Marine Diesel Generator Set – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Diesel Generator Set

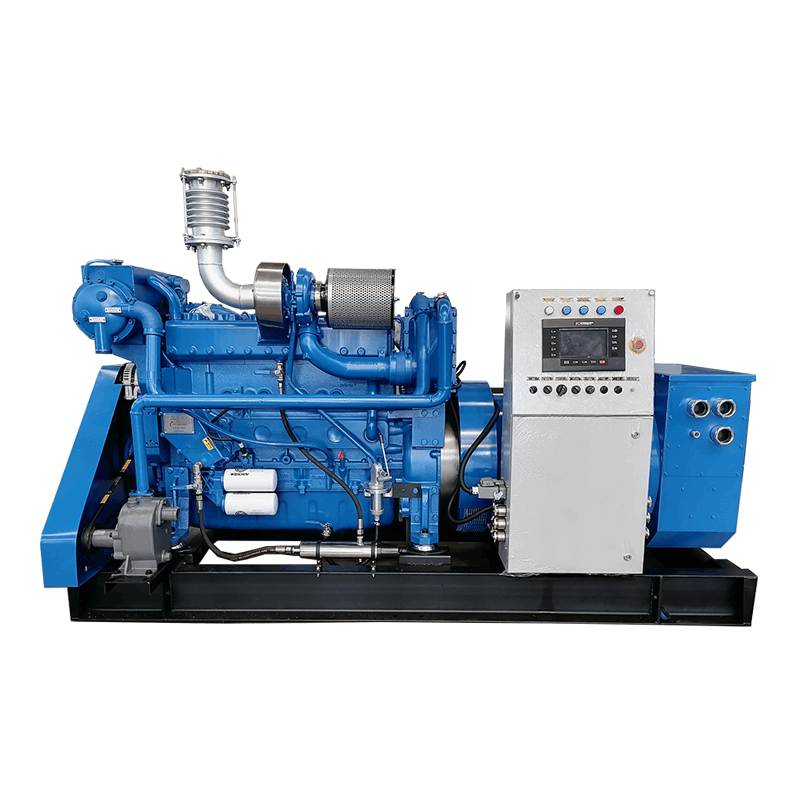

Marine Diesel Generator Set: A Critical Component for Vessel Safety and Operational Efficiency

In the maritime industry, the marine diesel generator set stands as one of the most vital auxiliary systems onboard any vessel. It serves as the primary source of electrical power, supporting essential operations ranging from navigation and communication systems to emergency lighting, fire pumps, and accommodation services. The reliability of this equipment directly impacts vessel safety, crew welfare, and compliance with international maritime regulations such as SOLAS (Safety of Life at Sea) and classification society standards.

A failure in the generator system can lead to catastrophic consequences, including loss of propulsion control, disabled emergency systems, and compromised navigation in adverse weather or congested waters. For this reason, marine diesel generator sets must be engineered to operate continuously under harsh marine conditions—resisting saltwater corrosion, enduring constant vibration, and maintaining performance across variable load profiles. The redundancy offered by auxiliary generators ensures that even if the main power source fails, critical systems remain operational, thereby safeguarding the vessel, its crew, and cargo.

Hangzhou Star Marine Technology Co., Ltd. specializes in the design, manufacturing, and export of high-performance marine diesel generator sets tailored for a wide range of vessel types, including cargo ships, offshore support vessels, fishing boats, and yachts. Our generators are built in strict accordance with ISO 8528, IMO Tier II emission standards, and classification approvals from CCS, ABS, DNV, LR, and other leading societies. Each unit undergoes rigorous factory acceptance testing, including load bank testing, to ensure reliability before shipment.

One of the key advantages of sourcing marine diesel generator sets from Star Marine China is cost-effectiveness without compromising quality. By leveraging advanced manufacturing techniques, strategic supplier partnerships, and streamlined logistics from our Hangzhou-based facility, we deliver competitively priced solutions that meet global performance benchmarks. Our in-house engineering team allows for customization based on vessel specifications, fuel type, ambient conditions, and noise reduction requirements, ensuring optimal integration and long-term durability.

The following table outlines key performance and compliance parameters of our standard marine diesel generator sets:

| Parameter | Specification |

|---|---|

| Power Range | 20 kVA – 2000 kVA |

| Prime/Standby Rating | ISO 8528-1 Compliant |

| Engine Type | 4-Stroke, Turbocharged, Water-Cooled Diesel |

| Fuel Type | Diesel (ISO 8217 compliant) |

| Emission Standard | IMO Tier II, EU Stage IIIA |

| Alternator | Brushless, AVR Regulated, IP23 Protection |

| Control System | PLC-Based Auto Start/Stop, Remote Monitoring |

| Classification Approvals | CCS, ABS, DNV, LR, BV, RINA |

| Noise Level (1m distance) | ≤98 dB(A) at full load |

| Operating Ambient Temperature | -15°C to +50°C |

Sourcing from Hangzhou Star Marine Technology ensures not only compliance with international maritime safety standards but also significant value through reliable performance, reduced lifecycle costs, and responsive technical support. In an industry where operational continuity and safety are paramount, investing in a high-quality marine diesel generator set from a trusted Chinese manufacturer is a strategic decision that supports long-term vessel integrity and efficiency.

Technical Specs & Approval

Technical Specifications: Marine Diesel Generator Sets

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures marine diesel generator sets to stringent international maritime standards, ensuring operational reliability, safety, and compliance across diverse vessel types. Our generator sets undergo rigorous testing per ISO 8528, SOLAS, and IMO guidelines, with material selection prioritizing corrosion resistance and structural integrity in harsh marine environments. Critical components utilize marine-grade aluminum alloys (5083/6061) for housings and enclosures to minimize weight while maintaining durability, alongside ASTM A36/A572 structural steel for frames and mounting bases to withstand dynamic loads and vibration. All wetted surfaces incorporate cathodic protection systems and epoxy-based anti-corrosion coatings certified for continuous seawater exposure. Watertight integrity is non-negotiable; generator sets achieve a minimum IP55 rating per IEC 60529, with optional IP66 configurations for installations in high-moisture zones such as engine rooms below the waterline or open decks. Sealing mechanisms employ fluorosilicone gaskets and labyrinth seals to prevent saltwater ingress during vessel motion or heavy weather conditions. Dimensional tolerances adhere to ISO 2768-mK standards, facilitating seamless integration into confined engine room layouts while allowing for thermal expansion and maintenance access.

The following table details core technical parameters for our standard marine diesel generator series:

| Parameter | Specification | Standard/Notes |

|---|---|---|

| Power Range | 20 kVA – 2000 kVA | Continuous duty, 50/60 Hz, 3-phase |

| Prime Mover | Tier III/IV Compliant Diesel Engine | Cummins, MAN, or Volvo Penta options |

| Material (Housing) | Marine-Grade Aluminum Alloy 5083 | Anodized and epoxy-coated |

| Material (Frame/Base) | ASTM A36 Structural Steel | Hot-dip galvanized, 500-hour salt spray tested |

| Ingress Protection | IP55 (Standard), IP66 (Optional) | IEC 60529; tested at 12.5mm/1mm solid ingress |

| Dimensions (L×W×H) | Varies by model (e.g., 2500×1200×1800 mm) | Tolerance: ±3 mm; includes mounting feet |

| Weight (Dry) | 1,200 kg – 15,000 kg | Excludes fuel, coolant, or soundproofing |

| Cooling System | Raw Water + Keel Cooled or Freshwater | Marine-grade cupronickel heat exchangers |

| Fuel Consumption | 198–205 g/kWh @ 75% load | ISO 3046-1 tested, MGO compliant |

| Noise Level | ≤ 85 dBA @ 1m | ISO 3744 compliant, with standard acoustic hood |

Dimensional precision is critical for retrofit projects and newbuild integrations. Our engineering team provides 3D CAD models (STEP/IGES formats) for clash detection, ensuring compatibility with existing vessel infrastructure. All units include vibration dampeners rated for 15–30 Hz resonance frequencies and flexible fuel/exhaust couplings to accommodate hull flexure. Electrical interfaces comply with IEC 60092-301, featuring marine-grade cable glands and terminal boxes with IP56 protection. For export compliance, each generator set is supplied with a Declaration of Conformity (DoC) referencing SOLAS II-1/43, EU Marine Equipment Directive (MED), and ABS/DNV/LR type approval certificates. Hangzhou Star’s specifications prioritize not only performance but also global regulatory acceptance, reducing customs clearance delays and ensuring seamless vessel commissioning worldwide. Customers receive detailed installation manuals with torque specifications, alignment tolerances, and maintenance intervals tailored to operational profiles.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive and reliable marine diesel generator set solutions tailored for shipbuilding and repair projects worldwide. As a specialized provider in marine outfittings, we integrate advanced engineering with rapid response logistics to support shipyards and vessel operators at every project stage. Our marine diesel generator sets are designed to meet international maritime standards, ensuring compliance with classification societies including CCS, ABS, DNV, LR, and BV. Whether for new vessel construction or retrofitting existing fleets, Star Marine offers a seamless turnkey solution that reduces downtime and enhances operational efficiency.

Our engineering team collaborates directly with shipbuilders and naval architects to customize generator sets based on vessel type, power demand, and operational profile. This collaborative approach ensures optimal integration with the vessel’s electrical system, fuel supply, and control architecture. We provide full technical documentation, including load charts, vibration analysis, and noise level reports, to support design approval and regulatory compliance. For repair and retrofit projects, our fast-response service includes on-site assessments, condition monitoring, and replacement unit deployment within compressed timelines, minimizing vessel idle time.

Star Marine’s production facility in Hangzhou is equipped with advanced manufacturing and testing capabilities. Each marine diesel generator undergoes 100% load bank testing, insulation resistance verification, and endurance runs prior to shipment. This rigorous quality control process ensures reliability under harsh marine conditions and extends equipment service life. Additionally, our global spare parts network and 24/7 technical support provide sustained operational backing, critical for both new builds and maintenance operations.

We understand that project timelines in shipbuilding and repair are critical. Star Marine maintains a strategic inventory of standard and high-demand configurations, enabling delivery within 4–6 weeks for most orders. For urgent repair cases, expedited manufacturing and shipping options are available, supported by our logistics partners with direct access to major Chinese ports.

The following table outlines key technical and service specifications for our standard marine diesel generator sets:

| Parameter | Specification |

|---|---|

| Power Range | 50 kVA – 2500 kVA |

| Voltage | 400 V, 440 V, 480 V (customizable) |

| Frequency | 50 Hz / 60 Hz |

| Engine Type | Turbocharged, 4-stroke, direct injection |

| Fuel Consumption | ≤ 198 g/kWh @ 75% load (typical) |

| Noise Level | ≤ 85 dB(A) at 1 meter (can be reduced with canopy) |

| Cooling System | Freshwater with heat exchanger |

| Control System | PLC-based auto-start, remote monitoring capable |

| Classification Approvals | CCS, ABS, DNV, LR, BV, RINA |

| Standard Delivery Time | 4–6 weeks (expedited options available) |

Hangzhou Star Marine Technology stands as a trusted partner in marine power solutions, combining technical excellence with agile project execution. Our commitment to speed, quality, and compliance ensures that shipbuilders and repair yards receive not just equipment—but a fully supported marine energy system ready for sea.

Packaging & Logistics

Packaging & Logistics for Marine Diesel Generator Sets

Hangzhou Star Marine Technology implements stringent packaging protocols for marine diesel generator sets to ensure integrity during global shipment. All wooden packaging materials comply with International Standards for Phytosanitary Measures No. 15 (ISPM 15), mandating heat treatment (HT) to 56°C core temperature for a minimum of 30 minutes. This process eliminates pest risks and aligns with IMO and SOLAS indirect requirements for cargo security. Each wooden case is stamped with the official ISPM 15 mark, including country code, producer code, and HT certification symbol, accompanied by a phytosanitary certificate issued by Chinese customs authorities. Cases are constructed from kiln-dried hardwood (typically birch or poplar) with reinforced corners and internal bracing to withstand dynamic forces during ocean transit. Critical components such as alternators and control panels receive additional VCI (Vapor Corrosion Inhibitor) wrapping to prevent salt-air exposure damage.

For heavy-duty units exceeding 2,000 kg, we utilize ISO-standard steel pallets fabricated from Q235B structural steel. These pallets feature non-slip surfaces, integrated lifting points, and corrosion-resistant powder coating. Steel palletization optimizes container space utilization while enabling secure multi-tier stacking in vessel holds. All units are anchored to pallets using marine-grade steel strapping (minimum 15 mm width) and anti-vibration pads to mitigate cargo shift risks. Desiccant packs are placed within sealed compartments to control humidity during extended voyages.

Export operations are centralized through Ningbo Port and Shanghai Port, leveraging their status as top-tier global container hubs with direct routes to all major maritime regions. Pre-shipment staging occurs in our climate-controlled warehouse within the Ningbo Free Trade Zone, ensuring units remain in a low-humidity environment prior to loading. Both ports offer dedicated roll-on/roll-off (RoRo) facilities for oversized generator sets and 24/7 customs clearance services under China’s Single Window system. We coordinate with certified freight forwarders specializing in heavy-lift marine cargo to manage lashing calculations per CSS Code guidelines and provide real-time GPS tracking.

The following table summarizes key packaging specifications:

| Packaging Type | Material Specification | Max. Unit Weight | Key Protective Features | Compliance Documentation |

|---|---|---|---|---|

| ISPM 15 Wooden Case | Kiln-dried hardwood (≥18 mm ply) | 5,000 kg | Corner braces, VCI film, desiccant packs | ISPM 15 stamp, Phytosanitary Certificate, Material Test Report |

| Steel Pallet System | Q235B structural steel (powder-coated) | 10,000 kg | Non-slip surface, lifting eyes, vibration dampers | ISO 18185 certification, Load Test Certificate |

All shipments undergo final verification per our ISO 9001:2015 quality protocol, including torque checks on securing points and moisture barrier validation. This integrated approach minimizes transit damage risks while ensuring seamless customs clearance across 120+ destination countries. Hangzhou Star Marine Technology maintains direct partnerships with COSCO and Maersk for priority booking on mainline vessels, guaranteeing reliable delivery windows for critical marine projects.

Contact Star Marine

For marine operators, shipbuilders, and offshore project managers seeking reliable, high-performance marine diesel generator sets, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in marine outfittings. Our engineered solutions are designed to meet the rigorous demands of maritime environments, ensuring fuel efficiency, durability, and compliance with international marine standards such as IMO Tier II/III, CCS, DNV, ABS, and other major classification societies. As a leading manufacturer specializing in marine power systems, we deliver tailor-made diesel generator sets that integrate seamlessly into a wide range of vessel types—including cargo ships, fishing vessels, offshore support vessels, and yachts.

Our marine diesel generator sets are built with premium-tier components, including globally recognized engine brands and advanced control systems, ensuring stable power output, low noise levels, and extended service life. Whether you require a single-unit installation or a complete power package with paralleling capabilities, our engineering team provides customized solutions to match your operational requirements and space constraints. All units undergo stringent factory acceptance testing, including load bank testing and vibration analysis, to guarantee performance before delivery.

To learn more about our marine diesel generator sets or to discuss a custom project, we invite you to contact Kacher YE, Product Manager at Hangzhou Star Marine Technology. With extensive experience in marine power systems and export operations, Kacher provides technical consultation, product selection guidance, and end-to-end project support—from initial inquiry to after-sales service. Our global export network ensures timely delivery to ports and shipyards worldwide, backed by comprehensive documentation and on-site commissioning support when required.

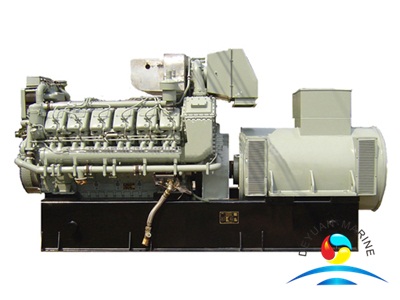

Below is an overview of standard specifications for our most commonly exported marine diesel generator set configurations:

| Parameter | Model Genset-150 | Model Genset-300 | Model Genset-600 | Model Genset-1000 |

|---|---|---|---|---|

| Rated Power (kW) | 150 | 300 | 600 | 1000 |

| Engine Type | 6-cylinder, 4-stroke, turbocharged | 6-cylinder, 4-stroke, turbocharged | 12-cylinder, 4-stroke, turbocharged | 16-cylinder, 4-stroke, turbocharged |

| Alternator Brand | Stamford or Leroy Somer | Stamford or Leroy Somer | Stamford or Leroy Somer | Stamford or Leroy Somer |

| Voltage (V) | 400 / 440 / 480 (customizable) | 400 / 440 / 480 (customizable) | 400 / 440 / 480 (customizable) | 400 / 440 / 480 (customizable) |

| Frequency (Hz) | 50 / 60 | 50 / 60 | 50 / 60 | 50 / 60 |

| Control System | Auto Start, AMF, Remote Monitoring | Auto Start, AMF, Remote Monitoring | Auto Start, AMF, Remote Monitoring | Auto Start, AMF, Remote Monitoring |

| Compliance | CCS, DNV-GL, ABS, LR, RINA | CCS, DNV-GL, ABS, LR, RINA | CCS, DNV-GL, ABS, LR, RINA | CCS, DNV-GL, ABS, LR, RINA |

For technical inquiries, quotations, or project collaboration, please contact Kacher YE directly at [email protected]. We respond promptly to all professional inquiries and are committed to delivering engineered marine power solutions that meet the highest global standards. Partner with Hangzhou Star Marine Technology for reliability you can trust, performance you can depend on, and service that goes beyond delivery.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160