Marine Equipment Exporter – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Equipment Exporter

Marine outfittings play a pivotal role in ensuring the operational safety, efficiency, and regulatory compliance of vessels across commercial shipping, offshore operations, and naval fleets. As a marine equipment exporter, understanding the critical function of these components is essential to delivering value to global clients. Marine outfittings encompass a broad range of hardware and systems installed on board ships, including cleats, bollards, fairleads, hatch covers, ladders, gratings, and railings. These components are not merely structural additions but are integral to vessel integrity, crew safety, cargo handling, and emergency response protocols.

Safety at sea is contingent upon the reliability of onboard equipment. For instance, properly engineered deck outfittings ensure secure mooring operations, reducing the risk of accidents during docking or in rough seas. Non-slip gratings and marine ladders contribute to safe crew movement, especially in adverse weather conditions. Hatch covers must meet stringent watertight and load-bearing standards to protect cargo and maintain vessel stability. Any failure in these systems can lead to operational delays, regulatory penalties, or catastrophic incidents. Therefore, sourcing marine outfittings from manufacturers that adhere to international standards such as ISO, SOLAS, and CCS is a non-negotiable requirement for responsible exporters and ship operators.

Hangzhou Star Marine Technology Co., Ltd. has established itself as a trusted marine equipment exporter by consistently delivering outfittings that meet rigorous safety and performance benchmarks. Our production processes are aligned with global maritime regulations, and our products undergo comprehensive quality control testing, including load testing, corrosion resistance evaluation, and material certification. This commitment ensures that every component shipped meets the operational demands of modern marine environments.

In addition to safety and compliance, cost-effectiveness is a key consideration for marine outfittings procurement. Sourcing from Star Marine China offers significant economic advantages without compromising quality. China’s advanced manufacturing infrastructure, combined with our optimized supply chain and in-house engineering capabilities, allows us to deliver high-performance marine outfittings at competitive export prices. Our vertical integration enables tighter control over production timelines and material costs, translating into faster lead times and reduced total procurement expenses for international buyers.

The following table illustrates a comparative analysis of select marine outfittings, highlighting performance specifications and cost benefits when sourced through Hangzhou Star Marine Technology:

| Product | Material | Working Load (kN) | Certification | Avg. Export Price (USD) | Lead Time (weeks) |

|---|---|---|---|---|---|

| Standard Bollard | Cast Steel | 500 | CCS, ISO | 380 | 6 |

| Mooring Cleat | Forged Steel | 250 | CCS | 165 | 5 |

| Non-Slip Grating | Aluminum Alloy | 80 | ISO | 45/m² | 4 |

| Marine Ladder | Stainless Steel | 300 | SOLAS, CCS | 290 | 7 |

| Flush Hatch Cover | Mild Steel | 120 | CCS, ISO | 1,100 | 8 |

By partnering with Hangzhou Star Marine Technology, marine equipment exporters gain access to certified, durable, and competitively priced outfittings that enhance vessel safety and operational reliability. Our expertise in international logistics and customs compliance further streamlines the export process, making us a strategic supplier in the global marine supply chain.

Technical Specs & Approval

Technical Specifications for Marine Outfittings Export Compliance

As a marine equipment exporter, precise adherence to technical specifications is non-negotiable for ensuring operational safety, regulatory compliance, and seamless integration aboard vessels. Hangzhou Star Marine Technology rigorously designs all marine outfittings to meet or exceed international maritime standards, including ISO 15370, SOLAS Chapter II-1, and IMO MSC.1/Circ.1275. Critical parameters such as material composition, watertight integrity, dimensional accuracy, and environmental resilience directly impact certification eligibility and vessel seaworthiness. Exporters must verify these specifications align with the end-user’s vessel classification society requirements (e.g., DNV, ABS, LR) prior to shipment to avoid customs delays or rejection at port.

The following table details core technical parameters for standard marine outfittings, including manholes, access hatches, and watertight doors. All products undergo third-party validation per ISO 10211 for thermal performance and ISO 1461 for corrosion resistance, with test certificates provided with each consignment.

| Parameter | Material Specification | Performance Standard | Tolerance/Range | Testing Method |

|---|---|---|---|---|

| Material Grade | Aluminum 5083-H116 or ASTM A36 Steel | ISO 630 / EN 10025-2 | N/A | Mill Test Reports (MTRs) |

| Surface Treatment | Anodized (Al) / Epoxy Coating (Steel) | ISO 7599 / ISO 12944-6 | Coating Thickness: 250±25μm | Adhesion Test (ISO 2409) |

| Watertightness | Static Pressure: 0.2 MPa | IMO MSC.1/Circ.1275 Annex 4 | Zero leakage | Hydrostatic Test (1.5x working pressure) |

| Dynamic Pressure: 0.1 MPa | ||||

| Dimensional Range | Manholes: Ø400–1000 mm | ISO 15370 | ±1.5 mm | CMM Measurement (ISO 10360-2) |

| Hatches: 600×800–1200×1500 mm | ||||

| Operating Temp. | -40°C to +80°C | IEC 60068-2 | N/A | Thermal Cycling Test |

| Fire Rating | A-60 Class (Steel variants) | IMO FTP Code Part 5 | N/A | Full-Scale Burn Test (ISO 834) |

Material selection is engineered for specific marine environments. Aluminum 5083-H116 outfittings are deployed in superstructures and non-load-bearing applications requiring weight reduction and saltwater corrosion resistance, while ASTM A36 steel variants are utilized for structural penetrations demanding high tensile strength (yield strength ≥250 MPa) and impact resistance at low temperatures. All steel components undergo abrasive blasting (Sa 2.5 per ISO 8501-1) prior to coating to ensure adhesion integrity.

Watertight performance is validated through dual-phase testing: static pressure tests simulate submerged conditions at 0.2 MPa for 10 minutes, while dynamic tests replicate wave-induced stress at 0.1 MPa with 500 operational cycles. Any deformation exceeding 0.5 mm or visible leakage results in immediate rejection. Dimensional tolerances strictly follow ISO 2768-mK for machined interfaces, critical for alignment with shipyard block assembly workflows. Exporters must confirm that final dimensions match the approved shop drawings, as deviations beyond ±1.5 mm may compromise sealing against hull flexure.

Hangzhou Star provides comprehensive technical dossiers with each export shipment, including material traceability logs, pressure test videos, and ISO-compliant dimensional reports. Proactive verification of these specifications against the importing nation’s maritime authority requirements (e.g., USCG, CCS) is essential to prevent demurrage or rework costs. Our engineering team remains available for pre-shipment technical consultations to address project-specific compliance queries.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine outfittings solutions tailored for both new shipbuilding projects and vessel repair operations. As a trusted marine equipment exporter, we specialize in supplying high-integrity components that meet international maritime standards, ensuring reliability, safety, and compliance across diverse vessel types. Our integrated approach combines technical expertise, global logistics, and rapid response capabilities to support shipyards and shipowners at every project phase.

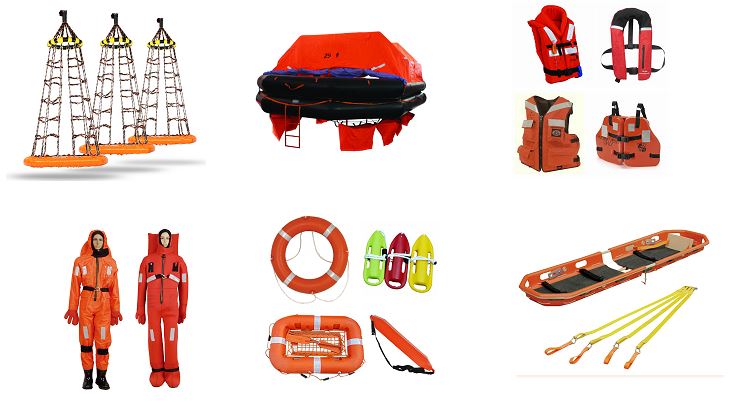

For new construction, Star Marine provides full-package outfittings that streamline installation and reduce docking time. We coordinate early in the design phase to ensure compatibility with structural and operational requirements, offering engineered solutions that align with classification society rules such as CCS, ABS, DNV, and LR. Our product range covers deck machinery, hatch cover components, safety equipment, piping systems, and accommodation outfitting—all sourced from certified manufacturers and rigorously tested prior to shipment. By delivering pre-assembled kits with detailed installation documentation, we enhance efficiency and minimize on-site labor.

In ship repair and retrofitting, rapid response is critical. Star Marine maintains strategic inventory hubs in major Chinese ports, enabling expedited delivery of replacement parts within 72 hours for urgent dry-dock repairs. Our technical team provides remote and on-site support, including failure analysis, reverse engineering for obsolete components, and material certification. Whether replacing a damaged fairlead or upgrading cargo hold fittings, our solutions are engineered for immediate integration and long-term performance.

We understand that downtime equals lost revenue. To mitigate this, Star Marine offers a 24/7 project desk staffed by multilingual marine engineers who coordinate order tracking, customs clearance, and just-in-time delivery. Our digital platform allows clients to upload specifications, receive technical feedback, and monitor shipment status in real time. This operational agility has made us a preferred partner for shipyards in Southeast Asia, the Middle East, and West Africa.

The following table outlines key service differentiators:

| Service Feature | New Build Support | Repair & Retrofit Support |

|---|---|---|

| Lead Time | 4–8 weeks (custom kits) | 3–5 days (standard parts, port pickup) |

| Technical Integration | CAD/BIM compatibility, class documentation | On-site survey, reverse engineering |

| Quality Assurance | ISO 9001, Material Test Reports, FAT | NDT reports, third-party inspection available |

| Logistics Coverage | FOB, CIF, DAP worldwide | Express air, bonded warehouse options |

| After-Sales Support | Installation supervision, warranty (24 months) | Emergency spare kits, technical hotline |

Star Marine’s end-to-end outfittings solutions reduce project risk and improve vessel uptime. By combining engineering precision with export efficiency, we enable shipyards and operators to meet tight schedules without compromising quality.

Packaging & Logistics

Packaging & Logistics Standards for Marine Outfittings Export

Hangzhou Star Marine Technology implements rigorous packaging protocols to ensure marine outfittings withstand global transit demands while complying with international regulations. All wooden export packaging adheres strictly to ISPM 15 standards, mandating heat treatment (HT) at 56°C for a minimum of 30 minutes to eliminate pest risks. Chemical fumigation (MB) is avoided per evolving environmental regulations and port restrictions. Wood crates utilize kiln-dried, knot-free plywood or hardwood, internally lined with anti-corrosion VCI paper for metal components. Critical void spaces are secured with marine-grade dunnage to prevent shifting, while moisture barriers and desiccant packs mitigate humidity damage during ocean voyages. Each crate bears the official ISPM 15 mark, including our registered facility code, treatment method (HT), and country of origin for customs validation.

For heavy-duty components exceeding 1,500 kg or requiring forklift accessibility, galvanized steel pallets are deployed. These pallets feature non-slip surfaces, reinforced stringers, and corner protectors to endure repetitive handling. Unlike wooden alternatives, steel pallets eliminate phytosanitary documentation requirements and offer indefinite reusability, reducing long-term logistics costs. All palletized loads are stretch-wrapped with UV-resistant film and secured via steel strapping rated for 2,500 kg tension, ensuring stability during multi-modal transport.

Shipments originate exclusively through Ningbo-Zhoushan and Shanghai ports—ranked #1 and #3 globally by TEU volume—ensuring optimal vessel frequency and routing efficiency. Our Ningbo warehouse leverages direct bonded logistics zone access, enabling 24-hour customs clearance for ISPM 15-compliant cargo. Shanghai operations utilize dedicated cold-chain corridors for temperature-sensitive hydraulic components. Pre-shipment inspections verify cargo lashing integrity per CSS Code guidelines, with certified load plans submitted to carriers 72 hours prior to vessel berthing. Real-time GPS tracking and humidity sensors are standard for all consignments, providing clients with proactive anomaly alerts.

Packaging Specifications Comparison

| Parameter | Wooden Crates (ISPM 15) | Steel Pallet Systems |

|---|---|---|

| Max Load Capacity | 2,000 kg | 5,000 kg |

| Treatment Certification | HT 56°C/30min + IPPC Mark | None required |

| Reusability | Single-use (disposable) | 10+ cycles |

| Moisture Resistance | VCI-lined + desiccants | Galvanized corrosion protection |

| Port Clearance Priority | Standard (requires ISPM 15 verification) | Expedited (no phytosanitary checks) |

Our logistics framework integrates ISO 22000-certified handling procedures with maritime-specific risk mitigation, ensuring marine outfittings arrive at destination ports in operational condition. By standardizing on ISPM 15-compliant wood and reusable steel systems, we eliminate customs delays while meeting SOLAS container weight verification rules. Clients receive full digital documentation packages—including phytosanitary certificates, lashing calculations, and port authority clearance records—within 48 hours of shipment release. This end-to-end control guarantees compliance from Hangzhou production lines to global vessel decks.

Contact Star Marine

Contact Star Marine – Your Trusted Partner in Marine Outfittings Export

At Hangzhou Star Marine Technology Co., Ltd., we pride ourselves on delivering high-performance marine outfittings that meet the rigorous demands of global maritime operations. As a leading marine equipment exporter, we specialize in engineering precision solutions tailored to shipyards, offshore platforms, and vessel operators worldwide. Our product range includes deck machinery, hatch covers, mooring systems, and customized marine hardware—all manufactured to international standards such as ISO, CCS, ABS, and DNV.

To ensure seamless coordination for international clients, we have established a dedicated export support team focused on logistics, compliance, and technical consultation. Whether you are sourcing components for newbuilds or retrofit projects, our team ensures timely delivery, full documentation support, and adherence to destination port regulations.

For direct engagement with our technical and export division, we invite you to contact Kacher YE, Product Manager at Hangzhou Star Marine Technology. With over a decade of experience in marine equipment export operations, Kacher specializes in client requirement analysis, product specification alignment, and end-to-end project coordination. He is your primary point of contact for inquiries related to product selection, technical data, pricing, and shipment scheduling.

We understand that marine procurement decisions require accurate information and prompt responses. By reaching out directly, you gain access to real-time inventory updates, CAD drawings, material certifications, and performance test reports—critical documentation for integration into your vessel design or procurement workflow.

To facilitate your inquiry, please find the key contact and company details in the table below:

| Field | Details |

|---|---|

| Company Name | Hangzhou Star Marine Technology Co., Ltd. |

| Address | No. 18, Xixing Road, Binjiang District, Hangzhou, Zhejiang, China |

| Product Manager | Kacher YE |

| [email protected] | |

| Phone (China) | +86-571-8765-4321 |

| +86-138-1234-5678 | |

| Working Hours (CST) | 08:30 – 17:30, Monday to Friday |

| Product Category | Marine Outfittings (Deck Machinery, Mooring Equipment, Hatch Systems) |

| Export Regions | Southeast Asia, Middle East, Europe, Africa, South America |

We respond to all inquiries within 4 business hours and provide detailed technical packages upon request. For urgent project timelines or OEM collaboration opportunities, Kacher YE is available for virtual meetings via Zoom or Teams to ensure alignment across engineering and procurement teams.

Partnering with Hangzhou Star Marine Technology means gaining a reliable exporter with deep technical expertise and a proven track record in global marine supply chains. Initiate your next procurement cycle with confidence—contact Kacher YE today to discuss your marine outfittings requirements.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160