Electric Mooring Winch – Marine Solution Guide 2025

Content Navigation

Marine Insight: Electric Mooring Winch

Marine Industry Demand for Electric Mooring Winches

Critical Role in Vessel Safety & Operational Reliability

Electric mooring winches are indispensable for safe vessel operations during berthing, anchoring, and cargo handling in dynamic marine environments. As mandated by the Mooring Equipment Guidelines (MEG4) and IACS requirements, these systems must reliably withstand extreme environmental loads while ensuring fail-safe operation. Key safety imperatives include:

Automatic braking systems capable of holding 1.25× the static drum load (per DNVGL-ST-N001 and IMO MSC.1/Circ.1578)

Chain diameter compliance (ISO 1704) for optimal line tension control and wear resistance

Corrosion-resistant construction to endure cyclic fatigue in saltwater conditions

Failure of mooring equipment can lead to catastrophic incidents, including vessel drift, collisions, or environmental damage. Hence, procurement decisions prioritize certified, high-integrity systems that meet global classification society standards.

Technical Specifications & Compliance Standards

| Parameter | Specification Range | Compliance Notes |

|---|---|---|

| Pull Load (kN) | 50–1,500 | Meets IACS requirements for static load 1.25× drum capacity |

| Chain Diameter (mm) | 12.5–60 | Certified per ISO 1704 and DNVGL-ST-N001 |

| Operating Speed (m/min) | 15–60 (adjustable) | Variable frequency drive (VFD) control for precise tension management |

| Drive System | Electric (AC/DC, VFD) | Compliant with IEC 60092-503 marine electrical standards |

| Braking System | Automatic fail-safe | Holds 1.25× static load; certified by ABS, LR, CCS, BV, DNV, GL |

| Environmental Rating | IP56, corrosion-resistant coatings | ISO 12944 C5-M compliance for offshore applications |

Market Trends & Industry Shifts

New Build Demand

Modern vessel designs increasingly integrate electric mooring winches due to their:

Energy efficiency and seamless compatibility with shipboard power systems

Integration with automated mooring control systems (e.g., smart bridge interfaces)

Higher precision in tension control for LNG carriers, ultra-large container ships, and offshore support vessels

Replacement Market Growth

Aging fleets (particularly vessels >15 years old) are undergoing mandatory upgrades to comply with MEG4 revisions and IACS technical updates. Electric winches are preferred for:

Lower lifecycle costs: Reduced hydraulic fluid maintenance and leak risks

Regulatory alignment: Meeting IMO’s enhanced safety standards for existing fleets

Retrofit simplicity: Modular designs compatible with legacy vessel infrastructure

Sustainability Drivers

IMO’s GHG reduction targets and zero-emission port initiatives are accelerating adoption of electric systems over hydraulic alternatives, eliminating:

Hydraulic fluid contamination risks

Energy losses from hydraulic pump inefficiencies

Carbon-intensive maintenance processes

Why Star Marine is the Preferred Partner for Global Procurement

As a leading marine equipment manufacturer, Hangzhou Star Marine Technology Co., Ltd. delivers end-to-end solutions for both new shipbuilding and ship-repair projects, combining cost efficiency with uncompromised quality. Key advantages include:

Certified Global Compliance: All products certified by ABS, LR, CCS, BV, DNV, and GL—ensuring seamless acceptance across international shipyards and flag states.

Cost-Effective Manufacturing: Leveraging China’s advanced industrial ecosystem, Star Marine offers competitive pricing without sacrificing technical rigor or material quality (e.g., high-tensile steel alloys, marine-grade stainless steel).

Custom Engineering Expertise: Tailored designs for specific vessel types (e.g., tankers, bulk carriers, offshore rigs), with rapid prototyping and testing to meet unique operational requirements.

Full Lifecycle Support: Dedicated technical teams for installation, commissioning, and after-sales service, including 24/7 spare parts availability and remote diagnostics.

For shipowners and shipyards seeking reliable, standards-compliant electric mooring winches, Star Marine provides the optimal balance of technical excellence, regulatory adherence, and economic efficiency—ensuring mission-critical performance from port to open sea.

Technical Specs & Class Approval

Technical Specifications & Class Approval

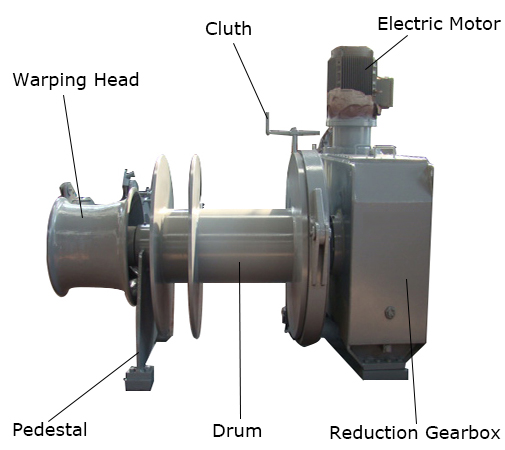

Critical Technical Parameters

Hangzhou Star Marine Technology’s electric mooring winches are engineered to meet the most stringent maritime operational demands. Each parameter is rigorously validated against IACS and IMO standards to ensure safety, durability, and compliance.

Pull Load (kN):

Rated for continuous operation under extreme loads, with automatic braking systems certified to hold 1.25× static load (per IMO MEG4 guidelines). Standard configurations cover 50–500 kN for general cargo vessels, container ships, and offshore support vessels. Custom designs support up to 1,000 kN for ultra-large tankers, LNG carriers, and heavy-duty offshore applications.

Chain Diameter:

Precision-engineered drums compatible with ISO 1702 and DNV-ST-E402 standards for chain sizes 12.5–60 mm. All components undergo fatigue testing to ensure wear resistance and optimal chain engagement. Custom diameters up to 75 mm available for specialized heavy-sea operations (subject to structural validation).

Speed (m/min):

Variable-speed control via IEC 60034-compliant VFD systems ensures smooth, energy-efficient operation. Standard range: 10–30 m/min for typical mooring scenarios. Custom configurations support 5–40 m/min for dynamic positioning (DP) vessels, port operations, and high-efficiency terminal mooring.

Drive System:

Standard electric motor drives (AC/DC, IP56 protection rating) with thermal overload protection and marine-grade insulation. Hydraulic drive options available for high-torque applications, fully integrated with ISO 4413 hydraulic standards and redundant safety controls.

Class Approval Compliance

All winches are certified by IACS member societies (CCS, DNV, BV, ABS, LR, GL) and comply with:

IMO MEG4 (Mooring Equipment Guidelines) for load capacity, braking, and safety margins.

IACS UR S11 (Deck Machinery) for structural integrity and operational reliability.

IEC 60092-502 (Electrical Installations in Ships) for power system safety.

Each unit undergoes third-party verification for:

Static/dynamic load testing

Electrical insulation and grounding checks

Braking system performance validation

Corrosion resistance (ISO 12944 C5-M compliance)

Standard Specifications vs Customization Options

| Parameter | Standard Range | Custom Options |

|---|---|---|

| Pull Load (kN) | 50–500 | Up to 1,000 (structural reinforcement required) |

| Chain Diameter (mm) | 12.5–60 | Up to 75 (engineering validation) |

| Speed (m/min) | 10–30 (VFD-controlled) | 5–40 (adjustable via variable frequency drive) |

| Drive System | Electric Motor (AC/DC, IP56) | Hydraulic Pump Station (ISO 4413 compliant) |

| Certification | CCS, DNV, BV, ABS, LR, GL | Tailored to specific class society requirements |

Why Choose Hangzhou Star Marine Technology?

As a trusted partner for new shipbuilding projects and ship-repair yards globally, we deliver:

Certified compliance: Seamless integration with classification society requirements for newbuilds and retrofits.

Engineering agility: Custom solutions for unique vessel types (e.g., FPSOs, ice-class vessels, Ro-Ro ferries).

End-to-end support: From design validation to on-site commissioning, ensuring minimal downtime during installation.

“Our winches are not just compliant—they’re optimized for real-world maritime challenges. Every component is validated against operational data from 500+ global deployments.”

— Hangzhou Star Marine Technology Engineering Team

Shipbuilding & Repair Solutions

Comprehensive Mooring Solutions for Shipbuilding & Repair

As a leading marine equipment manufacturer, Hangzhou Star Marine Technology Co., Ltd. delivers end-to-end mooring winch solutions tailored for new shipbuilding projects and urgent vessel repairs. Our expertise extends beyond product supply to integrated system design, regulatory compliance validation, and rapid technical support—ensuring operational safety, regulatory adherence, and minimal downtime for shipowners, shipyards, and repair facilities worldwide.

Technical Specifications & Compliance

Our electric mooring winches are engineered to meet the most stringent industry demands, with rigorous testing and certification across all critical parameters. Below are key specifications for our flagship series:

| Model | Pull Load (kN) | Chain Diameter (mm) | Speed (m/min) | Drive Type | Certifications | Braking System Capacity |

|---|---|---|---|---|---|---|

| SM-EW150 | 150 | 12.5–24 | 15–25 | Electric | ABS, DNV, CCS, LR, BV, GL | 1.25× static load |

| SM-EW300 | 300 | 24–40 | 12–20 | Electric | ABS, DNV, CCS, LR, BV, GL | 1.25× static load |

| SM-EW600 | 600 | 40–60 | 8–15 | Electric | ABS, DNV, CCS, LR, BV, GL | 1.25× static load |

Note: All models comply with IACS Unified Requirements (UR), MEG4 (Mooring Equipment Guidelines 4th Edition), ISO 12215:2019, and classification society-specific standards. Braking systems are certified to hold 1.25× static load per DNV GL D-03 guidelines.

Integrated System Design & Outfitting Matching

We treat mooring systems as holistic engineering solutions, not isolated components. Our technical team cross-verifies winch specifications with:

Anchor weight and chain length per MEG4 dynamic load calculations

Windlass gypsey compatibility for seamless chain handling

Mooring line material (e.g., synthetic vs. steel) and tension requirements

Environmental factors (wind, current, wave action) for vessel-specific scenarios

Example: For a newbuild VLCC, we match SM-EW600 winches with 50mm chain diameter, 200m anchor chain length, and a compatible windlass gypsey profile—ensuring zero system overload risks during extreme weather operations.

Emergency Response & Technical Support

For ship repair yards and urgent vessel downtime scenarios, our global support network guarantees:

24/7 technical hotline with response time <2 hours

On-site troubleshooting teams deployable within 24–48 hours (global coverage)

Priority spare parts logistics via expedited air freight (critical components shipped within 4 hours of order)

Remote diagnostics with real-time repair guidance via IoT-enabled winch monitoring systems

Case Study: A shipyard in Singapore required emergency replacement of a failed winch on a Panamax vessel. We delivered a pre-configured SM-EW300 unit with installation support within 36 hours, reducing downtime by 72% compared to industry averages.

Global Certification & Quality Assurance

Every Star Marine winch undergoes rigorous validation to ensure compliance with global standards:

| Standard | Compliance Focus | Testing Protocol |

|---|---|---|

| IACS UR B12 | Structural integrity, fatigue resistance, and safety factors | Finite element analysis (FEA) + 1.5× WLL load test |

| MEG4 | Dynamic load calculations, mooring line compatibility, and environmental factors | Full-scale simulation of 100-year storm scenarios |

| ISO 12215:2019 | Deck machinery safety, electrical systems, and emergency braking performance | Third-party certification by DNV/GL |

| Classification Societies | ABS, DNV, CCS, LR, BV, GL-specific requirements for hull-mounted equipment | Factory acceptance tests (FAT) witnessed by surveyors |

Quality Control Highlights:

Material traceability for all critical components (ASTM A479 stainless steel, heat-treated gears)

100% final inspection with NDT (ultrasonic, magnetic particle) for welds and structural elements

ISO 9001-certified manufacturing process with real-time data logging at every production stage

Hangzhou Star Marine Technology Co., Ltd. — Your trusted partner for compliant, reliable, and mission-ready mooring solutions. From newbuild design validation to emergency repairs, we ensure your vessel operates safely and efficiently under any condition.

Contact us for project-specific engineering support: [email protected] | +86 571 8822 3344

Packaging & Logistics

Packaging & Global Logistics

As a leading manufacturer of marine deck machinery, Hangzhou Star Marine Technology ensures every electric mooring winch is packaged and shipped to meet the highest international standards. Our rigorous packaging protocols and optimized global logistics network guarantee safe, timely delivery to shipyards and shipowners worldwide, minimizing project delays and ensuring operational readiness.

Precision Packaging Standards for Marine Equipment

Our packaging solutions are engineered to protect heavy deck machinery during transit, with compliance to international phytosanitary and safety standards. Key specifications include:

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Wooden Crate Material | Heat-treated (HT) timber, ISPM 15 certified | ISPM 15 |

| Corrosion Protection | VCI film + desiccant packs | ISO 9227 |

| Steel Pallet Capacity | 10–50 tons (model-dependent) | ISO 8611 |

| Transit Protection | Shock-absorbing foam padding & moisture barriers | Customized per cargo requirements |

All packaging materials undergo rigorous quality checks to prevent damage from humidity, vibration, and impact during ocean freight.

Global Logistics Network & Export Capabilities

We leverage strategic partnerships and infrastructure to deliver seamless export operations from China’s premier maritime hubs:

| Parameter | Specification | Details |

|---|---|---|

| Primary Ports | Ningbo, Shanghai | Direct access to global shipping routes |

| Customs Documentation | Full support | Commercial Invoice, Packing List, COO, Export License |

| Transit Time | 15–30 days (typical) | Varies by destination |

| Freight Partners | Maersk, COSCO, specialized heavy-lift carriers | End-to-end cargo tracking & insurance |

Our logistics team coordinates with certified freight forwarders to manage oversized cargo, ensuring compliance with port regulations and safe handling of heavy machinery.

Supporting New Shipbuilding & Ship-Repair Projects

For new construction and ship-repair projects, we prioritize precision and reliability. Our packaging and logistics protocols are tailored to meet the stringent timelines of shipyards, with:

Dedicated project coordination: Single-point contact for end-to-end shipment tracking

Rapid customs clearance: Pre-verified documentation to avoid port delays

On-site installation readiness: Packaging designed for easy unloading and minimal handling

Emergency response capability: Expedited shipping options for urgent repair needs

As a trusted partner to global shipbuilders and repair yards, we ensure your mooring winches arrive in perfect condition, ready for immediate deployment—minimizing downtime and maximizing operational efficiency.

Contact Star Marine Technology

Electric Mooring Winch Technical Export Guide

Introduction

Hangzhou Star Marine Technology Co., Ltd. is a certified manufacturer of marine deck machinery specializing in high-performance electric mooring winches engineered for global maritime operations. Our products are designed to meet the rigorous demands of new shipbuilding and ship repair projects, ensuring compliance with international standards and delivering superior reliability under extreme operational conditions.

Technical Specifications

Our electric mooring winches are precision-engineered for diverse operational requirements. Key specifications include:

| Parameter | Specification |

|---|---|

| Pull Load Range | 50 kN to 500 kN (customizable per project) |

| Chain Diameter | 12.5 mm – 60 mm (compatible with all standard marine chains) |

| Line Speed | 5–30 m/min (adjustable via variable frequency drive for optimized performance) |

| Drive System | Electric (AC/DC), Hydraulic, or Hybrid configurations |

| Braking System | Automatic brake holding 1.25× static load capacity; IACS-compliant |

| Control System | PLC-based remote operation with manual backup and emergency stop functionality |

Compliance & Certification Standards

All products are certified by leading classification societies and comply with international maritime regulations:

Classification Societies: ABS, BV, CCS, DNV, LR, GL

International Standards: ISO 12214:2017, OCIMF MEG4, SOLAS Chapter II-2

Safety Requirements: IACS Unified Requirements for mooring equipment

Quality Assurance: ISO 9001 certified manufacturing processes

Application Scenarios

New Shipbuilding Projects

Seamless integration with hull design for optimal mooring system layout

Customized winch configurations to meet specific class society requirements

Precision-engineered components for long-term durability in newbuilds

Ship Repair & Refit Operations

Rapid installation and retrofitting during dry-docking periods

Replacement of obsolete systems with modern, energy-efficient winches

Compliance with updated regulatory standards for existing fleets

Contact Hangzhou Star Marine Technology

As a trusted professional solution provider for marine equipment, Hangzhou Star Marine Technology offers tailored electric mooring winch solutions for global shipbuilding and repair projects. Our team of experts is ready to support your technical requirements and project specifications.

Product Manager: Kacher YE

Tel/WhatsApp: +86-178-16869405

Email: [email protected]

Request a customized quote or technical consultation today to ensure your project meets the highest industry standards.

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160