Marine Gasoline Generator – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Gasoline Generator

Marine Industry Demand for Gasoline Generators: Ensuring Vessel Safety and Operational Efficiency

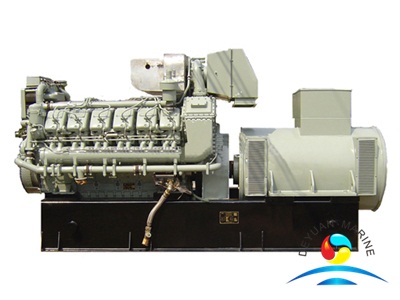

The marine gasoline generator is a critical component in the safe and efficient operation of a wide range of vessels, from small recreational boats to commercial fishing craft and auxiliary watercraft. Its primary function—providing reliable electrical power in marine environments—directly supports vital onboard systems including navigation electronics, communication equipment, bilge pumps, lighting, and emergency systems. In the absence of a dependable power source, vessels face increased risk of operational failure, especially during extended offshore operations or in adverse weather conditions. A marine gasoline generator ensures that critical safety systems remain functional, thereby reducing the likelihood of accidents, improving response capabilities during emergencies, and enhancing overall maritime safety compliance.

Modern maritime regulations emphasize the importance of redundant power systems, particularly on vessels operating beyond sheltered waters. A properly installed and maintained gasoline generator provides this redundancy, ensuring that electrical loads are consistently met even when the main engine is not running. Given the corrosive marine environment, these generators must be specifically engineered to resist saltwater exposure, vibration, and fluctuating temperatures. Off-the-shelf land-based generators are not suitable for marine applications due to their lack of protective coatings, inadequate ventilation, and insufficient grounding—factors that can lead to premature failure and safety hazards.

Hangzhou Star Marine Technology Co., Ltd. specializes in the design and export of marine-grade gasoline generators that meet international safety and performance standards, including CE and ISO certifications. Our generators are built with marine-specific components such as anti-corrosion enclosures, waterproof wiring, and vibration-dampening mounts, ensuring long service life and uninterrupted operation in demanding sea conditions. By integrating advanced fuel-efficient engines with robust alternators, our systems deliver stable power output while minimizing fuel consumption and emissions.

Sourcing marine gasoline generators from Star Marine China offers significant cost advantages without compromising quality. As a vertically integrated manufacturer based in Hangzhou, we control the entire production process—from component sourcing to final assembly and testing—allowing us to reduce overhead and pass savings directly to our international clients. Our strategic location in China’s industrial hub provides access to high-quality raw materials and skilled labor at competitive rates, further enhancing cost-efficiency.

The following table outlines key performance specifications of our standard marine gasoline generator models:

| Model | Power Output (kW) | Engine Type | Fuel Type | Noise Level (dB) | Weight (kg) | Certification |

|---|---|---|---|---|---|---|

| SMG-2.8 | 2.8 | 4-stroke, OHV | Gasoline | 72 | 38 | CE, ISO |

| SMG-4.5 | 4.5 | 4-stroke, OHV | Gasoline | 75 | 52 | CE, ISO |

| SMG-6.0 | 6.0 | 4-stroke, OHV | Gasoline | 78 | 65 | CE, ISO |

These units are designed for easy integration into existing vessel systems and are supported by comprehensive technical documentation and global after-sales service. By choosing Hangzhou Star Marine Technology, international buyers gain access to reliable, compliant, and cost-effective power solutions tailored for the unique challenges of the marine environment.

Technical Specs & Approval

Technical Specifications: Marine Gasoline Generator Systems

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures marine gasoline generators engineered for demanding offshore and coastal applications. Our systems adhere to ISO 8528, CE, and SOLAS regulatory frameworks, ensuring operational safety and environmental compliance. Critical design elements prioritize corrosion resistance, structural integrity, and resilience against marine environmental stressors. Material selection follows stringent maritime protocols: primary enclosures utilize marine-grade aluminum alloy 5083 for optimal weight-to-strength ratio and superior saltwater corrosion resistance, while structural mounting frames and internal supports employ ASTM A36 carbon steel with epoxy-polyamide marine coating (minimum 250μm dry film thickness). All fasteners are AISI 316 stainless steel to prevent galvanic degradation.

Watertight integrity is non-negotiable for marine power systems. Generators achieve IP66 ingress protection per IEC 60529, validated through 15-minute high-pressure water jet testing at 100 L/min and 100 kPa. Critical electrical components reside within IP55-rated compartments, featuring silicone-sealed cable glands and double-lipped shaft seals on rotating assemblies. Fuel systems incorporate self-sealing breakaway couplings and vapor recovery mechanisms compliant with EPA 40 CFR Part 1060. Exhaust manifolds utilize water-jacketed stainless steel (AISI 321) with thermal insulation rated to 650°C, preventing deck surface ignition risks.

Dimensions and weight optimization ensure seamless integration into vessel engine rooms with space constraints. Compact footprint designs minimize installation complexity while maintaining service accessibility. Standard configurations include integrated anti-vibration mounts (deflection ≥15mm) to dampen hull-transmitted resonance. Noise emissions are controlled to ≤78 dBA at 1 meter under full load, achieved through multi-stage acoustic insulation and tuned exhaust silencers meeting ISO 14858.

The following table details core technical parameters for our standard marine gasoline generator series:

| Parameter | Model STG-3.5K | Model STG-6.0K | Model STG-10K |

|---|---|---|---|

| Rated Output (kW) | 3.5 | 6.0 | 10.0 |

| Prime Output (kW) | 3.2 | 5.5 | 9.0 |

| Dimensions (L×W×H) mm | 680×450×520 | 820×520×610 | 980×620×730 |

| Dry Weight (kg) | 85 | 135 | 210 |

| Enclosure Material | Al 5083 | Al 5083 | Al 5083/Steel Frame |

| IP Rating | IP66 | IP66 | IP66 |

| Fuel Type | Unleaded Gasoline (RON 95) | Unleaded Gasoline (RON 95) | Unleaded Gasoline (RON 95) |

| Noise Level (dBA @1m) | ≤75 | ≤77 | ≤78 |

| Compliance Standards | ISO 8528, CE, MED | ISO 8528, CE, MED | ISO 8528, CE, MED |

All units undergo 100% factory testing per IEC 60034-1, including 4-hour continuous load bank validation at 110% rated capacity, salt spray exposure (ASTM B117, 500 hours), and thermal cycle endurance. Fuel efficiency is optimized through electronic fuel injection (EFI) systems with automatic altitude compensation up to 2,000 meters. Hangzhou Star Marine Technology provides comprehensive technical documentation, including 3D CAD models for installation planning and class society certification packages for global regulatory acceptance. This rigorous engineering approach ensures reliable power generation across diverse maritime operational profiles.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine outfittings solutions tailored for shipbuilding and repair projects worldwide. As a trusted provider of marine-grade equipment, we specialize in the supply and integration of marine gasoline generators, ensuring seamless performance, regulatory compliance, and operational reliability. Our focus on engineered excellence and rapid response enables shipyards and repair facilities to meet tight deadlines without compromising on quality.

For new shipbuilding projects, Star Marine collaborates closely with naval architects, shipbuilders, and classification societies to deliver gasoline generators that meet exact power requirements and space constraints. Our generators are designed to operate efficiently in harsh marine environments, featuring corrosion-resistant enclosures, vibration-damping mounts, and fuel systems optimized for stable combustion under dynamic vessel motion. Each unit undergoes rigorous testing, including load bank trials and safety shutdown verification, to ensure compliance with international standards such as ISO 8846 (explosion-proof design), IMO MEPC.1/Circ.763 (emissions), and classification society rules (CCS, ABS, DNV, etc.).

In ship repair and retrofit applications, our marine gasoline generators offer a plug-and-play solution for auxiliary power needs. Whether replacing obsolete units or upgrading power systems on fishing vessels, yachts, or workboats, our technical team provides on-site support, retrofit kits, and compatibility assessments to minimize downtime. We maintain a global logistics network that enables fast delivery of standard and customized units, with emergency response times averaging under 72 hours for critical spares and technical assistance.

Our engineering support extends beyond supply. Star Marine offers full documentation packages, including 3D mounting drawings, installation manuals, and maintenance schedules. Remote diagnostics and digital monitoring integration are available upon request, allowing ship operators to monitor generator health in real time. This turnkey approach ensures that both new builds and repair projects benefit from reduced commissioning time and long-term operational efficiency.

The following table outlines key specifications and customization options available for our marine gasoline generator series:

| Parameter | Standard Specification | Customization Options Available |

|---|---|---|

| Power Output Range | 5 kVA – 30 kVA | Up to 50 kVA with parallel operation |

| Engine Type | 4-stroke, OHV, air-cooled | Liquid-cooled for high ambient temps |

| Alternator | Brushless, AVR-controlled | PMG excitation for sensitive loads |

| Fuel Type | Unleaded gasoline (93 RON min) | Dual-fuel (gasoline/LPG) on request |

| Protection Rating | IP23 (standard), IP55 (optional) | Fully enclosed acoustic canopy |

| Noise Level (1m distance) | 72–78 dBA | Low-noise version: ≤68 dBA |

| Compliance | ISO 8846, IMO Tier II, CCS, ABS, DNV | Additional certifications on demand |

By combining advanced engineering, global support, and fast turnaround, Hangzhou Star Marine Technology ensures that every marine gasoline generator installation contributes to vessel safety, efficiency, and compliance. We are committed to being a strategic partner in marine construction and repair, delivering solutions that perform—on schedule, every time.

Packaging & Logistics

Packaging & Logistics for Marine Gasoline Generators

Hangzhou Star Marine Technology implements stringent packaging protocols for all marine gasoline generators to ensure integrity during global maritime transit. As critical power solutions for vessels, these units require specialized protection against moisture, shock, vibration, and environmental contaminants inherent in ocean freight. Our methodology adheres to ISO 11607 and IMO hazardous cargo guidelines, with primary reliance on ISPM 15-certified wooden cases and reinforced steel pallet systems. This dual approach balances structural resilience with international regulatory compliance, minimizing cargo claims and port clearance delays.

Wooden export cases form the foundational layer of protection for generators up to 50 kVA. Constructed from kiln-dried softwood (typically spruce or pine), these cases undergo mandatory heat treatment per ISPM 15 standards, eliminating pest risks and securing global acceptance. Each case features triple-laminated plywood walls (18–22 mm thickness), internal foam cushioning at critical stress points, and marine-grade sealant applied to all joints. The ISPM 15 compliance mark—stamped with the IPPC logo, country code (CN), and our registered facility number—is visibly affixed to exterior surfaces. Cases include integrated lifting lugs rated for 150% of the generator’s gross weight and ventilation channels to prevent condensation buildup during extended voyages. For units exceeding 50 kVA, we transition to steel pallet systems due to weight distribution requirements.

Steel pallets utilize hot-dip galvanized frameworks with anti-corrosion coating, engineered to withstand saline environments and repeated handling. Generators are secured via welded steel cradles matching the unit’s chassis geometry, with vibration-dampening mounts isolating the engine from transit stresses. All steel components undergo salt-spray testing (ASTM B117) to verify 500+ hours of corrosion resistance. This system eliminates wood-related moisture absorption risks while providing superior load stability for containerized shipping.

The following table summarizes key packaging specifications:

| Feature | Wooden Case System | Steel Pallet System |

|---|---|---|

| Max. Unit Capacity | 50 kVA | 250 kVA |

| Primary Material | ISPM 15-certified softwood | Hot-dip galvanized steel |

| Treatment | 56°C minimum core temp, 30+ min | Zinc coating ≥ 275 g/m² |

| Load Capacity | 3,000 kg | 10,000 kg |

| Moisture Protection | Breathable vapor barrier | Fully sealed base deck |

| Regulatory Mark | IPPC ISPM 15 stamp | CE/ISO 10218-1 certification |

All shipments originate from our bonded warehouse in Hangzhou, with final export via Ningbo Port (ZJNB) or Shanghai Port (CNSHG)—China’s premier deep-water facilities for Ro-Ro and containerized cargo. We coordinate pre-shipment inspections with SGS or Bureau Veritas upon client request, providing certified documentation for customs authorities. Generators are containerized within 24 hours of packaging completion, with desiccant packs and humidity indicators deployed inside each enclosure. Our logistics partners utilize real-time GPS tracking and climate-monitored containers for destinations requiring temperature control. This integrated packaging-logistics framework ensures generators arrive operational, reducing commissioning delays and safeguarding your investment from factory to vessel integration.

Contact Star Marine

For marine professionals and vessel outfitters seeking reliable, high-performance power solutions, Hangzhou Star Marine Technology Co., Ltd. stands at the forefront of innovation in marine gasoline generators. As a specialized manufacturer in marine outfittings, we design and engineer every generator to meet the rigorous demands of marine environments—ensuring durability, fuel efficiency, and uninterrupted electrical output across a wide range of maritime applications.

Our marine gasoline generators are engineered with advanced cooling systems, corrosion-resistant materials, and noise-dampening enclosures to deliver optimal performance even under extreme conditions. Whether for commercial fishing boats, offshore support vessels, or luxury yachts, our units are built to international marine standards, including compliance with ISO 8846 for explosion protection and CE certification for maritime safety. Each generator undergoes comprehensive testing for vibration resistance, salt spray endurance, and operational stability at various load levels, ensuring seamless integration into onboard power systems.

At Hangzhou Star Marine Technology, we understand that every vessel has unique power requirements. That’s why we offer customizable configurations—including output ranges from 3kVA to 20kVA, single and three-phase options, and 50Hz or 60Hz frequency settings—allowing integration with global electrical systems. Our compact, modular designs maximize space utilization in engine rooms while minimizing maintenance intervals, reducing total cost of ownership over the generator’s lifecycle.

We invite project managers, marine equipment suppliers, and shipbuilders to connect directly with our Product Manager, Kacher YE, for technical consultations, OEM/ODM collaboration, or project-specific quotations. With extensive experience in marine power systems and export logistics, Kacher provides expert guidance on product selection, compliance documentation, and after-sales support tailored to your region’s regulatory environment.

Below are key specifications of our standard marine gasoline generator series:

| Model | Rated Power (kVA) | Phase | Frequency (Hz) | Engine Type | Fuel Type | Noise Level (dB @ 7m) | Dimensions (L×W×H, mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| HSMG-5GF | 5.0 | Single | 50 | 4-stroke, OHV | Gasoline | ≤72 | 850×500×650 | 115 |

| HSMG-8GF | 8.0 | Single | 50/60 | 4-stroke, OHV | Gasoline | ≤74 | 980×550×680 | 145 |

| HSMG-12TF | 12.0 | Three | 50/60 | 4-stroke, OHV | Gasoline | ≤76 | 1100×600×720 | 180 |

| HSMG-18TF | 18.0 | Three | 50/60 | 4-stroke, V-twin | Gasoline | ≤78 | 1250×700×750 | 230 |

All models feature electric start, digital control panels, automatic voltage regulation (AVR), and optional remote monitoring interfaces for integration with vessel automation systems.

To discuss your marine power needs or request technical documentation, contact Kacher YE directly at [email protected]. We respond to all inquiries within 12 business hours and support English, Mandarin, and Spanish communications. Let Hangzhou Star Marine Technology power your next maritime project with precision-engineered reliability.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160