Black Painting Anchor Chain – Marine Solution Guide 2025

Content Navigation

Marine Insight: Black Painting Anchor Chain

Marine Industry Demand for Black Painting Anchor Chain

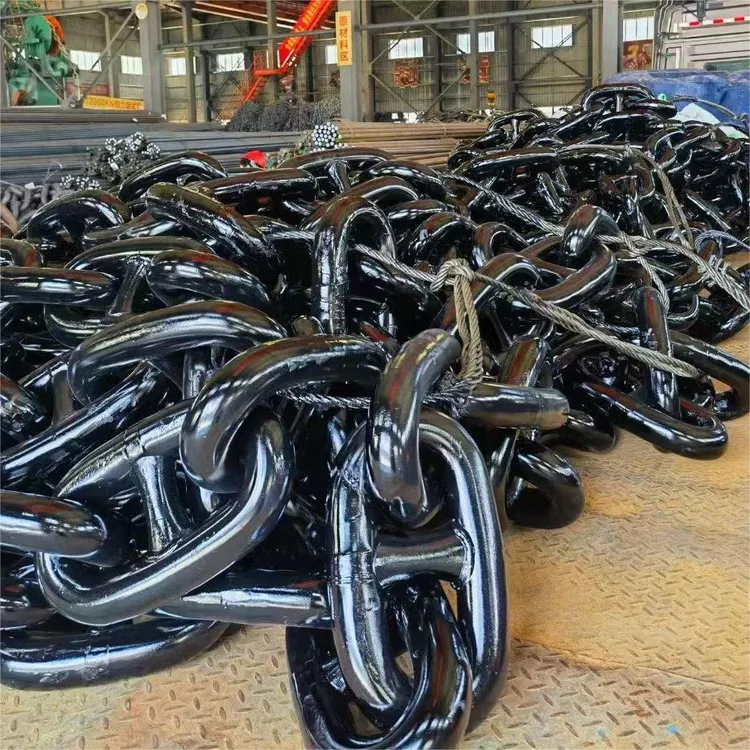

The black painting anchor chain is a critical component in marine anchoring systems, playing a pivotal role in ensuring vessel safety during mooring, anchoring, and offshore operations. As vessels grow larger and operate in increasingly challenging maritime environments, the demand for reliable, corrosion-resistant, and high-strength anchor chains has intensified. The black paint coating applied to these chains serves both functional and protective purposes. It acts as a preliminary anti-corrosion barrier, shielding the underlying steel from saltwater exposure, humidity, and atmospheric degradation during storage and transportation. This protective layer also facilitates visual inspection, allowing crew and surveyors to detect wear, pitting, or coating breakdown before operational deployment.

In commercial shipping, offshore platforms, and fishing vessels, the integrity of the anchoring system directly impacts operational safety and regulatory compliance. A failure in the anchor chain can lead to drifting, collisions, or grounding—events that pose significant environmental, financial, and human risks. The black painting anchor chain, typically manufactured from high-tensile steel grades such as Grade R3, R3S, or R4, is engineered to meet international standards including ISO 1704, ISO 1834, and the classification society rules of ABS, DNV, LR, and CCS. These standards govern mechanical properties, dimensional accuracy, and traceability, ensuring that every chain link can withstand extreme loads and dynamic stresses encountered at sea.

Sourcing black painting anchor chains from Hangzhou Star Marine Technology Co., Ltd. offers a strategic advantage in terms of cost-efficiency without compromising quality. As a specialized marine equipment manufacturer based in China, Star Marine leverages advanced production technologies, economies of scale, and streamlined supply chain logistics to deliver competitively priced anchoring solutions. Our manufacturing process includes controlled forging, heat treatment, and precision welding, followed by rigorous testing such as tensile strength verification, hardness checks, and non-destructive examination. Each chain is marked with identification codes for full traceability and compliance documentation.

Additionally, China’s robust industrial infrastructure and access to high-quality raw materials contribute to reduced production costs, which are passed on to global clients. Star Marine maintains long-term partnerships with steel suppliers and classification societies, ensuring consistent product conformity and faster delivery times. With an export network spanning Southeast Asia, the Middle East, Africa, and Europe, we provide tailored packaging, international certification support, and technical consultation to meet diverse client requirements.

The following table outlines key specifications and advantages of Star Marine’s black painting anchor chain offerings:

| Parameter | Specification |

|---|---|

| Material Grade | R3, R3S, R4 (ISO 1704 compliant) |

| Diameter Range | 16 mm – 130 mm |

| Coating Type | Black anti-rust paint (temporary protection) |

| Certification | ABS, DNV, LR, CCS, BV, and other IACS members |

| Testing Standards | ISO 1834, EN 13828, IACS E13/E22 |

| Packaging | Loose in bulk or on reels, seaworthy export packing |

| Lead Time | 4–8 weeks depending on order volume |

| Export Experience | Over 50 countries served |

By combining technical excellence with cost-effective manufacturing, Hangzhou Star Marine Technology ensures that global maritime operators receive durable, compliant, and reliable anchoring solutions that enhance vessel safety and operational efficiency.

Technical Specs & Approval

Technical Specifications: Black Painting Anchor Chain

Hangzhou Star Marine Technology Co. Ltd. supplies premium black painting anchor chains engineered for optimal performance in global marine environments. These chains undergo a specialized dual-protection process: electro-galvanization followed by a high-adhesion bitumen-based black paint coating. This combination delivers exceptional corrosion resistance in seawater, brackish conditions, and harsh offshore climates, significantly extending service life compared to standard galvanized chains. The black painting process also minimizes zinc oxide runoff, making it environmentally compliant for sensitive marine ecosystems. Our chains strictly adhere to ISO 1704:2019 and EN 245:2008 standards, with rigorous quality control at every production stage.

The critical technical parameters for our black painting anchor chains are detailed in the table below. These specifications ensure compatibility with international anchoring systems and classification society requirements.

| Parameter | U2 Grade Specification | U3 Grade Specification | Notes |

|---|---|---|---|

| Material | Non-alloy steel | Non-alloy steel | Controlled chemical composition for ductility and weldability |

| Tensile Strength | 400–530 N/mm² | 500–630 N/mm² | Minimum yield strength 240 N/mm² (U2), 320 N/mm² (U3) |

| Proof Load | 200 N/mm² | 250 N/mm² | Minimum test load per ISO 1704 |

| Weight per Meter | Diameter-dependent | Diameter-dependent | Approx. 0.39 kg/m (10mm) to 10.5 kg/m (52mm); 5% tolerance |

| Diameter Range | 10 mm – 52 mm | 10 mm – 52 mm | Custom diameters available upon request |

| Surface Treatment | Electro-galvanized + Bitumen paint | Electro-galvanized + Bitumen paint | Paint thickness 80–120 µm; uniform black finish; salt spray tested ≥1,000 hrs |

| Certifications | DNV, ABS, LR, BV, CCS, RINA | DNV, ABS, LR, BV, CCS, RINA | Full MTC traceability; FAT reports available |

Weight optimization is a key design factor, balancing structural integrity with vessel stability requirements. Our chains are manufactured to precise weight tolerances, ensuring predictable handling characteristics during deployment and retrieval. The black painting process adds negligible weight while providing critical corrosion mitigation, particularly in the crevices and weld zones where standard galvanization may be less effective.

Holding power is intrinsically linked to seabed composition and chain scope, but the U3 grade’s higher tensile strength (25% greater than U2) provides a significant safety margin for vessels operating in severe weather or challenging bottom conditions such as rock or coral. For standard harbor mooring or benign seabeds, U2 offers a cost-effective solution with proven reliability. Both grades maintain consistent elongation properties (≥20%) to absorb dynamic loads without brittle failure.

Surface integrity is non-negotiable in marine applications. The bitumen coating on our black painting chains forms a seamless, abrasion-resistant barrier that prevents direct seawater contact with the galvanized layer. This dual-layer system outperforms single-coat solutions in cyclic wet-dry conditions, where traditional galvanization alone may degrade prematurely. All chains undergo 100% magnetic particle inspection (MPI) to detect surface discontinuities, ensuring zero defects in critical load-bearing areas.

Hangzhou Star Marine Technology prioritizes export compliance, with all black painting anchor chains supplied with full documentation packages meeting IMO MSC.1/Circ.1175 guidelines and regional regulations. Our technical team provides direct support for classification society surveys and vessel-specific certification needs, guaranteeing seamless integration into global fleet operations.

Shipbuilding Solutions

Complete Anchoring Solutions for Shipbuilding and Repair – Black Painting Anchor Chain by Hangzhou Star Marine Technology

Hangzhou Star Marine Technology Co., Ltd. delivers integrated anchoring equipment solutions tailored for both new shipbuilding projects and vessel repair operations. As a trusted supplier in the maritime industry, we specialize in high-performance black painting anchor chains engineered to meet international standards and the rigorous demands of modern marine environments. Our comprehensive service model ensures fast response, technical precision, and seamless integration into shipyard workflows.

Black painting anchor chains are a critical component in anchoring systems, providing reliable strength, corrosion resistance, and operational safety. At Star Marine, we manufacture these chains using premium-grade materials, heat-treated for durability and coated with a protective black paint finish to enhance resistance against environmental degradation. This finish not only extends service life but also facilitates visual inspection and maintenance during vessel repairs. Our chains comply with classification society standards including CCS, ABS, DNV, LR, and NK, ensuring global acceptance and regulatory compliance.

For shipbuilders, we offer end-to-end support from design consultation to just-in-time delivery. Our engineering team collaborates closely with naval architects and shipyards to ensure chain dimensions, grade, and length are optimized for each vessel’s displacement, anchoring requirements, and operational profile. This technical alignment reduces installation delays and enhances system reliability. In repair scenarios, our rapid-response logistics network enables quick turnaround, minimizing vessel downtime. We maintain strategic inventory levels of standard chain sizes and accessories, allowing for immediate dispatch to major ship repair hubs across Asia, the Middle East, and Europe.

Our commitment to quality is reinforced through rigorous in-house testing, including load verification, dimensional accuracy checks, and coating integrity assessments. Each batch is supplied with full material test certificates and traceability documentation, meeting ISO 9001 and IACS requirements.

Below is an overview of our standard black painting anchor chain specifications available for immediate supply:

| Chain Diameter (mm) | Minimum Breaking Load (kN) | Grade | Length per Shackle (fathoms) | Coating Type |

|---|---|---|---|---|

| 28 | 672 | Grade 2 | 27.5 | Black Paint |

| 32 | 868 | Grade 2 | 27.5 | Black Paint |

| 38 | 1220 | Grade 3 | 27.5 | Black Paint |

| 44 | 1639 | Grade 3 | 27.5 | Black Paint |

| 50 | 2120 | Grade 3 | 27.5 | Black Paint |

Hangzhou Star Marine Technology stands out by combining technical expertise, responsive service, and adherence to maritime standards. Whether supporting large-scale shipbuilding programs or urgent repair campaigns, we deliver anchoring solutions that ensure safety, efficiency, and compliance. Partner with Star Marine for reliable, high-quality black painting anchor chains backed by global support and engineering excellence.

Packaging & Logistics

Packaging & Logistics for Black Painted Anchor Chain Exports

Hangzhou Star Marine Technology implements rigorously engineered packaging protocols for black painted anchor chains to ensure integrity during global maritime transit. Anchor chains represent critical safety equipment, and any compromise during shipment risks operational failure. Our dual-method packaging system—utilizing ISPM 15 certified wooden crates or reusable steel pallets—is tailored to chain dimensions, destination regulations, and carrier requirements. All packaging undergoes internal validation against ISO 10225 and IACS standards to prevent coating damage, deformation, or corrosion during voyages exceeding 30 days.

Wooden Crate Packaging

We construct custom wooden crates from kiln-dried, non-resin hardwood compliant with International Standards for Phytosanitary Measures No. 15 (ISPM 15). Each crate features 100x100mm timber frames with marine-grade plywood sheathing, internally lined with VCI (Vapor Corrosion Inhibitor) paper to protect the black epoxy coating. Crates include integrated dunnage blocks and tensioned steel strapping at 500mm intervals, securing chains against lateral movement. The ISPM 15 mark—certifying heat treatment to 56°C for 30 minutes—is permanently branded on all crate surfaces, satisfying EU, US, and APAC phytosanitary entry requirements. This method is mandatory for shipments to regions with strict biosecurity laws, including Australia, New Zealand, and the Americas.

Steel Pallet Solutions

For repeat customers or regions with relaxed timber regulations, we deploy heavy-duty galvanized steel pallets. Fabricated from 1.2mm thick structural steel with anti-slip crossbars, these pallets support loads up to 15,000kg. Chains are vertically stacked using separator plates to prevent interlink abrasion, then secured via hydraulic tensioners to pallet shackle points. The black paint finish is safeguarded by edge protectors at all contact zones. Steel pallets are reusable, reducing waste and long-term costs for fleet operators. They require no phytosanitary documentation, accelerating customs clearance in ports like Rotterdam or Singapore.

The following table summarizes key specifications:

| Packaging Type | Construction Details | Compliance Features | Best Use Cases |

|---|---|---|---|

| ISPM 15 Wooden Crates | 100x100mm hardwood frame, marine plywood sheathing, VCI paper lining | ISPM 15 heat treatment certification, IATA-compliant strapping | Shipments to biosecurity-sensitive regions (e.g., USA, Australia, Canada) |

| Steel Pallets | 1.2mm galvanized steel, 15,000kg load capacity, anti-slip crossbars | ISO 18185 certified lashing points, no phytosanitary restrictions | Repeat orders, EU/MEA destinations, eco-conscious clients |

Export Execution from Ningbo/Shanghai

All shipments originate from Hangzhou Star’s bonded warehouses at Ningbo-Zhoushan Port (world’s busiest container port) or Shanghai Port. We coordinate with pre-vetted maritime freight forwarders specializing in heavy marine cargo, ensuring direct vessel allocation to avoid transshipment handling. Documentation includes ISPM 15 certificates, paint batch traceability reports, and DGSA-certified hazard labels where applicable. Our logistics team monitors real-time container conditions (humidity, shock) via IoT sensors, providing clients with verifiable transit data. Pre-shipment inspections by SGS or Bureau Veritas are available upon request, guaranteeing adherence to MARPOL Annex III and SOLAS cargo securing guidelines. This integrated approach minimizes delays and ensures black painted anchor chains arrive operationally ready for immediate deployment.

Contact Star Marine

For marine operators, shipbuilders, and offshore project managers seeking high-performance anchoring solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in the global maritime supply chain. Our specialty in engineered anchoring equipment, including black painted anchor chains, ensures compliance with international standards while delivering durability, corrosion resistance, and operational reliability under extreme marine conditions. As a leading exporter based in Hangzhou, China, we serve clients across Asia, Europe, the Middle East, Africa, and the Americas with precision-manufactured products tailored to project-specific requirements.

Our black painted anchor chains are designed for applications requiring enhanced surface protection and identification, commonly used in commercial shipping, offshore mooring systems, and marine construction. Manufactured from high-tensile-strength steel and coated with a durable black anti-corrosive paint, these chains offer extended service life in both saltwater and freshwater environments. Each chain undergoes rigorous quality control, including load testing and dimensional verification, to meet the certification requirements of major classification societies such as CCS, ABS, DNV, LR, and BV.

To ensure seamless integration into your vessel or offshore structure, we provide full technical documentation, material test certificates (MTC), and traceability reports. Custom lengths, grades (R3, R3S, R4, R4S, R5), and packaging configurations—including ISO containers and wooden reels—are available to meet logistics and operational demands.

For detailed technical specifications, pricing, or project consultation, we encourage direct engagement with our dedicated export team. Kacher YE, Product Manager at Hangzhou Star Marine Technology, oversees the international distribution of our anchoring equipment and is available to support your procurement needs with technical expertise and responsive service.

Below are key technical parameters for our standard black painted anchor chain offerings:

| Parameter | Specification |

|---|---|

| Material Grade | Grade R3, R3S, R4, R4S, R5 |

| Diameter Range | 12 mm – 114 mm |

| Coating Type | Black Anti-Corrosive Paint (Epoxy-Based) |

| Compliance Standards | ISO 1704, ISO 1817, CCS, ABS, DNV, LR, BV |

| Test Certificate | MTC 3.1 / 3.2 Available |

| Packaging | Loose in bulk, on reels, or in containers |

| Lead Time | 4–8 weeks (varies by order volume) |

| Payment Terms | T/T, L/C at sight |

| Port of Loading | Ningbo or Shanghai, China |

We understand that timely delivery, product traceability, and technical accuracy are critical in marine procurement. By partnering with Star Marine, you gain access to a streamlined export process backed by engineering insight and maritime industry experience.

Contact Kacher YE directly at [email protected] to request a quotation, technical datasheet, or certification sample. Let us support your next project with reliable, export-ready anchoring solutions built to perform in the world’s most demanding marine environments.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160