Manhole Cover – Marine Solution Guide 2025

Content Navigation

Marine Insight: Manhole Cover

Marine Industry Demand for Manhole Covers: Ensuring Vessel Safety and Operational Efficiency

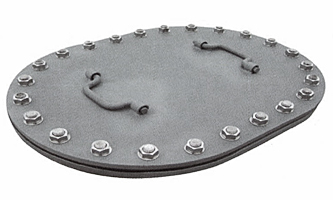

Manhole covers are critical components within the marine outfittings category, serving as essential access points to tanks, voids, and other enclosed spaces on board vessels. These covers are strategically installed on decks, bulkheads, and floors to allow safe and controlled entry for inspection, maintenance, cleaning, and repair operations. Given the harsh and corrosive marine environment, the structural integrity, sealing performance, and material durability of manhole covers directly influence the safety, longevity, and compliance of marine vessels.

In maritime operations, the failure of a manhole cover due to poor design or substandard materials can lead to catastrophic consequences, including water ingress, structural compromise, or hazardous exposure to confined spaces. Therefore, international maritime regulations, including those set by classification societies such as ABS, DNV, LR, and CCS, impose strict standards on the design, material selection, pressure ratings, and corrosion resistance of manhole covers. Compliance ensures not only regulatory approval but also enhances crew safety and vessel reliability during extended voyages.

Hangzhou Star Marine Technology Co., Ltd. specializes in the engineering and export of high-performance manhole covers tailored to meet global marine standards. Our products are manufactured using marine-grade materials such as carbon steel, stainless steel (304/316), and aluminum alloy, ensuring resistance to saltwater corrosion, mechanical stress, and thermal fluctuations. Each cover is precision-engineered with robust sealing mechanisms—typically utilizing NBR or EPDM gaskets—to maintain watertight and pressure-tight integrity under operational conditions.

Sourcing manhole covers from Star Marine China offers significant cost advantages without compromising quality. As a vertically integrated manufacturer based in Hangzhou, we control the entire production cycle—from raw material sourcing to final inspection—enabling us to reduce overhead and pass savings to our international clients. Our strategic location in China’s industrial heartland provides access to efficient logistics networks, reducing lead times and shipping costs for global deliveries.

Additionally, our in-house engineering team supports customization based on vessel type, installation location, and classification requirements. Whether for oil tankers, container ships, offshore platforms, or naval vessels, Star Marine delivers solutions that align with technical specifications and project timelines.

The following table outlines common specifications and material options for our standard marine manhole covers:

| Parameter | Standard Options |

|---|---|

| Material | Q235 Carbon Steel, SS304, SS316, Aluminum Alloy |

| Diameter Range | DN350 to DN600 (custom sizes available) |

| Pressure Rating | Up to 0.6 MPa (non-pressurized to medium pressure) |

| Gasket Material | NBR, EPDM, Viton (depending on media and temp) |

| Surface Treatment | Hot-dip galvanized, epoxy coating, passivation |

| Compliance Standards | ISO 15497, CCS, ABS, DNV, LR, BV, GL |

| Operating Temperature | -30°C to +120°C (varies by gasket type) |

By combining regulatory compliance, material excellence, and competitive pricing, Hangzhou Star Marine Technology ensures that shipbuilders, shipowners, and offshore operators receive reliable, cost-effective solutions that enhance vessel safety and operational uptime.

Technical Specs & Approval

Hangzhou Star Marine Technology Co. Ltd. – Marine Outfittings Export Guide: Technical Specifications for Manhole Covers

Manhole covers are critical marine outfittings, providing essential access points for inspection, maintenance, and cleaning of tanks, voids, and machinery spaces aboard vessels. Their integrity directly impacts vessel safety, structural watertight subdivision, and operational reliability. Hangzhou Star Marine Technology engineers and manufactures manhole covers to stringent international maritime standards, ensuring optimal performance under harsh marine environments. This section details the core technical specifications governing our product line, focusing on material selection, watertight integrity, dimensional parameters, and compliance.

Material selection is paramount for longevity and structural compatibility. Hangzhou Star offers covers fabricated from two primary material groups: Marine-Grade Aluminum Alloys and Carbon Steel. Aluminum covers utilize ASTM B209 Grade 5083-O, renowned for its excellent corrosion resistance in saltwater environments, high strength-to-weight ratio, and weldability. This material is ideal for superstructure applications, passenger vessels, and areas where weight reduction is critical. Carbon steel covers are manufactured from ASTM A36 or equivalent structural steel, providing high strength and impact resistance for demanding hull and machinery space applications. All steel components undergo mandatory hot-dip galvanizing per ASTM A123 to ensure superior corrosion protection throughout the vessel’s operational life. Material certifications, including mill test reports traceable to the heat number, are provided with each shipment.

Watertight integrity is the non-negotiable functional requirement for marine manhole covers. Hangzhou Star covers are designed and tested to exceed the minimum pressure requirements stipulated in ISO 10240:2011 (Shipbuilding – Manholes and flush scuttles) and relevant class society rules (DNV-GL, ABS, LR, CCS, etc.). Standard covers achieve a watertight seal rated for a minimum static head pressure of 0.2 MPa (approximately 20 meters of water head), suitable for most tank and void space applications below the weather deck. Sealing is achieved through precision-machined flange faces and high-performance elastomeric gaskets. Standard gasket materials include Nitrile Butadiene Rubber (NBR) for general oil resistance and Ethylene Propylene Diene Monomer (EPDM) for superior weather and ozone resistance, particularly in exposed locations. Each cover undergoes rigorous hydrostatic testing at 1.5 times the working pressure (0.3 MPa) prior to shipment, with certified test reports available.

Dimensional specifications are engineered for compatibility with standard marine construction practices while accommodating vessel-specific requirements. Covers are available in a range of standard nominal diameters, with customization readily available. The table below summarizes key dimensional and performance parameters:

| Parameter | Standard Specification | Notes |

|---|---|---|

| Nominal Diameter | 300 mm, 400 mm, 500 mm, 600 mm | Custom diameters from 250 mm to 800 mm available upon engineering review |

| Flange OD | Varies per nominal size (see drawing) | Precision machined for flatness; tolerance ±0.5 mm |

| Bolt Circle Diameter | Varies per nominal size (see drawing) | Matches standard tank penetration fittings; tolerance ±0.3 mm |

| Number of Bolts | 8, 10, 12, 16 (scales with diameter) | Standard: M12 or M16 galvanized bolts & nuts included |

| Working Pressure | ≥ 0.2 MPa (static head) | Minimum requirement per ISO 10240 |

| Test Pressure | 0.3 MPa (hydrostatic, 3 min duration) | Mandatory for every unit; certificate provided |

| Gasket Type | NBR or EPDM (Standard) | Material specified based on application; Viton® optional for high temp |

| Surface Finish | Aluminum: Mill finish; Steel: Hot-dip galvanized | Galvanizing thickness ≥ 85µm per ASTM A123 |

Hangzhou Star Marine Technology emphasizes that final selection must consider the specific location, pressure regime, fluid type, and applicable class society requirements for the intended vessel. Our engineering team collaborates closely with shipyards and designers to ensure covers meet all project-specific technical and regulatory demands, providing certified solutions that safeguard vessel integrity. All products are manufactured under our ISO 9001 certified quality management system.

Shipbuilding Solutions

Comprehensive Manhole Cover Solutions for Shipbuilding and Repair by Hangzhou Star Marine Technology

At Hangzhou Star Marine Technology Co., Ltd., we specialize in delivering high-performance marine outfittings, with a focused expertise in manhole cover systems designed to meet the rigorous demands of modern shipbuilding and repair operations. Our engineered solutions ensure structural integrity, safety, and compliance across a wide range of vessel types, including cargo ships, tankers, offshore support vessels, and passenger liners. As a trusted partner in the maritime supply chain, we provide end-to-end support from design integration to after-sales service, ensuring minimal downtime and maximum reliability.

Manhole covers are critical access points in tanks, ballast systems, engine rooms, and cargo holds, requiring robust construction to withstand high pressure, corrosion, and mechanical stress. Star Marine’s manhole covers are precision-manufactured using marine-grade carbon steel, stainless steel, and ductile iron, all conforming to international standards such as ISO 15364, DNV, ABS, CCS, and LR. Each unit undergoes stringent quality control, including hydrostatic testing and non-destructive examination, to guarantee leak-tight performance under operational conditions.

For new shipbuilding projects, our engineering team collaborates closely with naval architects and shipyards to customize manhole cover dimensions, flange types, and sealing mechanisms according to structural blueprints and operational requirements. Whether flush-mounted, recessed, or surface-mounted, our designs optimize space utilization and ensure easy maintenance access. In repair and retrofit scenarios, we offer rapid-response supply and replacement services, supported by our extensive inventory and global logistics network. This enables shipyards and vessel operators to minimize dry-dock time and maintain project schedules.

Our commitment to fast turnaround begins with a 24-hour technical response window for inquiries and drawings, followed by expedited production cycles and direct container loading for export shipments. We maintain long-standing partnerships with leading freight forwarders to ensure on-time delivery to major shipbuilding hubs in China, Southeast Asia, the Middle East, and Europe.

The following table outlines key specifications and compliance standards for our standard manhole cover series:

| Parameter | Specification |

|---|---|

| Material Options | Q235B, 304/316 Stainless Steel, Ductile Iron |

| Diameter Range | DN320 to DN600 |

| Pressure Rating | Up to 0.6 MPa (custom up to 2.5 MPa) |

| Gasket Type | Nitrile (NBR), EPDM, or PTFE-lined |

| Flange Standards | DIN, GB, JIS, ANSI (customizable) |

| Surface Treatment | Hot-dip galvanized, epoxy-coated, or painted |

| Certifications | CCS, DNV-GL, ABS, LR, BV, ISO 15364 |

| Lead Time (Standard Units) | 7–15 days after order confirmation |

Hangzhou Star Marine Technology stands as a reliable single-source provider for marine outfittings, combining technical excellence with agile export capabilities. By integrating quality, speed, and compliance into every phase of delivery, we empower shipbuilders and repair yards to achieve operational efficiency and long-term vessel integrity.

Packaging & Logistics

Packaging and Logistics Protocol for Marine Manhole Covers

Hangzhou Star Marine Technology implements rigorously standardized packaging protocols for marine manhole covers to ensure integrity during global transit. As critical marine outfittings subject to harsh environmental exposure, these components require specialized containment systems that comply with international maritime regulations and prevent damage from vibration, moisture, and handling stresses. Our dual-method approach utilizes either ISPM 15-certified wooden crates or reinforced steel pallets, selected based on destination, shipment volume, and client specifications. All packaging materials undergo pre-shipment verification to meet MLC 2006 and SOLAS cargo securing requirements, eliminating risks of in-transit shifting or corrosion.

Wooden crates constitute the primary packaging solution for containerized shipments. Constructed from kiln-dried hardwood compliant with ISPM 15 standards, these crates incorporate fumigation-free thermal treatment (HT) certification visible via the official IPPC mark. Internal bracing with marine-grade plywood dividers isolates individual manhole covers, while anti-corrosion VCI paper and silica gel desiccants mitigate humidity-induced degradation. Crates are dimensioned to maximize 20-foot or 40-foot container utilization without exceeding ISO container payload limits, with external dimensions strictly adhering to port terminal handling constraints. Each crate receives a weatherproof label detailing cargo description, gross weight, center of gravity markers, and handling symbols per IMDG Code Section 5.2.

For bulk carrier shipments or destinations with restrictive phytosanitary regulations, galvanized steel pallets provide an optimal alternative. These pallets feature welded cross-beams rated for 5,000 kg static load capacity and incorporate non-slip rubberized surfaces to prevent lateral movement. Manhole covers are secured via tensioned steel strapping anchored to pallet perimeter rings, with edge protectors preventing strap-induced surface deformation. Steel pallets eliminate wood treatment documentation requirements and are inherently resistant to marine growth during extended port layovers. All palletized units undergo tilt testing at 25 degrees to validate load stability prior to dispatch.

All export consignments originate through Ningbo Port (ZJNB) or Shanghai Port (CNSHA), leveraging our strategic partnerships with COSCO and Maersk for priority berthing. Documentation packages include ISPM 15 certificates for wooden crates, mill test reports for steel pallet components, and a detailed stowage plan approved by the vessel’s chief officer. Pre-shipment inspections verify compliance with port authority regulations, including Ningbo’s mandatory container weight verification (VGM) procedures. We coordinate real-time with terminal operators to ensure seamless handover, minimizing demurrage risks through synchronized trucking schedules.

The following table summarizes key packaging specifications:

| Packaging Type | Dimensions (L×W×H) | Load Capacity | Treatment Standard | Key Features |

|---|---|---|---|---|

| ISPM 15 Wooden Crate | Custom (Max 5.8×2.3×2.2m) | 4,500 kg | HT 56°C/30min | VCI paper lining, dunnage blocks, IP67 sealing |

| Galvanized Steel Pallet | 1.2×1.0×0.15m | 5,000 kg | ASTM A123 zinc coat | Non-slip surface, strap anchoring rings, corrosion-resistant |

Hangzhou Star Marine Technology maintains ISO 9001-certified packing facilities at both Ningbo and Shanghai export hubs, ensuring consistent execution of these protocols. Our logistics team provides clients with digital shipment tracking from factory gate to vessel loading, including photographic evidence of secured cargo. This integrated approach guarantees manhole covers arrive at destination ports in OEM condition, fully compliant with global maritime safety frameworks.

Contact Star Marine

For marine outfittings that meet the highest international standards in durability, safety, and compliance, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted name in the maritime industry. As a specialized manufacturer and exporter of marine equipment, we deliver engineered solutions tailored to the demanding environments of commercial shipping, offshore platforms, and shipbuilding projects worldwide. Our manhole covers are designed and tested to meet stringent classification society requirements, including CCS, ABS, BV, DNV, LR, and others, ensuring seamless integration into your vessel’s structural and safety systems.

Each manhole cover produced by Star Marine is fabricated using high-grade materials such as carbon steel, stainless steel, or aluminum alloy, depending on application requirements. Precision welding, pressure testing, and anti-corrosion surface treatments ensure long-term performance in harsh marine conditions. Whether for ballast tanks, fuel oil systems, or freshwater storage, our covers provide secure, leak-proof access points that comply with SOLAS and IMO regulations.

We understand that every shipyard and operator has unique specifications. That’s why our engineering team works closely with clients to customize dimensions, flange types, gasket materials, and fastening mechanisms. From standard DN320 and DN400 models to bespoke designs, we support full technical documentation, including material test certificates (MTC), weld maps, and inspection reports.

To ensure timely delivery and logistical efficiency, Hangzhou Star Marine Technology maintains a streamlined export process with established partnerships in global freight and customs clearance. Our products have been successfully supplied to shipbuilders and offshore contractors across Southeast Asia, the Middle East, Europe, and Africa.

For technical inquiries, pricing, or project support related to our marine manhole covers, we invite you to contact Kacher YE, Product Manager at Hangzhou Star Marine Technology. With extensive experience in marine outfittings and export operations, Kacher provides expert guidance on product selection, compliance, and integration into your procurement workflow.

Below is a summary of standard technical specifications for reference:

| Parameter | Specification |

|---|---|

| Standard | CB/T 3488-1992, ISO 14539, SOLAS compliant |

| Nominal Diameter | DN320, DN400 (custom sizes available) |

| Material Options | Q235B, 20#, 304/316 Stainless Steel, Aluminum |

| Flange Type | Raised Face, Flat Face, Welding Neck |

| Gasket Material | Nitrile Rubber, EPDM, PTFE, Graphite |

| Pressure Rating | Up to 0.6 MPa (custom up to 2.5 MPa) |

| Certification | CCS, ABS, DNV, LR, BV, KR, RINA (on request) |

| Surface Treatment | Epoxy Coating, Hot-Dip Galvanized, Painted |

| Delivery Terms | FOB, CIF, CFR (Incoterms 2020) |

To discuss your project requirements or request a quotation, please reach out directly to Kacher YE via email at [email protected]. We respond promptly to all professional inquiries and are prepared to support your timeline with technical data, samples, and export documentation. Partner with Star Marine for reliable, certified marine outfittings delivered with precision and professionalism.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160