Hydraulic Mooring Winch – Marine Solution Guide 2025

Content Navigation

Marine Insight: Hydraulic Mooring Winch

Marine Industry Demand for Hydraulic Mooring Winches: Ensuring Vessel Safety and Operational Efficiency

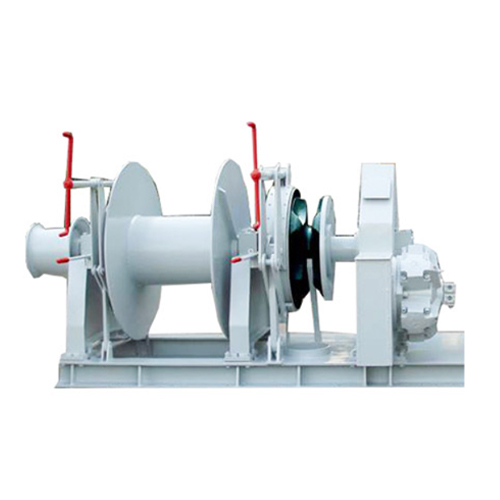

Hydraulic mooring winches are critical components of modern deck machinery systems, playing a vital role in ensuring the safe and efficient mooring of vessels at ports, terminals, and offshore facilities. As global maritime trade continues to expand, the demand for reliable, high-performance mooring solutions has intensified. These winches are engineered to handle extreme loads and dynamic environmental conditions, providing controlled tensioning and retraction of mooring lines during berthing and unmooring operations. Their hydraulic drive systems offer superior power density, smooth operation, and consistent performance under variable load conditions, making them the preferred choice for commercial ships, offshore support vessels, and large tankers.

The importance of hydraulic mooring winches in vessel safety cannot be overstated. Improper mooring can lead to line breakage, vessel drift, and catastrophic accidents, particularly in adverse weather or high-traffic ports. A well-designed hydraulic winch ensures even load distribution across mooring lines, reduces operator fatigue through automated tension control, and enhances response time during emergency situations. Features such as automatic tension mode, overload protection, and fail-safe braking systems contribute significantly to operational safety and compliance with international maritime regulations, including those set by the International Maritime Organization (IMO) and classification societies like ABS, DNV, and CCS.

In addition to performance and safety, cost-effectiveness is a key consideration for shipowners and operators when sourcing deck machinery. Hangzhou Star Marine Technology Co., Ltd. has established itself as a trusted supplier of hydraulic mooring winches by offering engineered solutions that balance high quality with competitive pricing. Based in China, Star Marine leverages advanced manufacturing capabilities, in-house R&D, and streamlined supply chain logistics to deliver reliable equipment at favorable cost points compared to Western manufacturers. The company adheres to strict ISO and marine classification standards, ensuring that every winch meets or exceeds international performance and safety benchmarks.

The following table outlines key specifications and comparative advantages of Star Marine’s standard hydraulic mooring winch models:

| Parameter | Model HMW-20T | Model HMW-50T | Model HMW-100T |

|---|---|---|---|

| Rated Line Pull (kN) | 200 | 500 | 1000 |

| Rope Capacity (m) | 300 | 400 | 500 |

| Drum Speed (m/min) | 15 | 12 | 10 |

| Hydraulic Pressure (bar) | 180 | 200 | 220 |

| Certification | CCS, ABS, DNV | CCS, ABS, DNV | CCS, ABS, DNV |

| Weight (kg) | 1,800 | 4,200 | 8,500 |

| Average Lead Time (weeks) | 8 | 10 | 12 |

| Cost Advantage vs. EU/US | 25–30% lower | 25–30% lower | 25–30% lower |

By combining technical excellence with economic efficiency, Hangzhou Star Marine Technology provides shipbuilders and fleet operators with a compelling value proposition. The company’s commitment to innovation, quality control, and after-sales support further reinforces its position as a strategic partner in the global marine equipment supply chain.

Technical Specs & Approval

Hydraulic Mooring Winch Technical Specifications

Hangzhou Star Marine Technology Co., Ltd. manufactures robust hydraulic mooring winches designed for demanding offshore and vessel mooring operations. These critical deck machinery components provide controlled tensioning and secure holding of mooring lines under extreme environmental conditions. Our winches adhere strictly to international maritime standards, including ABS, DNV, LR, CCS, and other major classification society requirements, ensuring global operability and safety compliance. Key technical parameters are engineered for reliability, longevity, and optimal performance across diverse vessel types, from offshore support vessels and tankers to large container ships and floating production units. Precise specification matching to vessel operational profiles is essential for safe and efficient mooring system integration.

The following table details the core technical specifications for Hangzhou Star’s standard hydraulic mooring winch series. Custom configurations are available to meet specific project demands and vessel design criteria.

| Parameter | Standard Range | Application Notes |

|---|---|---|

| Line Pull (Static) | 50 kN to 2000+ kN | Determined by drum layer, hydraulic pressure, and motor torque. Higher pulls require reinforced structural design. |

| Chain Diameter | 12.5 mm to 60 mm | Compatible with ISO 1704, ISO 4565, and EN 818-7 stud link chain standards. Gypsy wheel profile precisely matched to chain type. |

| Drive System | Hydraulic Motor (Radial Piston) | Primary drive via high-torque, low-speed hydraulic motor. Power source options: Electric Motor Driven Pump Unit or Direct Engine Driven Pump. |

| Hydraulic Pressure | 14 MPa to 21 MPa (Operating) | System designed for continuous duty cycle. Includes pressure relief valves and thermal protection. |

| Brake Type | Fail-Safe, Spring-Set, Hydraulic Release | Automatically engages on hydraulic pressure loss. Holding torque ≥ 1.5x max static line pull. |

| Drum Capacity | Varies by Model (e.g., 150m-500m) | Capacity specified for single part line at nominal wire rope diameter (e.g., 28mm-72mm). Chain gypsies hold 1-2 shots. |

| Rotation Speed | 0.1 rpm to 1.5 rpm (Variable) | Infinitely variable speed control via hydraulic flow control valve. Controlled heave capability optional. |

| Hydraulic Fluid | ISO VG 46 or 68 (Mineral Oil) | Compatibility with biodegradable fluids available. Requires filtration to NAS 1638 Class 8 or better. |

| Design Ambient Temp | -25°C to +50°C | Cold climate packages available for Arctic operations (-45°C). Corrosion protection per ISO 12944 C5-M. |

Critical performance factors include the winch’s ability to maintain consistent line tension during vessel movement, particularly under dynamic loading scenarios common in offshore mooring. The hydraulic system incorporates redundant safety features, including non-return valves and emergency manual pump options for brake release. Structural components are fabricated from high-yield strength marine-grade steel (e.g., ASTM A131 Grade EH36) and undergo rigorous non-destructive testing (NDT) per classification rules. All winches feature integrated load cells or pressure transducers for real-time tension monitoring, interfacing with vessel control systems. Drum construction utilizes a split-shell design for simplified wire rope replacement and maintenance access. Environmental sealing meets IP56 standards for saltwater and dust ingress protection. Hangzhou Star provides comprehensive technical documentation, including hydraulic schematics, load charts, and classification society certificates, supporting seamless global export and installation. Final specifications are validated through factory acceptance tests (FAT) simulating maximum working load and emergency stop conditions.

Shipbuilding Solutions

Hydraulic Mooring Winch Solutions for Shipbuilding & Repair – Hangzhou Star Marine Technology Co., Ltd.

Hangzhou Star Marine Technology Co., Ltd. delivers engineered hydraulic mooring winch systems tailored for shipbuilders and repair yards worldwide. As a specialized provider of deck machinery, we integrate performance, reliability, and compliance into every solution, ensuring seamless integration in both new vessel construction and retrofit or repair projects. Our hydraulic mooring winches are engineered to meet the demanding operational conditions of commercial, offshore, and naval vessels, offering high holding strength, smooth control, and long service life.

For newbuild projects, Star Marine collaborates closely with shipyards during the design and integration phase. We provide full technical documentation, including load calculations, hydraulic schematics, and 3D models, enabling precise deck layout planning and early-stage system validation. Our engineering team supports classification society submissions, ensuring compliance with ABS, DNV, LR, BV, and other major international standards. This proactive approach minimizes delays and ensures regulatory approval at each milestone.

In ship repair and retrofit applications, we offer rapid-response solutions with flexible configurations. Whether replacing obsolete winches or upgrading deck machinery for enhanced performance, our modular hydraulic systems can be adapted to existing foundations and hydraulic power units. We maintain a responsive project management workflow, with typical lead times starting from 4 weeks for standard models and expedited manufacturing for urgent repair needs. Our global service network supports on-site commissioning, troubleshooting, and operator training, ensuring minimal downtime.

All hydraulic mooring winches from Star Marine are built to ISO 15037 and IACS M26 standards, featuring hardened steel drums, fail-safe braking systems, and corrosion-resistant coatings suitable for offshore and tropical environments. We offer both vertical and horizontal configurations with customizable rope capacity, pull force, and control interfaces, including local and remote operation panels.

Below is an overview of standard technical specifications for our most widely deployed hydraulic mooring winch series:

| Parameter | Specification |

|---|---|

| Rated Line Pull (kN) | 50 – 500 kN |

| Rope Capacity (mm x length) | 16–32 mm diameter, up to 300 m |

| Drum Speed (m/min) | 15 – 30 (under full load) |

| Hydraulic Pressure (bar) | 180 – 250 bar |

| Motor Power (kW) | 15 – 110 (hydraulic motor driven) |

| Brake Safety Factor | ≥ 1.5 times static load |

| Classification Compliance | ABS, DNV, LR, BV, CCS, RINA, NK, KR |

| Operating Temperature Range | -25°C to +55°C |

Star Marine’s commitment to quality is reinforced through ISO 9001-certified manufacturing processes and in-house testing facilities, including full-load dynamometer trials. By combining technical expertise with fast turnaround and global support, we deliver complete hydraulic mooring winch solutions that enhance vessel safety and operational efficiency in both shipbuilding and repair environments.

Packaging & Logistics

Packaging & Logistics Protocol for Hydraulic Mooring Winch Exports

Hangzhou Star Marine Technology implements rigorous, industry-standard packaging and logistics procedures for all hydraulic mooring winch exports to ensure equipment integrity and seamless global delivery. Our methodology adheres strictly to international maritime regulations and carrier requirements, minimizing transit risks and facilitating efficient customs clearance. All deck machinery shipments originate from our primary export hubs at Ningbo-Zhoushan Port and Shanghai Port, leveraging China’s most advanced maritime infrastructure for global connectivity.

Wooden cases constitute the primary packaging solution for critical hydraulic components, control panels, and precision parts. These cases are constructed from high-grade, kiln-dried softwood meeting International Standards for Phytosanitary Measures No. 15 (ISPM 15). Compliance is verified through the internationally recognized IPPC mark, signifying mandatory heat treatment (HT) at a minimum core temperature of 56°C for 30 minutes. This process eliminates pest risks without chemical fumigation, ensuring acceptance in all major markets including the EU, USA, Australia, and Japan. Cases feature internal bracing, custom foam inserts, and moisture barrier wrapping to immobilize contents and prevent condensation damage during ocean transit. Exterior surfaces are treated with marine-grade preservatives and clearly labeled with handling instructions, cargo dimensions, weight, and destination details per IMO guidelines.

For complete winch assemblies and heavy structural elements exceeding standard case dimensions, we utilize reinforced steel pallets. These pallets are engineered to ISO container dimensions (20ft/40ft) and feature welded steel frames with non-slip decks capable of supporting concentrated loads up to 25 metric tons. Winches are securely fastened using high-tensile steel strapping and corner bracing, with all moving parts immobilized via transit locks. Critical surfaces receive temporary protective coatings, and hydraulic systems are nitrogen-purged and sealed to prevent internal corrosion. Steel pallet shipments are further secured within flat-rack containers or on deck using lashing points compliant with CSS Code standards.

Ningbo-Zhoushan and Shanghai ports provide optimal export advantages due to their specialized heavy-lift capabilities and direct services to all major global terminals. Our logistics team coordinates pre-shipment inspections, customs documentation, and carrier handover to ensure zero delays. The table below summarizes key port specifications relevant to deck machinery shipments.

| Port | Annual Container Throughput (TEU) | Maximum Crane Capacity | Average Vessel Turnaround Time | Key Advantage for Deck Machinery |

|---|---|---|---|---|

| Ningbo-Zhoushan | > 35 Million | 100 Tons | 24-36 Hours | Dedicated heavy-lift berths; minimal congestion for oversized cargo |

| Shanghai (Yangshan) | > 47 Million | 120 Tons | 36-48 Hours | Deepest draft (18m); direct ULCC services; integrated customs clearance |

All export documentation, including ISPM 15 certificates, packing lists, and material test reports, is prepared in English and submitted electronically 72 hours prior to vessel loading. This integrated approach guarantees that Hangzhou Star Marine Technology’s hydraulic mooring winches arrive at destination ports in operational condition, fully compliant with global shipping and environmental regulations.

Contact Star Marine

For global shipbuilders, offshore operators, and marine engineering firms seeking high-performance hydraulic mooring winches, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted manufacturer and exporter of advanced deck machinery. As a specialized supplier in the marine equipment sector, we deliver engineered solutions that meet the rigorous demands of commercial shipping, offshore support vessels, and port operations. Our hydraulic mooring winches are designed for reliability, durability, and precise control under extreme marine conditions, incorporating ISO 15036, DNV, CCS, and ABS compliance standards.

At Star Marine, we understand that each vessel and operational profile presents unique requirements. Whether you are integrating a new winch system into a vessel design or replacing legacy equipment, our engineering team works closely with clients to customize drum capacity, rope pull, line speed, braking torque, and control configurations. Our hydraulic systems are optimized for energy efficiency and minimal maintenance, featuring robust piston motors, fail-safe band or disc brakes, and integrated overload protection.

To ensure seamless project execution, we provide comprehensive technical documentation, including 3D models, load charts, hydraulic schematics, and installation manuals. In addition, our quality assurance protocols follow strict manufacturing standards, with full traceability of materials and third-party inspection support upon request.

For immediate assistance with product selection, technical specifications, or project quotations, we encourage direct engagement with our Product Manager responsible for deck machinery systems.

Contact Information

Name: Kacher YE

Position: Product Manager – Deck Machinery

Company: Hangzhou Star Marine Technology Co., Ltd.

Email: [email protected]

Phone: +86 571 8868 9120

Address: No. 18, Tianmu West Road, Yuhang District, Hangzhou, Zhejiang Province, China

We respond to all inquiries within 12 business hours and offer virtual technical consultations for international clients.

Hydraulic Mooring Winch – Standard Technical Overview

| Parameter | Specification Range |

|---|---|

| Rated Line Pull | 50 kN – 1000 kN |

| Rope Capacity | 200 m – 1500 m (depending on rope diameter) |

| Rope Diameter | 16 mm – 60 mm |

| Drum Type | Single or dual drum, grooved |

| Hydraulic Motor Type | Axial piston, radial piston |

| Working Pressure | 150 bar – 350 bar |

| Brake Type | Fail-safe hydraulic release, disc or band |

| Control System | Local control panel with remote I/O options |

| Certifications | ABS, DNV, LR, CCS, BV, RINA (available upon request) |

Partnering with Star Marine means gaining access to engineered solutions backed by technical expertise and export experience across Southeast Asia, the Middle East, Europe, and the Americas. Contact Kacher YE today to discuss your hydraulic mooring winch requirements and receive a tailored proposal for your next marine project.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160