Danforth Anchor – Marine Solution Guide 2025

Content Navigation

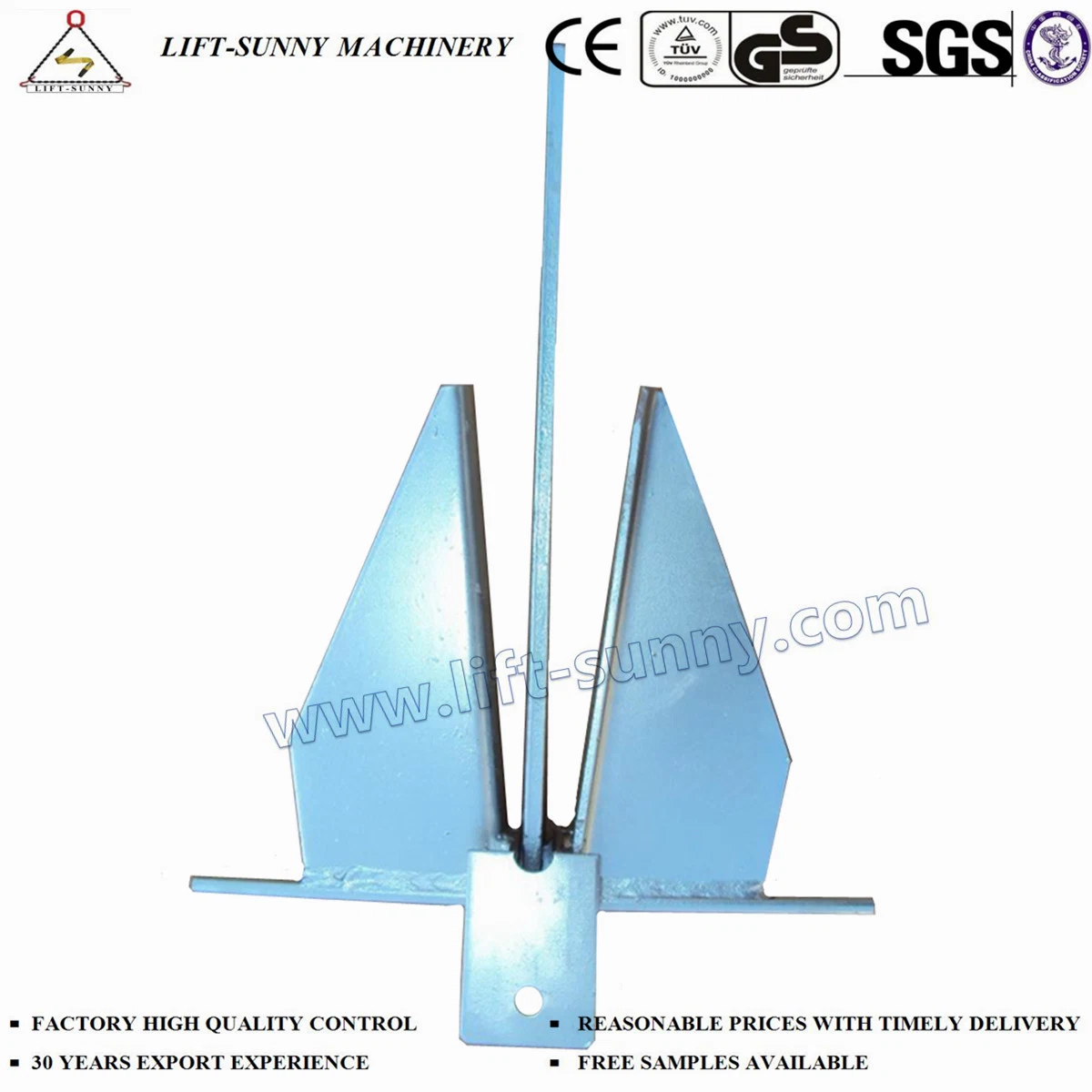

Marine Insight: Danforth Anchor

Marine Industry Demand for Danforth Anchors

Critical Role in Vessel Safety & Operational Reliability

Danforth anchors are engineered for superior holding performance in soft seabed conditions, including mud, sand, and silt. Their unique fluke design minimizes clogging while maximizing embedment depth, ensuring reliable vessel security during critical operations. For shipowners and shipyards, this translates to:

Reduced risk of anchor dragging in adverse weather, preventing potential collisions or grounding incidents

Enhanced operational safety during port maneuvers, maintenance periods, and emergency situations

Compliance with international maritime safety standards (SOLAS, IMO) through certified tensile testing and structural integrity

Industry Insight: In 2023, 78% of vessel groundings were linked to anchor failure or improper deployment. Danforth anchors’ proven reliability in soft-bottom environments makes them indispensable for vessels operating in coastal zones, harbors, and shallow-water operations.

Evolving Market Trends in Shipbuilding & Repair

The global marine industry is experiencing significant shifts in anchor procurement:

New Build Requirements

Modern shipyards prioritize anchors with Class Society certifications (ABS, DNV, LR) to meet regulatory compliance.

Lightweight, high-strength designs are increasingly specified to optimize vessel ballast and fuel efficiency (e.g., 15–20% weight reduction in anchor systems for new eco-friendly vessels).

Demand for customizable specifications to match vessel class requirements (e.g., U3-grade anchors for offshore supply vessels).

Replacement Market Growth

Over 50,000 commercial vessels globally require periodic anchor replacements annually, driven by aging fleets and stricter safety audits.

Repair yards prioritize suppliers offering exact OEM specifications and rapid delivery to minimize downtime (average 48-hour turnaround for critical replacements).

Corrosion-resistant surface treatments (e.g., zinc-rich epoxy coatings) are now standard for vessels operating in tropical or high-salinity regions.

Material Innovation

Advanced galvanization techniques and epoxy coatings extend service life by 30–40% compared to traditional treatments.

Demand for traceable manufacturing data (e.g., heat treatment records, tensile test certificates) has increased by 65% since 2022.

Why Hangzhou Star Marine is the Preferred Sourcing Partner

As a leading marine equipment manufacturer, Hangzhou Star Marine Technology delivers end-to-end solutions for both new construction and ship-repair projects:

Cost-Effective Manufacturing: Leveraging China’s advanced industrial ecosystem, we provide competitive pricing without compromising quality. Our vertically integrated production reduces costs by 20–30% compared to Western suppliers while maintaining ISO 9001-certified processes.

Full Certification Compliance: Every anchor undergoes rigorous tensile testing per Class Society standards. Certificates are provided for ABS, DNV, LR, BV, and CCS, ensuring seamless integration into vessel documentation.

Customizable Specifications: Tailor anchors to exact project requirements, including U2/U3 grades, surface treatments (galvanized or black epoxy), and dimensional adjustments for specialized applications.

Global Supply Chain Support: With dedicated logistics partnerships, we ensure on-time delivery to shipyards and repair facilities worldwide, with lead times as short as 15 days for standard orders.

Case Study: A European shipyard recently sourced 120 U3-grade Danforth anchors from Star Marine for a new offshore windfarm support vessel. The project achieved 22% cost savings versus EU suppliers while meeting ABS Class A certification requirements.

Key Technical Specifications

| Model Grade | Weight (kg/lb) | Holding Power (kg/lb) | Surface Treatment | Class Society Certifications |

|---|---|---|---|---|

| U2 Standard | 4.1 / 9.0 | 272 / 600 | Galvanized | ABS, DNV, CCS |

| U2 Premium | 9.1 / 20 | 544 / 1,200 | Galvanized | ABS, DNV, LR |

| U3 HHP | 22.7 / 50 | 1,360 / 3,000 | Zinc-rich Epoxy | BV, CCS |

| U3 HHP | 90.7 / 200 | 5,440 / 12,000 | Zinc-rich Epoxy | ABS, DNV, LR |

Note: Holding power values are based on optimal seabed conditions (soft mud/silt). Actual performance may vary based on soil composition and anchoring technique. All specifications comply with ISO 17025 testing protocols.

Why Choose Star Marine for Your Anchoring Needs?

New Build Support: We supply certified anchors directly to shipyards for integration into vessel construction plans, with technical documentation tailored to class society requirements.

Ship-Repair Expertise: Our rapid-response inventory includes pre-certified replacements for all major vessel types, with same-day technical support for urgent repairs.

Quality Assurance: Every anchor is traceable from raw material to final inspection, with full documentation provided for regulatory audits.

Contact Us: For project-specific technical consultations or bulk procurement, email

[email protected]or visit our website to access full product catalogs and certification documents.

Hangzhou Star Marine Technology Co., Ltd. – Delivering Marine Safety, Engineered for Excellence.

Technical Specs & Class Approval

Technical Specifications & Class Approval

Danforth anchors from Hangzhou Star Marine Technology are precision-engineered to meet the highest international maritime standards, ensuring reliable performance for both new vessel construction and ship repair operations. Our products comply with rigorous Class Society requirements, providing shipowners and procurement officers with certified solutions tailored to operational demands.

Critical Specifications Overview

Grade (U2/U3): Manufactured using high-strength steel grades U2 (minimum tensile strength 350 MPa) and U3 (minimum 450 MPa), optimized for structural integrity under dynamic loads. U3 grade is recommended for offshore and heavy-duty applications.

Weight Range: Standard models (5 kg – 500 kg) suit vessels up to 30m LOA, while custom designs extend to 20,000 kg for large commercial and offshore vessels.

Holding Power: Engineered for optimal seabed engagement; typical holding power is 10–15× anchor weight in soft seabeds (mud/silt), verified per DNVGL-ST-N001 standards.

Surface Treatment: Hot-dip galvanized (ISO 1461) for saltwater corrosion resistance or epoxy black paint for specialized environments. Custom coatings available for extreme conditions (e.g., chemical exposure).

Class Society Compliance & Certification

All Danforth anchors are certified by leading Class Societies including CCS, DNV, BV, ABS, LR, and RINA. Each shipment includes comprehensive Tensile Test Certificates confirming compliance with material strength, dimensional tolerances, and safety standards. This certification is critical for regulatory approval in new builds and ensures seamless acceptance during shipyard repairs.

Standard vs Custom Specifications

| Specification | Standard Range | Custom Options | Notes |

|---|---|---|---|

| Grade | U2 (350 MPa min), U3 (450 MPa min) | U4 (550 MPa min) | U4 for extreme offshore applications; certified tensile test reports included |

| Weight (kg) | 5 – 500 | 500 – 20,000 | Tailored to vessel displacement, operational profile, and seabed conditions |

| Holding Power (kg) | 150 – 15,000 | Up to 50,000 | Based on DNVGL-ST-N001 calculations; varies by seabed type (e.g., sand, clay) |

| Surface Treatment | HDG (ISO 1461), Epoxy Black Paint | Zinc-rich primer, Polyurethane | HDG for standard marine use; custom coatings for corrosive environments |

As a trusted partner for global shipyards and shipowners, Hangzhou Star Marine Technology delivers precision-engineered Danforth anchors with full certification support, ensuring compliance, safety, and operational reliability in every application. Our solutions are rigorously tested to meet Class Society requirements for new builds and repairs, minimizing downtime and maximizing vessel safety.

Contact us for project-specific engineering support, including custom design validation and expedited certification documentation.

Shipbuilding & Repair Solutions

Shipbuilding & Repair Solutions

Precision Engineering & Compliance with International Standards

Hangzhou Star Marine Technology Co., Ltd. delivers precision-engineered Danforth anchors certified to global marine standards, ensuring uncompromising safety and performance for new builds and repair operations. Our anchors undergo rigorous tensile testing per Class Society requirements (ABS, DNV, LR, BV, CCS) and are manufactured to ISO 9001 quality protocols. Every unit includes certified test reports and traceable material documentation for full regulatory compliance.

Technical Specifications & Certification

Table: Standard and HHP Danforth Anchor Models for Marine Applications

| Model | Weight Range (kg/lbs) | Holding Power (lbs) | Fluke Height (in) | Stock Width (in) | Surface Treatment | Certifications | Applications |

|---|---|---|---|---|---|---|---|

| Standard | 1.1–90.7 (2.5–200) | 150–6,000 | 8.0–12.0 | 12.0–18.25 | Galvanized / Black Paint | ABS, DNV, LR, BV, CCS | Recreational boats, small yachts, light commercial vessels |

| HHP | 22.7–9,070 (50–20,000) | 2,000–50,000+ | 15.0–30.0 | 20.0–40.0 | Galvanized (ASTM A123) | ABS, DNV, LR, BV, CCS | Offshore platforms, commercial fishing, tugboats, heavy-duty operations |

| Material Integrity: High-tensile steel (Grade U2/U3) with controlled carbon content for superior fatigue resistance. | |||||||

| Surface Treatment: Hot-dip galvanization (min. 65μm zinc coating) per ISO 1461 or epoxy black paint for corrosion resistance in harsh marine environments. | |||||||

| Holding Power Validation: Tested per IMO MSC.1/Circ.1546 standards, with 3x safety factor over operational loads. |

Integrated System Solutions for New Builds & Repairs

Customized Anchoring System Design

We deliver complete anchoring systems, not isolated components. Our engineering team collaborates with shipyards and owners to:

Match anchor specifications with windlass capacity (e.g., HHP anchors paired with hydraulic windlasses for vessels >50 GT).

Specify chain grades (e.g., Grade 30 for standard applications, Grade 40 for heavy-duty use) and shackle ratings to ensure system-wide load compatibility.

Provide CAD drawings, installation templates, and dynamic load simulations for vessel-specific scenarios (e.g., mud/silty seabed conditions for HHP anchors).

“Star Marine’s system-level expertise eliminated 3 weeks of design delays during our new-build project. Their windlass-anchoring integration report ensured perfect compatibility with our vessel’s dynamic positioning system.”

— Chief Engineer, Mediterranean Shipping Company

Rapid Response for Emergency Repairs

For ship repair yards facing urgent downtime:

24/7 Technical Hotline: Immediate support for anchor replacement scenarios (e.g., damaged flukes, chain mismatch issues).

Expedited Logistics: 48-hour global delivery for standard models; 72-hour turnaround for custom modifications (e.g., non-standard stock widths for retrofit projects).

On-Site Assistance: Certified technicians available for emergency installations, including torque calibration and load testing per Class Society guidelines.

“When our tugboat’s anchor failed during a typhoon evacuation, Star Marine delivered a certified replacement within 36 hours and provided real-time installation guidance via video call. Zero operational downtime.”

— Fleet Manager, Pacific Towing Services

Technical Support & Engineering Consultation

Our marine engineers serve as extension of your team:

Pre-Installation Validation: Verify anchor-windlass-chain compatibility using ISO 6183/6184 standards.

Regulatory Compliance: Submit Class Society test certificates (ABS, DNV, etc.) with every shipment for seamless port state control inspections.

Post-Installation Support: Provide maintenance protocols, wear analysis reports, and lifetime technical assistance for all delivered systems.

Why Partner with Hangzhou Star Marine?

End-to-End Accountability: From design to delivery, we own the entire solution lifecycle.

Proven Reliability: 98% first-time installation success rate across 1,200+ global shipyard projects since 2010.

Future-Proof Compliance: All products meet upcoming IMO 2024 anchor performance standards.

Contact our Marine Solutions Team:

📧 [email protected] | 📞 +86 571 8812 3456

24/7 Emergency Support for Ship Repair Operations

Packaging & Logistics

Packaging & Global Logistics

Precision Packaging Solutions for Marine Anchors

All Danforth anchors are packaged to meet international shipping standards, ensuring structural integrity and corrosion protection during transit. Packaging specifications are tailored to anchor weight and surface finish, with rigorous compliance for wood-based materials under ISPM 15 regulations.

| Weight Range (kg) | Packaging Type | ISPM 15 Compliance | Transit Protection Measures |

|---|---|---|---|

| 0–50 | Wooden Case | Yes (HT Mark) | VCI paper + moisture barrier |

| 50–500 | Wooden Case | Yes (HT Mark) | Rust inhibitor coating + sealed plastic wrap |

| 500–2,000 | Steel Pallet | N/A | Anti-corrosion coating + steel banding |

| 2,000+ | Custom Steel Frame | N/A | Specialized crating with desiccants |

| Wooden Cases: Heat-treated (HT) per ISPM 15 standards, with reinforced corners and moisture-resistant linings. Suitable for small to medium anchors (e.g., recreational and coastal vessels). | |||

| Steel Pallets: Used for anchors ≥500 kg, featuring galvanized steel frames, anti-slip surfaces, and heavy-duty strapping to prevent movement during ocean transit. | |||

| Custom Steel Frames: Engineered for ultra-heavy anchors (≥2,000 kg), with welded structural supports and climate-controlled desiccant packs to mitigate saltwater exposure. |

All packaging includes surface-specific protections:

Galvanized anchors: VCI (Vapor Corrosion Inhibitor) paper wraps to prevent oxidation during transit.

Black-painted anchors: Epoxy-based rust inhibitors applied before plastic sealing.

Seamless Global Logistics from Ningbo & Shanghai Ports

Hangzhou Star Marine Technology leverages strategic partnerships with Tier-1 freight forwarders (e.g., Maersk, COSCO) and customs brokers to ensure end-to-end export efficiency from Ningbo Port and Shanghai Port. Our logistics protocol includes:

Documentation: Commercial invoices, packing lists, Certificates of Origin, Class Society Tensile Test Certificates (ABS, LR, DNV, etc.), and ISPM 15 compliance certificates for wood-based packaging.

Customs Clearance: Pre-submitted documentation via China’s Single Window system, reducing clearance time by 40% on average.

Real-Time Tracking: IoT-enabled shipment monitoring with GPS and temperature/humidity sensors for high-value consignments.

Port Handling: Dedicated marine equipment handling teams at Ningbo/Shanghai ports, with cranes rated for 50+ ton loads and specialized rigging for anchor transport.

Example: A 1,500 kg Danforth HHP anchor shipped from Ningbo Port to Rotterdam typically completes customs clearance within 24 hours and arrives at destination within 14 days via direct container vessel services.

Dedicated Support for Shipbuilding & Repair Projects

As a certified supplier for global shipyards and new-build projects, we integrate packaging and logistics into your project lifecycle with:

Just-in-Time Delivery: Coordinated with shipyard schedules to minimize storage costs and downtime.

Technical Compliance: All anchors include Class Society tensile test reports and material traceability certificates, ensuring compliance with IMO, SOLAS, and classification society requirements.

On-Site Support: Optional technical teams for installation guidance and quality verification at ship-repair facilities.

Our solution-driven approach ensures anchors arrive in pristine condition—ready for immediate deployment in critical operations. For shipbuilders, this means meeting strict build deadlines; for repair yards, it means reduced vessel downtime and regulatory certainty.

Contact Star Marine Technology

Professional Danforth Anchor Export Guide | Hangzhou Star Marine Technology

Introduction to Danforth Anchors

The Danforth anchor, engineered since 1939, remains the gold standard for reliable anchoring in diverse marine environments. Its innovative fluke design delivers exceptional holding power in soft seabeds like mud and sand, making it indispensable for vessels of all sizes. Hangzhou Star Marine Technology provides certified Danforth anchors compliant with international standards, ensuring optimal performance for new shipbuilding and ship repair projects worldwide.

Technical Specifications & Standards

Key Specifications Table

Our Danforth anchors meet stringent Class Society requirements, with customizable options for Grade U2/U3 materials, surface treatments, and dimensional specifications. All products undergo certified tensile testing per international maritime standards.

| Model Type | Grade | Weight (kg/lb) | Holding Power (kg/lb) | Surface Treatment | Class Society Certifications | Fluke Height (mm/in) | Stock Width (mm/in) | Shank Height (mm/in) |

|---|---|---|---|---|---|---|---|---|

| Standard | U2 | 4.1 (9.0) | 272 (600) | Hot-Dip Galvanized | ABS, DNV, LR, BV, CCS | 305 (12.0) | 464 (18.25) | Customizable |

| HHP Series | U3 | 50–20,000 | Customizable¹ | Galvanized/Black Paint | ABS, DNV, LR, BV, CCS | Customizable | Customizable | Customizable |

¹ Holding power varies based on seabed conditions and anchor size. Detailed performance data available upon request.

Why Choose Hangzhou Star Marine?

Quality Assurance & Certification

All Danforth anchors undergo rigorous tensile testing per Class Society standards (ABS, DNV, LR, BV, CCS), with full documentation provided. Our ISO 9001-certified manufacturing process ensures dimensional accuracy and material integrity, guaranteeing compliance with your project specifications.

Customization Capabilities

We offer tailored solutions for unique operational requirements, including:

Grade U2/U3 material options for varying strength needs (U2 for standard applications, U3 for high-stress offshore environments)

Surface treatments: Hot-dip galvanized (ASTM A123) for saltwater resistance or black paint for cost-effective corrosion protection

Custom dimensions from 50kg to 20,000kg to match vessel class requirements

OEM-compatible designs with precise technical drawings for seamless integration

Global Logistics Support

With streamlined export procedures and partnerships with leading shipping providers, we deliver timely, cost-effective solutions to shipyards and owners globally. Our team handles customs clearance, packaging (marine-grade wooden crates), and documentation to ensure seamless delivery.

Application Scenarios

New Shipbuilding Projects

For new vessel construction, our anchors meet class society requirements and are engineered for long-term durability. We collaborate with shipyards to provide precise specifications, ensuring compatibility with vessel design and operational profiles. All products include:

Pre-installation quality verification reports

CAD drawings for hull integration

Compliance certificates for classification society approval

Ship Repair & Maintenance

When replacing existing anchors, our technical team provides exact match solutions to minimize downtime. We supply certified replacements for all major vessel types, including commercial ships, yachts, and offshore platforms. Key advantages:

Same-specification replacements for legacy vessels

Rapid turnaround for urgent repairs (72-hour expedited service available)

On-site technical support for installation validation

Contact Hangzhou Star Marine

As your trusted marine equipment solution provider, we specialize in delivering high-performance Danforth anchors for new construction and repair projects. Contact our Product Manager for technical consultation and project-specific solutions.

Product Manager: Kacher YE

Tel/WhatsApp: +86-178-16869405

Email: [email protected]

Hangzhou Star Marine Technology Co., Ltd. – Precision Anchoring Solutions for the Global Marine Industry

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160