Hydraulic Anchor Windlass – Marine Solution Guide 2025

Content Navigation

Marine Insight: Hydraulic Anchor Windlass

Marine Industry Demand for Hydraulic Anchor Windlass

The hydraulic anchor windlass is a critical component of modern deck machinery, playing a pivotal role in vessel safety, operational efficiency, and crew reliability during anchoring and mooring operations. As vessels grow in size and operate in increasingly challenging maritime environments, the demand for robust, high-performance hydraulic windlasses has intensified across commercial shipping, offshore support, fishing, and luxury yachting sectors. The ability to deploy and retrieve anchors swiftly and securely under varying sea conditions directly impacts navigational safety and emergency response readiness. A failure in anchoring systems can lead to drifting, collisions, or grounding—incidents that pose severe risks to crew, cargo, and the environment.

Hydraulic anchor windlasses are preferred over electric or electro-hydraulic variants in many marine applications due to their superior torque output, consistent performance under continuous load, and resilience in harsh saltwater environments. Their design allows for smooth operation even when handling heavy anchor chains in deep waters, making them ideal for larger vessels and those operating in remote or adverse conditions. Additionally, hydraulic systems offer better overload protection and are less prone to electrical failures, enhancing overall system reliability.

In the current global marine equipment market, there is a growing emphasis on sourcing high-quality, certified deck machinery that meets international standards such as ISO 13779, DNV, ABS, and CCS. These standards ensure that windlasses are designed and manufactured to withstand specified load conditions, corrosion, and operational stress. Compliance not only ensures safety but also facilitates vessel classification and insurance approval.

Hangzhou Star Marine Technology Co., Ltd. has established itself as a trusted manufacturer and exporter of hydraulic anchor windlasses, offering engineered solutions that meet rigorous international requirements. By integrating advanced hydraulic technology with durable marine-grade materials, Star Marine delivers products that ensure long service life and minimal maintenance. The company’s in-house R&D, precision manufacturing, and comprehensive testing protocols enable consistent quality control across all production stages.

Sourcing hydraulic anchor windlasses from Star Marine China presents significant cost advantages without compromising performance or safety. The company leverages China’s efficient manufacturing ecosystem, economies of scale, and optimized supply chain logistics to offer competitively priced solutions. This cost-effectiveness is particularly beneficial for shipbuilders, fleet operators, and marine equipment suppliers aiming to balance budget constraints with high technical specifications.

The following table outlines key performance parameters of Star Marine’s standard hydraulic anchor windlass models:

| Model | Rated Pull (kN) | Chain Wheel Type | Chain Size (mm) | Hydraulic Pressure (bar) | Compliance Standards |

|---|---|---|---|---|---|

| HAW-10 | 100 | Vertical | 18–20 | 140 | ISO 13779, CCS |

| HAW-16 | 160 | Horizontal | 22–24 | 160 | DNV-GL, ABS |

| HAW-25 | 250 | Vertical | 26–28 | 180 | LR, BV, NK |

By combining technical excellence, regulatory compliance, and cost-efficient manufacturing, Hangzhou Star Marine Technology provides a strategic sourcing advantage in the global marine equipment market.

Technical Specs & Approval

Technical Specifications: Hydraulic Anchor Windlass

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures hydraulic anchor windlasses to stringent international maritime standards, ensuring reliability and performance across global vessel operations. Our hydraulic windlasses are engineered for efficient anchor handling under extreme marine conditions, featuring robust construction, precise control systems, and compliance with SOLAS, ISO 3911, and major classification society requirements including DNV GL, ABS, and LR. The core technical parameters are optimized for seamless integration with vessel deck layouts and hydraulic power units, with critical design focus on pull load capacity, chain compatibility, and operational safety margins. All units undergo 100% factory testing for pressure integrity, dynamic load performance, and emergency free-fall functionality prior to shipment.

The following table details the standardized technical parameters for our hydraulic anchor windlass series, covering vessels from coastal workboats to large commercial carriers. Specifications are adjustable per client project requirements while maintaining adherence to regulatory frameworks.

| Parameter | Value Range | Notes |

|---|---|---|

| Pull Load (kN) | 25 – 1000 | Minimum breaking load (MBL) at first layer; tested to 1.5x working load |

| Chain Diameter (mm) | 12.5 – 60 | Compatible with ISO 1704, ISO 4565, and EN 13889 stud link chain |

| Drive Type | Hydraulic Motor | Fixed or variable displacement options; integrated brake system |

| Working Pressure (MPa) | 16 – 21 | Standard system pressure; custom up to 25 MPa for high-capacity units |

| Freefall Speed (m/min) | 9.0 – 12.5 | Controlled descent under full load; meets ISO 3911 safety thresholds |

| Chain Wheel Material | Forged Alloy Steel (QT) | Hardened and tempered; certified material traceability per EN 10204 3.1 |

| Compliance Standards | SOLAS II-1/25, ISO 3911, DNV GL | Full documentation package including Type Test Certificates (TTC) |

Material selection prioritizes marine-grade forged alloy steel for chain wheels and critical drivetrain components, ensuring fatigue resistance and longevity in corrosive seawater environments. Hydraulic circuits incorporate anti-cavitation valves and thermal relief protection to prevent system damage during abrupt load changes or extended operation. All dynamic seals utilize nitrile rubber (NBR) or polyurethane compounds rated for -25°C to +80°C ambient temperatures, with optional Viton® for high-temperature applications.

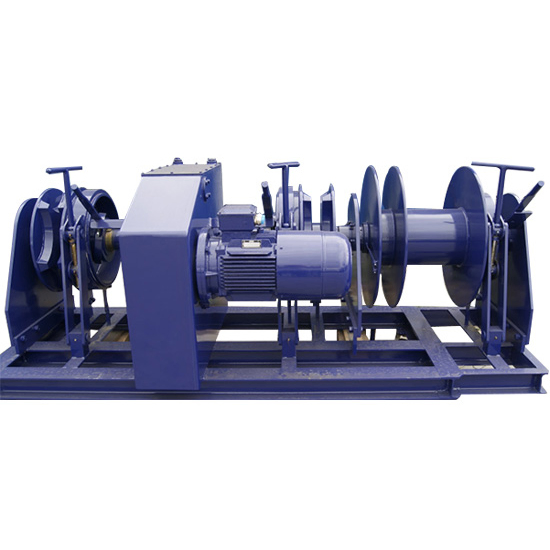

Our windlasses support both single-drum and dual-drum configurations with independent control, featuring electro-hydraulic proportional valves for smooth speed modulation during heaving and veering operations. The integrated mechanical band brake achieves 1.5x static holding capacity with automatic wear compensation, while the overload relief valve protects against chain jamming incidents. Noise levels are maintained below 85 dBA at 1 meter distance during standard operation through optimized gear housing design and vibration damping mounts.

Hangzhou Star provides comprehensive technical documentation for export compliance, including hydraulic schematics, 3D mounting drawings, and classification society certification dossiers. Customization options cover non-standard chain sizes, explosion-proof electrical components for hazardous zones, and remote control systems compatible with integrated bridge solutions. All units are supplied with detailed operation and maintenance manuals in English, with additional language support available per regional export requirements. Final inspection reports and material test certificates accompany every shipment to facilitate customs clearance and vessel installation.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive deck machinery solutions tailored for shipbuilding and repair projects worldwide. As a trusted provider of hydraulic anchor windlasses, we specialize in engineered systems that ensure reliable anchoring performance across a wide range of vessel types, including commercial cargo ships, offshore support vessels, fishing boats, and luxury yachts. Our approach integrates design, manufacturing, installation support, and after-sales service into a seamless export process, ensuring clients receive a complete and compliant solution on schedule.

For new shipbuilding projects, Star Marine collaborates closely with shipyards and naval architects during the design phase to ensure full compatibility with vessel specifications, including deck layout, power systems, and classification requirements. Our hydraulic anchor windlasses are engineered to meet international standards such as ISO 13779, DNV, ABS, CCS, LR, and other major classification societies. This proactive collaboration minimizes integration issues and accelerates delivery timelines. We offer customizable configurations including single or dual drum setups, chain wheel sizes from 16mm to 52mm, and hydraulic motor options designed for optimal torque and endurance under harsh marine conditions.

In ship repair and retrofit applications, Star Marine provides fast-response technical evaluations and replacement solutions that minimize vessel downtime. Our team can reverse-engineer legacy systems to ensure form, fit, and function compatibility, even when original specifications are unavailable. With a streamlined global logistics network, we deliver fully tested units to major shipyards and repair facilities within 4–6 weeks, depending on configuration. All units undergo rigorous factory acceptance testing, including pressure testing, load simulation, and endurance runs, to guarantee operational readiness upon arrival.

To support both new builds and repairs, we provide full technical documentation, including 3D drawings, hydraulic schematics, operation manuals, and certification packages. Our in-house engineering team is available for on-site or remote commissioning assistance, ensuring smooth installation and crew training.

The following table outlines key technical specifications and delivery capabilities for our standard hydraulic anchor windlass series:

| Parameter | Specification Range |

|---|---|

| Chain Wheel Size | 16 mm – 52 mm (ISO & Class Approved) |

| Working Pressure | 140 – 210 bar |

| Maximum Pulling Force | 50 kN – 800 kN |

| Drums | Single or Dual (customizable) |

| Rotation Speed | 6 – 12 rpm (adjustable via hydraulic control) |

| Classification Compliance | DNV, ABS, LR, CCS, BV, NK, RINA, etc. |

| Lead Time (Standard Units) | 4 – 6 weeks (custom designs: 8–12 weeks) |

| Testing Protocol | FAT, Load Test, Pressure Test, Classification Survey |

With decades of marine engineering expertise and a customer-first export model, Hangzhou Star Marine Technology ensures reliable, high-performance anchoring systems delivered with speed and precision. Whether supporting new construction or urgent repair operations, we provide the technical depth and logistical agility required in modern maritime projects.

Packaging & Logistics

Packaging & Logistics for Hydraulic Anchor Windlass Exports

Hangzhou Star Marine Technology implements rigorous, internationally compliant packaging protocols for all hydraulic anchor windlass shipments to ensure equipment integrity during global transit. Our methodology adheres strictly to maritime industry best practices and destination country regulatory requirements, particularly concerning wood packaging materials. The primary packaging system utilizes ISPM 15 certified wooden export crates combined with robust steel pallet bases, forming a secure, multi-layered protective solution designed for the demanding marine environment and heavy deck machinery characteristics of anchor windlasses.

All wooden components, including crates, dunnage, and bracing, are manufactured from solid wood compliant with International Standards for Phytosanitary Measures No. 15 (ISPM 15). This mandatory standard requires wood packaging material to undergo approved phytosanitary treatment, specifically kiln-drying to a minimum core temperature of 56°C for at least 30 minutes, followed by debarking. Each wooden element is permanently marked with the official ISPM 15 stamp, clearly displaying the IPPC logo, country code (CN for China), our unique producer code registered with Chinese authorities, and the treatment abbreviation (HT for Heat Treatment). This certification is non-negotiable for entry into the vast majority of global markets, including the European Union, United States, Australia, and Japan, and eliminates the risk of shipment rejection or costly on-arrival fumigation. The wooden crates provide essential structural support and impact resistance while allowing secure internal bracing of the windlass unit.

The anchor windlass is securely mounted onto a custom-fabricated, heavy-duty steel pallet base prior to crating. These pallets are engineered to withstand the significant weight and dynamic stresses of ocean transport, featuring reinforced stringers and deck boards. They facilitate safe and efficient handling using standard marine cargo equipment, including forklifts and shipboard cranes, at both origin and destination ports. The steel base ensures the windlass remains stable and level throughout the logistics chain, preventing shifting or damage during lifting operations. Critical components, such as hydraulic motors, control panels, and electrical connections, receive additional protection using corrosion-inhibiting VCI (Vapor Corrosion Inhibitor) films and desiccants within the crate to mitigate moisture exposure during extended sea voyages.

All export shipments originate from the major international container ports of Ningbo-Zhoushan or Shanghai, leveraging their world-class infrastructure, extensive global carrier networks, and efficient customs clearance procedures. Our logistics team coordinates seamless movement from our Hangzhou facility to the port terminal, ensuring timely container stuffing under supervision. Comprehensive export documentation, including the mandatory ISPM 15 declaration within the packing list and bill of lading, is meticulously prepared to expedite customs formalities at origin and destination. We provide clients with detailed packing lists specifying the exact packaging configuration and dimensions for accurate freight calculation and handling planning.

The following table summarizes the standard packaging specifications for our hydraulic anchor windlass units:

| Packaging Component | Material & Treatment | Key Features & Compliance | Typical Dimensions (L x W x H) | Max Load Capacity |

|---|---|---|---|---|

| Primary Crate | Solid Wood (ISPM 15 HT) | Kiln-dried, debarked, IPPC stamped, internal bracing | Varies by model (e.g., 2.5m x 2.0m x 2.2m) | Model Dependent |

| Base Pallet | Heavy-Duty Steel | Welded construction, fork lift entry points, anti-slip surface | Matches crate base | 10,000 kg – 25,000 kg |

| Internal Protection | VCI Film, Desiccant, Foam | Corrosion inhibition, moisture absorption, impact cushioning | As required per component | N/A |

This integrated packaging system, combined with our strategic use of Ningbo and Shanghai ports, guarantees that Hangzhou Star Marine Technology’s hydraulic anchor windlasses arrive at the vessel or final destination in optimal condition, ready for immediate installation and commissioning, meeting the highest standards of reliability expected in the global maritime sector.

Contact Star Marine

For marine operators, shipbuilders, and offshore project managers seeking high-performance deck machinery, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted leader in the design and export of advanced hydraulic anchor windlasses. As a specialized manufacturer in marine deck equipment, we deliver robust, reliable, and customized solutions engineered to meet international maritime standards, including ISO, DNV, ABS, CCS, and other classification society requirements.

Our hydraulic anchor windlasses are precision-engineered for optimal performance in demanding offshore and open-sea conditions. Whether you are outfitting a new vessel or upgrading existing deck systems, our product line supports a wide range of vessel types — from commercial cargo ships and offshore support vessels to luxury yachts and naval craft. Each unit is built with high-tensile steel components, advanced hydraulic power units, and fail-safe braking systems to ensure secure anchoring operations under extreme loads and environmental stress.

At Hangzhou Star Marine Technology, we understand that every marine project has unique technical and operational requirements. That’s why we offer fully customizable windlass configurations, including variations in pulling force, chain wheel specifications, control system integration, and mounting arrangements. Our engineering team works closely with clients to ensure seamless integration with existing deck layouts and vessel dynamics.

To discuss your specific project needs or request technical documentation, we encourage direct communication with our Product Manager, Kacher YE. With extensive experience in marine machinery export and client technical support, Mr. Ye serves as the primary liaison for international clients, providing expert guidance on product selection, compliance, logistics, and after-sales service.

We invite you to contact Mr. Kacher YE via email at [email protected] to initiate a technical consultation, request a quotation, or obtain CAD drawings and product specifications. Our team responds to all inquiries within 24 hours during business days and supports communication in English, Mandarin, and Spanish to facilitate smooth global collaboration.

For your reference, key technical parameters of our standard hydraulic anchor windlass models are summarized below:

| Model Series | Chain Size (mm) | Maximum Pulling Force (kN) | Rated Working Pressure (bar) | Power Source | Classification Approvals |

|---|---|---|---|---|---|

| HAW-100 | 20 – 22 | 100 | 180 | Hydraulic (custom HP) | CCS, DNV, ABS, LR, BV |

| HAW-150 | 24 – 27 | 150 | 180 | Hydraulic (custom HP) | CCS, DNV, ABS, LR, BV |

| HAW-200 | 28 – 32 | 200 | 200 | Hydraulic (electric/pump station) | CCS, DNV, ABS, LR, BV |

| HAW-250 | 34 – 38 | 250 | 200 | Hydraulic (dual station) | CCS, DNV, ABS, LR, BV |

All models are designed for long service life, minimal maintenance, and compliance with SOLAS and IMO guidelines where applicable. We also offer remote technical support, installation supervision, and OEM services for large-scale marine projects.

Partner with Hangzhou Star Marine Technology for engineered excellence in deck machinery. Contact Kacher YE today to advance your vessel’s reliability and operational safety.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160