Accommodation Ladder – Marine Solution Guide 2025

Content Navigation

Marine Insight: Accommodation Ladder

Marine Industry Demand for Accommodation Ladders

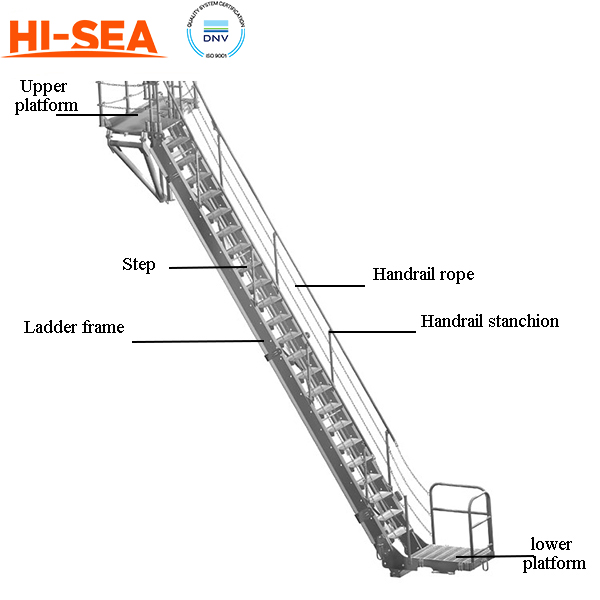

Accommodation ladders are critical marine outfittings that ensure safe and reliable access between vessels and shore facilities, especially during port calls, crew changes, and emergency evacuations. These ladders are typically installed on the ship’s side to bridge the gap between the deck and the dock or pilot boat, operating effectively across varying tidal conditions and vessel drafts. Their structural integrity, compliance with international safety standards, and ease of deployment make them indispensable in modern maritime operations.

Safety remains the foremost concern in the marine industry, and the accommodation ladder plays a pivotal role in mitigating risks associated with personnel transfer. A poorly designed or substandard ladder can lead to slips, falls, or even catastrophic accidents, particularly in adverse weather or rough sea conditions. International regulations, including SOLAS (International Convention for the Safety of Life at Sea) Chapter II-1 and Chapter V, mandate strict design and operational criteria for accommodation ladders. These include load-bearing capacity, non-slip treads, handrails, inclination angles, and corrosion resistance. Compliance with such standards ensures not only regulatory approval but also the protection of crew, passengers, and port personnel.

Hangzhou Star Marine Technology Co., Ltd. specializes in the design, manufacturing, and export of high-performance accommodation ladders tailored to meet global maritime requirements. Our products are engineered using marine-grade aluminum alloy or stainless steel, offering exceptional durability, lightweight handling, and resistance to saltwater corrosion. Each ladder undergoes rigorous load testing, non-destructive examination, and quality assurance protocols in accordance with ISO 9001 and recognized classification societies such as CCS, ABS, DNV, and LR.

Sourcing accommodation ladders from Star Marine China presents a significant cost advantage without compromising on quality. China’s advanced manufacturing infrastructure, combined with our vertically integrated production process, allows us to deliver premium marine outfittings at competitive pricing. Our strategic location in Hangzhou provides efficient access to major ports such as Ningbo-Zhoushan and Shanghai, ensuring timely delivery and reduced logistics expenses. Additionally, our in-house engineering team supports customization based on vessel specifications, including telescopic designs, hydraulic stabilization systems, and folding mechanisms for compact storage.

The following table outlines key technical and economic advantages of Star Marine’s accommodation ladders compared to industry benchmarks:

| Feature | Star Marine Accommodation Ladder | Industry Average |

|---|---|---|

| Material Options | Marine-grade aluminum, stainless steel | Mild steel with coating |

| Load Capacity | Up to 3,000 kg (SOLAS compliant) | 2,000–2,500 kg |

| Corrosion Resistance | High (passivated surfaces, sealed joints) | Moderate (requires frequent maintenance) |

| Customization Lead Time | 4–6 weeks | 8–12 weeks |

| FOB Price (Standard 3.5m x 1.2m) | $8,500–$10,500 | $11,000–$14,000 |

| Classification Society Certification | Full compliance (CCS, ABS, DNV, LR, etc.) | Varies by supplier |

By combining regulatory compliance, structural reliability, and economic efficiency, Hangzhou Star Marine Technology delivers accommodation ladders that enhance vessel safety while optimizing procurement costs for shipowners and operators worldwide.

Technical Specs & Approval

Technical Specifications: Accommodation Ladder Systems

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures SOLAS-compliant accommodation ladders meeting stringent global maritime safety standards. Our systems prioritize structural integrity, operational reliability, and seamless integration with vessel superstructures. Material selection is critical for performance and longevity, with options tailored to vessel type, operational profile, and environmental exposure. Aluminum alloy (typically 6082-T6 or 5083 marine grade) is standard for offshore supply vessels, yachts, and passenger ships due to its high strength-to-weight ratio, inherent corrosion resistance, and reduced deck load. For heavy-duty applications on tankers, bulk carriers, or naval vessels, hot-dip galvanized structural steel (S355JR or equivalent) is deployed, offering superior impact resistance and load capacity. All aluminum components undergo rigorous anodization or powder coating, while steel variants feature multi-coat epoxy/polyurethane systems per ISO 12944 C5-M standards.

Watertight integrity of the embarkation platform and associated deck penetrations is non-negotiable. Our ladder systems incorporate SOLAS II-1/20-1 compliant sealing mechanisms, utilizing EPDM or nitrile rubber gaskets rated for continuous immersion and temperature ranges from -25°C to +70°C. Platform coamings integrate drainage scuppers with non-return valves to prevent water ingress during pitching. Each unit undergoes factory hydrostatic testing at 0.05 MPa for 30 minutes, with zero leakage tolerance. Certification documentation includes pressure test reports traceable to serial numbers, verified by recognized classification societies (DNV, LR, ABS, etc.).

Dimensions adhere to SOLAS Chapter II-1, Regulation 20, mandating minimum clear width (570 mm), tread depth (85 mm), and handrail height (1,000 mm above treads). Vertical drop ranges from 3.5 m to 12 m, with intermediate landings required for drops exceeding 6 m. Tread spacing is fixed at 250–300 mm to prevent slippage. Custom configurations accommodate vessel-specific freeboard variations, including telescopic sections for tidal differentials up to 10 m. Stowage dimensions are optimized for minimal deck footprint, with folded heights typically ≤ 2.8 m. All moving parts (winches, davits, hinges) comply with ISO 30081 for marine ladder mechanisms, ensuring smooth operation under 55 m/s wind loads.

Key technical parameters are summarized below:

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Material Options | Marine-grade Aluminum 6082-T6 / S355JR Steel | EN 573-3, EN 10025-2 |

| Load Capacity | 3.0 kN/m² (uniform), 1.5 kN point load | SOLAS II-1/20.4 |

| Watertight Test Pressure | 0.05 MPa for 30 minutes, zero leakage | ISO 15743 |

| Tread Dimensions | Min. 570 mm width, 85 mm depth, 250–300 mm spacing | SOLAS II-1/20.5.2 |

| Handrail Height | 1,000 mm above treads | ISO 14122-3 |

| Corrosion Protection | Anodization (Al) / HDG + 350μm epoxy (Steel) | ISO 12944 C5-M |

| Operating Temperature | -25°C to +55°C | IEC 60068-2 |

| Certification | Full Type Approval by Major Class Societies | SOLAS, ISO 30081 |

Hangzhou Star Marine Technology ensures all accommodation ladders undergo third-party witnessed FAT (Factory Acceptance Testing) per ISO 15743, including dynamic load testing, corrosion assessment, and operational cycle validation. Lead times for standard units are 8–10 weeks, with expedited fabrication available for critical projects. Comprehensive export documentation, including EU Marine Equipment Directive (MED) certificates and USCG approval packages, is provided to facilitate global customs clearance. Partner with us for solutions engineered to exceed maritime safety expectations while optimizing vessel operational efficiency.

Shipbuilding Solutions

Comprehensive Accommodation Ladder Solutions for Shipbuilding and Repair by Hangzhou Star Marine Technology

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine outfittings solutions tailored for modern shipbuilding and repair operations. As a trusted partner in the maritime industry, we specialize in accommodation ladders that meet stringent international safety, load, and durability standards. Our end-to-end service model ensures seamless integration from design and manufacturing to certification and global delivery, supporting shipyards and repair facilities with fast response times and technical precision.

Accommodation ladders are critical marine access systems, enabling safe embarkation and disembarkation between vessel and shore. At Star Marine, we design and fabricate ladders in compliance with SOLAS, ISO 7466, and classification society requirements including CCS, ABS, DNV, LR, and BV. Our engineering team works closely with shipbuilders and repair planners to customize solutions based on vessel type, freeboard height, deck configuration, and environmental conditions. Whether for new construction or retrofit applications, our ladders are built for long service life, corrosion resistance, and operational safety.

We offer both fixed and davit-launched accommodation ladders, constructed from high-grade aluminum alloy or marine-grade stainless steel, depending on client specifications and operational demands. All units feature non-slip treads, handrails with intermediate supports, and robust hinge mechanisms to ensure stability under variable load and sea conditions. For repair projects, we provide on-site assessment, reverse engineering, and rapid replacement services to minimize vessel downtime.

Our production facility in Hangzhou integrates CNC fabrication, precision welding, and rigorous quality control protocols. Each ladder undergoes load testing, dimensional verification, and surface finish inspection prior to shipment. We maintain an extensive inventory of standard models for urgent repair needs, while our agile manufacturing line supports custom builds with lead times as short as 15–20 days.

To support global logistics, Star Marine coordinates export packaging, customs documentation, and multimodal shipping, ensuring timely delivery to shipyards and dry docks worldwide. Our technical team also provides installation supervision and commissioning support when required.

Below is an overview of our standard accommodation ladder specifications:

| Parameter | Specification |

|---|---|

| Compliance Standards | SOLAS II-2/22, ISO 7466, CCS, ABS, DNV, LR, BV |

| Materials | Marine-grade aluminum alloy or 316 stainless steel |

| Load Capacity | 3 kN/m² (minimum), tested to 1.5x working load |

| Step Spacing | 300 mm (nominal), non-slip rubber inserts |

| Handrail Height | 1000 mm above step nosing |

| Working Angle Range | 45° to 60° from horizontal |

| Custom Freeboard Range | 2.5 m to 12 m |

| Certification | Available with full Class Society documentation |

| Lead Time (Custom) | 15–25 days from order confirmation |

| Packaging | Seaworthy, wooden crate with protective wrapping |

Hangzhou Star Marine Technology is committed to delivering reliable, code-compliant accommodation ladders that enhance vessel safety and operational efficiency. With technical expertise, fast turnaround, and global export readiness, we are the preferred outfittings partner for shipbuilders and repair yards worldwide.

Packaging & Logistics

Packaging & Logistics Protocol for Accommodation Ladders

Hangzhou Star Marine Technology implements rigorous packaging standards for accommodation ladders to ensure structural integrity and regulatory compliance during global transit. All wooden export packaging adheres strictly to International Standards for Phytosanitary Measures No. 15 (ISPM 15). This certification mandates heat treatment of solid wood components to a minimum core temperature of 56°C for 30 minutes, eliminating pest risks. Each wooden case bears the official ISPM 15 mark, including the IPPC logo, country code (CN), unique producer code, and treatment indicator (HT). Cases are constructed from kiln-dried hardwood or plywood with a minimum thickness of 18mm, reinforced with galvanized steel strapping at 300mm intervals. Internal bracing secures ladder sections against torsional stress, while moisture-resistant VCI paper wraps critical components to prevent corrosion.

For heavy-duty or custom-sized ladders exceeding 2,500 kg, we utilize ISO-standard steel pallets with a 5,000 kg dynamic load capacity. These pallets feature non-slip surfaces, integrated lifting points, and corrosion-resistant powder coating. Steel palletization eliminates wood treatment requirements, streamlining clearance for destinations with stringent phytosanitary regulations. All packaging configurations include shock-absorbing corner protectors and custom cradles to immobilize moving parts, preventing hydraulic or mechanical damage during vessel motion.

Shipments originate exclusively from China’s premier deep-water ports: Ningbo-Zhoushan Port (CODE: CNNBO) and Shanghai Port (CODE: CNSHA). Ningbo offers dedicated roll-on/roll-off (RoRo) facilities for oversized ladder assemblies, while Shanghai provides optimized container terminal access for standard configurations. Our logistics team coordinates pre-shipment inspections with SGS or Bureau Veritas, securing necessary certificates of origin and packing lists 72 hours prior to vessel departure. Standard lead time from factory readiness to port loading is 5–7 working days, inclusive of customs clearance documentation.

The following table summarizes key packaging specifications:

| Material Type | Key Features | Primary Applications |

|---|---|---|

| ISPM 15 Wooden Case | Heat-treated hardwood, VCI paper lining, steel strapping | Standard ladders ≤ 2,500 kg; global shipments to EU, Americas, Africa |

| Steel Pallet System | Powder-coated, 5T load capacity, integrated lifting eyes | Oversized/custom ladders > 2,500 kg; shipments to Australia, New Zealand, Japan |

Final packaging verification includes torque checks on all securing points and humidity-controlled sealing of desiccant packs. Each unit receives a tamper-evident security seal with unique serial numbering, cross-referenced in our digital export manifest. Lashings comply with CSS Code Annex 13 for securing heavy cargo on deck. Clients receive real-time shipment tracking via our integrated logistics portal, with proactive alerts for port congestion or weather delays. This end-to-end protocol ensures accommodation ladders arrive at destination ports fully operational, minimizing demurrage risks and meeting SOLAS Chapter VI stowage requirements.

Contact Star Marine

For maritime operators, shipbuilders, and offshore project managers seeking premium-grade accommodation ladders that meet stringent international safety and performance standards, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in marine outfittings. As a specialized manufacturer with deep expertise in naval architecture and offshore access solutions, we deliver robust, SOLAS-compliant accommodation ladders engineered for durability, ease of deployment, and long-term reliability across diverse vessel types and operational environments.

Our accommodation ladders are precision-fabricated using marine-grade aluminum alloy or corrosion-resistant steel, depending on client specifications and service conditions. Designed in accordance with ISO 3961, SOLAS Chapter II-1, and IMO A.1023(26) guidelines, each unit undergoes rigorous load testing, non-destructive examination, and weatherproofing procedures to ensure optimal performance under extreme marine exposure. Whether deployed on container vessels, offshore support vessels, LNG carriers, or floating production units, our ladders provide safe, stable, and code-compliant embarkation and disembarkation for crew, pilots, and service personnel.

At Hangzhou Star Marine Technology, we recognize that every vessel integration presents unique dimensional, load, and regulatory challenges. Our engineering team works closely with clients to customize ladder configurations, including platform dimensions, handrail geometry, hinge mechanisms, and anti-slip step treatments. Integration options include single or dual-ladder setups, telescopic designs, and davit-assisted deployment systems, all tailored to the ship’s freeboard, deck layout, and operational profile.

To support global clients throughout the procurement and installation lifecycle, we offer comprehensive technical documentation, 3D modeling support, factory acceptance testing (FAT), and on-site commissioning assistance. Our quality management system is certified to ISO 9001:2015, and all products are supplied with full material traceability, third-party inspection reports (including CCS, ABS, DNV, or LR upon request), and a standard 24-month warranty.

For detailed technical specifications, custom design consultation, or project quotation, we invite you to contact our dedicated Product Manager, Kacher YE, who brings over a decade of experience in marine access systems and export logistics. Mr. Ye serves as the primary liaison for international clients and ensures seamless coordination from initial inquiry to final delivery.

Below are key technical parameters commonly associated with our standard accommodation ladder series:

| Parameter | Specification |

|---|---|

| Material Options | Marine-grade aluminum alloy, galvanized steel |

| Step Type | Extruded aluminum or checkered steel with anti-slip coating |

| Working Load Capacity | 3.0 kN uniformly distributed load |

| Platform Size (Standard) | 1.2 m x 1.2 m or customized |

| Inclination Angle | Adjustable between 45° and 55° |

| Compliance Standards | SOLAS, ISO 3961, IMO A.1023(26) |

| Certification Availability | CCS, ABS, DNV, LR, BV (upon request) |

| Corrosion Protection | Hot-dip galvanizing or powder coating |

To initiate a technical discussion or request a project-specific proposal, please contact Kacher YE directly at [email protected]. We respond to all inquiries within 12 business hours and support communication in English, Mandarin, and Spanish. Partner with Hangzhou Star Marine Technology for engineered access solutions that meet the highest benchmarks in marine safety and operational excellence.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160