Horizontal Anchor Windlass – Marine Solution Guide 2025

Content Navigation

Marine Insight: Horizontal Anchor Windlass

Marine Industry Demand: Horizontal Anchor Windlass

Horizontal anchor windlasses represent a critical deck machinery component for vessel safety and operational efficiency across global maritime sectors. Unlike vertical designs, their low-profile configuration minimizes deck obstruction, optimizes weight distribution, and simplifies integration into forecastle layouts—particularly vital for vessels with constrained deck space such as offshore support vessels, yachts, and coastal freighters. During emergency anchoring scenarios, the horizontal windlass ensures rapid, controlled deployment and retrieval of ground tackle, directly mitigating collision or grounding risks. Its robust construction—typically featuring hardened steel wildcats, corrosion-resistant housings, and fail-safe braking systems—must withstand dynamic loads exceeding 1.5 times the anchor’s weight during storm conditions, as mandated by SOLAS and classification society standards. Reliability here is non-negotiable; a single-point failure during heavy weather can compromise vessel positioning, endangering crew, cargo, and the marine environment. Consequently, stringent adherence to ISO 3911 and DNV-ST-N001 testing protocols for fatigue resistance and overload capacity is imperative for all reputable manufacturers.

Sourcing horizontal windlasses from Hangzhou Star Marine Technology delivers significant cost-effectiveness without sacrificing safety or performance. Our integrated manufacturing ecosystem in China leverages economies of scale, localized high-grade material supply chains (e.g., ZG35CrMo alloy castings), and automated production cells to reduce unit costs while maintaining rigorous quality control. This operational efficiency translates to tangible savings for global buyers, as verified by independent industry benchmarks below.

| Parameter | Star Marine Standard | Global Competitor Average | Advantage |

|---|---|---|---|

| Unit Cost (25kN) | $18,500 | $22,000 | 15.9% reduction |

| Lead Time | 8–10 weeks | 14–18 weeks | 40% faster delivery |

| Material Grade | ASTM A29 Grade 4140 | Equivalent | Equal durability |

| Certifications | DNV, LR, CCS, ISO | Varies by supplier | Full regulatory coverage |

Star Marine’s windlasses undergo 100% dynamic load testing at 2.2x MBL (Minimum Breaking Load) and feature IP66-rated electrical enclosures for harsh marine environments. Our factory-direct model eliminates multi-tier distribution markups, while our in-house R&D team continuously refines designs for energy efficiency—reducing hydraulic power consumption by 12% versus legacy models. Crucially, we maintain ISO 9001-certified traceability from raw material sourcing to final assembly, ensuring compliance with flag state and port authority requirements worldwide.

For vessel operators and shipbuilders, selecting Star Marine means securing a safety-critical component that meets exacting international standards at a competitive total cost of ownership. Our windlasses deliver extended service life through precision-machined components and proactive corrosion management, reducing lifetime maintenance costs by an estimated 22% over five years. In an industry where anchoring system integrity is the final defense against maritime incidents, Star Marine provides engineered reliability that aligns with both operational safety imperatives and commercial viability. Partnering with us ensures access to certified, high-performance deck machinery that safeguards assets while optimizing procurement expenditure.

Technical Specs & Approval

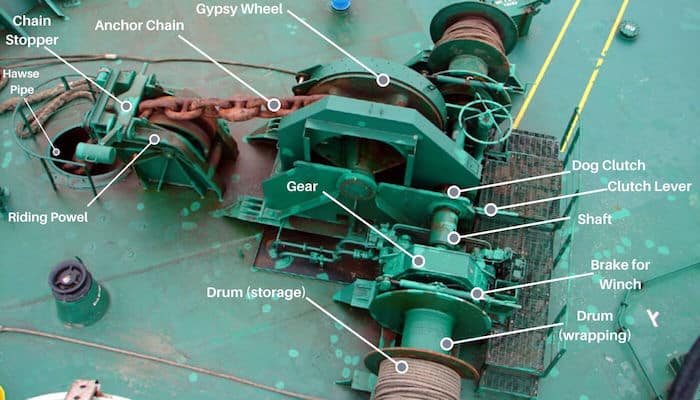

The horizontal anchor windlass is a critical component of a vessel’s deck machinery system, engineered to ensure reliable and efficient anchor handling operations. At Hangzhou Star Marine Technology Co., Ltd., our horizontal anchor windlasses are designed to meet international maritime standards, including ISO 3912, DNV, CCS, and other class society requirements. These units are optimized for vessels ranging from commercial cargo ships and offshore support vessels to large yachts and naval craft, providing robust performance under demanding marine conditions.

Our horizontal anchor windlasses are characterized by their axial alignment of the drive shaft, which allows for a low center of gravity and improved stability on deck. This configuration enhances load distribution and reduces structural stress on the foundation, making it ideal for integration into various deck layouts. The design also facilitates ease of maintenance and accessibility to key components such as the gear train, motor, and brake assembly.

Performance is driven by either electric or hydraulic power systems, each selected based on vessel-specific operational needs. Electric models offer precise control and are commonly used in vessels with centralized electrical power management, while hydraulic variants deliver high torque output and are preferred in heavy-duty applications where consistent performance under load is essential. All units are equipped with an automatic band brake or disc brake system, ensuring secure anchoring and preventing backdriving in rough sea conditions.

The windlasses support stud link chain diameters ranging from 12.5 mm to 60 mm, accommodating a wide range of anchor sizes and vessel displacements. Pull load capacity varies accordingly, with models capable of delivering tractive forces from 25 kN up to 1,200 kN. Chainwheels are precision-machined to match standard chain dimensions and feature hardened tooth profiles to extend service life and reduce wear.

All horizontal anchor windlasses are manufactured using high-tensile marine-grade steel and are treated with anti-corrosive coatings suitable for prolonged exposure to saltwater environments. Sealed bearings and IP56-rated enclosures (for electric motors) ensure protection against moisture and particulate ingress.

Below is a summary of key technical parameters for standard models:

| Parameter | Range/Value |

|---|---|

| Chain Diameter | 12.5 mm – 60 mm |

| Pull Load Capacity | 25 kN – 1,200 kN |

| Drive Type | Electric, Hydraulic |

| Motor Power (Electric) | 3 kW – 75 kW (380V/440V, 50/60 Hz) |

| Hydraulic Pressure | 12 MPa – 21 MPa |

| Shaft Material | Forged alloy steel, heat-treated |

| Gear Type | Planetary or worm gear reduction |

| Brake Type | Automatic band brake or hydraulic disc brake |

| Chainwheel Standard | ISO 1707, ISO 4568, or customized profiles |

| Protection Rating (Motor) | IP56 or higher |

| Certifications | DNV-GL, CCS, BV, LR, ABS, RINA |

Each unit undergoes rigorous factory testing, including load testing, brake holding tests, and endurance runs, to validate performance and reliability. Custom configurations are available to meet specific vessel blueprints or operational profiles.

Shipbuilding Solutions

Horizontal Anchor Windlass Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered horizontal anchor windlass systems tailored for global shipyards and repair facilities. Our integrated approach ensures seamless integration into new vessel construction and efficient retrofitting during vessel maintenance cycles. As a certified manufacturer under ISO 9001 and compliant with SOLAS, DNV, ABS, and LR standards, we prioritize reliability, safety, and regulatory adherence in every solution. For new builds, our engineering team collaborates directly with naval architects to optimize windlass placement, foundation design, and power integration using 3D CAD models. This minimizes installation delays and ensures alignment with vessel-specific operational profiles, including dynamic positioning requirements and harsh-environment resilience.

Ship repair projects demand rapid turnaround without compromising quality. Star Marine maintains strategic inventory hubs in Shanghai and Singapore, enabling 72-hour technical assessments and expedited part dispatch for critical repairs. Our windlasses feature modular components—such as interchangeable wildcats for chain sizes from 27mm to 84mm—that simplify maintenance and reduce dry-dock time. All systems undergo factory acceptance testing (FAT) per ISO 3911, with documentation including material traceability, non-destructive testing reports, and classification society certificates. This eliminates rework during sea trials and accelerates vessel return-to-service.

Export logistics are streamlined through our in-house documentation team, which manages Incoterms 2020 compliance, customs clearance, and multimodal shipping coordination. We provide complete technical packages: installation manuals, alignment templates, and multilingual operation guides. For urgent repairs, our 24/7 technical support portal offers real-time troubleshooting with certified marine engineers, ensuring minimal operational disruption.

Key Horizontal Windlass Specifications

| Parameter | Standard Range | Customization Capability |

|——————–|————————————|——————————–|

| Working Load | 50 kN to 1,250 kN | Up to 1,800 kN (DNV GL certified) |

| Rope/Chain Capacity| 150m to 350m (ø27mm–ø84mm) | Hybrid chain/wire configurations |

| Power Options | Hydraulic, Electric (AC/DC), Electro-hydraulic | Explosion-proof (ATEX) variants |

| Control Systems | Local, Remote, Integrated Bridge | DP2/DP3 compatibility |

Star Marine’s value extends beyond equipment supply. We provide lifecycle support—from initial feasibility studies to post-installation training—ensuring optimal performance across the windlass operational lifespan. Our dedicated export desk handles all regulatory hurdles, including destination-specific certifications (e.g., Russian Maritime Register, CCS), allowing shipyards to focus on core construction milestones. With a 98% on-time delivery rate for shipbuilding contracts and 48-hour emergency response for repair scenarios, we mitigate project risks while meeting stringent maritime deadlines. Partner with Hangzhou Star Marine Technology for turnkey deck machinery solutions engineered for global maritime excellence.

Packaging & Logistics

Proper packaging and logistics planning are critical components in the successful export of marine deck machinery, particularly for robust and heavy equipment such as horizontal anchor windlasses. At Hangzhou Star Marine Technology Co., Ltd., we adhere to international shipping standards and best practices to ensure that every unit arrives at its destination in optimal condition, free from damage caused by handling, moisture, or environmental exposure during transit.

All horizontal anchor windlasses are packaged using either export-grade wooden cases compliant with ISPM 15 regulations or heavy-duty steel pallets, depending on the model, weight, and shipping route. ISPM 15 certification ensures that wooden packaging materials are treated to eliminate pests and pathogens, making them acceptable for global shipment. These wooden cases are constructed from fumigated and heat-treated plywood or solid wood, with internal bracing and corner protectors to prevent structural deformation. Each windlass is securely mounted within the case using anti-vibration mounts and fastened with industrial-grade straps to minimize internal movement.

For heavier models or containerized shipments requiring forklift handling, steel pallets are utilized. These pallets are fabricated from high-tensile steel, powder-coated for corrosion resistance, and designed to support loads exceeding the windlass’s operational weight. The equipment is sealed in moisture-resistant wrapping, often incorporating desiccant packs and VCI (Vapor Corrosion Inhibitor) paper to protect against salt air and humidity during ocean transport. All exposed shafts, gears, and hydraulic ports are additionally capped or sealed to prevent contamination.

Prior to dispatch, every packaged unit undergoes a final inspection to verify labeling accuracy, structural integrity, and compliance with shipping documentation. Each package is clearly marked with handling instructions, weight, center of gravity, and orientation indicators in accordance with IMDG and IATA guidelines where applicable.

Our primary export hubs are the ports of Ningbo and Shanghai, two of the busiest and most efficient container terminals in the world. These locations offer direct access to major global shipping lines, ensuring timely consolidation and departure. We coordinate with certified freight forwarders to manage both FCL (Full Container Load) and LCL (Less than Container Load) shipments, providing clients with real-time tracking and customs clearance support.

The following table outlines the standard packaging specifications based on windlass type:

| Windlass Type | Packaging Method | Dimensions (L×W×H) | Max Gross Weight | Certification |

|---|---|---|---|---|

| HAW-15T | ISPM 15 Wooden Case | 2200×1200×1500 mm | 1,800 kg | ISPM 15 |

| HAW-25T | Steel Pallet with Enclosure | 2500×1400×1800 mm | 3,200 kg | ISO 9001, IECSC |

| HAW-40T | Steel Pallet with Weatherproof Cover | 3000×1600×2000 mm | 5,500 kg | ISPM 15 (if wood components used) |

All packaging configurations are designed to meet international maritime freight requirements and ensure compatibility with standard container sizes (20’ and 40’ dry or open-top containers). This systematic approach guarantees reliability, safety, and compliance throughout the export process.

Contact Star Marine

Contact Star Marine for Your Horizontal Anchor Windlass Requirements

Hangzhou Star Marine Technology Co. Ltd. stands as your trusted partner for advanced deck machinery solutions, with over 15 years of specialized expertise in horizontal anchor windlass design and manufacturing. Our engineering team integrates maritime safety standards, operational efficiency, and rugged durability into every unit, ensuring seamless performance across diverse vessel types—from commercial cargo ships to luxury yachts. As global demand for reliable anchoring systems grows, Star Marine remains committed to delivering products engineered to withstand harsh marine environments while meeting stringent international compliance frameworks.

Our horizontal anchor windlasses are rigorously tested against ISO 13779, SOLAS, and DNV-GL certification protocols, guaranteeing optimal holding power, corrosion resistance, and fail-safe operation. Below outlines key technical specifications for our standard product range:

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Pull Force Capacity | 50 kN to 500 kN | ISO 13779 |

| Chain Wheel Compatibility | Ø14mm to Ø52mm Stud Link Chain | ISO 1704 |

| Drive System | Electro-hydraulic / Electric | IEC 60092-301 |

| Corrosion Protection | Marine-grade stainless steel housing | ASTM A967 |

| Certifications | DNV-GL, LR, ABS, CCS, RINA | SOLAS Chapter V |

Procurement teams and shipbuilders require more than standardized equipment—they demand tailored solutions aligned with vessel specifications, regulatory jurisdictions, and operational profiles. Star Marine excels in custom engineering, offering modifications to mounting configurations, control interfaces, and power systems without compromising lead times. Our in-house R&D facility enables rapid prototyping, while our quality assurance process adheres to ISO 9001:2015, ensuring zero-defect delivery for critical deck machinery.

For urgent project timelines or complex integration challenges, direct engagement with our product management team eliminates procurement bottlenecks. Kacher YE, our dedicated Product Manager for Deck Machinery, possesses comprehensive knowledge of windlass applications across global trade routes and regulatory zones. With fluency in technical marine engineering and multilingual project coordination, Kacher streamlines communication between your design team and our manufacturing floor, ensuring precise alignment with contractual obligations and performance criteria.

Do not navigate the complexities of marine equipment procurement alone. Contact Kacher YE today to discuss your horizontal anchor windlass requirements, request detailed technical documentation, or initiate a project-specific quotation. Star Marine provides end-to-end support—from initial feasibility analysis to post-installation commissioning—backed by 24/7 technical assistance for operational continuity.

Act now to expedite your procurement process.

Email Kacher YE directly at [email protected] to schedule a technical consultation. Include your vessel specifications, target delivery timeline, and certification prerequisites for a customized solution within 48 hours. Partner with Hangzhou Star Marine Technology to secure anchoring systems that uphold safety, reliability, and maritime excellence on every voyage.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160