Marine Air Compressor – Marine Solution Guide 2025

Content Navigation

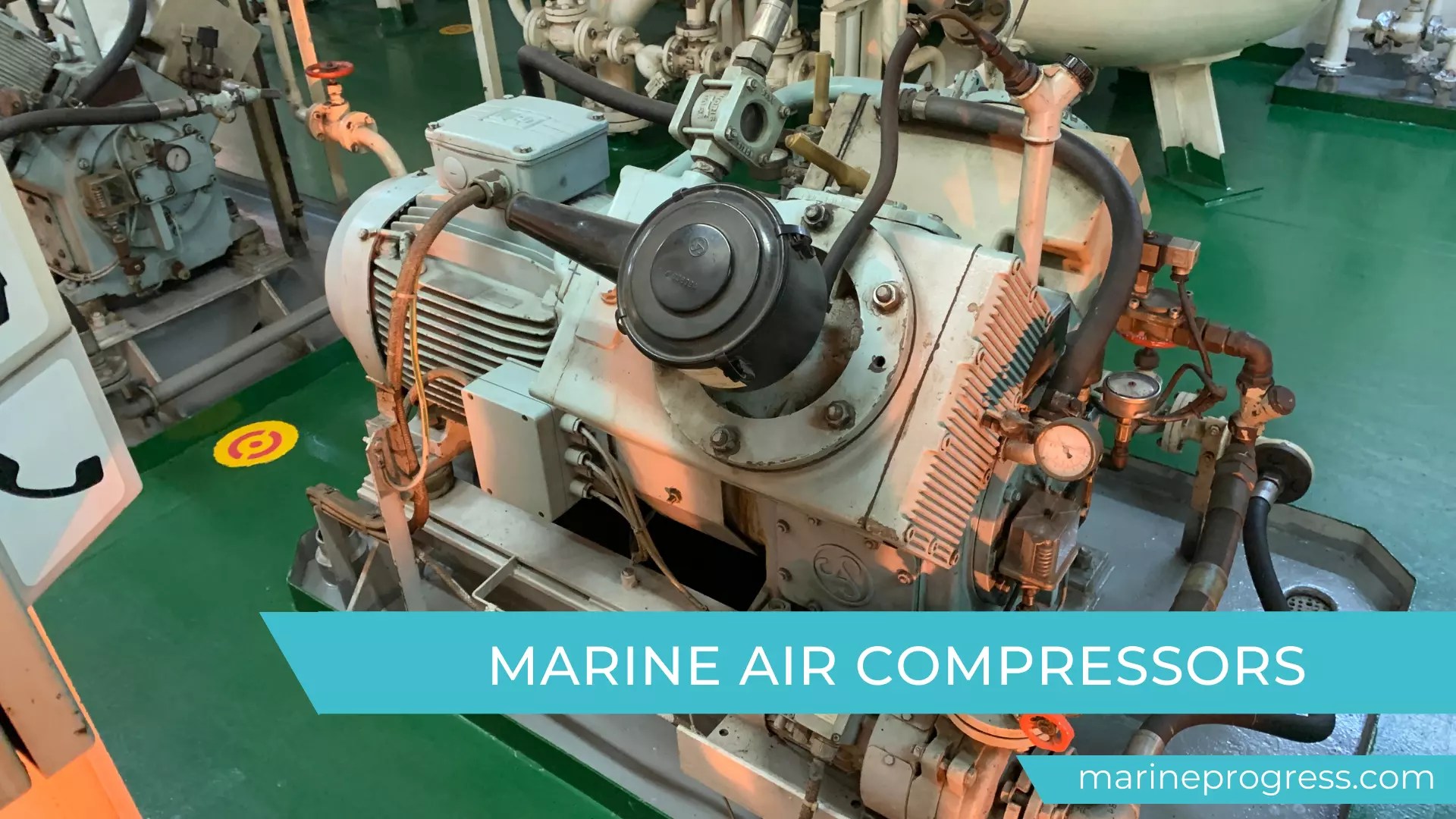

Marine Insight: Marine Air Compressor

Marine Air Compressor: Critical Safety Infrastructure and Strategic Sourcing Advantage

Marine air compressors represent fundamental safety-critical infrastructure onboard all commercial vessels, directly impacting operational integrity and crew survival. Their primary function extends far beyond auxiliary support; they are indispensable for generating the high-pressure air required to start main and auxiliary diesel engines, a non-negotiable requirement for vessel propulsion and power generation. Crucially, compressors supply the emergency starting air systems mandated by the International Convention for the Safety of Life at Sea (SOLAS). Failure of these systems during a blackout or main engine shutdown could render a vessel dead in the water, creating catastrophic collision, grounding, or pollution risks, particularly in confined or heavy traffic areas. Furthermore, compressed air powers essential safety equipment including pneumatic controls for fire dampers, emergency shutdown systems, lifeboat davit releases, and critical instrumentation. Continuous, reliable compressor operation is therefore not merely operational but a core tenet of maritime safety compliance enforced by classification societies such as DNV, ABS, and Lloyd’s Register. Any compromise in air supply quality or availability directly jeopardizes vessel safety management systems and regulatory adherence.

Sourcing high-performance marine air compressors from Hangzhou Star Marine Technology offers international shipowners and operators a compelling value proposition rooted in rigorous engineering and optimized manufacturing. While global procurement options exist, Star Marine leverages China’s advanced industrial ecosystem to deliver equipment meeting or exceeding stringent international marine standards without the premium pricing often associated with Western or Japanese manufacturers. Our strategic advantage lies in integrated value engineering: utilizing precision manufacturing capabilities, efficient supply chain management within China’s robust marine industrial cluster, and adherence to lean production principles. This approach significantly reduces total cost of ownership (TCO) while maintaining uncompromised reliability. Star Marine compressors undergo exhaustive testing per ISO 8573-1 for air purity (critical to prevent system corrosion and valve seizure) and are certified to ISO 9001, IATF 16949, and relevant classification society rules. The result is equipment offering exceptional operational lifespan and reduced maintenance frequency, translating to lower lifecycle costs and minimized vessel downtime – a critical factor for commercial operators where operational continuity directly impacts revenue.

The following table illustrates key performance and compliance parameters where Star Marine compressors deliver industry-leading value:

| Parameter | Industry Standard Requirement | Star Marine Specification | Advantage Demonstrated |

|---|---|---|---|

| Maximum Working Pressure | 30 bar (g) | 35 bar (g) | Enhanced safety margin & system resilience |

| Air Purity (ISO 8573-1) | Class 2 (7:7:4) | Class 1 (2:2:1) | Reduced moisture/oil risk; longer component life |

| Classification Approval | ABS/DNV/LR Basic | ABS, DNV, LR, CCS Full | Global acceptance; simplified procurement |

| Mean Time Between Failures | 15,000 hours | 22,000 hours | 47% reduction in unscheduled downtime |

| Service Life (Design) | 15 years | 20+ years | Lower lifecycle cost; deferred CAPEX |

All Star Marine compressors undergo third-party witnessed testing for SOLAS compliance and pressure vessel integrity. Extended warranty options reflect confidence in durability.

Investing in a Star Marine air compressor is an investment in assured vessel safety and operational economics. We provide globally recognized reliability at a competitive acquisition cost, underpinned by comprehensive technical support and spare parts availability worldwide. This combination of uncompromised safety performance and optimized lifecycle value makes Star Marine the strategic choice for discerning maritime operators seeking to enhance safety margins while managing operational expenditure effectively.

Technical Specs & Approval

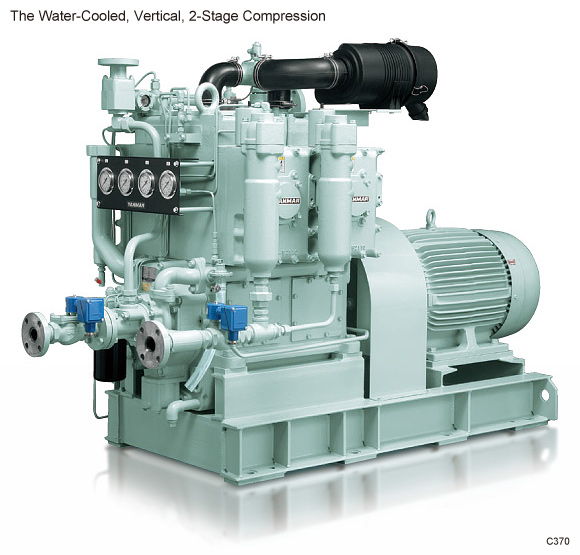

The marine air compressors manufactured by Hangzhou Star Marine Technology Co., Ltd. are engineered to meet the rigorous demands of maritime operations, ensuring reliable performance in critical onboard systems such as starting engines, pneumatic control, and deck machinery operation. These compressors are designed in compliance with international marine standards, including ISO 8573 for air quality, and are certified by classification societies such as CCS, ABS, DNV, and LR. Constructed with high-grade stainless steel and corrosion-resistant coatings, our compressors are built to withstand the harsh marine environment, including high humidity, salt spray, and continuous vibration.

Our marine air compressors are available in single-stage and multi-stage configurations, optimized for efficiency and longevity. A key technical highlight is the maximum discharge pressure of up to 30 MPa, making them suitable for high-pressure applications such as subsea equipment testing and emergency shutdown systems. The compressors are equipped with precision-machined pistons, reinforced cylinder liners, and advanced sealing technology to maintain pressure integrity and minimize leakage over extended operational cycles. Flow rate options range from 0.5 m³/min to 10 m³/min, allowing customization based on vessel size and air demand profiles. This scalability ensures optimal integration with auxiliary systems on commercial vessels, offshore platforms, and naval craft.

Cooling is achieved through a forced water-cooling system, which maintains stable operating temperatures even under continuous duty. The water-cooled intercoolers and aftercoolers enhance efficiency by reducing air temperature between stages, thereby increasing volumetric efficiency and minimizing moisture carryover. An integrated moisture separator and coalescing filter further ensure clean, dry air output, critical for sensitive pneumatic components. The compressors are driven by marine-duty electric motors rated IP55 or higher, with optional diesel engine drives for backup or remote applications.

Noise and vibration are mitigated through elastomeric mounts and acoustic enclosures, contributing to a quieter engine room environment. All models feature a centralized control panel with digital monitoring of pressure, temperature, and operating hours, along with automatic shutdown protection in case of overpressure, overheating, or low lubrication.

Below is a summary of key technical parameters for standard models:

| Parameter | Specification Range |

|---|---|

| Discharge Pressure | Up to 30 MPa (4350 psi) |

| Flow Rate (FAD) | 0.5 – 10 m³/min |

| Stages | 2 or 3 stage |

| Cooling Method | Forced water-cooling with intercooler |

| Drive Type | Electric motor (IEC standard), optional diesel |

| Lubrication System | Splash and pressure lubrication |

| Air Outlet Temperature | ≤ ambient + 15°C after aftercooler |

| Noise Level | ≤ 85 dB(A) at 1 meter |

| Protection Class (Motor) | IP55 or higher |

| Certifications | CCS, ABS, DNV, LR, ISO 8573 |

These technical specifications reflect Hangzhou Star Marine Technology’s commitment to delivering robust, high-performance marine air compressors tailored for global maritime applications.

Shipbuilding Solutions

Marine Air Compressor Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine air compressor systems tailored for global shipbuilding and repair operations. Our expertise ensures seamless integration into new vessel construction and rapid restoration of critical pneumatic functions during dry-dock repairs. As a certified manufacturer under ISO 9001:2015 and SOLAS Chapter II-1 compliance frameworks, we prioritize reliability, regulatory adherence, and operational efficiency across all project phases.

Integrated New Build Support

For shipyards, we provide end-to-end compressor package engineering from initial design to sea trial validation. Our technical team collaborates directly with naval architects to optimize compressor selection based on vessel type, deck machinery requirements, and engine room constraints. This includes 3D modeling for spatial verification, vibration analysis, and noise mitigation planning. All systems undergo factory acceptance testing (FAT) per ABS, DNV-GL, or LR standards, ensuring zero rework during installation. Our modular skid-mounted designs reduce on-site commissioning time by up to 40%, accelerating vessel delivery schedules without compromising safety margins.

Rapid Repair and Retrofit Capability

In repair scenarios, downtime equates to significant revenue loss. Star Marine maintains strategic inventory hubs in Shanghai, Rotterdam, and Singapore, enabling 72-hour global dispatch for critical spares. Our field service engineers deploy within 24 hours of call-off to diagnose failures, perform root-cause analysis, and execute repairs using OEM-certified components. We specialize in legacy system retrofits, upgrading obsolete compressors to energy-efficient models while retaining existing piping interfaces. This approach minimizes dry-dock extension risks and extends asset lifecycle through predictive maintenance planning.

Technical Specifications at a Glance

The table below summarizes our standard marine air compressor offerings for immediate deployment:

| Parameter | Range/Value | Compliance Standard |

|---|---|---|

| Pressure Capacity | 30–40 bar | SOLAS II-1/42.1 |

| Air Flow Rate | 20–500 m³/h | ISO 1217 Annex C |

| Drive Type | Electric (IE3/IE4), Diesel, PTO | IEC 60034-30 |

| Cooling Method | Freshwater/Jacketed | ISO 8528-10 |

| Certifications | ABS, DNV, LR, BV, CCS, RINA | IMO MSC.338(91) |

| Customization | Explosion-proof (ATEX), Marine Coatings | IEC 60079-0 |

Export Execution Excellence

Our export management protocol guarantees documentation precision for customs clearance in 180+ countries, including type-specific marine declarations and certificate of origin validation. All units ship with multilingual operation manuals, 3D CAD files, and IoT-ready monitoring interfaces for remote performance tracking. For urgent repair cases, we leverage bonded warehouse networks to bypass port delays, ensuring compressors reach vessels before dry-dock deadlines.

Partner with Hangzhou Star Marine Technology to transform air compressor procurement from a logistical hurdle into a strategic advantage. Our engineering rigor and responsive export framework deliver operational continuity for new builds and repairs—anywhere, anytime. Contact our export team for project-specific technical dossiers and lead time confirmation.

Packaging & Logistics

All marine air compressors supplied by Hangzhou Star Marine Technology Co., Ltd. are packaged to meet international export standards, ensuring safe and secure transportation under diverse maritime and overland shipping conditions. The packaging design prioritizes equipment protection during handling, transit, and storage, while complying with global phytosanitary regulations for wooden materials.

For standard export shipments, marine air compressors are enclosed in custom-engineered wooden cases constructed from high-grade plywood or solid timber. These cases conform to ISPM 15 (International Standards for Phytosanitary Measures No. 15), which mandates that all wood packaging material crossing international borders must be heat-treated to eliminate pests and pathogens. Each wooden case is stamped with the official ISPM 15 mark, certifying compliance with the standard. The interior of the case includes shock-absorbing materials such as foam padding or rubber mounts to minimize vibration impact, and all compressor components are sealed in moisture-resistant polyethylene film to prevent corrosion during ocean transit.

In applications where enhanced structural support is required—particularly for larger or high-capacity marine air compressors—steel pallets are utilized. These pallets are fabricated from galvanized or powder-coated steel to resist rust and provide long-term durability. Units are securely fastened to the pallet using industrial-grade straps or bolted fixtures, ensuring zero displacement during loading and unloading operations. Steel pallets are ideal for containerized freight and are fully compatible with forklift handling at ports and terminals.

Hangzhou Star Marine Technology coordinates all export logistics through the major Chinese shipping hubs of Ningbo and Shanghai. Both ports offer world-class container terminal facilities, direct access to global shipping lines, and efficient customs clearance procedures. Our logistics partners are experienced in handling marine equipment shipments and ensure timely documentation, including packing lists, certificates of origin, and compliance certifications. Standard container sizes used are 20-foot and 40-foot dry or high-cube containers, depending on order volume and compressor model dimensions.

The following table outlines the standard packaging and logistics specifications for our marine air compressors:

| Parameter | Specification |

|---|---|

| Packaging Type | ISPM 15-compliant wooden cases; optional steel pallets for heavy-duty units |

| Wood Treatment | Heat-treated and stamped per ISPM 15 standards |

| Internal Protection | Foam padding, rubber mounts, moisture barrier film |

| Securing Method | Bolted or strapped to base; internal bracing as needed |

| Pallet Material (if used) | Galvanized or powder-coated steel |

| Export Ports | Ningbo Port and Shanghai Port, China |

| Container Types | 20-foot and 40-foot dry or high-cube containers |

| Handling Compatibility | Forklift and crane-ready design |

All packaging configurations are designed to meet or exceed IEC and IMO guidelines for the transport of critical marine machinery. Hangzhou Star Marine Technology ensures that every shipment arrives at its destination in optimal condition, ready for installation and operation.

Contact Star Marine

Contact Star Marine for Expert Marine Air Compressor Solutions

Hangzhou Star Marine Technology Co., Ltd. stands at the forefront of marine air compressor innovation, delivering systems engineered to meet the rigorous demands of global maritime operations. Our compressors are meticulously designed for reliability, efficiency, and compliance with international maritime regulations, including SOLAS Chapter II-1, IMO MEPC resolutions, and ISO 8573 standards for compressed air purity. Whether for main propulsion starting, deck machinery, or critical safety systems, our solutions ensure uninterrupted vessel performance across diverse operational profiles—from offshore support vessels to deep-sea cargo carriers. Partnering with Star Marine means accessing not only cutting-edge technology but also dedicated engineering support that anticipates the unique challenges of marine environments, such as saltwater corrosion resistance, vibration tolerance, and compact space integration.

Our engineering team provides comprehensive technical consultation from initial specification through installation and lifecycle maintenance. We understand that compressor selection directly impacts vessel safety, operational uptime, and fuel efficiency. This is why we prioritize collaborative engagement with shipyards, owners, and classification societies to tailor solutions that align with project timelines, regulatory frameworks, and performance benchmarks. All Star Marine compressors undergo stringent factory acceptance testing (FAT) per ABS, DNV, LR, or CCS protocols, with full documentation packages including material certificates, pressure test reports, and noise/vibration analysis. For export projects, our export management team ensures seamless logistics coordination, INCOTERMS 2020 compliance, and customs documentation accuracy to minimize port delays and demurrage risks.

To facilitate your procurement process, we provide immediate access to detailed technical specifications and compatibility assessments. The table below outlines key parameters for our standard marine air compressor series, serving as a preliminary reference for system integration planning.

| Compressor Type | Capacity Range (m³/min) | Pressure Rating (bar) | Compliance Standards | Typical Application |

|---|---|---|---|---|

| Reciprocating (Oil-Lub) | 0.5 – 5.0 | 30 – 35 | SOLAS, ISO 8573-1 Class 1 | Main Engine Starting |

| Screw (Oil-Free) | 1.0 – 20.0 | 25 – 30 | IMO MSC.338(91), ISO 8573-1 Class 0 | Deck Machinery, Pneumatic Tools |

| Portable Emergency | 0.3 – 1.5 | 35 | SOLAS II-2/4.2.1, MED | Lifeboat Systems, Emergency Air |

Initiate your procurement process by contacting Kacher YE, our Product Manager for Marine Air Compressors, who combines 12 years of marine engineering expertise with direct oversight of global export operations. Mr. YE leads technical validation, quotation structuring, and post-sale support coordination, ensuring alignment between your operational requirements and Star Marine’s engineering capabilities. He will promptly provide customized performance curves, 3D mounting diagrams, and lifecycle cost analysis to support your decision-making. For urgent project timelines or complex retrofit scenarios, his team offers expedited technical review within 24 business hours.

Do not navigate marine compressor procurement without expert guidance. Email Kacher YE directly at [email protected] to request a project-specific technical dossier or schedule a virtual engineering consultation. Include your vessel type, required capacity, and applicable class society for a prioritized response. Star Marine’s commitment to engineering excellence and export efficiency begins with a single point of contact—reach out today to secure a solution engineered for the sea.

[email protected]

Product Manager | Marine Air Compressors | Hangzhou Star Marine Technology Co., Ltd.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160