Marine Cable – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Cable

Marine cable is a critical component in the structural and operational integrity of all types of vessels, playing a fundamental role in rigging, mooring, towing, and anchoring systems. These cables are engineered to withstand extreme environmental conditions, including high tensile stress, saltwater corrosion, UV exposure, and constant mechanical wear. In the maritime industry, the reliability of marine cable directly impacts vessel safety, crew protection, and operational continuity. A failure in mooring or towing systems due to substandard cable performance can lead to catastrophic incidents, including vessel drift, collisions, or loss of life. As global shipping volumes increase and vessel sizes grow, particularly in offshore and deep-sea operations, the demand for high-performance marine cables has risen significantly.

The marine industry requires cables that meet stringent international standards such as ISO 2415, ISO 17893, and classification society rules from ABS, DNV, LR, and BV. These standards govern material composition, breaking strength, elongation properties, and corrosion resistance. High-quality marine cables are typically constructed from galvanized steel wire rope, stainless steel, or advanced synthetic fibers such as Dyneema, depending on the application. For example, synthetic cables offer high strength-to-weight ratios and are increasingly used in dynamic mooring systems on offshore platforms and large yachts, while steel cables remain the standard for heavy-duty towing and anchoring operations on commercial vessels.

Hangzhou Star Marine Technology Co., Ltd. specializes in the design, manufacturing, and export of marine cables that meet and exceed these international requirements. As a trusted supplier in the marine outfittings sector, Star Marine China leverages advanced production technologies, rigorous quality control processes, and extensive material sourcing networks to deliver cables with certified performance metrics. Our products undergo comprehensive testing, including tensile strength verification, salt spray resistance, and fatigue cycle evaluation, ensuring compliance with the operational demands of modern maritime applications.

Sourcing marine cable from Hangzhou Star Marine Technology offers significant cost advantages without compromising on quality. China’s mature manufacturing ecosystem, combined with our vertical integration and export expertise, allows us to provide competitive pricing, shorter lead times, and flexible customization options. Additionally, our strategic location near major shipping ports in East China enables efficient global logistics, reducing transportation costs and delivery times for international clients.

The following table outlines key performance specifications of Star Marine’s standard marine cable offerings:

| Cable Type | Diameter Range (mm) | Minimum Breaking Load (kN) | Material | Compliance Standards |

|---|---|---|---|---|

| Galvanized Steel Wire Rope | 12 – 60 | 200 – 3,200 | Galvanized Steel | ISO 2415, DNV-GL, ABS |

| Stainless Steel Cable | 10 – 50 | 150 – 2,800 | AISI 316 Stainless | ISO 17893, LR, BV |

| Synthetic Fiber Cable | 20 – 80 | 300 – 4,500 | Dyneema® SK78 | DNV-OS-E301, ABS High Modulus |

By combining technical excellence with cost-effective manufacturing, Hangzhou Star Marine Technology provides marine operators and outfitters with a reliable, economical solution for critical cable systems, enhancing both safety and operational efficiency across the global fleet.

Technical Specs & Approval

Technical Specifications: Marine Power and Control Cables

Marine power and control cables constitute critical infrastructure for vessel electrical systems, demanding rigorous adherence to international safety and performance standards. Hangzhou Star Marine Technology designs and manufactures cables meeting IEC 60092 series requirements, specifically IEC 60092-350 (General Construction Requirements) and IEC 60092-353 (Single-Core and Multi-Core Extruded Solid Dielectric Insulated Cables). These cables ensure operational integrity in harsh maritime environments characterized by saltwater exposure, mechanical stress, vibration, and fire hazards. Material selection prioritizes corrosion resistance, electrical conductivity, and longevity, with aluminum and steel variants serving distinct application needs.

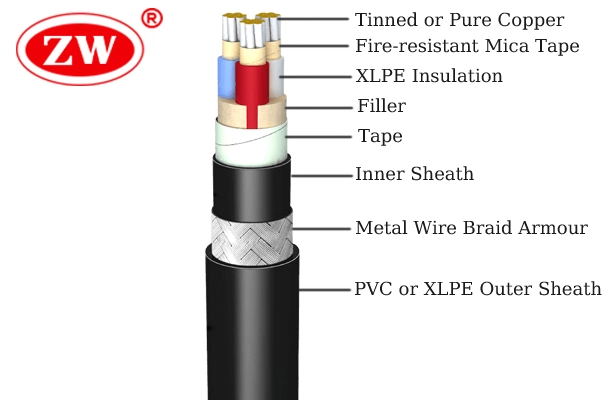

Conductor material is specified based on current-carrying capacity and weight considerations. Aluminum conductors offer significant weight savings advantageous for large-scale installations but require careful termination to prevent galvanic corrosion. Steel-armored variants provide superior mechanical protection against crushing and rodent damage in high-risk zones like engine rooms or deck penetrations, though at increased weight. All conductors utilize high-purity stranded copper or aluminum meeting IEC 60228 Class 2 standards for flexibility. Insulation employs cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR), selected for thermal stability (90°C continuous operation) and resistance to oil, chemicals, and abrasion. The outer sheath utilizes flame-retardant, halogen-free compounds compliant with IEC 60092-359, ensuring low smoke emission and toxicity during fire events to facilitate crew evacuation.

Watertightness is non-negotiable for cables traversing watertight bulkheads or exposed deck areas. Our cables achieve IP68/IP69K ratings through seamless extrusion processes and specialized glanding systems. Integral metallic barriers (aluminum or steel tape/armour) combined with moisture-blocking swellable tapes prevent longitudinal water propagation under sustained pressure, exceeding IEC 60092-376 requirements for submersion at 3 meters depth for 24 hours without degradation. Dimensional tolerances strictly follow IEC 60092-350, ensuring compatibility with standard marine cable glands and conduits. Outer diameter tolerances are maintained within ±0.5mm for precise sealing, while conductor cross-sections adhere to ±1.5% variance to guarantee ampacity performance. Minimum bending radii are defined as 6x the overall cable diameter during installation and 4x under operational conditions to prevent insulation damage.

Key technical parameters for our standard marine cable range are summarized below:

| Parameter | Specification | Standard Reference |

|---|---|---|

| Conductor Material | Stranded Copper (Class 2) or Aluminum (Class 2) | IEC 60228 |

| Insulation Material | XLPE or EPR (90°C Rating) | IEC 60092-353 |

| Sheath Material | Halogen-Free Flame Retardant Compound (HFFR) | IEC 60092-359 |

| Voltage Rating | 0.6/1 kV (AC) | IEC 60092-353 |

| Armour Type | Galvanized Steel Wire Braid (SWA) or Aluminum Tape | IEC 60092-375 |

| Water Tightness | IP68 (3m depth, 24h) | IEC 60529 / IEC 60092 |

| Fire Performance | IEC 60332-3 Cat A, IEC 60092-359 Low Smoke & Toxicity | IEC 60332-3 / IEC 60092 |

| Operating Temperature | -25°C to +90°C (Fixed Installations) | IEC 60092-350 |

| Minimum Bend Radius | 6x OD (Installation), 4x OD (Operational) | IEC 60092-350 |

Hangzhou Star Marine Technology implements 100% electrical testing per IEC 60885-3 (partial discharge) and IEC 60060-1 (high-voltage withstand) on all production batches. Dimensional verification and material traceability are integral to our ISO 9001-certified quality management system. Compliance documentation, including Type Test Certificates from accredited bodies like DNV or Bureau Veritas, is provided for all export shipments to validate adherence to flag state and classification society requirements. This rigorous technical foundation ensures our marine cables deliver decades of reliable service in global maritime operations.

Shipbuilding Solutions

Marine Cable Solutions for Shipbuilding and Repair – A Complete Outfitting Approach by Hangzhou Star Marine Technology

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine cable solutions tailored for both new shipbuilding projects and vessel repair operations. As a specialized provider in marine outfittings, we understand the critical role that high-performance cabling systems play in ensuring the safety, reliability, and operational efficiency of modern vessels. Our engineering-driven approach integrates product quality, technical support, and rapid logistics to meet the dynamic demands of shipyards and maritime operators worldwide.

Marine cables are essential components in a vessel’s electrical architecture, supporting power distribution, control systems, communication networks, and automation. The harsh marine environment—characterized by saltwater exposure, vibration, temperature fluctuations, and fire risk—demands cables that meet stringent international standards. At Star Marine, we supply a full range of marine-grade cables compliant with IEC 60092, ISO 13222, and船级社 certifications including CCS, ABS, DNV, LR, and BV. Our product portfolio includes low-voltage (LV), medium-voltage (MV), instrumentation, fiber optic, and fire-resistant (circuit integrity) cables, all designed for long-term durability and optimal signal integrity.

For new shipbuilding projects, we collaborate closely with design teams and shipyards during the early outfitting phase. Our engineers provide technical consultation on cable routing, segregation, and selection based on load requirements and environmental conditions. This proactive engagement ensures seamless integration into the vessel’s overall system design, minimizing rework and enhancing project timelines. We support full BOM (Bill of Materials) fulfillment, offering bundled cable packages that reduce procurement complexity and improve cost efficiency.

In ship repair and retrofit applications, Star Marine excels in rapid response and customization. Our global inventory network enables fast delivery of replacement cables, even for legacy or non-standard specifications. Our team conducts on-site assessments when needed, supporting classification society surveys and compliance upgrades. Whether replacing damaged sections or modernizing communication systems, our solutions are engineered for compatibility, safety, and minimal downtime.

To ensure operational excellence, we also provide value-added services such as pre-termination, labeling, drum handling, and technical documentation in multiple languages. These services streamline installation and support quality assurance during commissioning.

The following table outlines key cable types and specifications available through Star Marine:

| Cable Type | Voltage Rating | Standards Compliance | Typical Application |

|---|---|---|---|

| Power Cable (PVC/LSOH) | 0.6/1 kV | IEC 60092-350, CCS | Main distribution, lighting, HVAC |

| MV Power Cable | 3.6/6 kV – 8.7/15 kV | IEC 60092-353, ABS | Main propulsion, large motors |

| Control Cable | 300/500 V | IEC 60092-354, DNV | Automation, monitoring, control panels |

| Instrumentation Cable | 300/500 V | IEC 60092-376, LR | Sensors, data transmission, bridge systems |

| Fire-Resistant Cable | 0.6/1 kV | IEC 60331, IEC 60092-359 | Emergency systems, fire pumps, exits |

| Fiber Optic Cable | N/A | ISO 13222, BV | High-speed data, navigation, CCTV |

With a commitment to technical precision and supply chain agility, Hangzhou Star Marine Technology stands as a trusted partner in marine cable outfitting. From concept to commissioning, we deliver complete, compliant, and reliable solutions for the global maritime industry.

Packaging & Logistics

Marine Cable Packaging & Logistics Protocol

Hangzhou Star Marine Technology implements rigorously standardized packaging protocols for marine cable exports to ensure compliance with international maritime regulations and safeguard product integrity during global transit. All wooden packaging materials strictly adhere to ISPM 15 (International Standards for Phytosanitary Measures No. 15) requirements. This mandates heat treatment (HT) of solid wood components to a minimum core temperature of 56°C for 30 minutes, eliminating pest risks. Each wooden crate or dunnage bears the globally recognized ISPM 15 compliance mark, including the IPPC logo, country code (CN for China), unique producer code, and treatment indicator (HT). This certification is non-negotiable for entry into all major maritime markets, including the EU, USA, Australia, and ASEAN nations, preventing customs delays or shipment rejection at destination ports.

Marine cables are inherently vulnerable to moisture, mechanical shock, and salt contamination. Our packaging integrates multiple protective layers: cables are first sealed in moisture-barrier VCI (Vapor Corrosion Inhibitor) polyethylene film, followed by robust wooden crates constructed from kiln-dried plywood or hardwood. Internal bracing and custom-cut foam inserts prevent cable drum movement during handling. For heavy-duty armored cables or large-diameter reels, reinforced steel pallets with galvanized finishes (minimum 80μm zinc coating) are utilized. These pallets feature welded structural integrity to support loads exceeding 5,000 kg and are designed for secure lashing within shipping containers. All external surfaces are treated with marine-grade anti-rust coatings to withstand Ningbo and Shanghai port humidity during pre-shipment staging.

The following table details our standard packaging configurations for marine cable shipments:

| Packaging Type | Key Specifications | Application Context |

|---|---|---|

| ISPM 15 Wooden Crate | Plywood thickness: 18–22 mm; HT-treated timber; IPX6 moisture seal; Lashing points rated 2,500 kg | Standard cable reels (≤ 3,000 kg); Moisture-sensitive installations |

| Galvanized Steel Pallet | Frame thickness: 6 mm steel; Zinc coating: ≥80μm; Load capacity: 5,000–8,000 kg; Non-slip deck | Heavy armored cables; Subsea cable reels; High-value projects requiring direct crane handling |

Export logistics originate exclusively from the Port of Ningbo-Zhoushan or Port of Shanghai, leveraging Hangzhou Star Marine Technology’s established partnerships with Tier-1 freight forwarders specializing in marine equipment. Shipments are consolidated into 40-foot High Cube (HC) containers, optimized for maximum cubic utilization while maintaining ISO container lashing standards (CSS Code). Pre-shipment documentation includes ISPM 15 certificates, detailed packing lists with gross/net weights, and moisture-content test reports for wooden components. All containers undergo pre-loading humidity checks (<65% RH) and are sealed with numbered customs seals immediately after stuffing. Our Ningbo/Shanghai logistics teams conduct final verification 72 hours prior to vessel departure, confirming container integrity, document accuracy, and compliance with destination port-specific regulations (e.g., AQIS for Australia, FDA for USA). This end-to-end control ensures zero damage incidents and 100% customs clearance success for marine cable consignments worldwide.

Contact Star Marine

For global shipbuilders, offshore platform operators, and marine equipment suppliers seeking high-performance marine cable solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in marine outfittings. Our engineered cable systems are designed to meet the rigorous demands of marine environments, from deep-sea vessels to coastal infrastructure. As a specialized manufacturer with full compliance to international maritime standards—including IEC 60092, CCS, DNV, ABS, and LR—we ensure every cable product delivers optimal electrical performance, flame resistance, oil resistance, and durability under extreme conditions.

Our marine cable range includes low-voltage (LV), medium-voltage (MV), instrumentation, control, and communication cables, all tailored to the unique requirements of marine applications. Whether for main power distribution, navigation systems, propulsion control, or emergency circuits, our cables are built to ensure operational continuity, crew safety, and regulatory compliance. With advanced production lines, in-house R&D, and a quality assurance system certified under ISO 9001, we maintain strict control over material selection, manufacturing precision, and final testing.

To support seamless integration into vessel design and retrofit projects, we offer customized cable solutions—including specific sheathing materials, shielding configurations, and length-cut services—with competitive lead times and global logistics coordination. Our technical team works closely with naval architects, electrical engineers, and procurement managers to deliver products that meet project-specific technical dossiers and classification society requirements.

For detailed technical specifications, project quotations, or OEM/ODM collaboration opportunities, we invite you to contact our dedicated Product Manager for marine cable systems, Kacher YE. With extensive experience in marine electrical systems and export operations, Mr. Ye provides expert guidance on product selection, compliance documentation, and supply chain logistics tailored to your region.

Below is an overview of our standard marine cable offerings:

| Cable Type | Voltage Rating | Conductor Size Range (mm²) | Key Applications | Certifications Available |

|---|---|---|---|---|

| Power Cable | 0.6/1 kV | 1.5 – 630 | Main power, auxiliary systems | CCS, DNV, ABS, LR, BV, RINA |

| Medium Voltage Cable | 3.6/6 kV – 8.7/15 kV | 25 – 500 | Propulsion motors, switchboards | DNV-GL, IEC 60092-354 |

| Control Cable | 450/750 V | 0.75 – 10 | Automation, monitoring systems | CCS, ABS, RINA |

| Instrumentation Cable | 300/500 V | 0.5 – 4 | Sensor networks, data transmission | IEC 60092-376, shielded variants |

| Communication Cable | Cat5e / Fiber Optic | N/A | Internal comms, bridge networks | IEC 60092-375 |

To initiate a technical discussion, request a product catalog, or submit a project inquiry, please reach out directly to Kacher YE via email at [email protected]. We respond to all inquiries within 24 hours during business days and provide multilingual support for English, Spanish, and Arabic-speaking clients. Partner with Hangzhou Star Marine Technology for reliable, certified, and engineered marine cable systems that meet the highest standards of maritime performance.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160