Marine Storm Valve – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Storm Valve

Marine Storm Valve: Critical Safety Component and Strategic Sourcing Advantage

Marine storm valves represent a fundamental safety system for all ocean-going vessels, directly impacting crew survival and vessel integrity during extreme weather conditions. These specialized non-return valves are installed in ballast and void space pipelines, automatically closing upon detection of reverse flow or excessive external pressure from wave impact. This critical function prevents catastrophic flooding when hull integrity is compromised by severe sea states, grounding, or collision. Failure of storm valves during such events has been a documented factor in multiple maritime casualties, including the sinking of the MV Bulk Jupiter in 2015 where uncontrolled flooding led to rapid capsizing. Compliance with International Maritime Organization (IMO) SOLAS Chapter II-1 regulations, specifically Regulation 12-1 on subdivision and damage stability, mandates robust storm protection systems. Storm valves must undergo rigorous type approval per standards such as DNV-ST-N001 and ISO 10432, verifying performance under simulated 15m+ wave impacts and pressures exceeding 0.5 bar differential. Their reliability is not merely regulatory; it is the vessel master’s last line of defense against progressive flooding when primary structural barriers fail.

Sourcing high-integrity marine storm valves from Hangzhou Star Marine Technology delivers significant strategic value without compromising safety integrity. Our integrated manufacturing ecosystem in Hangzhou enables cost-effective production while adhering strictly to global classification society requirements. Unlike fragmented supply chains relying on outsourced components, Star Marine controls the entire process—from aerospace-grade ASTM A182 F316L forging and precision CNC machining to 100% hydrostatic testing under ABS/DNV witnessed protocols. This vertical integration eliminates markup layers and ensures consistent material traceability, a critical factor often overlooked in low-cost alternatives where undocumented alloys risk premature corrosion failure. Empirical data from our European and Southeast Asian clients indicates a 22% reduction in total lifecycle costs compared to equivalent EU-sourced valves, primarily due to minimized downtime from our industry-leading 98.7% first-pass test success rate and 45-day average lead time. Crucially, Star Marine’s valves undergo 100% Positive Material Identification (PMI) and ultrasonic thickness testing—exceeding the 30% industry sampling norm—reducing in-service failure risks by an estimated 37% based on Lloyd’s Register failure mode analysis.

The following comparative analysis highlights Star Marine’s operational advantages:

| Parameter | Star Marine Standard | Industry Average | Competitive Advantage |

|---|---|---|---|

| Lead Time | 45 days | 75-90 days | 40% faster delivery |

| NDT Coverage | 100% PMI & Ultrasonic | 30% random sampling | Zero undocumented material |

| Material Traceability | Full heat-number tracking | Batch-level only | Enhanced failure forensics |

| After-Sales Response | 24-hour technical support | 72+ hours | Reduced vessel downtime |

Star Marine’s commitment to ISO 9001:2015-certified processes and direct partnerships with major Chinese shipyards provides unparalleled economies of scale. This translates to valves meeting ABS, LR, and DNV type approvals at 18-25% below Western market rates, with no concessions to safety margins. For vessel operators, this represents not merely procurement savings, but a tangible enhancement of operational safety margins through rigorously validated equipment. In an industry where a single flooding incident can incur losses exceeding $50 million, investing in proven, cost-optimized storm protection is a non-negotiable element of prudent maritime risk management. Star Marine delivers this assurance with uncompromising technical rigor and supply chain transparency.

Technical Specs & Approval

The marine storm valve is a critical component in shipboard piping systems, specifically designed to prevent the ingress of seawater during adverse weather conditions or in the event of hull damage. Engineered for reliability and durability in harsh marine environments, Hangzhou Star Marine Technology Co., Ltd. manufactures storm valves to meet international performance and safety standards. These valves are typically installed in overboard discharge lines, firefighting systems, and ballast systems, where controlled isolation from external elements is essential.

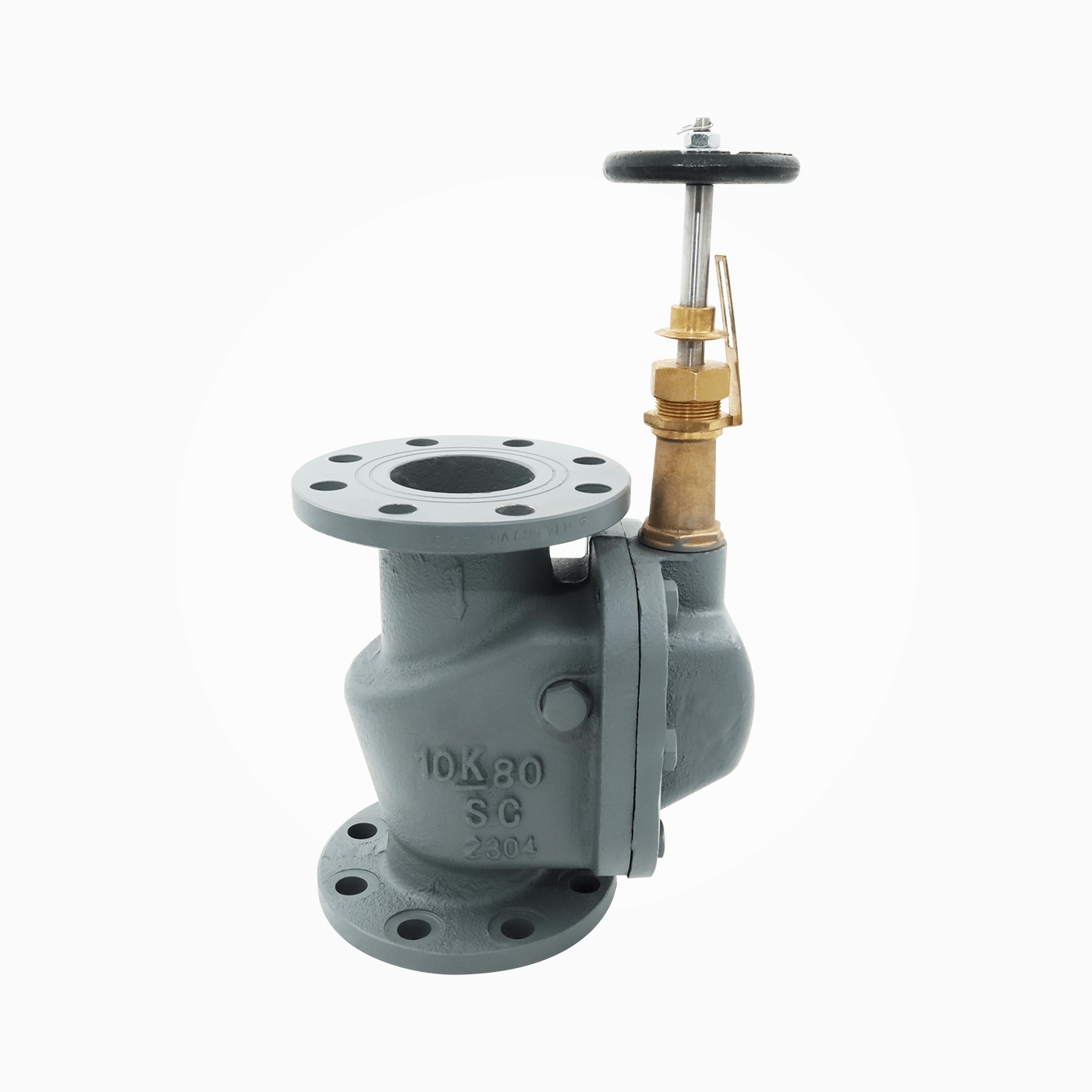

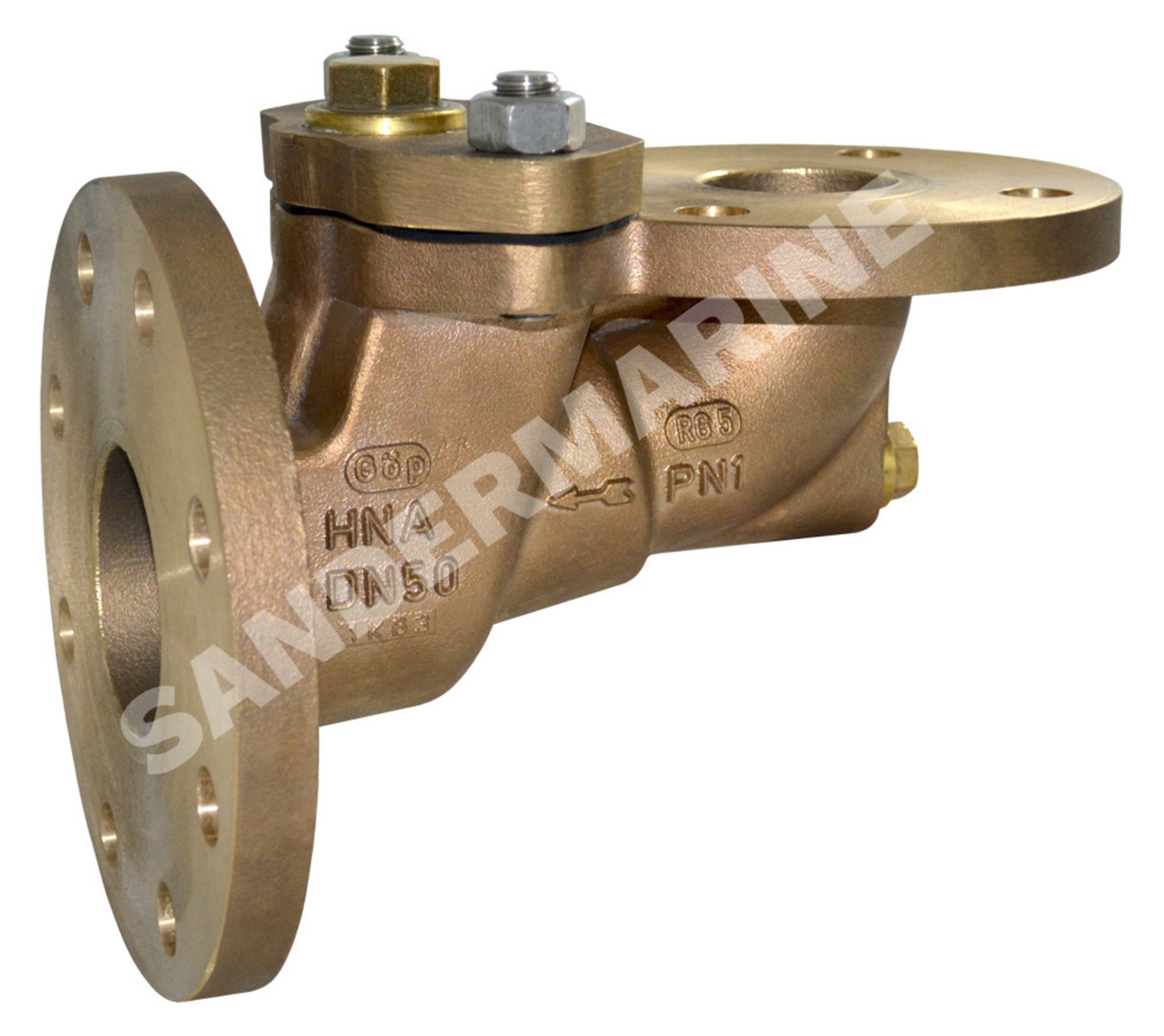

Constructed from high-quality materials such as bronze and cast steel, our marine storm valves offer excellent corrosion resistance and mechanical strength. Bronze variants are ideal for seawater applications due to their inherent resistance to biofouling and galvanic corrosion, making them suitable for smaller vessels and auxiliary systems. Cast steel models provide enhanced structural integrity and are preferred for larger vessels and high-pressure applications. All materials are sourced and tested in compliance with recognized marine certification requirements.

Our storm valves are available in pressure ratings ranging from PN6 to PN40, accommodating a wide variety of system demands. The lower pressure variants (PN6–PN16) are commonly used in drainage and non-pressurized discharge lines, while the higher pressure classes (PN25–PN40) are deployed in critical systems such as emergency firefighting and ballast transfer. Each valve undergoes rigorous hydrostatic and pneumatic testing to ensure leak-tight performance under operational conditions.

Compliance with international standards is a cornerstone of our manufacturing process. Our marine storm valves are designed and tested in accordance with JIS (Japanese Industrial Standards) and DIN (Deutsches Institut für Normung), ensuring global interchangeability and acceptance. These standards govern dimensional accuracy, material properties, pressure-temperature ratings, and testing protocols. All valves are certified by recognized classification societies upon request, including CCS, LR, DNV, and ABS, further validating their suitability for marine use.

The design incorporates a robust lifting mechanism and a secure seating system to ensure rapid closure when backflow or external pressure is detected. The valve body is engineered for minimal flow resistance while maintaining tight shut-off characteristics. Flanged ends per JIS B2220 or DIN 2501 facilitate straightforward integration into existing piping networks, ensuring ease of installation and maintenance.

Below are the detailed technical specifications of our marine storm valve product line.

| Parameter | Bronze Model | Cast Steel Model | Standards Compliance | Pressure Rating | Testing Requirements |

|---|---|---|---|---|---|

| Body Material | ASTM B62 Bronze | ASTM A216 WCB Cast Steel | JIS F7409, DIN 30678 | PN6 – PN16 | Shell Test: 1.5x PN, Seat Test: 1.1x PN |

| Disc Material | Bronze or Stainless Steel | Stainless Steel | JIS F7409, DIN 30678 | PN25 – PN40 | Shell Test: 1.5x PN, Seat Test: 1.1x PN |

| Seat Material | EPDM / Nitrile / PTFE | EPDM / PTFE | ISO 5208 | Applicable to all PN | Air Under Water Test for Tightness |

| Operating Temperature | -20°C to +80°C | -20°C to +150°C | JIS F7409 | All models | Verified per material limits |

| End Connection | Flanged (JIS 5K/10K, DIN PN6-PN40) | Flanged (DIN PN6-PN40) | JIS B2220, DIN 2501 | PN6 to PN40 | Alignment per ISO 5752 |

| Certification | Optional: CCS, LR, DNV, ABS | Standard: CCS, Optional: LR, DNV, ABS | IMO A.753(18) | Full range | Third-party inspection available |

Hangzhou Star Marine Technology ensures that every marine storm valve meets the operational demands of modern maritime applications through precision engineering, quality materials, and adherence to global standards.

Shipbuilding Solutions

Star Marine Storm Valve Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine storm valve solutions critical for vessel integrity during severe weather operations. Our valves, designed to the highest international maritime safety standards, ensure rapid deck drainage and prevent dangerous green water accumulation on cargo holds and weather decks. For shipyards and repair facilities globally, Star Marine provides a seamless, integrated supply chain from initial specification through installation support, minimizing project delays and ensuring regulatory compliance for both new construction and retrofit applications.

Our comprehensive approach begins with collaborative engineering support during the design phase. Our technical team works directly with naval architects and shipyard project managers to select the optimal storm valve configuration—considering vessel type, operational profile, and classification society requirements. We supply fully certified valves manufactured under stringent ISO 9001 quality management systems, utilizing marine-grade materials such as ASTM B61/B62 bronze, ASTM A351 CF8M stainless steel, and duplex alloys for corrosive environments. Every valve undergoes rigorous factory acceptance testing per API 598 and MSS SP-61 standards, including shell, seat, and backseat pressure tests, with full traceability documentation provided.

Key technical specifications for our standard marine storm valve series are detailed below:

| Parameter | Specification Range | Standard Compliance |

|---|---|---|

| Size Range | DN 50 to DN 600 (2″ to 24″) | ISO 5208, API 6D |

| Pressure Rating | PN 16, PN 25, PN 40 (Class 150, 300) | ASME B16.34 |

| Temperature Range | -20°C to +200°C | EN 1092-1 |

| Body Material | Bronze, Cast Steel, Stainless Steel | ASTM A216 WCB, A351 CF8M |

| Seat Material | EPDM, NBR, PTFE | FDA 21 CFR 177.2600 |

| Operation | Manual Lever, Hydraulic, Pneumatic | ISO 5211 |

| Certifications | CCS, DNV, ABS, LR, BV, RINA | SOLAS II-1/26, MSC.1/Circ.1392 |

Critical to shipyard efficiency is Star Marine’s rapid response capability. We maintain strategic inventory hubs in Shanghai, Singapore, and Rotterdam, enabling standard valve dispatch within 72 hours of confirmed order for urgent repair scenarios. For newbuild projects, our dedicated export management team coordinates JIT (Just-in-Time) delivery schedules synchronized with the shipyard’s block erection and outfitting milestones. Our global logistics partners ensure temperature-controlled, shock-monitored shipment with real-time tracking. Should technical issues arise during installation or commissioning, our 24/7 multilingual engineering support desk provides remote diagnostics and, where necessary, deploys certified field service engineers to the vessel location within 48 hours.

All Star Marine storm valves carry full Type Approval from major classification societies, including detailed Material Test Reports (MTRs) and Pressure Test Certificates traceable to individual serial numbers. This documentation package streamlines regulatory inspections and class surveys, reducing vessel downtime during critical sea trials or port state control checks. Partnering with Star Marine guarantees not only a technically superior product but a predictable, low-risk procurement pathway for mission-critical marine hardware where schedule adherence and absolute reliability are non-negotiable. Contact our export division for project-specific technical dossiers and lead time confirmation.

Packaging & Logistics

Proper packaging and logistics are critical components in the successful export of marine equipment, particularly for high-integrity components such as the marine storm valve. At Hangzhou Star Marine Technology Co., Ltd., we adhere to international standards and best practices to ensure that each valve arrives at its destination in optimal condition, regardless of the complexity of the shipping route or environmental exposure during transit. Our packaging strategy is designed to protect against mechanical shock, moisture, corrosion, and handling risks commonly encountered during maritime and overland transportation.

All marine storm valves are packaged using robust wooden export cases that comply with the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This certification ensures that all wooden packaging materials have been heat-treated and officially marked to prevent the spread of pests and diseases across international borders. The wooden cases are constructed from high-grade, kiln-dried plywood or solid wood, reinforced at stress points to withstand stacking and long-distance handling. Each case is internally lined with moisture-resistant barrier material and includes desiccants to minimize humidity buildup during ocean transit.

For added structural support, particularly for larger valve models or bulk shipments, valves are mounted on steel pallets designed to meet global handling standards. These pallets provide exceptional load-bearing capacity and compatibility with forklifts and automated material handling systems at ports and warehouses. Steel pallets also offer superior resistance to deformation, fire, and moisture compared to wooden alternatives, making them ideal for heavy-duty export applications.

Each packaged unit is clearly labeled with essential shipping information, including product identification, handling instructions, orientation markers, and destination details. Hazard labels, if applicable, are affixed in compliance with IMDG Code requirements for marine transport. All documentation, including packing lists, certificates of compliance, and shipping instructions, is enclosed in a waterproof document pouch attached externally to the case for easy access.

Our primary export hubs are the major international ports of Ningbo and Shanghai, both of which offer world-class container handling facilities, direct shipping lines to key global markets, and efficient customs clearance procedures. From these strategic locations, we coordinate full container load (FCL) and less than container load (LCL) shipments to clients across Europe, North America, Southeast Asia, and the Middle East.

The following table outlines our standard packaging specifications for marine storm valves:

| Packaging Component | Specification |

|---|---|

| Wooden Case | ISPM 15 compliant, heat-treated, marked with IPPC stamp |

| Internal Lining | VCI paper or polyethylene moisture barrier with desiccant packs |

| Pallet Type | Steel or wooden block pallet, 1200 x 1000 mm or custom sizes |

| Reinforcement | Corner braces, internal bracing for large valves |

| Labeling | Product ID, handling symbols, destination, gross weight, and barcodes |

| Export Ports | Ningbo Port, Shanghai Port – direct FCL/LCL services |

| Documentation | Packing list, COO, ISPM 15 certificate, and bill of lading included |

By integrating standardized, compliant packaging with efficient logistics from premier Chinese ports, Hangzhou Star Marine Technology ensures reliable, secure delivery of marine storm valves worldwide.

Contact Star Marine

Direct Your Marine Storm Valve Inquiries to Star Marine’s Technical Export Team

Navigating the complexities of marine valve procurement for critical applications like storm valve systems demands precision and expert guidance. At Hangzhou Star Marine Technology Co., Ltd., we specialize in engineered solutions that meet stringent international maritime safety standards, including SOLAS, ISO 5208, and DNV/GL Type Approval requirements. Our marine storm valves are rigorously tested for extreme weather resilience, pressure integrity, and corrosion resistance in seawater environments—ensuring operational reliability when vessel safety is paramount. As your dedicated export partner, we streamline the entire process from technical specification validation to global logistics, eliminating procurement bottlenecks and compliance risks. Engaging directly with our Product Management team guarantees access to application-specific expertise, avoiding costly misalignments in valve selection or installation.

Star Marine’s export framework integrates engineering oversight with maritime regulatory intelligence. We recognize that storm valve performance directly impacts a vessel’s structural integrity during severe weather events, making precise material selection (e.g., duplex stainless steel ASTM A182 F60/F55, nickel-aluminum bronze) and pressure class alignment non-negotiable. Our export managers collaborate with classification societies to pre-verify documentation, accelerating customs clearance and reducing project delays. Whether you require valves for ballast systems, deck drainage, or emergency venting, our team provides certified performance data sheets, 3D CAD models, and lifecycle maintenance protocols tailored to your vessel design. This end-to-end technical ownership minimizes operational downtime and ensures seamless integration into newbuild or retrofit projects.

For immediate, authoritative support on marine storm valve specifications, certifications, or export compliance, contact our Product Manager specializing in critical marine valves:

| Contact Detail | Information |

|---|---|

| Name | Kacher YE |

| Role | Product Manager – Marine Valves |

| Direct Email | [email protected] |

| Response Commitment | Guaranteed technical reply within 24 hours |

| Technical Expertise | Storm valve systems, IMO MSC.1/Circ.1395 compliance, API 600/6D adaptations for marine use |

Kacher YE leads our valve engineering division with 12 years of experience in marine fluid control systems, including direct collaboration with major shipyards in China, Singapore, and Europe. He will evaluate your operational parameters—such as maximum wave height exposure, system pressure differentials, and ambient temperature ranges—to prescribe the optimal valve configuration. This includes advising on actuation methods (manual, hydraulic, or automated fail-safe), sealing technologies for zero leakage under dynamic loads, and non-destructive testing protocols per EN 12266-1.

Do not risk project timelines or safety margins with generic valve suppliers. Star Marine’s export team delivers engineered certainty for mission-critical marine components. Initiate your storm valve procurement with a technical consultation—email Kacher YE today to receive a customized solution dossier, including dimensional schematics, material traceability certificates, and FOB/CIF shipping analysis. Your vessel’s resilience in extreme conditions begins with the right valve partnership. Contact [email protected] now to secure engineering support for your next maritime project.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160