Marine Ball Valve – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Ball Valve

Marine Ball Valve Criticality and Strategic Sourcing Advantage

Marine ball valves represent a fundamental safety component across all vessel types, directly impacting operational integrity and crew protection. Their primary function—providing rapid, reliable on/off control of fluid systems—is non-negotiable for critical applications including seawater intake, firemain systems, ballast control, and fuel transfer. Failure within these systems can lead to catastrophic outcomes such as uncontrolled flooding, fire escalation, or loss of stability. International regulations, particularly SOLAS Chapter II-1, mandate stringent performance standards for valves in essential piping circuits to ensure watertight subdivision and machinery safety. A marine ball valve must consistently deliver zero leakage under extreme pressure cycles, resist corrosion from seawater and fuels, and operate smoothly even after prolonged exposure to harsh marine environments. Compromised valve performance directly jeopardizes vessel seaworthiness and crew safety, making specification and sourcing of certified, high-integrity units a paramount procurement priority for shipbuilders and operators globally.

Sourcing high-performance marine ball valves from Hangzhou Star Marine Technology offers significant strategic and economic advantages without compromising safety. Our vertically integrated manufacturing facility in Hangzhou adheres strictly to international marine standards, including ISO 5208 for leakage testing and ISO 10434 for bolting. We utilize marine-grade materials such as ASTM A351 CF8M (316 stainless steel) and ASTM A216 WCB with NACE MR0175 compliance for sour service, ensuring resilience against galvanic corrosion and hydrogen sulfide. Every valve undergoes 100% hydrostatic pressure testing at 1.5x design pressure and pneumatic shell testing per API 598, with full traceability from raw material certification through final inspection. This rigorous quality control, coupled with direct factory oversight, eliminates intermediary markups and supply chain redundancies inherent in traditional import channels. The table below summarizes key performance and value metrics:

| Parameter | Star Marine Standard | Typical Industry Baseline | Advantage |

|---|---|---|---|

| Material Certification | MTRs + PMI Verified | Basic Mill Certs | Enhanced traceability & compliance |

| Pressure Testing | 100% Hydrostatic | Sample Batch Testing | Guaranteed unit reliability |

| Lead Time (4″ 150#) | 4-6 Weeks | 8-12+ Weeks | Faster project completion |

| ABS/DNV/NK Certification | Direct Factory Scope | Post-manufacture Survey | Reduced certification costs |

| Total Landed Cost (FOB) | Competitive Baseline | Higher with intermediaries | 15-25% Cost efficiency |

This operational excellence translates to demonstrable cost-effectiveness. By eliminating multi-tier distribution and leveraging China’s advanced marine manufacturing ecosystem, Star Marine delivers valves meeting ABS, DNV, LR, and CCS Type Approval specifications at a significantly lower total landed cost compared to European or North American alternatives. Our dedicated export team ensures seamless documentation compliance—including Form A for preferential tariffs—and coordinates logistics to global ports, minimizing customs delays. For vessel operators and shipyards prioritizing uncompromised safety and lifecycle value, Star Marine provides certified marine ball valves where rigorous engineering integrity aligns with optimal procurement economics. The investment in properly specified, certified valves from a proven manufacturer is not an expenditure but a fundamental safeguard against far greater operational and safety liabilities.

Technical Specs & Approval

Hangzhou Star Marine Technology Co., Ltd. provides high-performance marine ball valves engineered to meet the rigorous demands of maritime applications. These valves are essential components in shipboard piping systems, offering reliable flow control for seawater, freshwater, fuel, lubricating oil, and other non-corrosive media. Designed for durability, leak-tight sealing, and ease of operation, our marine ball valves comply with international standards and are widely used in propulsion systems, ballast systems, cooling circuits, and auxiliary machinery.

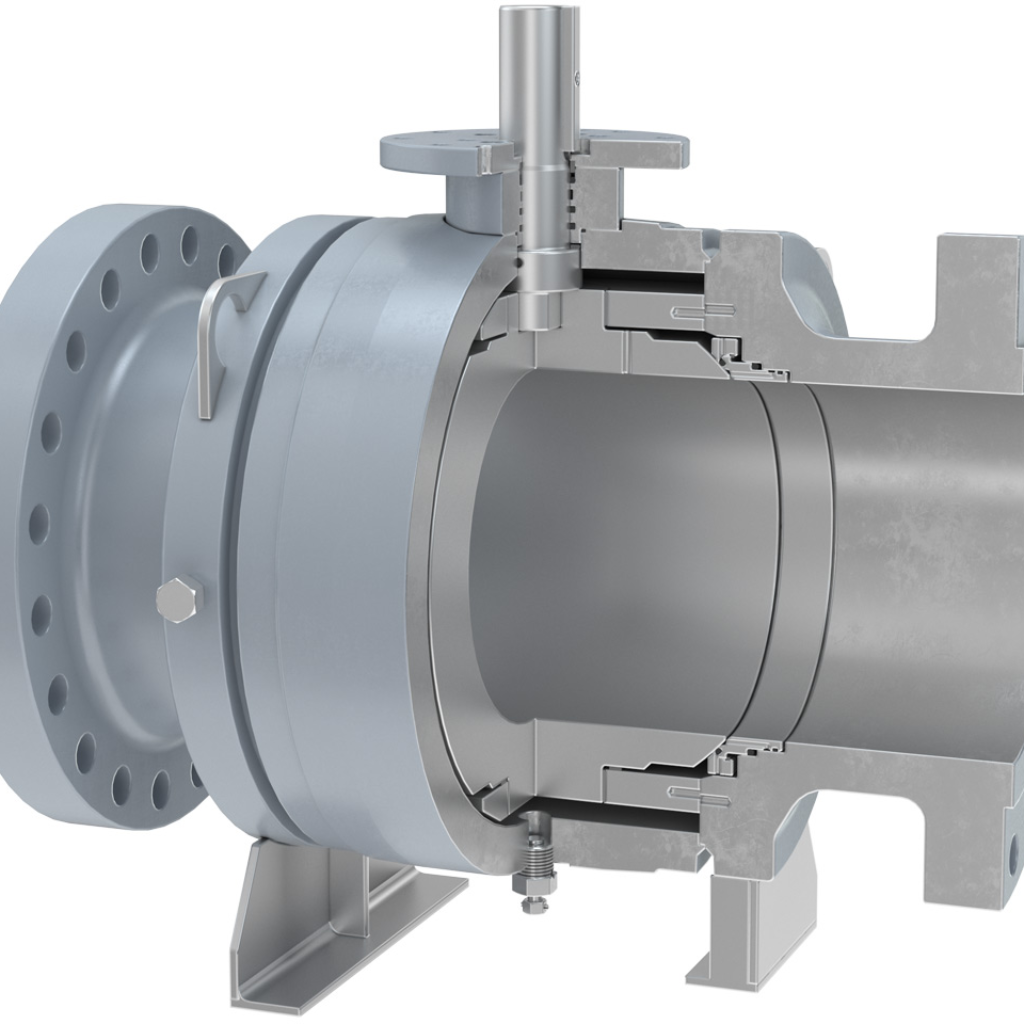

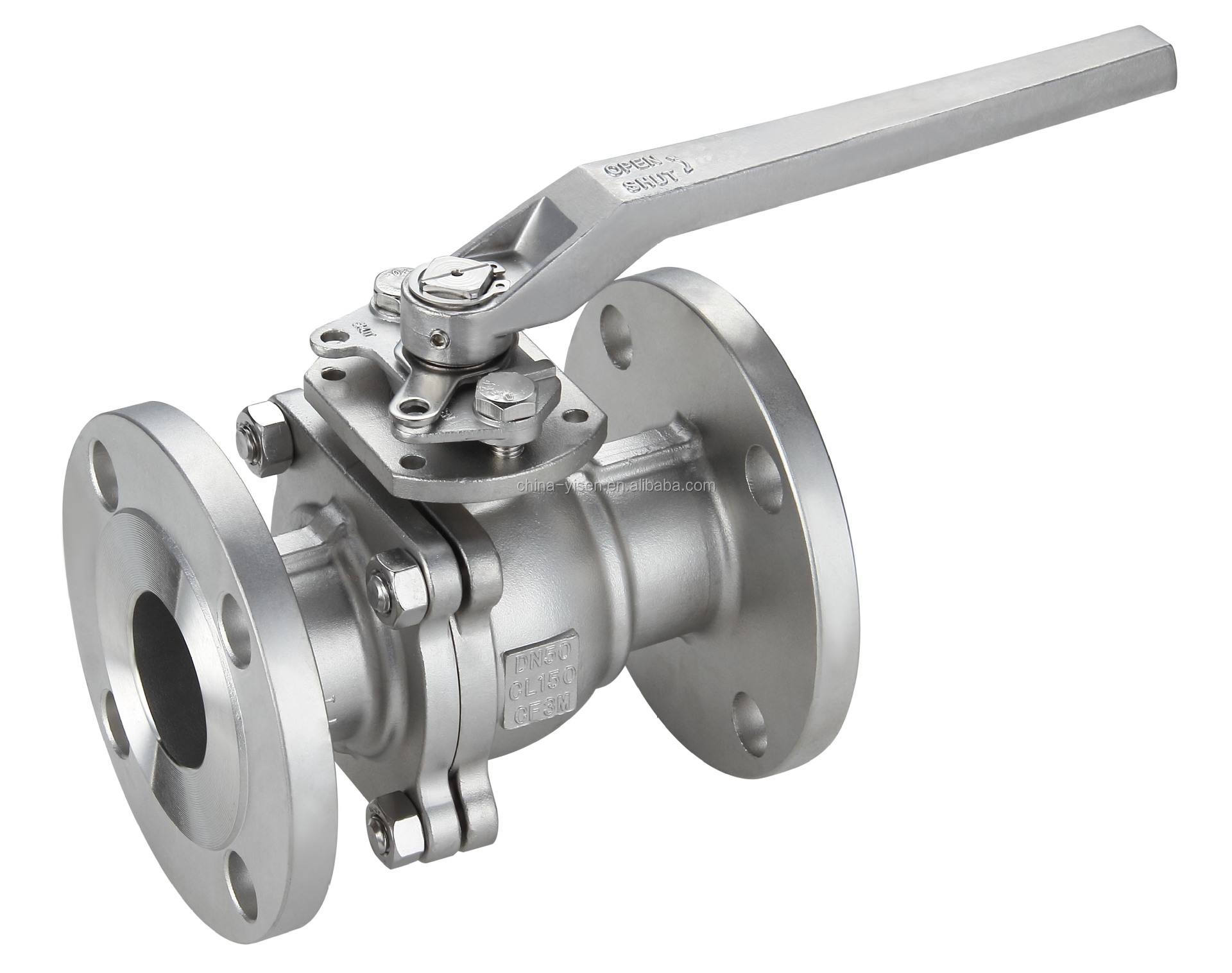

The technical design of our marine ball valves emphasizes material integrity, pressure resilience, and dimensional consistency. Two primary body materials are offered: high-grade bronze and cast steel. Bronze ball valves are ideal for low to medium pressure systems in seawater and freshwater applications due to their excellent corrosion resistance and machinability. Cast steel variants are selected for higher pressure and temperature environments, particularly in fuel and steam service lines, where mechanical strength and thermal stability are critical.

Valve pressure ratings are standardized across the PN6 to PN40 range, ensuring compatibility with diverse system requirements. A PN6 valve is suitable for low-pressure ballast and cooling water lines, while PN40-rated models are deployed in high-stress zones such as main engine fuel supply circuits. All valves undergo hydrostatic and pneumatic testing to verify pressure integrity and sealing performance under maximum rated conditions.

Our marine ball valves are manufactured in accordance with JIS and DIN standards, ensuring global interchangeability and regulatory compliance. JIS-compliant valves follow Japanese Industrial Standards for dimensions, flange connections, and performance testing, making them ideal for vessels built in or servicing Asian shipyards. DIN-compliant models adhere to German engineering standards, offering precise tolerances and robust construction preferred in European and international fleets.

Actuation options include manual lever, gear-operated, and automated (pneumatic or electric) configurations, allowing integration into both local and centralized control systems. The full-bore design ensures minimal pressure drop and facilitates pigging operations in larger pipeline networks. Seats are constructed from reinforced PTFE or graphite, providing long-term sealing performance and resistance to thermal cycling.

All valves are marked with material grade, pressure rating, standard designation, and serial number for full traceability. Packaging is seaworthy, with anti-corrosion protection and secure crating for long-distance export logistics.

The following table summarizes the key technical parameters of our marine ball valve product line:

| Parameter | Bronze Body Valves | Cast Steel Body Valves |

|---|---|---|

| Body Material | High-Tin Bronze (CuSn6Zn6Pb3) | Cast Carbon Steel (WCB) |

| Ball Material | Stainless Steel (SS316) | Stainless Steel (SS316) |

| Stem Material | AISI 410 Stainless Steel | AISI 410 Stainless Steel |

| Seat Material | Reinforced PTFE / Graphite | Reinforced PTFE / Graphite |

| Pressure Rating | PN6 – PN25 | PN6 – PN40 |

| Temperature Range | -20°C to +180°C | -29°C to +425°C |

| End Connection | Flanged (JIS 10K/16K, DIN PN10/16/25/40) | Flanged (JIS 10K/20K, DIN PN10/16/25/40) |

| Design Standard | JIS F 7405, DIN 3355 | JIS F 7405, DIN 3355 |

| Testing Standard | GB/T 13927, API 598 | GB/T 13927, API 598 |

| Size Range (DN) | DN15 – DN200 | DN15 – DN300 |

These specifications reflect Hangzhou Star Marine Technology’s commitment to quality, safety, and performance in marine valve engineering. Each valve is inspected and certified to ensure compliance with classification society requirements including CCS, ABS, DNV, LR, and NK.

Shipbuilding Solutions

Star Marine Ball Valve Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine ball valve solutions meeting the rigorous demands of global shipbuilding and repair operations. Our valves adhere strictly to ISO 5211, DNV-GL Type Approval, and SOLAS standards, ensuring compliance with international maritime regulations. For new vessel construction, Star Marine integrates seamlessly with shipyard schedules through pre-engineered valve packages tailored to specific vessel blueprints. This proactive approach minimizes installation delays and reduces project risk by aligning with critical path timelines. Our valves feature robust monobloc or three-piece designs with reinforced seats for enhanced sealing under vibration and thermal cycling, critical for propulsion, ballast, and fuel systems.

In ship repair and retrofit scenarios, rapid response is paramount. Star Marine maintains strategic inventory hubs in Shanghai, Rotterdam, and Singapore, enabling 72-hour delivery for standard valves and 10-day turnaround for custom configurations. Our repair kits include laser-etched replacement seats and stem assemblies compatible with legacy valves, eliminating vessel downtime during dry-dock periods. Certified technicians provide on-site support for emergency valve replacements, ensuring adherence to class society survey requirements without schedule disruption. This operational agility directly supports shipowners’ need to minimize port turnaround time while maintaining safety integrity.

Technical excellence is reinforced by our material science expertise. All ball valves undergo 1.5x working pressure hydrostatic testing and helium leak detection per API 598. We prioritize seawater resistance through duplex stainless steel (ASTM A182 F51) and nickel-aluminum bronze options, with optional PTFE or reinforced graphite seating for high-temperature applications. The table below summarizes core specifications for our flagship marine ball valve series:

| Parameter | Standard Specification | Optional Upgrade |

|---|---|---|

| Body Material | ASTM A351 CF8M (SS316) | ASTM B148 C95800 (Ni-Al Bronze) |

| Pressure Rating | PN16 / Class 150 (ASME B16.34) | PN40 / Class 300 |

| Temperature Range | -20°C to +200°C | -40°C to +350°C (Graphite) |

| Size Range | DN15 to DN300 (1/2″ to 12″) | DN350 (14″) |

| Certifications | DNV-GL, LR, CCS, ABS, BV | RINA, KR, NK |

Star Marine’s export infrastructure ensures seamless global deployment. Our dedicated project managers coordinate documentation (including Material Test Reports and 3.2 Certificates per EN 10204) and handle customs clearance under INCOTERMS® 2020. For urgent repair needs, our 24/7 technical support desk provides multilingual troubleshooting, reducing diagnostic delays. By combining certified product reliability with responsive logistics, Hangzhou Star Marine Technology becomes a strategic partner in vessel lifecycle management—accelerating new build completion and restoring operational readiness during repairs. Trust Star Marine to uphold safety, compliance, and schedule integrity across your fleet.

Packaging & Logistics

Packaging and Logistics for Marine Ball Valves – Hangzhou Star Marine Technology Co., Ltd.

At Hangzhou Star Marine Technology Co., Ltd., the packaging and logistics of marine ball valves are designed to meet international maritime standards, ensuring product integrity, compliance with global regulations, and seamless delivery to customers worldwide. As a leading supplier in the marine valves category, we recognize that proper packaging is critical not only for protecting high-performance equipment during transit but also for complying with phytosanitary and customs requirements across different markets.

All marine ball valves are packaged using ISPM 15 certified wooden cases for international shipments. The International Standards for Phytosanitary Measures No. 15 (ISPM 15) is a globally recognized regulation that governs the use of wood packaging materials in international trade. These wooden cases are heat-treated to eliminate pests and pathogens, stamped with the official ISPM 15 mark, and constructed to withstand the rigors of sea freight. The design of the wooden cases includes internal cushioning and secure fastening mechanisms to prevent movement, vibration, and environmental exposure during long-haul transportation.

For added structural support, particularly for bulk orders or heavy-duty valve models, we utilize steel pallets. Steel pallets offer superior durability, resistance to moisture and corrosion, and enhanced load-bearing capacity. This method is especially recommended for containerized shipments where stacking stability and protection against compression damage are essential. The combination of ISPM 15 wooden enclosures and steel pallets ensures that our marine ball valves arrive at their destination in optimal condition, ready for immediate integration into marine systems.

All export operations are coordinated through China’s major maritime hubs—Ningbo and Shanghai ports. These ports are among the busiest and most efficient in the world, offering direct connections to key markets in Europe, North America, Southeast Asia, and the Middle East. Our logistics partners are experienced in handling marine-grade equipment and ensure timely customs clearance, proper documentation, and real-time shipment tracking.

We maintain strict internal protocols to align packaging specifications with the valve type, size, and destination. Each shipment is labeled with essential handling instructions, product identification, and compliance markings to facilitate smooth logistics operations.

The following table outlines the standard packaging configurations based on valve specifications:

| Valve Size (DN) | Quantity per Package | Packaging Type | Pallet Material | Gross Weight (kg) | Stackable |

|---|---|---|---|---|---|

| DN15–DN50 | 10–20 units | Wooden Case | Steel | 80–150 | Yes |

| DN65–DN150 | 5–10 units | Wooden Case | Steel | 150–300 | Yes |

| DN200–DN300 | 1–3 units | Wooden Crate | Steel | 300–600 | Limited |

All packaging designs undergo routine quality audits and are subject to internal load and drop testing to verify performance under real-world shipping conditions. Through this systematic approach to packaging and logistics, Hangzhou Star Marine Technology ensures the reliable and compliant delivery of marine ball valves to shipyards, OEMs, and marine equipment distributors worldwide.

Contact Star Marine

Direct Engineering Support for Mission-Critical Marine Ball Valve Integration

Selecting and integrating the correct marine ball valve is not merely a procurement decision; it is a fundamental requirement for vessel safety, operational integrity, and regulatory compliance. The demanding marine environment – characterized by constant vibration, corrosive seawater exposure, extreme temperature fluctuations, and stringent safety protocols – demands valves engineered to exacting international standards. Generic solutions or off-the-shelf components often fail to meet the specific pressure, temperature, material compatibility, and certification requirements mandated by classification societies and flag states. At Hangzhou Star Marine Technology, our ball valves are purpose-built for maritime applications, undergoing rigorous testing to exceed ISO 5208 leakage standards, DNV Type Approval, and ABS certification protocols. However, the optimal solution for your unique vessel system requires expert technical evaluation. Factors such as fluid media composition, operational pressure cycles, installation orientation, required actuation method, and integration with existing piping systems significantly influence the ideal valve specification. Relying solely on catalog data risks suboptimal performance, premature failure, or costly non-compliance during surveys.

To ensure your ball valve selection delivers maximum reliability and seamless integration, we strongly recommend initiating a direct technical consultation. Our Product Manager, Kacher YE, possesses over 12 years of specialized experience in marine valve engineering and global project execution. Kacher leads our technical export team and is uniquely positioned to translate your operational requirements into a validated valve solution. He will collaborate with your engineering staff to review system schematics, clarify application specifics, address complex installation challenges, and confirm all necessary certifications for your vessel’s registry and classification society. This proactive engagement mitigates project risk, avoids costly redesigns or delays, and guarantees the valve performs flawlessly throughout its service life under the harshest marine conditions. The table below outlines critical parameters where our technical guidance is essential for optimal selection:

| Parameter | Standard Range for Marine Ball Valves | Critical Consideration for Selection |

|---|---|---|

| Pressure Rating | PN16 to PN40 / 150lb to 300lb | Must exceed max system pressure + safety margin |

| Temperature Range | -20°C to +200°C | Compatibility with fluid media and ambient conditions |

| Body Material | ASTM A216 WCB, CF8M (316SS) | Corrosion resistance for seawater/fuel/oil |

| Seat Material | PTFE, RPTFE, Metal-Seated | Media compatibility, fire safety (API 607) |

| End Connection | Flanged (PN/DN, ANSI), Threaded, Weld | Precise match to vessel piping system |

Do not compromise vessel safety or project timelines with an uninformed valve choice. Contact Kacher YE directly to leverage Hangzhou Star Marine Technology’s engineering expertise for your specific application. He will provide a comprehensive technical review, formal quotation with full certification documentation, and dedicated project support from specification through final delivery and commissioning. Forward your project specifications, P&ID excerpts, or system requirements to [email protected]. Clearly reference your vessel name, project number, and specific valve application (e.g., main seawater cooling line, fuel transfer system, ballast control). Kacher typically responds within 4 business hours during working days (GMT+8) to initiate the technical validation process. Partner with Star Marine to ensure your ball valve installation meets the uncompromising demands of maritime operations, safeguarding your vessel’s performance and crew safety. Your project’s success begins with the right technical dialogue.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160