Emergency Air Compressor – Marine Solution Guide 2025

Content Navigation

Marine Insight: Emergency Air Compressor

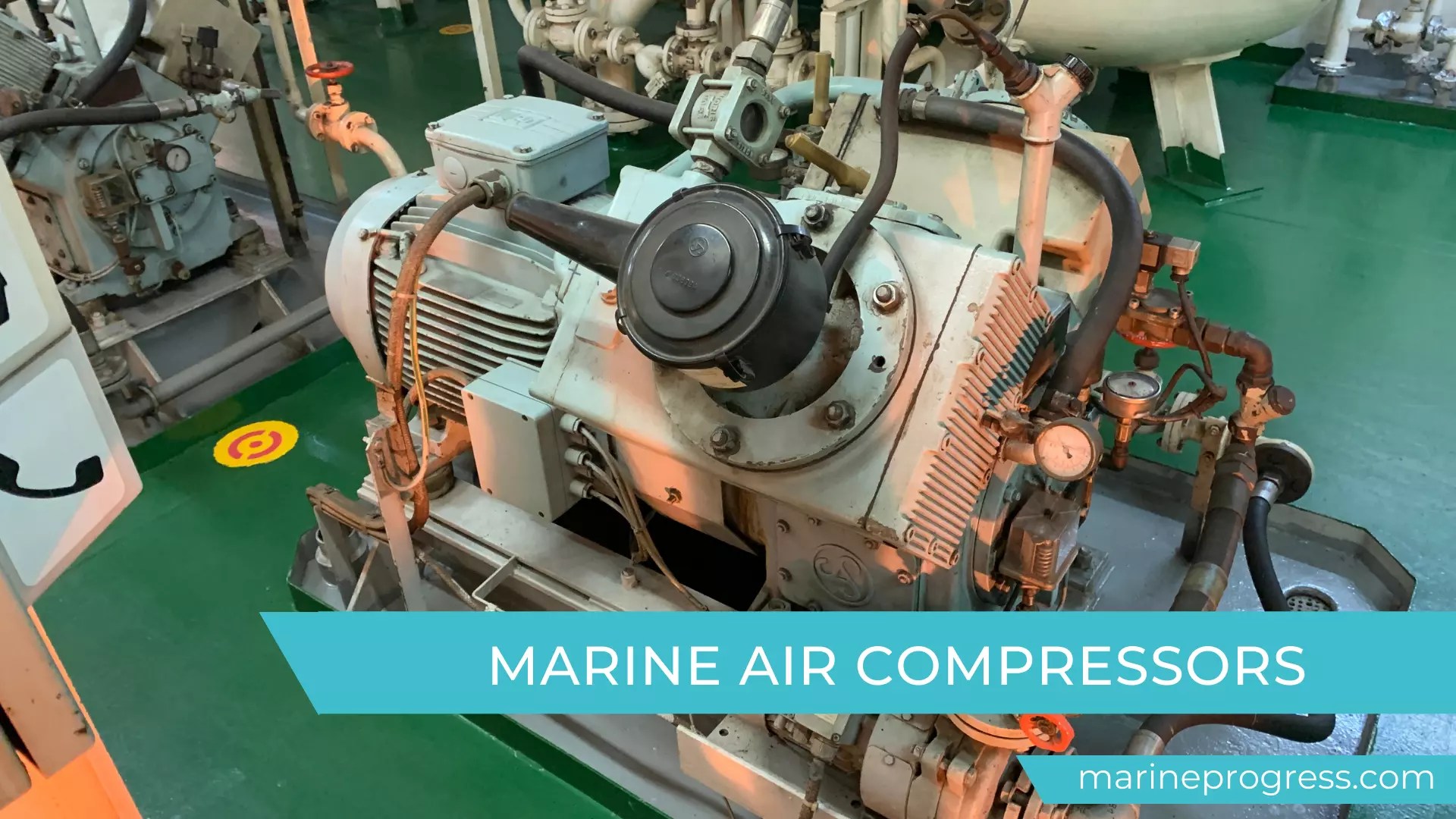

The emergency air compressor is a critical component in the marine engineering systems of commercial vessels, offshore platforms, and naval fleets. Its primary function is to supply compressed air for the restarting of main and auxiliary diesel engines in the event of a total power blackout or failure of the primary compressed air system. In maritime operations, where engine reliability directly affects navigation, propulsion, and safety, the ability to restart engines without external assistance is paramount. Emergency air compressors ensure that vessels can regain propulsion and maneuverability swiftly, minimizing risks in congested waterways, adverse weather, or emergency situations such as fire or collision.

Marine classification societies, including Lloyd’s Register, DNV, ABS, and CCS, mandate the installation of independent emergency air systems on most seagoing vessels above a specified gross tonnage. These regulations underscore the importance of having a dedicated, self-contained air source that remains operational even when primary power systems fail. The emergency air compressor must be capable of building sufficient air pressure in the emergency air bottles within a defined period, typically within 1 hour from a completely depleted state, to ensure operational readiness at all times.

Beyond regulatory compliance, the reliability and durability of the emergency air compressor directly influence a vessel’s safety management system under the International Safety Management (ISM) Code. A failure in this system could lead to delayed engine starts, extended downtime, and increased risk during critical operations such as port entry, anchoring, or emergency response.

Hangzhou Star Marine Technology Co., Ltd. specializes in the design and export of marine air compressors that meet international performance and safety standards. Our emergency air compressors are engineered for robust operation in harsh marine environments, featuring corrosion-resistant materials, compact footprints, and low maintenance requirements. Each unit undergoes rigorous testing for pressure integrity, cycle endurance, and performance under extreme temperatures to ensure compliance with ISO 9001 and relevant marine classification standards.

Sourcing emergency air compressors from Star Marine China offers significant cost advantages without compromising quality. China’s advanced manufacturing infrastructure, combined with our in-house engineering expertise, allows us to deliver high-performance compressors at competitive price points. Additionally, our strategic location in Hangzhou provides efficient logistics access to major global ports, reducing lead times and shipping costs for international buyers.

The following table outlines key specifications of our standard emergency air compressor model suitable for vessels ranging from 5,000 to 50,000 DWT:

| Parameter | Specification |

|---|---|

| Air Delivery Capacity | 120 L/min at 30 bar |

| Drive Type | Electric motor (IEC standard) |

| Power Supply | 440 V AC, 60 Hz, 3-phase |

| Maximum Working Pressure | 35 bar |

| Cooling Method | Air-cooled |

| Ambient Operating Temperature | -20°C to +50°C |

| Noise Level | ≤78 dB(A) at 1 meter |

| Classification Approvals | CCS, ISO 9001, DNV-GL (upon request) |

| Material Housing | Cast iron with anti-corrosion coating |

By combining regulatory compliance, engineering excellence, and cost-effective manufacturing, Hangzhou Star Marine Technology provides shipbuilders, operators, and marine equipment suppliers with a trusted solution for critical vessel safety systems.

Technical Specs & Approval

Technical Specifications: Emergency Air Compressor Systems

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures SOLAS-compliant emergency air compressors exclusively for critical marine applications. These systems ensure reliable starting air supply for main and auxiliary engines during power failure scenarios, adhering strictly to IMO MSC.338(91) and classification society rules (DNV, ABS, LR, CCS). Our compressors integrate robust engineering with fail-safe mechanisms to operate continuously under harsh maritime conditions, including high humidity, salt spray, and vessel motion. All units undergo rigorous factory acceptance testing per ISO 1217 Annex C and are certified for installation on commercial vessels, offshore platforms, and naval assets. The following technical parameters define the operational envelope and performance standards for our STARMARINE EAC Series emergency air compressors.

Technical Parameters

| Parameter | Specification | Notes |

|---|---|---|

| Discharge Pressure | 25–30 MPa (adjustable) | Maximum 30 MPa certified; pressure switch accuracy ±0.5 MPa |

| Free Air Delivery | 12–18 Nm³/h @ 30 MPa | Measured at ISO 1217 reference conditions (1.013 bar, 20°C) |

| Cooling Method | Forced air with marine-grade aluminum fins | Ambient operating range: -25°C to +55°C; corrosion-resistant coating |

| Drive Motor | 11 kW, 440V AC, 60 Hz, TEFC IP56 | Dual-voltage option (380V/440V); marine insulation class H |

| Starting Cycle | Continuous duty (S1) | 100% load capacity for 120 minutes minimum |

| Noise Level | ≤78 dB(A) at 1 meter | Measured per ISO 2151; compliant with IMO MSC/Circ.1474 |

| Lubrication System | Oil-free piston design | ISO 8573-1 Class 0 certified; no hydrocarbon contamination |

| Safety Systems | Dual-stage pressure relief valve | Thermal overload protection; automatic shutdown at 110°C winding temp |

| Dimensions (L×W×H) | 1,250 × 850 × 1,050 mm | Compact footprint for engine room integration |

| Weight (dry) | 420 kg | Includes vibration-damping mounts |

Discharge pressure capability up to 30 MPa ensures compatibility with modern high-pressure starting systems for large-bore marine diesel engines, exceeding the minimum 25 MPa requirement in SOLAS Chapter II-1/4.3. The forced air cooling system utilizes oversized finned heat exchangers with epoxy-coated surfaces to resist salt-induced corrosion, maintaining thermal efficiency in tropical environments. Flow rates are validated at 30 MPa to guarantee sufficient air volume for three consecutive engine starts without auxiliary storage depletion.

The oil-free piston mechanism eliminates combustion risks and meets stringent air purity standards for engine starting circuits. All electrical components feature moisture-resistant windings and conformal coating to withstand condensation during extended standby periods. Pressure regulation incorporates redundant safety valves set at 110% of working pressure, with real-time monitoring via integrated pressure transducers compatible with vessel automation systems. Mounting bases include ISO 8506-compliant anti-vibration elements to isolate structure-borne noise and prevent fatigue failure from hull stresses. These specifications collectively ensure 15,000+ hours of maintenance-free operation between major overhauls, supporting extended vessel deployment cycles without compromising emergency readiness.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine air compressor solutions tailored specifically for shipbuilding and repair applications. As a trusted supplier in the maritime industry, we specialize in emergency air compressors that ensure operational continuity and safety compliance across a wide range of vessel types. Our engineered systems support critical start-up functions for main and auxiliary engines, particularly during blackout scenarios, where rapid and reliable air supply is essential.

In new shipbuilding projects, Star Marine collaborates closely with shipyards and design teams to integrate emergency air compressors that meet exact project specifications and classification society requirements. Our compressors are designed to comply with international standards including ISO 8573, SOLAS, and certifications from CCS, ABS, DNV, LR, and BV. This ensures seamless approval processes and integration within the vessel’s compressed air system. Our engineering team provides technical documentation, 3D modeling support, and on-site commissioning assistance to ensure timely delivery and installation.

For ship repair and retrofitting, Star Marine offers fast-response service and drop-in replacement solutions. Aging or obsolete compressors can be upgraded with modern, energy-efficient models that improve reliability and reduce maintenance costs. Our global spare parts network and technical support team enable rapid turnaround, minimizing vessel downtime. We maintain an extensive inventory of standard and customized units, allowing us to dispatch equipment within 72 hours for urgent repair cases.

Our emergency air compressors are engineered for harsh marine environments, featuring corrosion-resistant materials, compact footprint designs, and low-noise operation. These units are typically powered by electric motors or diesel engines, ensuring functionality even during total power failure. With automatic start/stop controls and integrated safety monitoring, our systems provide uninterrupted readiness for emergency engine restarts.

Below is an overview of standard technical specifications for our marine emergency air compressor series:

| Parameter | Specification |

|---|---|

| Capacity Range | 0.6 – 3.0 m³/min |

| Working Pressure | 30 – 35 bar |

| Power Supply | 220/380V, 50Hz or customized voltage/frequency |

| Drive Type | Electric or Diesel Engine |

| Cooling Method | Air or Water Cooled |

| Lubrication | Oil-lubricated or Oil-free options |

| Noise Level | ≤78 dB(A) at 1 meter |

| Protection Class | IP55 (standard), up to IP66 on request |

| Classification Approvals | CCS, ABS, DNV, LR, BV, RINA |

| Ambient Operating Temperature | -25°C to +50°C |

Star Marine’s commitment to quality, speed, and technical excellence makes us a preferred partner in both new construction and repair sectors. With in-house manufacturing, rigorous testing protocols, and a customer-first approach, we ensure every emergency air compressor delivers optimal performance throughout its service life. For shipyards and fleet operators, this translates into reduced project risk, faster delivery, and long-term operational reliability.

Packaging & Logistics

Packaging & Logistics Standards for Emergency Air Compressors

Hangzhou Star Marine Technology Co., Ltd. implements rigorous packaging protocols for all emergency air compressors to ensure global shipment integrity and compliance with international maritime regulations. Our standard export packaging utilizes custom-engineered wooden cases adhering strictly to ISPM 15 (International Standards for Phytosanitary Measures No. 15). These cases are constructed from heat-treated (HT) lumber, eliminating the risk of pest infestation during transit. Each wooden crate undergoes mandatory phytosanitary certification, bearing the official ISPM 15 mark with country code, producer code, and HT designation. This certification is non-negotiable for entry into all major global ports, including the United States, European Union member states, and Australia, preventing customs delays or rejection.

For structural resilience during ocean transport, all wooden cases are mounted on heavy-duty steel pallets with reinforced cross-members. These pallets provide critical load distribution and facilitate secure lashing within containers or on vessel decks. Internal bracing includes anti-vibration mounts and custom-cut foam inserts to immobilize the compressor unit, safeguarding sensitive components such as pressure switches, control panels, and valve assemblies against shock and moisture ingress. Desiccant packs are strategically placed within sealed compartments to mitigate humidity risks during extended voyages. All external surfaces are treated with marine-grade corrosion inhibitors, and critical connection points are coated with protective grease prior to sealing.

The following table details our standard packaging specifications for emergency air compressors:

| Packaging Component | Material Specification | Treatment Standard | Load Capacity | Port Handling Notes |

|---|---|---|---|---|

| Primary Wooden Crate | Kiln-dried plywood (18mm) | ISPM 15 HT Certified | Up to 3,500 kg | Forklift pockets integrated; ISPM 15 mark visible on all sides |

| Base Pallet | Hot-dip galvanized steel | Salt-spray tested (72h) | 5,000 kg static | Welded lashing points (4x per pallet); non-slip surface |

| Internal Bracing | Closed-cell polyethylene foam | Anti-static coating | Vibration damping ≤0.5g | Pre-cut to unit dimensions; reusable design |

| Sealing & Protection | Industrial-grade polypropylene strapping | UV-resistant | Tensile strength 5,000 kg | Tamper-evident seals applied at factory |

Shipments originate exclusively from China’s premier deep-water ports: Ningbo-Zhoushan Port (world’s busiest container port) and Shanghai Port (Yangshan Deep-Water Terminal). Both facilities offer seamless integration with global container lines and specialized handling for heavy marine equipment. All units are pre-staged at our bonded warehouse in Hangzhou for direct trucking to port, minimizing inland transit exposure. We coordinate closely with certified maritime freight forwarders to ensure container selection (typically 20ft or 40ft high-cube) aligns with compressor dimensions and weight. Critical documentation—including ISPM 15 certificates, packing lists, and commercial invoices—is digitized and submitted 72 hours prior to vessel departure to expedite customs clearance.

Hangzhou Star Marine Technology maintains direct oversight of port loading operations, verifying proper dunnage placement and lashing compliance per CSS Code (Code of Safe Practice for Cargo Stowage and Securing). This end-to-end control guarantees that emergency air compressors arrive at destination ports in operational condition, fully aligned with SOLAS and IMDG requirements for marine safety equipment.

Contact Star Marine

For maritime operators, shipbuilders, and offshore engineering firms requiring reliable and certified emergency air compressor solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in marine equipment innovation and export. Our emergency air compressors are engineered to meet the rigorous demands of marine environments, ensuring fail-safe operation during critical scenarios such as main engine starting, pneumatic system recovery, and auxiliary power support. Designed in strict compliance with international maritime standards—including ISO, SOLAS, and classification society requirements such as CCS, ABS, DNV, and LR—our compressors deliver performance you can trust when it matters most.

At Hangzhou Star Marine Technology, we specialize in the design, manufacturing, and global export of marine air compression systems tailored to both newbuild and retrofit applications. Our emergency air compressors are constructed using high-grade marine materials, corrosion-resistant coatings, and precision-engineered components to ensure long service life and minimal maintenance. Each unit undergoes comprehensive performance testing, including load cycling, pressure integrity checks, and endurance runs under simulated offshore conditions.

To support our international clients, we offer full technical documentation, including 3D models, installation manuals, and compliance certificates. Our export team manages end-to-end logistics, ensuring timely delivery to ports worldwide with complete customs compliance and packaging suitable for marine transport.

For project-specific inquiries, technical consultations, or OEM/ODM collaboration, we encourage direct engagement with our Product Manager, Kacher YE. With extensive experience in marine system integration and global export operations, Kacher provides expert guidance on product selection, customization options, and compliance alignment with regional maritime regulations. Whether you are specifying equipment for a new vessel build or upgrading an existing fleet, our engineering team works closely with clients to deliver optimized solutions.

Below are key specifications representative of our emergency air compressor series:

| Parameter | Specification |

|---|---|

| Working Pressure | 30 bar (max) |

| Air Delivery Capacity | 1.2 – 3.5 m³/min |

| Power Supply | 380V/440V, 50/60Hz, 3-phase |

| Drive Type | Electric or Diesel-Driven (optional) |

| Cooling Method | Water-cooled / Air-cooled |

| Noise Level | ≤78 dB(A) at 1 meter |

| Protection Class | IP55 (standard), up to IP66 on request |

| Classification Approvals | CCS, ABS, DNV, LR, BV, RINA |

| Ambient Operating Temperature | -25°C to +50°C |

| Customization Availability | Yes (voltage, materials, footprint, controls) |

To request a quotation, technical datasheet, or schedule a product consultation, contact Kacher YE directly at [email protected]. We respond to all inquiries within 12 business hours and support communication in English, Mandarin, and Spanish. Let Hangzhou Star Marine Technology be your strategic partner in marine safety and system reliability.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160