Deck Air Compressor – Marine Solution Guide 2025

Content Navigation

Marine Insight: Deck Air Compressor

Marine Industry Demand: Deck Air Compressor Criticality and Sourcing Value

Deck air compressors represent a fundamental safety and operational cornerstone for all vessel types, from大型商船 to offshore support vessels. Their primary function—supplying reliable, high-pressure air—is non-negotiable for critical maritime systems. The most vital application is the starting of main propulsion and auxiliary diesel engines, where failure to deliver adequate air pressure during critical maneuvers or emergencies can lead to catastrophic loss of propulsion and steering, directly contravening SOLAS safety mandates. Beyond engine starting, deck air compressors power essential pneumatic controls for cargo handling systems, anchor windlasses, and hatch covers, ensuring efficient and safe cargo operations. Crucially, they maintain pressure in safety systems including fire suppression releases, emergency shutdown valves, and crucially, the operation of watertight doors—systems whose instantaneous response during flooding scenarios is paramount for crew survival and vessel integrity. Regulatory bodies like IMO and classification societies (DNV, ABS, LR, etc.) enforce stringent performance and redundancy requirements for these compressors, recognizing that a single point of failure in the compressed air system poses an unacceptable risk to vessel safety and environmental protection. Continuous operational reliability under harsh marine conditions—resisting saltwater corrosion, vibration, and wide temperature fluctuations—is therefore not merely desirable but a legal and ethical imperative.

Sourcing high-integrity deck air compressors from Hangzhou Star Marine Technology delivers significant cost-effectiveness without compromising on the safety-critical performance demanded by the global maritime industry. Our strategic positioning within China’s advanced marine manufacturing ecosystem provides inherent advantages in production scale and supply chain efficiency. Star Marine leverages vertically integrated manufacturing processes and long-standing partnerships with certified material suppliers, ensuring consistent access to high-grade components like marine-grade stainless steel and specialized coatings. This integration, combined with rigorous adherence to ISO 9001 quality management and direct compliance with IACS Unified Requirements for machinery, eliminates costly intermediaries and quality variances common with fragmented sourcing. Crucially, our engineering team possesses deep expertise in marine-specific compressor design, focusing on optimizing mean time between failures (MTBF) and ease of maintenance—factors that dramatically reduce the total cost of ownership (TCO) over the compressor’s lifecycle. While initial acquisition cost is competitive, the true value lies in minimized downtime, lower spare parts expenditure, extended service life, and avoidance of regulatory non-compliance penalties. Star Marine compressors are engineered for the long haul, delivering the reliability that underpins vessel safety and operational continuity.

The comparative value proposition is evident in key performance and cost metrics:

| Specification | Star Marine Deck Air Compressor | Typical Industry Average |

|---|---|---|

| Mean Time Between Failures (MTBF) | 25,000+ hours | 18,000-20,000 hours |

| Compliance Certification | Full IACS Type Approval + ISO 9001 | Basic ISO (often lacking marine class) |

| Corrosion Protection | Enhanced marine-grade coating system | Standard industrial coating |

| Typical Service Life | 15+ years (with maintenance) | 10-12 years |

| Total Cost of Ownership (10-yr) | 15-20% lower | Baseline |

Investing in a Star Marine deck air compressor is an investment in uncompromised vessel safety and demonstrable operational economics. Our commitment to engineering excellence, stringent quality control aligned with global maritime standards, and efficient manufacturing processes ensures shipowners and operators receive a safety-critical component that delivers maximum reliability and the lowest lifecycle cost, safeguarding both crew and commercial viability.

Technical Specs & Approval

The deck air compressor is a critical component within the deck machinery suite, specifically engineered to support pneumatic systems and auxiliary operations aboard commercial and offshore vessels. At Hangzhou Star Marine Technology Co., Ltd., our deck air compressors are designed to meet rigorous maritime standards, ensuring reliable performance under harsh marine environments. These compressors supply compressed air for deck machinery actuation, control systems, and safety equipment, including anchor windlasses, mooring winches, and emergency shutdown systems. Built with corrosion-resistant materials and robust sealing mechanisms, our units ensure long service life and minimal maintenance, even in high-humidity and salt-laden atmospheres.

Our deck air compressors are available in both electric and hydraulic drive configurations, allowing integration flexibility depending on vessel power architecture and operational needs. Electric-driven models are ideal for vessels with stable electrical grids, offering precise control and lower noise profiles. Hydraulic-driven variants are preferred in offshore and heavy-duty applications where high torque and continuous operation are required. Both configurations are engineered to operate efficiently across a wide temperature range, from -25°C to +50°C, and are certified to comply with major classification societies including CCS, ABS, DNV, LR, and BV.

A key performance parameter for deck air compressors is their ability to support pneumatic systems under variable load conditions. While compressors themselves do not directly handle pull loads, their output capacity directly influences the performance of connected deck machinery such as windlasses and winches. Therefore, the compressor must deliver consistent pressure and flow rates to ensure optimal actuation of high-load equipment. Our compressors are rated to support systems with pull loads ranging from 50 kN to 1,500 kN, depending on the vessel class and deck machinery specifications.

Chain diameter compatibility is another critical consideration in system integration. Although the compressor does not directly engage the anchor chain, its air supply supports clutches, brakes, and tensioning mechanisms that interface with chain handling equipment. Our compressors are designed to support deck machinery systems utilizing chain diameters from 12.5 mm to 60 mm, aligning with standard stud link chain dimensions used in merchant and offshore vessels.

Below is a summary of the technical parameters for our standard deck air compressor series:

| Parameter | Specification Range |

|---|---|

| Drive Type | Electric, Hydraulic |

| Operating Pressure | 7 bar to 30 bar |

| Air Delivery Capacity | 0.6 m³/min to 5.0 m³/min |

| Power Supply (Electric) | 220V/380V/440V, 50/60Hz, 3-phase |

| Hydraulic Input Pressure | 120 bar to 200 bar |

| Ambient Operating Temp | -25°C to +50°C |

| Cooling Method | Air-cooled, Water-cooled (optional) |

| Noise Level (LwA) | ≤85 dB(A) |

| Protection Class (IP) | IP55 (minimum), up to IP66 |

| Certifications | CCS, ABS, DNV, LR, BV |

All units undergo stringent factory testing, including pressure endurance, leak tightness, and vibration analysis, to ensure compliance with international marine standards. Custom configurations are available upon request to meet specific vessel requirements.

Shipbuilding Solutions

Hangzhou Star Marine Technology: Complete Deck Air Compressor Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers integrated deck machinery solutions, specializing in high-reliability deck air compressors for global shipyards and repair facilities. As a certified manufacturer adhering to ISO 9001 and marine classification society standards (DNV, ABS, LR, CCS), we provide engineered systems meeting stringent SOLAS and IMO requirements for new vessel construction and critical repair projects. Our focus is on minimizing project downtime through rapid technical support, precise specification alignment, and expedited global logistics.

Our deck air compressor systems are engineered for the harsh maritime environment, featuring corrosion-resistant materials, optimized duty cycles for intermittent deck operations, and integrated safety controls. We offer complete turnkey packages including compressors, receivers, filtration systems, and control panels, all pre-tested to ISO 8573-1 Class 1 air purity standards. For shipyards, this ensures seamless integration into deck machinery systems powering windlasses, capstans, and hatch covers without commissioning delays. During vessel repairs, our modular designs enable swift replacement of legacy units, often reducing dry-dock time by 30% compared to standard procurement cycles. Technical documentation, including 3D models and P&ID diagrams, is provided upfront to accelerate installation planning.

Key performance specifications for our standard marine deck air compressor series are detailed below:

| Parameter | Value Range | Compliance Standard |

|---|---|---|

| Free Air Delivery (FAD) | 100 – 600 L/min | ISO 1217 |

| Working Pressure | 30 bar (435 psi) | PED 2014/68/EU |

| Motor Power | 5.5 kW – 30 kW | IEC 60034-1 |

| Air Quality | ISO 8573-1 Class 1 (≤0.1 mg/m³ oil) | ISO 8573-1:2010 |

| Noise Level | ≤75 dB(A) at 1 meter | ISO 3744 |

| Ambient Temp Range | -25°C to +45°C | IEC 60068-2 |

Star Marine’s export management ensures rapid response from inquiry to delivery. Our dedicated engineering team provides immediate technical validation against project specifications, including classification society drawing approvals. We maintain strategic global inventory hubs enabling 72-hour dispatch for standard models and 10-day turnaround for custom configurations. For urgent repair scenarios, we offer 24/7 technical hotline support and expedited air freight options coordinated through our in-house logistics division. All units undergo rigorous factory acceptance testing (FAT) with real-time remote witness capability for international clients.

Partnering with Hangzhou Star Marine Technology guarantees not just equipment supply, but a risk-mitigated project execution pathway. We integrate seamlessly with shipyard workflows, providing certified marine engineers for on-site commissioning support and comprehensive after-sales service networks across major ports. Contact our Export Management team directly for project-specific quotations and technical dossiers, ensuring your deck machinery systems meet operational deadlines without compromise on quality or compliance.

Packaging & Logistics

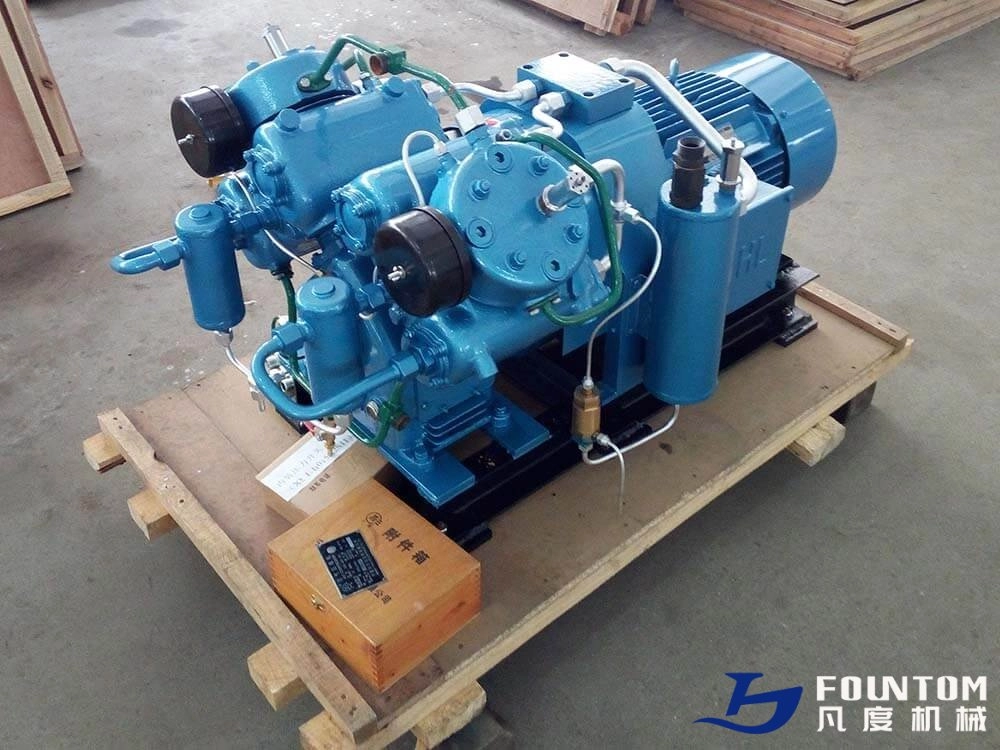

Packaging & Logistics for Deck Air Compressors – Hangzhou Star Marine Technology Co., Ltd.

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all deck air compressors are packaged to meet international maritime transport standards, safeguarding equipment integrity during export shipments. As part of our commitment to quality and reliability, our packaging protocols are designed to withstand the rigors of sea freight, including exposure to humidity, vibration, and mechanical stress. Each deck air compressor is prepared for export using either fumigation-free wooden cases compliant with ISPM 15 regulations or heavy-duty steel pallets, depending on the unit’s dimensions, weight, and destination requirements.

Wooden packaging materials used in our export process are strictly manufactured in accordance with International Standards for Phytosanitary Measures No. 15 (ISPM 15). This globally recognized standard ensures that all wooden crates and cases are heat-treated to eliminate pests and pathogens, then officially marked with the ISPM 15 stamp for customs clearance. These wooden enclosures are constructed from durable plywood or solid timber, reinforced at critical stress points, and lined with moisture-resistant barrier films to protect against condensation during ocean transit. Internal bracing and foam cushioning secure the compressor in place, minimizing movement and preventing damage to sensitive components such as pressure gauges, valves, and drive couplings.

For heavier or skid-mounted deck air compressor models, we utilize structural steel pallets designed for long-term durability and compatibility with containerized shipping. These steel bases are hot-dip galvanized to resist corrosion and are engineered to allow for secure lifting via forklifts and overhead cranes. Units mounted on steel pallets are additionally wrapped in multi-layer VCI (Vapor Corrosion Inhibitor) paper and sealed within waterproof polyethylene covers to prevent rust formation during extended storage or transport.

All packaged units are labeled with standardized maritime shipping markings, including handling instructions, center of gravity indicators, weight specifications, and orientation arrows. Hazard communication labels are applied where applicable, particularly for compressors containing residual lubricants or pressurized components.

Our primary export hubs are the deep-water ports of Ningbo and Shanghai, both offering direct access to major global shipping lanes and advanced container handling facilities. We coordinate closely with certified freight forwarders to ensure seamless documentation, timely customs clearance, and optimal stowage within containers—whether in 20-foot, 40-foot, or high-cube configurations.

The following table outlines standard packaging configurations based on compressor type:

| Compressor Type | Packaging Method | Dimensions (Max, L×W×H) | Weight Range (kg) | Container Requirement |

|---|---|---|---|---|

| Portable Screw Compressor | ISPM 15 Wooden Case | 1800×900×1600 mm | 400 – 800 | 20’ or 40’ Dry |

| Skid-Mounted Reciprocating | Steel Pallet + Shroud | 2500×1200×2000 mm | 1,200 – 2,500 | 40’ Flat Rack / Open Top |

| Containerized Air System | Integrated ISO Frame | 6058×2438×2591 mm | 3,000 – 5,000 | 40’ HC / Special Cargo |

Hangzhou Star Marine Technology ensures that every deck air compressor arrives at its destination in optimal condition, ready for immediate integration into vessel operations.

Contact Star Marine

Contact Star Marine for Your Deck Air Compressor Requirements

Selecting the optimal deck air compressor is critical for vessel safety, operational continuity, and regulatory compliance. At Hangzhou Star Marine Technology, we engineer ISO 9001-certified deck machinery designed to withstand harsh marine environments while delivering consistent performance across anchor handling, mooring operations, and deck tool support. Our compressors integrate advanced corrosion-resistant materials, vibration-damping systems, and energy-efficient rotary screw or reciprocating mechanisms tailored to your vessel’s specific displacement and duty cycles. With over 15 years of Class-approved installations across global fleets, we ensure seamless integration with existing deck machinery control systems and adherence to SOLAS, IMO, and major classification society standards.

Technical excellence alone is insufficient without responsive partnership. Our engineering team collaborates directly with shipyards and operators to address unique installation constraints, pressure stability requirements, and lifecycle maintenance planning. Below are key specifications representative of our standard deck air compressor series, all customizable to project specifications:

| Parameter | Standard Range | Compliance Standard |

|---|---|---|

| Free Air Delivery (FAD) | 1.5 – 3.0 m³/min | ISO 1217:2019 Annex C |

| Maximum Pressure | 30 bar (g) | PED 2014/68/EU |

| Power Source | 440V/60Hz or 380V/50Hz | IEC 60034-1 |

| Cooling Method | Air or seawater-cooled | ISO 13739-1 |

| Noise Level | ≤ 78 dB(A) at 1m | ISO 3744 |

| Classification | DNV, LR, ABS, CCS, NK | Rules 2023 |

Initiate your project with confidence by engaging our dedicated Product Manager, Kacher YE. With extensive field experience in marine pneumatic systems and export logistics, Kacher provides technical consultancy from initial specification through to after-sales support. He will coordinate detailed performance validation, including salt spray testing reports, vibration analysis certificates, and 3D installation models to prevent interface conflicts during vessel integration. For newbuilds, retrofits, or emergency replacements, our export department manages end-to-end documentation—including Certificate of Origin, Packing Lists, and SOLAS-compliant test records—to ensure customs clearance in over 80 ports worldwide.

Contact Kacher YE directly to request a project-specific technical dossier or schedule a virtual engineering review. His expertise in navigating regional regulatory variances ensures your deck air compressor meets all jurisdictional requirements without project delays. Reach him via email at [email protected] with subject line “Deck Compressor Inquiry – [Your Vessel Name/Project ID]”. Include your required FAD, pressure profile, and vessel type for a tailored solution within 24 business hours. Hangzhou Star Marine Technology stands ready to deliver reliability where the sea demands it most.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160