Tugger Winch – Marine Solution Guide 2025

Content Navigation

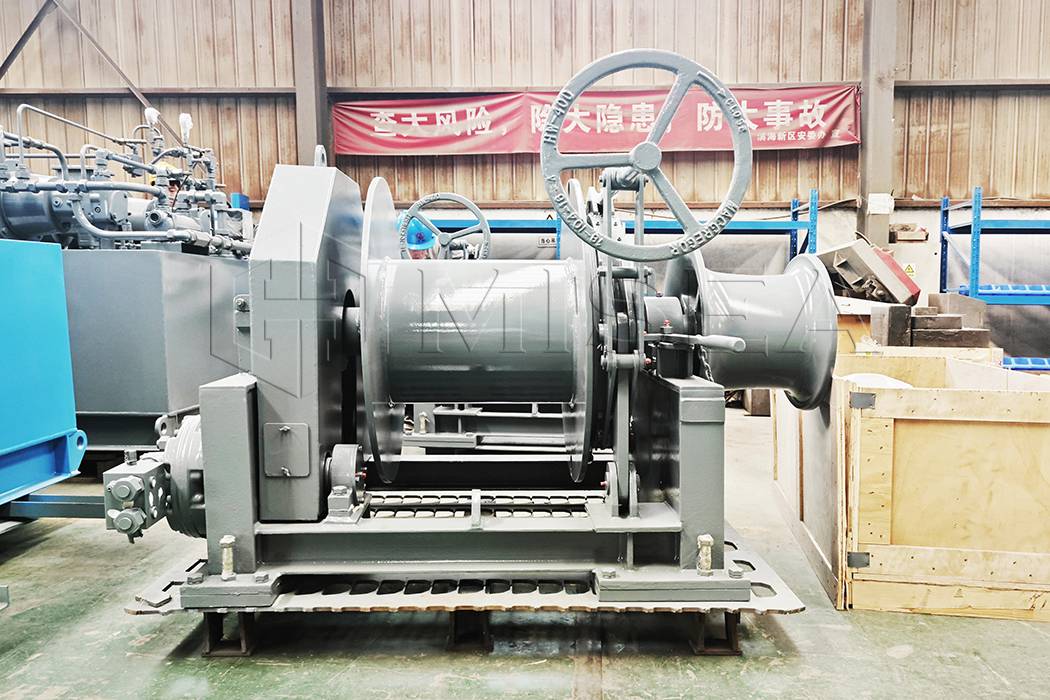

Marine Insight: Tugger Winch

The tugger winch is a critical component of modern deck machinery systems, playing a vital role in ensuring vessel safety and operational efficiency across a wide range of maritime applications. Designed to provide controlled pulling force for mooring, towing, and positioning operations, tugger winches are commonly deployed on offshore support vessels, tugboats, fishing vessels, and workboats. Their compact design and high mechanical advantage make them ideal for auxiliary pulling tasks where space is limited but reliable performance is essential. In emergency situations, such as man-overboard recovery or emergency towing, tugger winches provide rapid response capability, directly contributing to crew safety and vessel integrity.

From a safety perspective, tugger winches are engineered to meet stringent marine standards, including compliance with classification societies such as CCS, ABS, DNV, and LR. These winches are built with robust braking systems, fail-safe mechanisms, and overload protection to prevent cable snap-back and mechanical failure under stress. The integration of advanced drum alignment and rope tension control systems ensures smooth operation, minimizing wear on synthetic or wire ropes and reducing the risk of operational accidents. Moreover, the use of corrosion-resistant materials and marine-grade coatings enhances durability in harsh saltwater environments, ensuring long-term reliability even under continuous duty cycles.

Hangzhou Star Marine Technology Co., Ltd. has established itself as a trusted manufacturer and exporter of high-performance tugger winches within the global marine supply chain. Our engineering team applies ISO 9001-certified quality management practices to every stage of production, from material sourcing to final testing. Each tugger winch undergoes rigorous load testing, dynamic braking verification, and environmental stress screening to ensure compliance with international maritime regulations. This commitment to quality ensures that our equipment supports safe and uninterrupted vessel operations worldwide.

In addition to superior engineering, sourcing tugger winches from Star Marine China offers significant cost advantages without compromising performance or safety. Our vertically integrated manufacturing process and strategic location in Hangzhou enable optimized production efficiency and reduced lead times. By maintaining direct control over casting, machining, and assembly, we eliminate intermediary markups and pass the savings directly to our clients. The following table outlines a comparative analysis of key performance and cost parameters:

| Parameter | Star Marine Tugger Winch | Average Market Equivalent |

|---|---|---|

| Breaking Load Capacity (kN) | 80 | 75 |

| Drum Capacity (m of 16mm wire) | 120 | 100 |

| Motor Power (kW) | 15 | 11 |

| Classification Certification | ABS, CCS, DNV | CCS only |

| Average Lead Time (weeks) | 6 | 10 |

| FOB Price (USD) | $8,200 | $9,500 |

This combination of enhanced performance, comprehensive certification, and competitive pricing positions Hangzhou Star Marine Technology as a preferred partner for cost-conscious yet safety-driven maritime operators. By investing in tugger winches from our facility, vessel owners and operators gain access to reliable, export-ready deck machinery that supports both operational safety and financial efficiency.

Technical Specs & Approval

Technical Specifications: Tugger Winch Series

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures precision-engineered tugger winches for demanding deck operations, including mooring, towing, and anchor handling across commercial vessels, offshore support craft, and naval applications. Our winches prioritize operational safety, durability in harsh marine environments, and seamless integration with vessel deck layouts. Key technical parameters are rigorously validated against ISO 13779 and classification society requirements to ensure global compliance and reliability. The following table details standard specifications for our modular tugger winch range, engineered for adaptability to diverse operational profiles.

| Parameter | Specification Range | Notes |

|---|---|---|

| Pull Load (Static) | 50 kN to 1000 kN | Custom configurations beyond 1000 kN available |

| Chain Diameter | 12.5 mm to 60 mm | Compatible with Stud Link Anchor Chain (ISO 1704) |

| Drive System | Electric (AC/DC) or Hydraulic | Electric: IE3/IE4 motors; Hydraulic: Radial piston motors |

| Line Pull Speed | 10 m/min to 30 m/min (variable) | Speed adjustable via control system |

| Drum Capacity | 50 m to 500 m (chain/wire) | Custom drum geometries per vessel layout |

| Braking System | Fail-safe hydraulic disc brake | 1.5x MBL holding capacity; SOLAS compliant |

| Classification | ABS, DNV, LR, BV, CCS, RINA | Full certification documentation provided |

| Environmental Rating | IP56 (standard); IP66 (optional) | Corrosion protection: Hot-dip galvanized or marine-grade epoxy coating |

Chain diameter compatibility spans 12.5 mm to 60 mm, accommodating standard anchor chain sizes for vessels from small workboats to large offshore units. Our winches integrate robust chain stoppers and wildcat gears engineered for precise chain engagement, minimizing wear and slippage during high-load operations. The drive system selection—electric or hydraulic—is determined by vessel power architecture and duty cycle requirements. Electric variants utilize high-efficiency motors with VFD control for smooth acceleration and energy optimization, while hydraulic models deliver exceptional torque density and overload tolerance, ideal for dynamic towing scenarios.

All winches feature a fully enclosed gearbox with forced lubrication, ensuring consistent performance under continuous operation. The fail-safe hydraulic disc brake system engages automatically upon power loss, meeting stringent SOLAS safety mandates for critical deck machinery. Drum capacity is configurable based on vessel-specific chain storage needs, with options for single or multi-layer spooling. Structural components are fabricated from high-tensile steel (S355 minimum), subjected to non-destructive testing (NDT) per EN 1090 standards.

Compliance with ABS MODU Code, DNV-ST-N001, and ISO 13779 is integral to our design process. Each unit undergoes 100% factory acceptance testing (FAT), including 1.25x MBL static load verification and dynamic cycle testing. Control interfaces support integration with centralized deck machinery control systems (DMCS) via CAN bus, Profibus, or analog signals. Hangzhou Star provides comprehensive technical support, including 3D installation drawings, load analysis reports, and classification society liaison services to facilitate seamless vessel integration and regulatory approval. Our commitment to ISO 9001:2015 quality management ensures every tugger winch meets the highest maritime engineering standards for global export.

Shipbuilding Solutions

Comprehensive Tugger Winch Solutions for Shipbuilding and Repair by Hangzhou Star Marine Technology

Hangzhou Star Marine Technology Co., Ltd. specializes in the design, manufacturing, and global export of high-performance deck machinery, with a focused expertise in tugger winches for shipbuilding and vessel repair applications. As a trusted partner in the maritime industry, we deliver engineered solutions that ensure operational efficiency, safety, and compliance with international standards such as ISO, CCS, ABS, DNV, and LR. Our integrated approach supports shipyards and repair facilities with fast response times, technical precision, and end-to-end project management.

Tugger winches are critical components in shipboard operations, used primarily for line handling, mooring adjustments, and positioning during docking or cargo operations. At Star Marine, we understand the demanding environments these winches operate in, which is why our designs emphasize durability, compact integration, and ease of maintenance. Whether for new vessel construction or retrofit projects, our tugger winches are customized to match vessel specifications, deck layouts, and operational requirements.

For new shipbuilding projects, we collaborate closely with naval architects and shipyards from the early design phase. Our engineering team provides load calculations, foundation drawings, hydraulic or electric drive integration, and 3D modeling support to ensure seamless installation. We offer both electric and electro-hydraulic models, with capacities ranging from 5 kN to 50 kN, suitable for a wide range of vessel types including offshore support vessels, tugboats, ferries, and cargo ships.

In repair and retrofit scenarios, Star Marine delivers rapid turnaround solutions. Our global service network enables on-site assessments, failure analysis, and replacement unit deployment within compressed timelines. We maintain a strategic inventory of standard models and spare parts, ensuring minimal downtime for vessel operators. Additionally, our winches are designed for backward compatibility, allowing upgrades without extensive deck modifications.

All tugger winches are manufactured in our ISO-certified facility using high-tensile steel, marine-grade corrosion protection, and tested sealing systems for harsh offshore conditions. Each unit undergoes rigorous performance testing, including load brake tests, endurance cycles, and environmental exposure simulations.

The following table outlines key technical specifications of our standard tugger winch series:

| Model | Rated Line Pull (kN) | Rope Capacity (m) | Drum Speed (m/min) | Power Source | Approvals |

|---|---|---|---|---|---|

| SM-TW-05 | 5 | 100 | 15 | Electric | CCS, ABS |

| SM-TW-10 | 10 | 120 | 12 | Electro-Hydraulic | DNV, LR |

| SM-TW-20 | 20 | 150 | 10 | Electro-Hydraulic | ABS, LR |

| SM-TW-30 | 30 | 180 | 8 | Electric | CCS, DNV |

| SM-TW-50 | 50 | 200 | 6 | Electro-Hydraulic | ABS, DNV, LR |

With a commitment to innovation and reliability, Hangzhou Star Marine Technology ensures that every tugger winch meets the exacting demands of modern maritime operations. From concept to commissioning, we provide a complete, responsive, and technically superior solution for shipbuilders and repair yards worldwide.

Packaging & Logistics

Packaging & Logistics Protocol for Tugger Winch Exports

Hangzhou Star Marine Technology implements rigorously defined packaging and logistics procedures for all tugger winch exports, ensuring compliance with international maritime standards and safeguarding equipment integrity throughout global transit. Our methodology prioritizes protection against mechanical shock, vibration, moisture ingress, and environmental exposure during extended sea voyages, adhering strictly to the requirements of the International Plant Protection Convention (IPPC) and major port authorities. All wooden packaging components are manufactured and treated in full conformity with ISPM 15 regulations. This mandates heat treatment of solid wood to a minimum core temperature of 56°C for at least 30 minutes, eliminating pest risks. Each wooden crate or dunnage piece bears the official, legible ISPM 15 stamp indicating the national plant protection organization, producer code, and HT (Heat Treated) certification. We utilize only kiln-dried, high-grade plywood or hardwood lumber meeting moisture content specifications to prevent warping or fungal growth. Steel pallets form the foundational structural element for heavier winch units, providing critical rigidity and facilitating secure lashing points compatible with vessel securing systems. These pallets are constructed from marine-grade steel, hot-dip galvanized for corrosion resistance, and engineered to withstand dynamic loads exceeding 150% of the winch’s operational weight during transit stresses.

Internal packaging employs a multi-layer strategy. Winches are meticulously coated with vapor corrosion inhibitors (VCI) and sealed within heavy-duty polyethylene moisture barriers. Critical components, including hydraulic units, electrical panels, and control systems, receive additional protective wrapping with anti-static and desiccant-treated materials. Precision-machined surfaces are safeguarded with specialized grease coatings and non-abrasive covers. Bracing within the wooden crate utilizes custom-fitted timber dunnage secured with steel strapping, immobilizing the winch assembly completely to prevent any movement during handling or rough seas. Desiccant packs are strategically placed within the sealed enclosure to maintain a low-humidity microclimate. The final packaged unit undergoes comprehensive lashing point verification and load distribution analysis prior to shipment release.

Export operations are executed through China’s premier maritime gateways, Ningbo-Zhoushan Port and Shanghai Port. Both facilities offer exceptional infrastructure for heavy lift and project cargo, featuring deep-water berths, specialized roll-on/roll-off (RoRo) capabilities, and seamless integration with major global shipping lines. Our logistics partners are pre-vetted for expertise in handling marine deck machinery, ensuring adherence to SOLAS lashing requirements and efficient port turnaround. Documentation, including the ISPM 15 certificate, packing list, and detailed stowage plan, is meticulously prepared to expedite customs clearance at origin and destination ports. This integrated approach minimizes transit risks and guarantees the tugger winch arrives at the vessel or end-client site in optimal operational condition, ready for immediate installation.

Tugger Winch Packaging Specifications

| Component | Specification | Purpose |

|---|---|---|

| Primary Structure | ISPM 15 Certified Heat Treated Plywood/Hardwood | Pest-free, dimensionally stable outer protection; meets global phytosanitary standards |

| Base Platform | Galvanized Steel Pallet (Min. 150% SWL capacity) | Provides structural rigidity, secure lashing points, and ground clearance |

| Internal Bracing | Custom-Fit Timber Dunnage w/ Steel Strapping | Immobilizes winch assembly; absorbs dynamic loads during transit |

| Moisture Control | VCI Film + Polyethylene Barrier + Desiccant Packs | Prevents corrosion; maintains low humidity within sealed environment |

| Critical Parts | Anti-Static Wrap + Desiccant + Protective Covers | Shields sensitive electrical/hydraulic components from ESD and moisture |

| External Marking | Weather-Resistant Labels (Handling, Orientation) | Ensures correct stowage, handling, and identification per IMDG/SOLAS |

Contact Star Marine

For marine operators, shipbuilders, and offshore project managers seeking high-performance deck machinery solutions, Hangzhou Star Marine Technology Co., Ltd. stands at the forefront of innovation and reliability in marine equipment engineering. As a specialized manufacturer in deck machinery, we deliver engineered-to-order tugger winches designed to meet the rigorous demands of modern maritime operations. Our tugger winches are built for durability, precision control, and seamless integration across a wide range of vessel types—including offshore support vessels, tugboats, research ships, and floating cranes.

At Star Marine, we understand that selecting the right tugger winch involves more than just technical specifications—it requires a partnership with a manufacturer who understands operational challenges, regulatory compliance, and lifecycle performance. Our engineering team applies decades of maritime industry experience to deliver winches with optimized drum capacity, line pull, and braking systems, ensuring safe and efficient handling of mooring lines, towing hawsers, and auxiliary loads.

All our tugger winches are manufactured in compliance with international marine standards, including ISO 15036, IACS, and DNV-GL classification requirements. We utilize high-grade marine steel, precision gearboxes, and fail-safe braking mechanisms to ensure long-term reliability under extreme environmental conditions. Customization options include electric, hydraulic, or electro-hydraulic drive systems, remote control integration, and corrosion-resistant coatings for offshore deployment.

To ensure a seamless procurement and integration process, we provide comprehensive technical documentation, 3D modeling support, factory acceptance testing (FAT), and on-site commissioning assistance. Our global service network ensures responsive support, spare parts availability, and after-sales engineering consultation.

For project-specific inquiries, technical consultations, or to request a detailed quotation for your tugger winch requirements, we encourage direct engagement with our Product Manager, Kacher YE. With in-depth knowledge of marine winch systems and export logistics, Kacher serves as the primary technical liaison for international clients, ensuring clarity, accuracy, and timely follow-up throughout the procurement cycle.

Below is an overview of standard tugger winch specifications available for customization:

| Parameter | Standard Range |

|---|---|

| Line Pull | 5 – 50 tons |

| Rope Capacity | 100 – 500 meters |

| Drum Diameter | 400 – 1200 mm |

| Drive Type | Electric, Hydraulic, Electro-Hydraulic |

| Control System | Local + Remote (optional PLC) |

| Classification | DNV-GL, ABS, LR, BV, CCS, RINA |

| Operating Environment | -25°C to +50°C, Marine Grade |

Contact Kacher YE directly at [email protected] to discuss your project requirements, request performance curves, or schedule a technical review. At Hangzhou Star Marine Technology, we are committed to delivering engineered excellence—connect with us to power your next marine operation with confidence.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160