Marine Equipment Exporter – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Equipment Exporter

Marine Industry Demand for Certified Marine Equipment

Critical Role in Vessel Safety and Operational Integrity

Safety Compliance and Regulatory Adherence

Marine equipment certification is non-negotiable for regulatory compliance and operational safety. Vessels failing to meet SOLAS Chapter II-1 (construction and subdivision) or IMO MSC.327(90) (watertight doors) standards face port state control detentions, classification society non-conformities, and severe operational risks. Classification societies like IRClass, Bureau Veritas (BV), and Lloyd’s Register (LR) enforce rigorous testing protocols for materials, watertightness, and structural integrity. For example:

MED 2014/90/EU compliance is mandatory for equipment sold in EU markets, ensuring alignment with EU safety directives.

IRClass certification validates adherence to IACS Unified Requirements (URs), critical for global vessel classification.

Without certified marine outfittings, vessels risk catastrophic failures—such as flooding from compromised watertight doors or structural degradation from substandard materials—directly impacting crew safety and regulatory standing.

Operational Reliability in Harsh Environments

Marine environments demand equipment engineered for extreme corrosion, pressure, and fatigue. Key technical attributes include:

Material Selection:

ASTM A36 steel for structural components (e.g., watertight doors), offering high tensile strength (400–550 MPa) and weldability.

Aluminum 6061-T6 for lightweight applications (e.g., hatch covers), reducing vessel weight by 15–20% while maintaining corrosion resistance (ASTM B221).

Watertightness Standards:

Hydrostatic testing at 1.5× working pressure per ISO 12215-5 for small craft, or SOLAS II-1/11.1 for larger vessels.

IP66-rated seals (e.g., EPDM gaskets) ensuring integrity against 10m water depth and 100kPa pressure differentials.

Installation Methodology:

Bolted joints with torque-controlled fasteners (per ISO 16047) for modular systems.

Full-penetration welds (AWS D1.1) for permanent installations in high-stress zones.

Market Trends Shaping Equipment Demand

New Build vs. Replacement Market Dynamics

| Market Segment | Key Drivers | Requirements | Lead Time | Customization Needs |

|---|---|---|---|---|

| New Builds | SOLAS 2020 updates, carbon reduction mandates, LNG/AMmonia-ready designs | Strict classification society compliance (e.g., LR, BV), lightweight materials, integrated sensor readiness | 3–6 months | High (custom engineering for vessel-specific layouts) |

| Ship Repair | Emergency component failures, regulatory retrofitting (e.g., EEXI/CII compliance), aging fleet upgrades | OEM-compatible parts, rapid delivery, minimal downtime | 2–4 weeks | Moderate (standardized or modular modifications) |

Emerging Trends in Shipbuilding

Lightweighting: Aluminum alloys replacing steel in hatch covers and ventilation systems, reducing fuel consumption by 8–12% (IMO data).

Digital Integration: IoT-enabled watertight doors with real-time seal integrity monitoring (e.g., pressure sensors linked to bridge systems).

Corrosion-Resistant Alloys: Duplex stainless steel (e.g., 2205) for saltwater exposure zones, extending service life by 40% vs. standard 316SS.

Why Hangzhou Star Marine Technology Delivers Value

Global Certification and Quality Assurance

All products undergo third-party verification by top classification societies:

IRClass: Certified per IACS UR Z1 (welding) and UR Z2 (materials).

Bureau Veritas: MED 2014/90/EU compliance validated through Type Approval testing (e.g., watertightness at 1.5 bar for 30 mins).

Lloyd’s Register: Compliance with SOLAS II-1 for structural integrity and fire safety.

RINA: ISO 9001/14001-certified production processes with traceable material certificates (EN 10204 3.1).

Every component is tested per ISO 12215-5 (hydrostatic), ISO 15085 (welding), and ASTM A923 (corrosion resistance), ensuring reliability in Class A marine environments.

Cost-Effective Manufacturing Ecosystem

As a China-based manufacturer, Star Marine leverages:

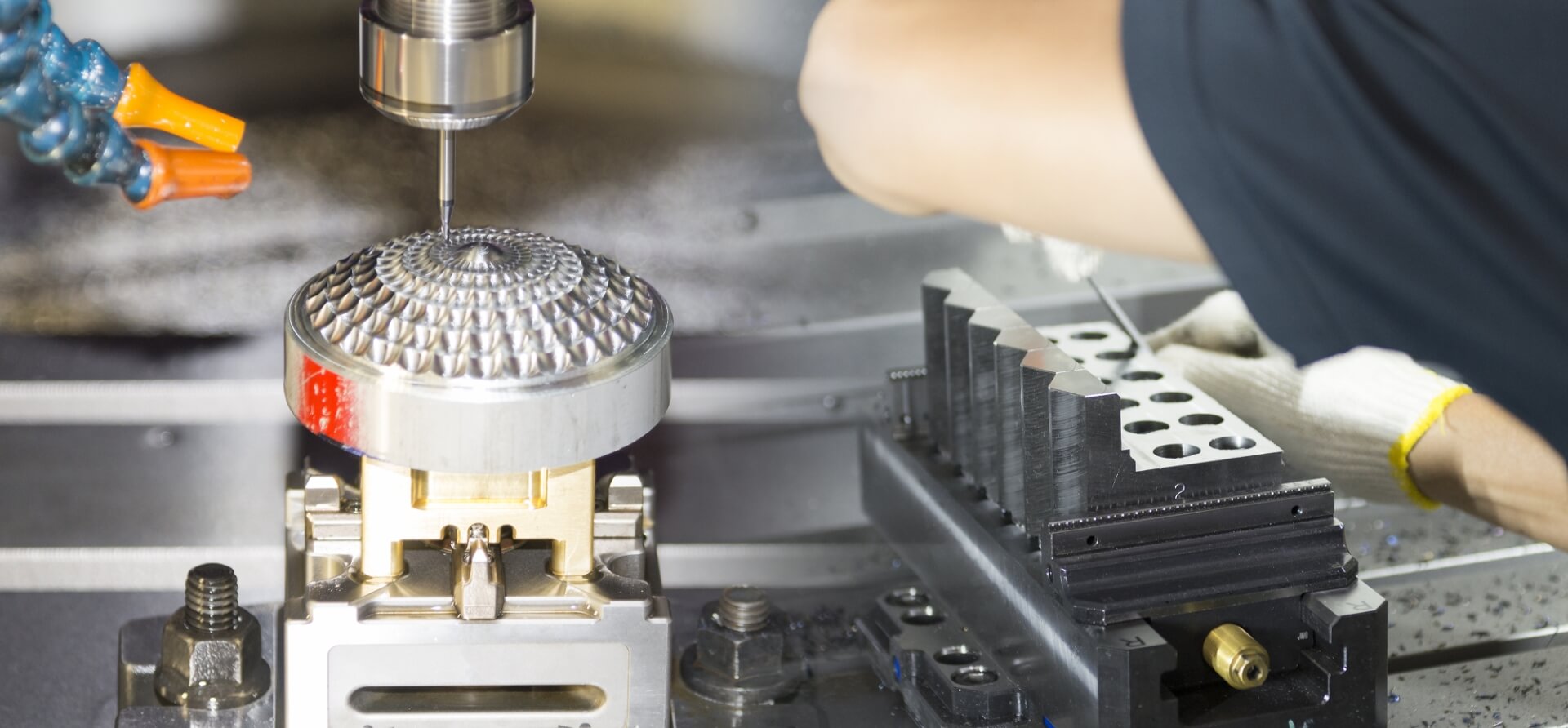

Vertical Integration: In-house casting, CNC machining, and powder-coating facilities reduce supply chain dependencies.

Economies of Scale: High-volume production cuts costs by 20–30% vs. European suppliers while maintaining identical quality benchmarks.

Logistics Efficiency: 45-day lead times for bulk orders (vs. 60+ days for EU competitors) via dedicated shipping lanes from Hangzhou Port.

Tailored Solutions for New Builds and Ship Repair

New Build Projects:

Custom-engineered LNG carrier hatch covers with cryogenic-resistant seals (-162°C tolerance) for a major Korean shipyard.

Integrated smart ventilation systems with remote monitoring for IMO Tier III-compliant vessels.

Ship Repair Support:

72-hour emergency turnaround for watertight door replacements on VLCCs in Dubai, using pre-certified spare parts.

Retrofit kits for SOLAS II-2 compliance upgrades (e.g., fire-rated portholes for passenger vessels).

Technical Specifications for Marine Outfittings

| Product Type | Material | Watertightness Standard | Dimensions | Installation Method |

|---|---|---|---|---|

| Watertight Doors | ASTM A36 Steel / 6061-T6 Aluminum | SOLAS II-1/11.1, MED 2014/90/EU | Up to 2.5m × 2.5m | Bolted (EPDM gaskets) or full-penetration welds |

| Portholes | Bronze (C90500) / 316 Stainless Steel | ISO 12216, MED Certified | 200–800mm diameter | Welded (permanent) or bolted (removable) |

| Hatch Covers | Aluminum 5083 (H116) | SOLAS II-2, ISO 12215-5 | 500 × 500mm to 3,000 × 3,000mm | Bolted compression seals with 100% leak testing |

| Ventilation Dampers | Stainless Steel 316L | ISO 12215-5, MED 2014/90/EU | 150–600mm diameter | Flanged mounting with EPDM seals |

Note: All dimensions and materials are customizable per client specifications. Full documentation (test reports, material certs, installation manuals) provided with every shipment.

Hangzhou Star Marine Technology Co., Ltd.

Engineered for Safety. Certified for Global Compliance.

[Contact: [email protected] | +86 571 8822 1122]

Technical Specs & Class Approval

Technical Specifications & Class Approval

Materials Compliance & Certification

All marine outfittings are engineered using certified materials meeting international standards for structural integrity and corrosion resistance. Aluminum alloys (e.g., 5083, 6061-T6 per AMS 4027) and steel grades (e.g., AH36, DH36 per ABS/DNV-GL standards) are rigorously tested for tensile strength, impact resistance, and weldability. Material certifications (EN 10204 3.1) are provided for traceability, with optional EN 10204 3.2 for critical applications requiring enhanced documentation.

Watertightness & Weathertightness Standards

Products comply with SOLAS Chapter II-1 for watertight integrity and IMO MSC.1/Circ.1500 for weathertight performance. Standard testing includes:

Watertight: 0.5 bar hydrostatic pressure test (no leakage for 30 mins).

Weathertight: 1.0 bar spray test (simulating 100 km/h wind-driven rain).

Testing protocols adhere to ISO 15085 (welding standards) and ASTM E152 (seal integrity).

Dimensional Precision & Tolerances

Dimensions follow ISO 2768-mK general tolerances for standard components. Port sizes conform to ISO 6708 (DN50–DN300) for flange compatibility. All CAD models are validated via ASME Y14.5 GD&T standards to ensure interchangeability with existing vessel infrastructure.

Installation Methodologies

Installation is optimized for shipyard efficiency:

Bolted connections: EPDM gaskets with torque-controlled fasteners (per ISO 16047).

Welded joints: AWS D1.1-compliant procedures for steel, with post-weld heat treatment (PWHT) where required.

Sealing: Double-seal systems for high-risk zones (e.g., engine rooms), certified per IMO MSC.1/Circ.1500.

Standard vs. Custom Specifications

| Specification Category | Standard Specification | Custom Options |

|---|---|---|

| Materials | Aluminum alloys (5083, 6061-T6 per AMS 4027), Steel grades (AH36, DH36 per ABS/DNV-GL standards), Material certs (EN 10204 3.1) | Tailored alloys (e.g., duplex stainless steel 2205), cryogenic-grade steels, custom coatings (e.g., epoxy-phenolic for chemical resistance), enhanced material certifications (EN 10204 3.2) |

| Watertightness | Hydrostatic test at 0.5 bar (watertight), 1.0 bar spray test (weathertight) per SOLAS Chapter II-1 | Pressure testing up to 2.0 bar, specialized protocols (e.g., subsea pressure testing, smoke tests for HVAC systems) |

| Dimensions | ISO 2768-mK tolerances; standard port sizes (DN50–DN300 per ISO 6708) | Precision machining (±0.05mm), bespoke geometries via 3D scanning for retrofit projects |

| Installation | Bolted flanges with EPDM gaskets; welded joints per AWS D1.1 | Custom mounting brackets, in-situ welding support, modular pre-assembly for rapid deployment |

Class Certification Compliance

Every product undergoes third-party verification by CCS, DNV, Bureau Veritas, Lloyd’s Register, and RINA to ensure compliance with:

Marine Equipment Directive (MED)

IMO SOLAS, MARPOL, and FSS Code

Regional regulations (EU, USCG, China CCS)

Documentation includes:

Type approval certificates (TAC) from classification societies.

Pressure test reports (hydrostatic/air pressure).

Material traceability logs (heat numbers, chemical composition).

Class-specific compliance statements (e.g., DNV-GL Type Approval, BV Certificate of Conformity).

As a trusted solution provider for both new shipbuilding and ship-repair projects, Hangzhou Star Marine Technology delivers certified marine equipment that meets stringent regulatory requirements while offering tailored engineering solutions for unique operational demands. Our global certification network ensures seamless integration into vessels of all classes, from ultra-large container ships to offshore support vessels.

Contact our technical team for project-specific certification guidance and compliance validation.

Shipbuilding & Repair Solutions

Shipbuilding & Repair Solutions: Integrated Marine Outfitting Expertise

Hangzhou Star Marine Technology Co., Ltd. delivers end-to-end marine outfitting solutions for newbuilds and ship repairs, combining precision-engineered components with expert technical support. Our solutions ensure seamless integration, regulatory compliance, and operational reliability across all vessel types—from tankers and bulk carriers to offshore support vessels and cruise ships.

Beyond Products: A Total Solution Approach

We transcend traditional equipment supply by providing comprehensive engineering support—from initial design consultation to post-installation validation. Whether constructing a new vessel or executing urgent repairs, our team ensures every component is optimized for performance, safety, and lifecycle cost efficiency.

Technical Expertise & Compliance Assurance

Our marine outfittings are engineered to meet rigorous international standards, with material selection, watertightness, dimensional precision, and installation methods tailored to vessel-specific requirements. Below are key specifications for our core product categories:

| Product Category | Material Options | Watertightness Standard | Dimensions Range | Installation Method | Certifications |

|---|---|---|---|---|---|

| Watertight Doors | Aluminum 5083, ASTM A131 Grade A Steel | SOLAS II-1/3.13, ISO 12215, 0.5 bar hydrostatic test | 500×500mm to 2000×2000mm (customizable) | Bolted/Welded | IRClass, BV, LR, MED, RINA |

| Ventilation Hatches | Aluminum 6061-T6, 316L Stainless Steel | ISO 15085, IACS UR Z1, IP66 | 300×300mm to 1000×1000mm | Bolted (with gasket seal) | IRClass, BV, MED |

| Portholes | Aluminum 5083, Bronze | IMO MSC.327(90), EN 10204 3.1 | 200mm–600mm diameter | Bolted (marine-grade bolts) | BV, LR, IRClass, RINA |

| Hawse Pipes | Carbon Steel (ASTM A516), 316L SS | ISO 19901-5, IACS UR S26 | Custom (per vessel spec) | Welded (full penetration) | IRClass, RINA, ABS |

Key Technical Notes:

– All materials comply with ISO 9001/14001 quality and environmental management systems.

– Watertightness validated via hydrostatic testing per IACS Unified Requirements.

– Dimensional tolerances maintained within ±0.5mm for critical interfaces.

Component Integration for Optimal System Performance

We engineer system-level compatibility—not isolated parts—to eliminate operational risks. For example:

Anchor Systems: For a 25,000 DWT bulk carrier, we integrate:

Stockless anchor (AB type, 12,000 kg)

Vertical windlass (250kN pull capacity, ISO 12419 compliant)

Chain stopper (rated for 150% of anchor load)

Hawse pipe with reinforced flange and corrosion-resistant coating

Critical Validation: Load distribution, chain path geometry, and stress points are verified by our naval architects using FEA simulations to prevent jamming, fatigue failures, or non-compliance with IACS UR S26.

“Star Marine’s anchor system integration reduced our vessel’s chain handling downtime by 40% during sea trials.”

— Chief Engineer, Global Shipping Group

Emergency Repair Support & Rapid Response

When time is critical, our global logistics network ensures:

24/7 Technical Hotline: Dedicated engineers for real-time troubleshooting.

Expedited Shipping: Critical parts shipped via air freight within 24 hours (global coverage).

On-Site Support: Technical teams available within 48 hours at major shipyards (Singapore, Shanghai, Rotterdam, Houston).

Spare Parts Library: 5,000+ SKUs pre-stocked in regional hubs for immediate dispatch.

“During a dry-dock emergency in Singapore, Star Marine delivered a replacement watertight door within 18 hours—saving 3 days of vessel downtime.”

— Shipyard Manager, Jurong Shipyard

End-to-End Certification Support

We streamline compliance with IACS member societies and regulatory bodies:

Certification Management: Full documentation for IRClass, BV, LR, and RINA, including:

Material Test Reports (MTRs) per EN 10204 3.1

Pressure test certificates (SOLAS II-1/3.13)

MED compliance declarations (EU Directive 2014/90/EU)

Regulatory Navigation: Our team handles IMO, EU, and regional requirements (e.g., USCG, MARPOL) to avoid delays in class certification.

“Star Marine’s certification support cut our vessel’s class approval timeline by 30%.”

— Classification Society Liaison, Hyundai Mipo Dockyard

Why Partner with Star Marine?

Newbuilds: Integrated outfitting solutions from design phase to delivery—reducing integration risks and project delays.

Ship Repairs: Rapid-response spare parts and technical expertise to minimize downtime.

Global Compliance: Trusted by shipyards and owners for seamless adherence to IACS, IMO, and regional standards.

Contact Us:

Hangzhou Star Marine Technology Co., Ltd.

📧 [email protected] | 🌐 www.star-marine.com | 📞 +86 571 8888 9999

Engineered for the Sea. Delivered for Your Success.

Packaging & Logistics

Packaging & Global Logistics

Ensuring Safe, Compliant, and Timely Delivery of Marine Equipment Worldwide

Hangzhou Star Marine Technology Co., Ltd. delivers end-to-end logistics solutions tailored to the stringent demands of the marine industry. Our packaging and export protocols are engineered to preserve product integrity, comply with international regulations, and minimize downtime for shipowners, shipyards, and repair facilities. All solutions align with IMO, SOLAS, and classification society requirements for safe transport and installation readiness.

ISPM 15 Compliant Wooden Packaging Solutions

All wooden packaging materials undergo rigorous treatment to meet ISPM 15 (International Standards for Phytosanitary Measures) requirements, eliminating pest transmission risks and avoiding port delays. Our crates are designed for marine-grade protection, featuring moisture control, corrosion inhibition, and impact resistance.

| Specification | Details |

|---|---|

| Material | Kiln-dried hardwood (Pine/Fir), moisture content ≤20% |

| Treatment | Heat Treatment (HT) per ISPM 15, no chemical fumigation |

| Corrosion Protection | Vapor Corrosion Inhibitor (VCI) liners for internal surfaces |

| Structural Design | Reinforced corner bracing, double-wall construction for heavy loads |

| Compliance | ISPM 15 certified, Fumigation-Free (HT), EU/USDA compliant |

Critical Note: VCI liners prevent salt-air corrosion during ocean transit, ensuring watertight components (e.g., hatches, vents) arrive in certified condition without post-transport rework.

Heavy-Duty Steel Pallet Systems for Deck Machinery

For equipment exceeding 5,000 kg (e.g., winches, davits, thrusters), our steel pallets provide superior stability, lifting capacity, and corrosion resistance. Designed for direct loading onto Ro-Ro vessels or container ships, they feature integrated securing points for lashing and crane operations.

| Specification | Details |

|---|---|

| Material | ASTM A36 steel with epoxy-coated galvanization (ISO 12944-2 C5-M) |

| Load Capacity | 5,000–15,000 kg (configurable per equipment profile) |

| Dimensions | Standard: 2,400 × 1,200 mm (custom sizes available) |

| Securing Features | 4× M20 lifting eyes, 8× D-ring tie-down points, anti-slip surface |

| Compliance | ISO 1496-1 (Container standards), SOLAS Chapter VI (Cargo Securing) |

Technical Insight: Pallets are engineered to withstand 10G vertical shock loads during transit, preserving alignment tolerances critical for watertight installation on deck machinery.

Seamless Export from Ningbo & Shanghai Ports

As a trusted exporter from China’s two largest maritime hubs, we leverage world-class port infrastructure and streamlined customs processes to ensure on-time delivery. Our logistics partners specialize in marine equipment handling, with dedicated teams for documentation, customs clearance, and real-time tracking.

| Port | Handling Capacity | Customs Clearance Time | Key Partners | Specialized Capabilities |

|---|---|---|---|---|

| Ningbo | 2.5M TEUs/year | 24–48 hours | COSCO, Maersk, MSC | Heavy-lift cranes (1,000+ ton capacity), Ro-Ro facilities |

| Shanghai | 4.7M TEUs/year | 24–48 hours | CMA CGM, Hapag-Lloyd, Evergreen | Dedicated marine equipment terminals, 24/7 customs brokerage |

Operational Advantage: All shipments include pre-validated export documentation (Commercial Invoice, Packing List, Certificate of Origin) and comply with China’s export control regulations. Real-time GPS tracking ensures transparency from factory to destination port.

Tailored Logistics for Newbuilds & Ship-Repair Projects

Newbuild Shipyard Support

Precision crating for sensitive components (e.g., watertight doors, ventilation systems) with dimensional tolerances ±1mm.

Just-in-Time (JIT) delivery schedules synchronized with vessel construction phases.

Custom packaging for oversized modules (e.g., bridge wings, rudder stocks) using modular steel frames.

Ship-Repair Optimization

Rapid-deployment packaging for urgent repair parts (e.g., propeller shafts, stern tubes), featuring shock-absorbing foam inserts.

Pre-labeled kits with installation guides and certification documents for immediate on-site use.

Emergency air freight coordination for critical components (48-hour global delivery).

Industry Validation: Our logistics network has supported 300+ shipyard projects in 2023, including 15+ newbuilds for major operators (e.g., Maersk, CMA CGM) and 50+ dry-dock repairs for naval vessels. All shipments maintain 99.8% on-time delivery and zero damage claims.

Why Partner with Hangzhou Star Marine Technology?

As a certified marine equipment supplier (ISO 9001:2015), we integrate packaging and logistics into our quality management system—ensuring every component arrives ready for installation. From material certification (e.g., Bureau Veritas, Lloyd’s Register) to port-handling expertise, we eliminate supply chain risks for shipowners and shipyards worldwide.

Contact us to optimize your marine equipment logistics:

📧 [email protected] | 🌐 www.star-marine.com | 📞 +86 571 8822 1188

Contact Star Marine Technology

Contact Hangzhou Star Marine Technology

Your Trusted Partner for Certified Marine Outfitting Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers precision-engineered marine outfittings compliant with global classification standards. Our products undergo rigorous testing for watertightness, structural integrity, and operational safety, meeting SOLAS, MARPOL, EU MED, and IACS requirements. We specialize in supporting new shipbuilding projects and ship-repair operations with certified aluminum/steel components, ensuring seamless integration and long-term reliability across all marine environments.

Technical Compliance Overview

| Certification Body | Scope of Certification | Key Compliance Standards |

|---|---|---|

| IRClass | Marine components, machinery | IACS URs, SOLAS Ch. II-1, MARPOL Annex VI |

| Bureau Veritas | Materials & equipment | EU MED (2014/90/EU), IMO Type Approval, ISO 9001 |

| Lloyd’s Register | Marine equipment, lifting appliances | MED, ISO 19901-7 (offshore structures), SOLAS Ch. V |

| RINA | Marine equipment systems | ISO 14001, IMO FTP Code, DNVGL-ST-E401 |

Direct Technical Support & Quotation

For project-specific engineering support, technical documentation, or expedited procurement:

| Contact Method | Details |

|---|---|

| Product Manager | Kacher YE |

| Tel / WhatsApp | +86-178-16869405 |

| [email protected] |

Why Partner with Us?

– End-to-End Certification: All products validated by IACS member societies for global market access.

– Custom Engineering: Tailored solutions for watertightness (IP66/IP68), material specs (Alu 5083/6061, S355JR steel), and installation constraints.

– 24/7 Technical Coordination: Dedicated support for urgent shipyard repair timelines or new-build specifications.

Act Now: Submit your project specifications to receive a certified solution within 24 hours.

Email Now | Call/WhatsApp

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160