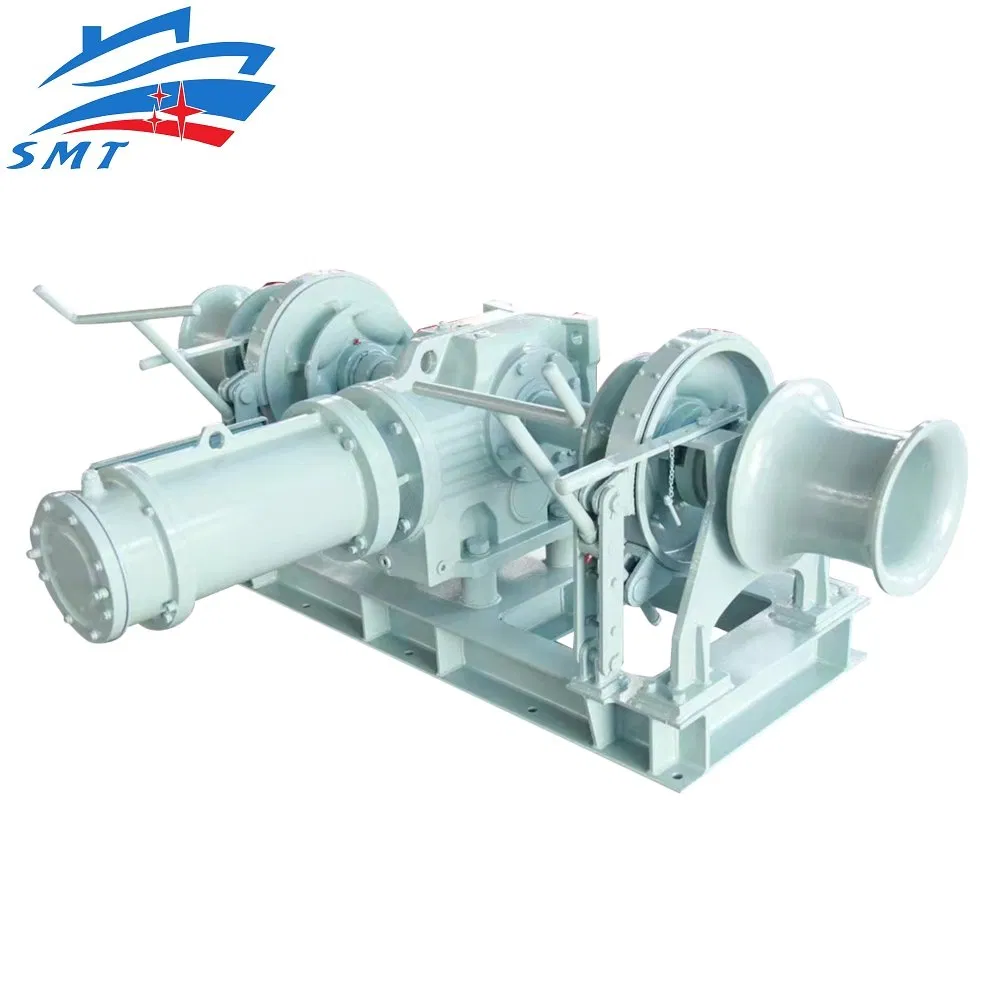

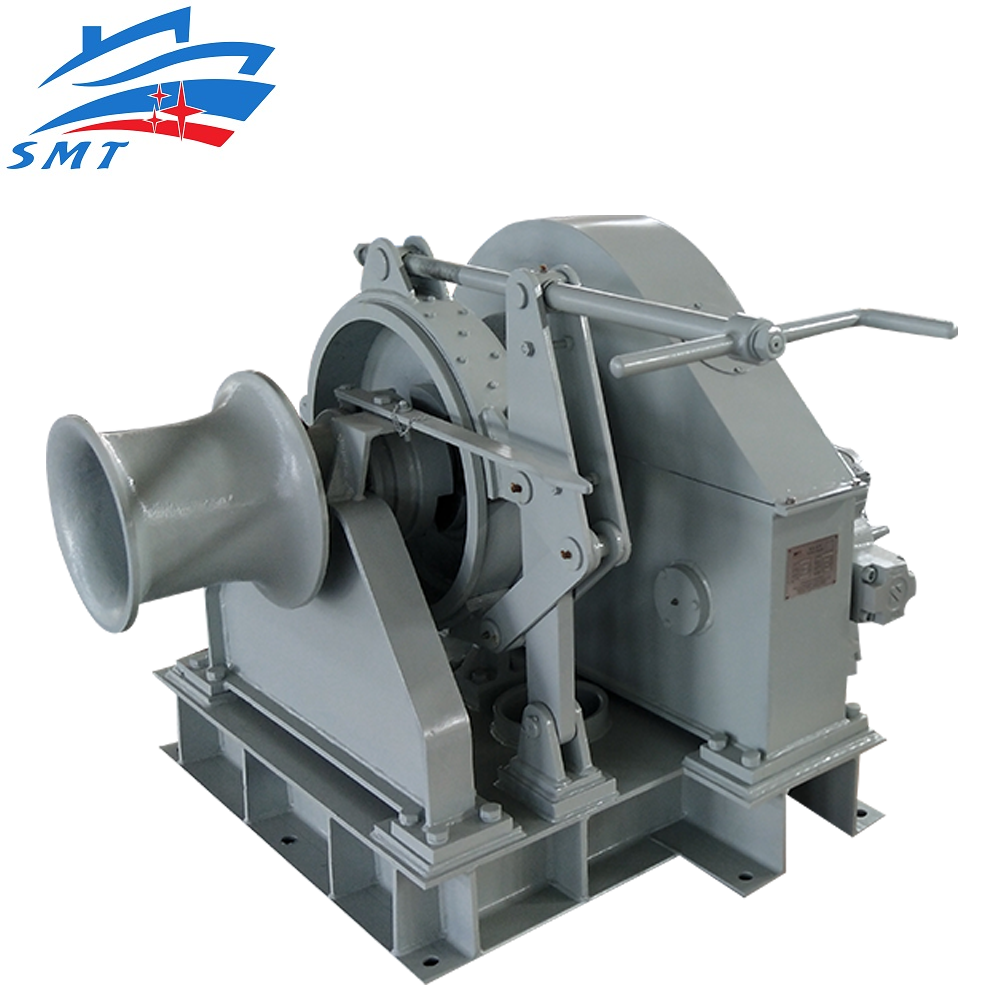

Technical Specs & Approval

The carbon steel windlass is a critical component of marine deck machinery, engineered to ensure reliable and efficient anchoring operations across a wide range of vessel types and operational conditions. Designed and manufactured by Hangzhou Star Marine Technology Co., Ltd., our carbon steel windlasses are built to meet international maritime standards, including ISO 3912 and DNV-GL, ABS, LR, and CCS classification society requirements. Constructed from high-strength carbon steel, these windlasses offer exceptional durability, resistance to mechanical stress, and long service life in harsh marine environments. The design incorporates precision-machined chainwheels (sprockets) that ensure smooth engagement with stud link anchor chains, minimizing wear and slippage during deployment and retrieval.

Our windlasses are available in both electric and hydraulic drive configurations, allowing vessel operators to select the most suitable power source based on onboard systems, power availability, and operational demands. Electric models are ideal for vessels with stable electrical systems and offer precise control and ease of integration with automated anchoring systems. Hydraulic variants are preferred for larger vessels or applications requiring high torque output under continuous load, benefiting from consistent performance even under variable voltage conditions. Both drive types are equipped with reliable braking systems and overload protection to enhance safety during operation.

The windlass is engineered to accommodate anchor chains with diameters ranging from 12.5 mm to 60 mm, making it suitable for use on small commercial vessels up to large offshore support and cargo ships. Pull load capacity is proportionally scaled to chain diameter, ensuring optimal performance and safety margins. Each unit undergoes rigorous load testing and quality control procedures prior to shipment to guarantee compliance with rated specifications. The modular design facilitates maintenance and replacement of wear components, reducing downtime and lifecycle costs.

All models are designed for horizontal or vertical shaft mounting configurations, providing flexibility in deck layout and integration. Surface treatments such as hot-dip galvanization or epoxy coating are available to enhance corrosion resistance, particularly in saltwater environments. Customization options include chain stopper integration, chain counters, and remote control systems, allowing for full compatibility with modern bridge-based anchoring control solutions.

The following table outlines the key technical parameters for the carbon steel windlass series:

| Chain Diameter (mm) | Pull Load (kN) | Drive Type | Nominal Speed (m/min) | Power Source (kW or kW equivalent) | Classification Approval |

|---|---|---|---|---|---|

| 12.5 – 17.5 | 45 – 90 | Electric/Hydraulic | 9 – 12 | 4.0 – 7.5 | DNV-GL, ABS, LR, CCS |

| 19 – 20.5 | 95 – 110 | Electric/Hydraulic | 9 – 12 | 7.5 – 11 | DNV-GL, ABS, LR, CCS |

| 22 – 28 | 120 – 180 | Electric/Hydraulic | 9 – 12 | 11 – 22 | DNV-GL, ABS, LR, CCS |

| 30 – 34 | 190 – 250 | Electric/Hydraulic | 9 – 12 | 22 – 37 | DNV-GL, ABS, LR, CCS |

| 36 – 42 | 260 – 350 | Electric/Hydraulic | 9 – 12 | 37 – 55 | DNV-GL, ABS, LR, CCS |

| 44 – 50 | 360 – 480 | Electric/Hydraulic | 9 – 12 | 55 – 90 | DNV-GL, ABS, LR, CCS |

| 52 – 60 | 490 – 650 | Electric/Hydraulic | 9 – 12 | 90 – 132 | DNV-GL, ABS, LR, CCS |

Hangzhou Star Marine Technology ensures each carbon steel windlass is tailored to meet the operational profile of the vessel, with comprehensive technical support and global after-sales service available to all clients.

Shipbuilding Solutions

Complete Carbon Steel Windlass Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered carbon steel windlass systems as a core component of our comprehensive deck machinery portfolio. Specializing in new vessel construction and critical repair operations, we integrate technical precision with rapid deployment to minimize project downtime. Our windlasses are fabricated to ABS, DNV, LR, and CCS standards, ensuring compliance with global regulatory frameworks while withstanding harsh marine environments through electro-galvanized or epoxy-coated carbon steel construction. This focus on material integrity and certification guarantees operational reliability for anchor handling across vessel types, from offshore support vessels to bulk carriers.

For new shipbuilding projects, Star Marine collaborates directly with naval architects and shipyards during the design phase. We provide 3D CAD models, load calculations, and structural integration support to ensure seamless installation within deck layouts. Our engineering team validates torque requirements, chain locker compatibility, and power interface specifications against vessel-specific operational profiles. This proactive approach prevents costly mid-construction modifications and accelerates delivery schedules without compromising safety margins.

In ship repair and retrofit scenarios, we address urgent operational failures through our global spare parts network and reverse-engineering capabilities. Our technicians rapidly diagnose windlass malfunctions—including gypsy wheel wear, clutch failures, or hydraulic system leaks—and supply OEM-specification components. For legacy vessels lacking original documentation, we utilize laser scanning to reproduce obsolete carbon steel parts, maintaining dimensional accuracy within ISO 2768-mK tolerances. This eliminates extended dry-dock periods caused by supply chain gaps.

Technical Specifications Reference

| Parameter | Value Range | Compliance Standard |

|---|---|---|

| Working Load Limit (WLL) | 50 kN to 1,250 kN | ISO 3911:2001 |

| Chain Size Compatibility | Ø16 mm to Ø102 mm Stud Link Chain | ISO 1704:2013 |

| Power Source | Hydraulic / Electric (380-690V) | IEC 60092-301 |

| Corrosion Protection | Hot-Dip Galvanizing / Epoxy 300μm | ISO 12944-C5M |

| Emergency Release | Manual Override w/ 150% Safety Factor | SOLAS II-1/29 |

Our export management system prioritizes speed without sacrificing documentation rigor. Upon inquiry receipt, our team provides technical quotations within 24 hours and coordinates FCL/LCL shipments via Ningbo Port with pre-validated customs documentation for 95+ countries. For emergency repairs, we expedite air freight of critical components—such as brake linings or motor assemblies—with real-time logistics tracking. All shipments include digital dossiers containing material test reports (MTRs), 3.2 EN 10204 certificates, and installation manuals in English or client-specified languages.

Star Marine’s end-to-end accountability—from initial specification review through post-installation commissioning support—ensures windlass systems meet operational deadlines while adhering to class society requirements. By combining carbon steel durability with responsive global logistics, we mitigate project risks for shipbuilders and repair yards worldwide. Partner with us to transform deck machinery procurement into a strategic asset for on-time vessel delivery.

Packaging & Logistics

Proper packaging and logistics planning are critical components in the successful export of marine deck machinery, particularly for heavy-duty equipment such as carbon steel windlasses. At Hangzhou Star Marine Technology Co., Ltd., we ensure that all exported windlasses meet international shipping standards and arrive at their destination in optimal condition. Our packaging protocols are designed to protect against mechanical damage, corrosion, and environmental exposure during long-distance maritime transport.

All carbon steel windlasses are packaged using robust wooden cases compliant with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This internationally recognized standard mandates that all wood packaging material used in international trade must be treated to prevent the spread of pests and pathogens. Our wooden cases are constructed from heat-treated plywood or fumigated hardwood, stamped with the official ISPM 15 mark, and designed to withstand the rigors of global shipping. The windlass units are securely mounted within the cases using internal bracing and vibration-dampening materials to minimize movement during transit. Additionally, all exposed metal surfaces are treated with temporary corrosion protection, such as VCI (Vapor Corrosion Inhibitor) paper and rust preventive coatings, to safeguard against moisture and salt exposure.

For larger or heavier windlass models, especially those intended for commercial vessels or offshore applications, we utilize steel pallets in conjunction with or as an alternative to wooden crates. Steel pallets offer superior load-bearing capacity, reusability, and resistance to deformation under heavy loads. These pallets are welded to specification, powder-coated for corrosion resistance, and designed to allow for forklift and crane handling at all stages of transport. Units secured on steel pallets are further protected with waterproof wrapping, corner guards, and reinforced strapping to ensure structural integrity.

All shipments originate from major Chinese ports, primarily Ningbo and Shanghai, both of which are among the world’s busiest and most efficient container hubs. These ports offer direct access to global shipping lanes, streamlined customs clearance, and multimodal connectivity, ensuring timely and cost-effective delivery. Our logistics team coordinates end-to-end export documentation, including packing lists, certificates of origin, and bill of lading, in full compliance with destination country requirements.

The following table outlines the standard packaging configurations based on windlass model and export destination:

| Windlass Model | Packaging Type | Dimensions (L×W×H) | Weight (kg) | Export Port | ISPM 15 Compliant |

|---|---|---|---|---|---|

| CSW-50 | Wooden Case | 1200×800×1100 mm | 280 | Ningbo | Yes |

| CSW-100 | Wooden Case + Steel Base | 1500×900×1300 mm | 520 | Shanghai | Yes |

| CSW-150 | Steel Pallet + Wrap | 1800×1000×1500 mm | 860 | Ningbo | No (all-metal) |

| CSW-200 | Steel Pallet + Crate | 2000×1100×1600 mm | 1150 | Shanghai | N/A |

Our standardized yet adaptable packaging and logistics framework ensures that every carbon steel windlass is delivered securely and efficiently, meeting both customer expectations and international regulatory requirements.

Contact Star Marine

Contact Star Marine for Your Carbon Steel Windlass Export Requirements

Selecting the correct carbon steel windlass is a critical decision impacting vessel safety, operational efficiency, and regulatory compliance across global maritime operations. At Hangzhou Star Marine Technology Co., Ltd., we understand that specifications must align precisely with your vessel’s design parameters, environmental operating conditions, and international classification society mandates. Generic solutions risk performance degradation, accelerated corrosion, or non-compliance during port state control inspections. Our engineering team ensures every windlass unit undergoes rigorous material verification, load testing, and certification validation prior to export, safeguarding your investment against costly downtime or retrofitting.

Product Manager Kacher YE possesses over 12 years of specialized expertise in marine deck machinery exports, with deep proficiency in carbon steel windlass applications for bulk carriers, offshore support vessels, and commercial fishing fleets. Kacher leads technical consultations to verify your project’s exact requirements, including working load limits, chain cable specifications, power supply integration, and environmental protection class (e.g., IP56 for saltwater resistance). He coordinates directly with our R&D and quality assurance departments to confirm manufacturability against your timeline while ensuring adherence to ABS, DNV, LR, CCS, and other flag state certifications. Engaging Kacher at the project’s inception phase mitigates procurement risks and optimizes technical documentation for smooth customs clearance in target markets.

Key technical parameters for our standard carbon steel windlass series are summarized below to initiate your inquiry:

| Model | Working Load (kN) | Chain Size (mm) | Power Supply (V/Hz) | Certifications | Corrosion Protection |

|---|---|---|---|---|---|

| HS-WL-30CS | 300 | Ø28–Ø32 | 440/60, 380/50 | ABS, DNV, CCS | Hot-dip galvanized + epoxy |

| HS-WL-50CS | 500 | Ø36–Ø42 | 440/60, 480/60 | ABS, LR, RINA | Dual-coat epoxy marine grade |

| HS-WL-80CS | 800 | Ø44–Ø52 | 660/60, 400/50 | DNV, BV, NK | Thermal-sprayed aluminum |

Initiate your export process by contacting Kacher YE directly via email at [email protected]. Provide your vessel particulars, intended operational profile (e.g., coastal, offshore, ice-class), and target delivery window. Kacher will respond within 4 business hours with a preliminary technical feasibility assessment and export documentation roadmap. For urgent project coordination, include “URGENT: [Your Project Name]” in the email subject line to prioritize review. We also support WeChat communication (ID: StarMarine_Kacher) for real-time file sharing of drawings, load charts, or certification excerpts during business hours (CST UTC+8).

Hangzhou Star Marine Technology operates a dedicated export compliance unit managing HS code classification, COO certification, and destination-specific customs formalities across 65+ countries. Partnering with us eliminates logistical bottlenecks through pre-shipment documentation audits and Incoterms 2020 optimization. Do not proceed with windlass procurement based on catalog data alone—contact Kacher YE to secure a technically validated, export-ready solution engineered for your vessel’s lifecycle demands. Your project’s success begins with precise technical alignment; let Star Marine deliver it.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160