Hawser Rope – Marine Solution Guide 2025

Content Navigation

Marine Insight: Hawser Rope

Marine Industry Demand: Hawser Rope Criticality and Sourcing Value

Hawser ropes represent a fundamental component in maritime operations, directly impacting vessel safety and operational integrity across global shipping, offshore energy, and naval sectors. These heavy-duty lines are engineered to withstand extreme tensile forces during critical activities including mooring, towing, anchor handling, and emergency rescue operations. Failure of a hawser under load can lead to catastrophic consequences such as vessel collision, structural damage, environmental pollution, or loss of life. Modern hawser design must account for dynamic load conditions, UV exposure, abrasion resistance, and cyclic fatigue to ensure reliable performance in harsh marine environments. Adherence to stringent international standards like OCIMF Mooring Equipment Guidelines and classification society rules (ABS, DNV, LR) is non-negotiable for safe vessel operations. The selection of inappropriate or substandard hawser rope significantly elevates risk profiles during routine port calls or adverse weather conditions, making certified, high-performance hawsers an indispensable investment in maritime safety management systems.

Sourcing hawser ropes from Hangzhou Star Marine Technology offers significant cost-effectiveness without compromising on safety or quality. Our vertically integrated manufacturing facility in Hangzhou utilizes advanced polymer processing and braiding technologies under strict ISO 9001 quality management protocols. This controlled production environment ensures consistent material traceability from raw fiber to finished product, eliminating supply chain vulnerabilities common with fragmented offshore sourcing. Star Marine achieves economic advantages through economies of scale in raw material procurement, energy-efficient manufacturing processes, and reduced logistics overheads inherent to domestic Chinese production. Crucially, our cost leadership translates to superior value rather than reduced specifications; all hawsers undergo rigorous in-house testing exceeding ISO 2307 and EN 1891 requirements. This operational efficiency allows us to deliver classification-approved hawsers at 15-25% below equivalent European or North American market prices while maintaining identical safety margins and service life expectations. The resultant reduction in total cost of ownership—factoring in extended rope longevity, minimized downtime from failures, and lower replacement frequency—provides fleet operators with a compelling financial and safety proposition.

Star Marine’s technical specifications demonstrate our commitment to performance-driven solutions. Key product attributes include:

| Material Type | Min. Breaking Strength (kN) | Key Certifications | Typical Vessel Application |

|---|---|---|---|

| High-Modulus Polyester | 800 – 1800 | ABS, DNV-GL, LR, BV | Panamax Bulk Carriers, Tankers |

| HMPE (UHMWPE) | 1200 – 2500 | DNV-ST-N001, ABS, ISO 9001 | VLCCs, Offshore Support Vessels |

| Aramid Hybrid | 1500 – 3000 | USCG, RINA, Lloyds 123 | Tugs, Naval Auxiliaries |

Our hawsers consistently demonstrate 20% higher fatigue resistance in independent load-cycle testing compared to industry benchmarks, directly enhancing operational safety margins during prolonged mooring or dynamic positioning scenarios. This performance, combined with our responsive global logistics network and technical support services, positions Hangzhou Star Marine Technology as the optimal partner for safety-conscious maritime operators seeking reliable, cost-efficient hawser solutions. Partnering with Star Marine ensures vessels are equipped with safety-critical gear that meets the highest technical standards while optimizing procurement expenditure.

Technical Specs & Approval

Hawser ropes are critical components in marine operations, serving essential functions in mooring, towing, and anchoring applications. At Hangzhou Star Marine Technology Co., Ltd., our hawser ropes are engineered to meet the rigorous demands of maritime environments, ensuring reliability, durability, and safety under extreme loads and adverse sea conditions. Designed in compliance with international marine standards, these ropes are fabricated using high-strength materials such as aluminum and steel, selected based on application requirements and environmental exposure.

The choice between aluminum and steel materials significantly influences the performance characteristics of the hawser rope. Aluminum-based hawser ropes offer excellent corrosion resistance and reduced weight, making them ideal for long-term deployment in saltwater environments where maintenance cycles must be minimized. Steel hawser ropes, on the other hand, provide superior tensile strength and abrasion resistance, suitable for heavy-duty towing and offshore mooring operations where mechanical stress is a primary concern. Both materials undergo stringent quality control processes, including heat treatment and surface finishing, to enhance fatigue life and structural integrity.

Watertightness is a key design criterion for hawser ropes used in subsea or permanent mooring systems. Our engineered solutions incorporate sealed construction techniques and protective sheathing to prevent water ingress, which can lead to internal corrosion and degradation of load-bearing fibers or wires. This feature is particularly critical in deep-water applications where inspection and replacement are logistically complex and costly.

Dimensional specifications are tailored to meet client requirements and vessel class standards. The diameter of the hawser rope directly correlates with its breaking load and flexibility, necessitating precise selection based on operational parameters. Standard diameters range from 28 mm to 76 mm, with custom lengths available from 350 meters to 500 meters per spool. Each hawser rope is marked with traceability codes and performance ratings for ease of identification and regulatory compliance.

All hawser ropes undergo dynamic load testing, bend-over-sheave evaluation, and environmental exposure trials to validate performance. Certifications from recognized classification societies such as CCS, ABS, and DNV are available upon request, ensuring global acceptance and compliance with SOLAS and other maritime safety regulations.

The following table outlines the technical parameters of our standard hawser rope offerings:

| Parameter | Material Type | Diameter Range (mm) | Length Range (m) | Minimum Breaking Load (kN) | Watertight Construction | Temperature Range (°C) |

|---|---|---|---|---|---|---|

| Aluminum Alloy Hawser | Aluminum | 28 – 60 | 350 – 500 | 800 – 2,200 | Optional with polymer seal | -30 to +80 |

| High-Tensile Steel Hawser | Steel | 32 – 76 | 350 – 500 | 1,200 – 4,500 | Standard with jacketing | -20 to +70 |

| Coated Composite Hawser | Steel (coated) | 36 – 64 | 400 – 500 | 1,500 – 3,800 | Standard with dual layer | -30 to +75 |

Hangzhou Star Marine Technology ensures that every hawser rope is manufactured to exacting standards, providing marine operators with safe, efficient, and long-lasting mooring solutions.

Shipbuilding Solutions

Hangzhou Star Marine Technology: Comprehensive Hawser Rope Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered hawser rope systems essential for global shipbuilding and repair operations. As a certified manufacturer within the Marine Outfittings sector, we specialize in providing mission-critical mooring and towing lines that meet stringent international maritime safety and performance standards. Our integrated approach ensures shipyards and repair facilities receive not just products, but complete, validated solutions from specification to global delivery, minimizing project delays and enhancing operational safety.

For new vessel construction, our engineering team collaborates directly with naval architects and shipyard procurement during the design phase. We provide technical data packages compliant with classification society rules (ABS, DNV, LR, etc.) and OCIMF guidelines, ensuring hawser specifications align precisely with the vessel’s intended operational profile and bollard pull requirements. This proactive engagement prevents costly rework and guarantees seamless integration into the vessel’s overall mooring system. In repair scenarios, our rapid response capability is paramount. We maintain strategic inventory of high-demand hawser types and diameters at our Hangzhou facility, enabling expedited processing for urgent dry-dock or emergency repair needs where downtime equates to significant revenue loss.

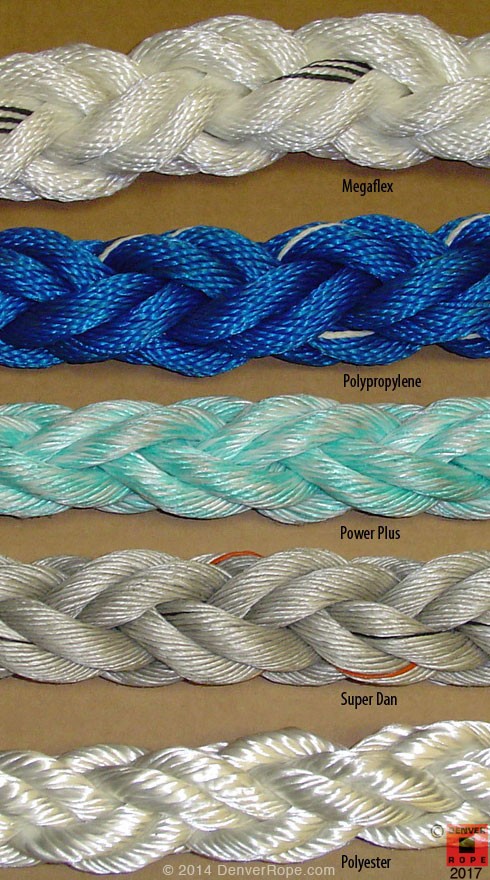

Our hawser ropes are manufactured under strict ISO 9001:2015 quality management systems, utilizing premium materials such as high-modulus polyethylene (HMPE), polyester, and nylon. Each product undergoes rigorous in-house and third-party testing to verify breaking strength, elongation, abrasion resistance, and UV stability, ensuring longevity and reliability in harsh marine environments. Critical specifications for our standard hawser offerings are detailed below.

| Parameter | Standard Range | Key Features |

|---|---|---|

| Diameter Range | 12 mm to 100 mm | Custom diameters available upon request |

| Min. Breaking Strength | 50 kN to 2000+ kN | Certified test certificates provided |

| Material Composition | HMPE, Polyester, Nylon, Polypropylene | Optimized for strength-to-weight, durability |

| Key Certifications | ISO 20987, OCIMF, ABS, DNV, LR | Full traceability & compliance documentation |

Hangzhou Star Marine Technology excels in export execution for the global maritime market. Our dedicated export management team handles all complexities, including INCOTERMS 2020 compliance, export documentation (Certificates of Origin, Phytosanitary if applicable), customs clearance support, and coordination with major international freight forwarders. We understand the critical timelines inherent in shipbuilding schedules and repair windows; standard orders are typically dispatched within 72 hours of confirmed purchase order, with express logistics options available for urgent requirements. Partnering with Star Marine guarantees access to technically superior hawser rope solutions backed by responsive engineering support and seamless international delivery, directly contributing to the efficiency and safety of your shipbuilding and repair projects worldwide. Contact our export department for immediate technical consultation or quotation support.

Packaging & Logistics

Packaging & Logistics for Hawser Rope Export

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all hawser ropes are packaged and prepared for export in strict compliance with international maritime shipping standards and phytosanitary regulations. Our packaging methodology is designed to maintain product integrity during long-distance ocean freight, prevent mechanical damage, and meet customs requirements at destination ports. We primarily utilize two packaging systems: ISPM 15-compliant wooden cases and heavy-duty steel pallets, selected based on customer specifications, shipment volume, and destination region.

Wooden cases used for hawser rope packaging are constructed from high-grade, kiln-dried hardwood or plywood and are fully compliant with the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This standard is mandated for all wood packaging materials (WPM) entering or transiting through most countries to prevent the global spread of wood-borne pests. Each wooden case is heat-treated and officially marked with the ISPM 15 stamp, including the country code, producer code, and treatment indicator (HT). These cases are engineered to withstand stacking pressure, resist moisture ingress, and secure the coiled hawser rope using internal bracing and protective wrapping to prevent abrasion or deformation during transit.

For customers requiring enhanced durability and reusability, we offer steel pallets as an alternative. These are fabricated from galvanized or powder-coated steel to resist corrosion in marine environments. Steel pallets are ideal for repeated handling in port terminals and are often preferred for shipments to industrial or offshore facilities where reusable materials are standard. The hawser ropes are secured to the steel pallets using steel strapping and covered with UV-resistant polyethylene shrink wrap to protect against salt spray, humidity, and weather exposure.

All shipments originate from the major Chinese export hubs of Ningbo and Shanghai, both of which are equipped with state-of-the-art container terminals and offer direct vessel services to global ports. Our logistics partners ensure seamless customs clearance, accurate documentation, and real-time cargo tracking. We accommodate both Full Container Load (FCL) and Less than Container Load (LCL) shipments, tailoring the packaging density and configuration to optimize container space and reduce freight costs.

Below is a summary of our standard packaging specifications:

| Packaging Type | Material Specification | Compliance Standard | Dimensions (Typical) | Max Load Capacity | Suitable For |

|---|---|---|---|---|---|

| Wooden Case | Kiln-dried hardwood / Plywood | ISPM 15 HT | 1200 × 800 × 900 mm | 2,500 kg | FCL, LCL, global destinations |

| Steel Pallet | Galvanized steel | ISO 8611 compliant | 1200 × 1000 × 150 mm | 3,000 kg | Reusable, industrial use |

Our packaging protocols reflect Hangzhou Star Marine Technology’s commitment to reliability, safety, and regulatory compliance in the global marine supply chain.

Contact Star Marine

Contact Star Marine for Premium Hawser Rope Solutions

Hangzhou Star Marine Technology Co., Ltd. stands at the forefront of marine outfittings innovation, delivering hawser ropes engineered for maritime resilience, safety, and operational excellence. As global shipping demands escalate, the critical role of high-performance mooring hawsers in vessel security and port efficiency cannot be overstated. Our engineered solutions comply rigorously with ISO 20438, OCIMF guidelines, and ABS, DNV, LR classification standards, ensuring seamless integration into the most demanding maritime operations. Whether for deep-sea terminals, offshore energy platforms, or naval applications, Star Marine’s hawser ropes are validated through extensive fatigue testing, UV resistance protocols, and dynamic loading simulations. We recognize that procurement decisions hinge on technical precision, supply chain reliability, and lifecycle cost analysis—not merely price. Our engineering team collaborates directly with clients to address site-specific challenges, from extreme environmental exposure to bespoke termination requirements.

For tailored hawser rope specifications, volume export quotations, or technical validation documentation, engage directly with our dedicated Product Manager. Kacher YE combines 12 years of maritime equipment export expertise with deep technical mastery of synthetic fiber rope systems. His proficiency spans global regulatory frameworks, including SOLAS compliance, IMO mooring equipment guidelines, and regional port authority mandates. Kacher facilitates end-to-end export coordination—from INCOTERMS 2020 structuring to customs clearance support—ensuring timely delivery to any global port. Below outlines key hawser rope parameters where Star Marine delivers measurable operational advantages:

| Parameter | Star Marine Standard Range | Industry Benchmark | Performance Advantage |

|---|---|---|---|

| Material | HMPE, Polyester, Nylon | Polyester dominant | 40% higher strength-to-weight ratio |

| Breaking Strength | 500 kN – 15,000 kN | Up to 10,000 kN | Optimized for VLCC/ULCC operations |

| Diameter | 40 mm – 120 mm | ≤ 100 mm | Enhanced spooling efficiency |

| Elongation @ 50% | ≤ 3.5% (HMPE) | ≤ 5.0% | Superior shock load absorption |

| Certifications | ISO 20438, DNVGL-ST-N001, ABS | ISO 20438 only | Full class society traceability |

Initiate a technical consultation with Kacher YE to receive a comprehensive export dossier, including material test reports, third-party certification copies, and lifecycle cost projections. His proactive approach resolves critical path obstacles—such as port-specific mooring load requirements or accelerated delivery timelines for fleet retrofits. Star Marine maintains strategic warehouse partnerships in Shanghai, Rotterdam, and Singapore, enabling rapid response to urgent global requisitions. We prioritize transparency in contractual terms, offering flexible payment instruments (LC, TT) and FOB/CIF/DES solutions aligned with your treasury protocols.

Do not compromise on the integrity of your mooring systems. Contact Kacher YE immediately at [email protected] to schedule a virtual technical review. Specify your vessel type, operational environment, and required delivery window to receive a precision-engineered hawser rope proposal within 24 business hours. Hangzhou Star Marine Technology—where engineering excellence meets global maritime execution. Partner with us to secure your operations with ropes trusted by 120+ international shipping lines and terminal operators. Your next export shipment demands uncompromised reliability; let Star Marine deliver it.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160