Low Pressure Marine Compressor – Marine Solution Guide 2025

Content Navigation

Marine Insight: Low Pressure Marine Compressor

Marine Industry Demand for Low Pressure Marine Compressors

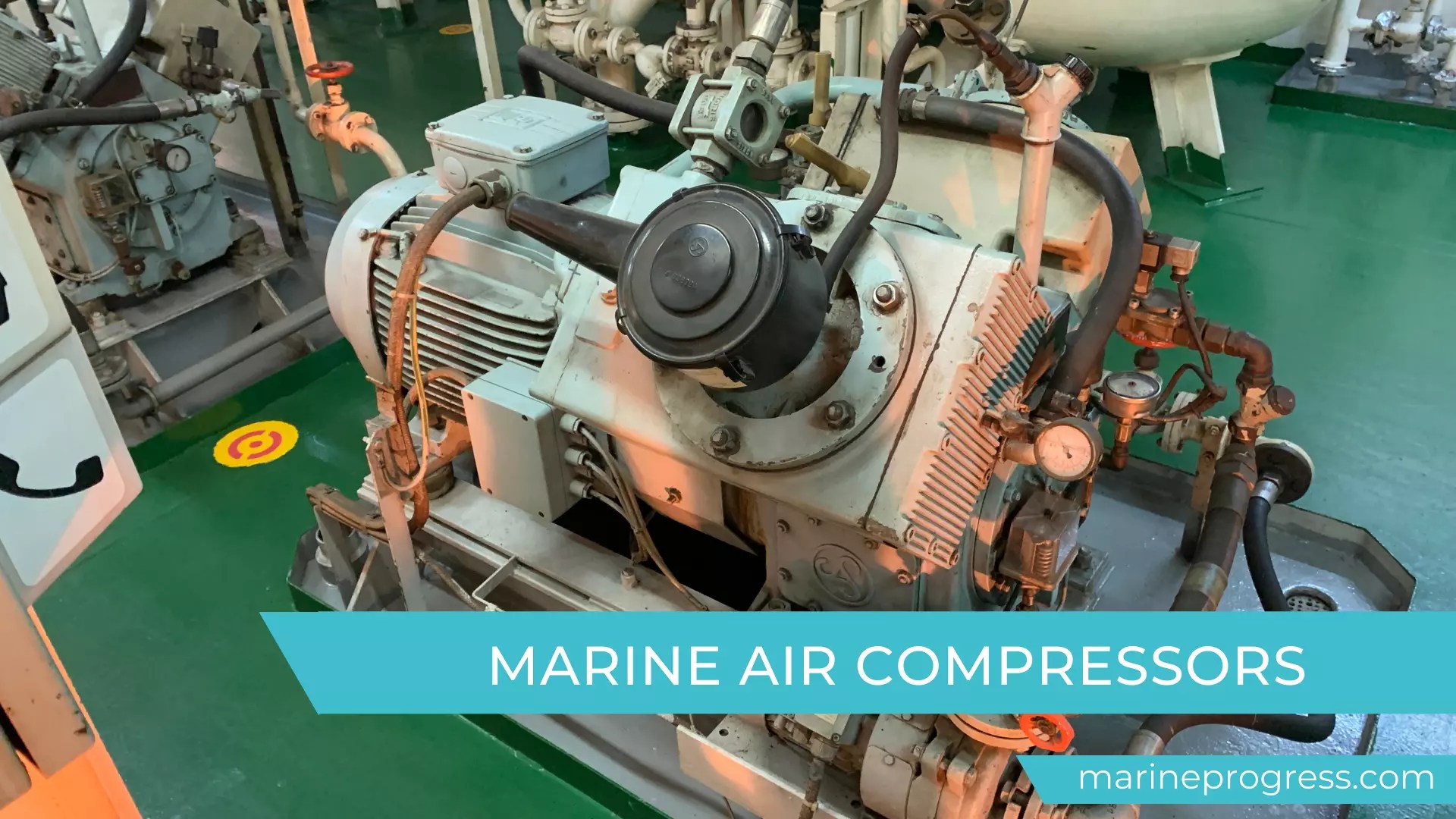

Low pressure marine compressors play a critical role in ensuring the safe and efficient operation of commercial and offshore vessels. These compressors are primarily used to supply clean, dry compressed air for essential onboard systems, including pneumatic control systems, engine starting mechanisms, safety equipment, and deck machinery operations. The reliability of these compressors directly impacts vessel uptime, crew safety, and regulatory compliance with international maritime standards such as those set by the International Maritime Organization (IMO) and classification societies like DNV, ABS, and LR.

One of the primary safety functions of low pressure marine compressors is supporting the vessel’s emergency air systems. In the event of a main engine failure or blackout, compressed air stored in receivers allows for rapid engine restart, ensuring that propulsion and navigation systems can be restored without delay. This capability is especially vital in confined waterways, adverse weather, or during critical maneuvers. Additionally, compressed air powers critical safety valves, fire suppression systems, and watertight door actuators, making the performance and dependability of the compressor a cornerstone of maritime safety protocols.

Another key application lies in maintaining the integrity of pneumatic instrumentation. Modern vessels rely heavily on automated control systems that use low pressure air signals to regulate fuel injection, boiler operations, and environmental controls. Any fluctuation or contamination in the air supply can lead to inaccurate readings, system malfunctions, or even hazardous operational conditions. Therefore, marine compressors must deliver consistent pressure and incorporate filtration systems to remove moisture, oil, and particulates.

Hangzhou Star Marine Technology Co., Ltd. has established itself as a trusted manufacturer of low pressure marine compressors designed specifically to meet the rigorous demands of the maritime environment. Our compressors are engineered with corrosion-resistant materials, compact footprints, and advanced thermal management systems to ensure long service life and minimal maintenance. All units undergo stringent testing, including performance validation under extreme temperature and humidity conditions, to guarantee compliance with international marine certifications.

Sourcing from Star Marine China offers significant cost advantages without compromising quality. By leveraging advanced manufacturing techniques and localized supply chains, we deliver high-performance compressors at competitive price points. This cost efficiency is further enhanced by reduced lead times and comprehensive after-sales support, including technical documentation, spare parts availability, and remote troubleshooting services.

The following table outlines key technical and economic advantages of Star Marine’s low pressure compressors compared to industry benchmarks:

| Parameter | Star Marine Compressor | Industry Average |

|---|---|---|

| Operating Pressure Range | 1.5 – 3.0 bar | 1.5 – 3.0 bar |

| Air Flow Capacity | Up to 120 L/min | Up to 100 L/min |

| Material Construction | Marine-grade stainless steel & aluminum | Mild steel with coating |

| Certification Compliance | DNV-GL, ABS, CCS, ISO 8573 | Varies by supplier |

| Average Lead Time | 4–6 weeks | 8–12 weeks |

| Total Cost of Ownership (5 yr) | 18% lower | Baseline |

By integrating robust engineering with cost-effective manufacturing, Hangzhou Star Marine Technology provides maritime operators with a reliable, compliant, and economical solution for low pressure air supply needs.

Technical Specs & Approval

Technical Specifications: Low Pressure Marine Compressors

Hangzhou Star Marine Technology designs low pressure marine compressors specifically for critical shipboard applications including diver air supply, emergency breathing systems, and pneumatic tool operation. Within the marine sector, “low pressure” denotes systems operating below 30 MPa, distinct from main engine starting systems. Our compressors prioritize safety, saltwater resistance, and compliance with international maritime regulations. Discharge pressure capabilities range from 1.5 MPa to 30 MPa, calibrated for precision in oxygen-enriched environments where contamination control is non-negotiable. Flow rates are engineered between 50 L/min and 1000 L/min at standard conditions (1 bar, 20°C), ensuring adaptability to vessel size and operational demands. All units utilize forced-air or seawater-cooled thermal management systems, with seawater variants featuring titanium heat exchangers and sacrificial anodes to mitigate galvanic corrosion. Power configurations support 440V AC three-phase marine electrical standards, with optional DC variants for auxiliary systems. Critical components, including cylinders and valves, are constructed from marine-grade stainless steel (AISI 316L) with food-grade lubricants to eliminate hydrocarbon contamination in breathing air circuits. Vibration damping meets ISO 10814 Class B thresholds, while acoustic insulation maintains ambient noise below 75 dBA at 1-meter distance.

The following table details core technical parameters for our standard low pressure marine compressor series:

| Parameter | Specification Range | Application Note |

|---|---|---|

| Discharge Pressure | 1.5 – 30 MPa | Adjustable via calibrated pressure switches |

| Free Air Delivery | 50 – 1000 L/min | Measured at 1 bar(a), 20°C, 0% RH |

| Cooling Method | Forced Air / Seawater | Seawater: Ti heat exchangers; Air: IP55 fans |

| Drive Motor | 3-Phase 440V AC, 50/60 Hz | Class F insulation; marine varnish winding |

| Lubrication | Oil-free piston or rotary screw | ISO 8573-1 Class 0 certified for breathing air |

| Material Construction | AISI 316L, Cu-Ni 90/10 | Wetted parts resistant to seawater corrosion |

| Certification | ABS, DNV, CCS, MED | Full Type Approval documentation provided |

| Ambient Operating Temp | -25°C to +45°C | Derating curve available for >40°C environments |

These specifications reflect rigorous adherence to IMO MSC/Circ.830 and ISO 15001 standards for diving air quality. Pressure relief valves are set at 110% of maximum working pressure, with dual-stage filtration (coalescing + activated carbon) achieving particle removal down to 0.01 µm and hydrocarbon levels <0.01 mg/m³. All compressors undergo 100% factory testing per EN 12021 protocols, including 72-hour continuous run-in cycles under simulated ship motion conditions. Electrical enclosures comply with IEC 60092-201 (IP56 minimum), and control panels feature intrinsically safe interfaces for hazardous zones. For export compliance, units are delivered with corrosion-resistant packaging meeting MIL-STD-2073-1A and include multilingual operation manuals per SOLAS III/19 requirements. Hangzhou Star Marine Technology’s engineering team provides pre-shipment validation reports and coordinates third-party certification body witnessing upon client request.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive shipbuilding and repair solutions through its advanced low pressure marine compressors, engineered to meet the rigorous demands of modern maritime operations. As a trusted provider in the marine equipment sector, Star Marine integrates reliability, efficiency, and compliance into every stage of vessel construction and maintenance. Our low pressure marine air compressors are designed to supply instrument air, control air, and service air across a wide range of onboard systems, ensuring optimal performance during both new builds and retrofit projects.

In new shipbuilding projects, Star Marine collaborates closely with shipyards and naval architects to deliver customized compressor systems that align with vessel specifications and classification requirements. Our engineering team provides technical support from design inception through installation and commissioning, ensuring seamless integration with existing pneumatic and automation systems. With compact footprints and low noise emissions, our compressors are ideal for confined engine room environments, while their robust construction ensures long service life under harsh marine conditions.

For ship repair and retrofit applications, Star Marine offers fast-response service and drop-in replacement solutions that minimize downtime. Our compressors are compatible with major OEM systems, allowing for straightforward upgrades without extensive modifications. We maintain a global spare parts inventory and provide on-site technical assistance, enabling shipowners and repair yards to restore operational capability swiftly. Whether replacing aging equipment or enhancing system redundancy, our solutions are backed by full documentation, including P&IDs, installation manuals, and classification certificates.

All Star Marine low pressure compressors are built to international standards, including ISO 8573 for air quality, and are certified by major classification societies such as CCS, ABS, DNV, LR, and BV. Our units feature integrated safety controls, automatic condensate drainage, and corrosion-resistant coatings to ensure reliable operation in salt-laden environments. Additionally, our compressors are available with variable speed drives (VSD) for improved energy efficiency and reduced maintenance costs over time.

The following table outlines key technical specifications of our standard low pressure marine compressor series:

| Parameter | Specification |

|---|---|

| Flow Rate | 50 – 600 L/min (free air delivery) |

| Working Pressure | 7 – 10 bar (g) |

| Power Supply | 230/400 VAC, 50/60 Hz, 3-phase |

| Drive Type | Direct or belt-driven |

| Cooling Method | Air-cooled or water-cooled |

| Lubrication | Oil-lubricated or oil-free options |

| Noise Level | ≤75 dB(A) at 1 meter |

| Protection Class | IP55 standard |

| Classification Approvals | CCS, ABS, DNV, LR, BV, RINA |

| Ambient Operating Temp | -25°C to +50°C |

Star Marine’s commitment to speed, quality, and technical excellence makes it a preferred partner in the global shipbuilding and repair industry. With streamlined logistics and responsive engineering support, we ensure that every compressor solution is delivered on time and built to last.

Packaging & Logistics

Packaging & Logistics for Low Pressure Marine Compressors

Hangzhou Star Marine Technology prioritizes robust packaging and seamless logistics to ensure low pressure marine compressors arrive at global destinations in operational condition, adhering strictly to maritime transport regulations and environmental standards. Our export process begins with engineered packaging solutions designed to withstand the rigors of ocean freight, including humidity, vibration, and mechanical shock during multimodal transit. All wooden export cases comply with International Standards for Phytosanitary Measures No. 15 (ISPM 15), eliminating the risk of pest transmission via wood packaging material. This certification is non-negotiable for entry into all major maritime markets, including the EU, USA, and Asia-Pacific regions.

Wooden cases are constructed from kiln-dried, certified softwood (typically pine) meeting ISPM 15 heat treatment requirements (minimum 56°C core temperature for 30 minutes). Each case is branded with the official ISPM 15 mark, including our registered facility code, country code (CN), and HT (Heat Treatment) indicator. Interior protection includes custom-cut polyethylene foam cradles, anti-corrosion VCI (Vapor Corrosion Inhibitor) paper wrapping for all metallic components, and desiccant packs to control moisture ingress. Critical components such as pressure vessels and control panels receive additional bracing with marine-grade plywood dividers. Steel pallets are utilized for heavier compressor units (exceeding 500 kg), fabricated from galvanized steel with reinforced cross-beams to prevent deformation under load. These pallets feature integrated forklift entry points on all four sides and are secured with tensioned steel strapping to the case base.

Key packaging specifications are detailed below for clarity and compliance verification.

| Parameter | Specification Detail | Compliance Standard |

|---|---|---|

| Wood Treatment | Kiln-dried softwood (56°C core, 30+ min) | ISPM 15 HT |

| Case Marking | Official ISPM 15 stamp with facility code CN-001 | IPPC Requirement |

| Interior Protection | VCI paper + 25mm polyethylene foam + desiccant | MIL-STD-2073 |

| Max Payload per Case | 1,200 kg (wood) / 2,500 kg (steel pallet) | ISO 11607 |

| Corner Protection | Extruded steel profiles (3mm thickness) | ASTM D6055 |

All shipments originate from China’s premier deep-water ports: Ningbo-Zhoushan (world’s third-busiest container port) and Shanghai Yangshan Deep-Water Port. These hubs offer direct access to major global shipping alliances, optimized container handling for heavy machinery, and streamlined customs clearance under China’s Electronic Port System. Our logistics team coordinates end-to-end freight management, including pre-shipment inspections, cargo insurance, and Bill of Lading documentation. Units are loaded onto vessels via shore cranes with precision slinging protocols to avoid stress on compressor housings. For RoRo (Roll-on/Roll-off) shipments, steel-palletized units are driven directly onto specialized heavy-lift vessels. Transit documentation includes ISPM 15 certificates, packing lists with gross/net weights, and marine insurance certificates issued by Lloyd’s of London-approved underwriters.

Hangzhou Star Marine Technology’s packaging and logistics framework ensures zero compromise on compressor integrity during export. By integrating ISPM 15-certified wood, industrial steel pallets, and strategic port operations, we mitigate transit risks while meeting all international maritime regulatory obligations. Clients receive fully traceable shipments with real-time logistics updates, underscoring our commitment to reliability in global marine supply chains.

Contact Star Marine

For marine operators, shipbuilders, and offshore support teams seeking reliable low pressure marine air compressors, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted engineering partner in the design and supply of high-performance marine equipment. Our low pressure marine compressors are engineered to meet the rigorous demands of maritime environments, delivering consistent air supply for pneumatic systems, control instrumentation, deck machinery, and safety applications. Built in compliance with international marine classification standards—including CCS, DNV, ABS, LR, and BV—our compressors are designed for durability, energy efficiency, and minimal maintenance.

At Star Marine, we understand that each vessel or offshore platform presents unique operational requirements. That’s why we prioritize direct technical engagement with our clients to ensure optimal product selection, customization, and integration support. Whether you are retrofitting existing systems or commissioning new builds, our engineering team provides comprehensive assistance from specification review to after-sales service.

To discuss your specific application, request technical documentation, or obtain a formal quotation, we invite you to contact our dedicated Product Manager for marine air compressors, Kacher YE. With extensive experience in marine system integration and compressor technology, Kacher serves as the primary technical liaison between our engineering department and global clients. He is available to provide detailed performance curves, dimensional drawings, material specifications, and certification details tailored to your project needs.

We encourage direct communication to ensure clarity, accuracy, and timely response. Below are the key technical parameters commonly associated with our standard low pressure marine compressor models. Please note that all units can be customized based on voltage, frequency, mounting configuration, and environmental protection ratings (IP55, IP56, etc.).

| Parameter | Standard Specification Range |

|---|---|

| Working Pressure | 1.0 – 3.0 bar (g) |

| Flow Rate (FAD) | 50 – 600 L/min |

| Drive Type | Electric Motor (IEC Standard) |

| Motor Power | 1.5 – 15 kW |

| Speed | 960 – 1450 rpm |

| Cooling Method | Air-cooled / Water-cooled options |

| Lubrication | Oil-lubricated / Oil-free variants |

| Protection Class | IP55, IP56, or customized |

| Noise Level | ≤78 dB(A) at 1 meter |

| Classification Approvals | CCS, DNV, ABS, LR, BV, RINA, NK |

To initiate a technical discussion or request a project-specific proposal, please reach out directly to Kacher YE via email at [email protected]. We respond to all inquiries within 12 business hours and offer virtual technical meetings upon request. For urgent matters, please indicate “Urgent – Marine Compressor Inquiry” in the subject line to ensure immediate routing.

Partner with Hangzhou Star Marine Technology for precision-engineered, class-approved low pressure marine compressors backed by expert support and global service capability.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160