Marine Valves – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Valves

Marine Valve Criticality and Strategic Sourcing Advantage

Marine valves represent fundamental safety-critical components within all vessel systems, directly impacting operational integrity and crew safety. These precision-engineered devices regulate the flow of essential fluids—including seawater, fuel, lubricants, ballast water, and firefighting media—across propulsion, steering, auxiliary, and emergency systems. A single valve failure in a critical circuit, such as main seawater cooling or fuel supply, can rapidly escalate into catastrophic scenarios including engine room flooding, loss of propulsion, fire, or environmental contamination. International maritime regulations, particularly SOLAS (Safety of Life at Sea) and MARPOL (Marine Pollution), mandate stringent performance, material, and certification standards for marine valves. Compliance with ISO 5208 (leakage rates), ISO 5209 (marking), and classification society rules (ABS, DNV, LR, etc.) is non-negotiable. Valves must withstand extreme pressures, corrosive seawater environments, wide temperature fluctuations, and constant vibration without compromising seal integrity or operational reliability. The inherent safety risk of substandard valves cannot be overstated; they are not merely fittings but vital barriers against system failure.

Global shipbuilders and repair yards increasingly recognize the strategic value of sourcing high-integrity marine valves from specialized manufacturers like Hangzhou Star Marine Technology. While initial procurement cost is a factor, the total cost of ownership—encompassing reliability, maintenance frequency, downtime risk, and regulatory compliance—dictates true value. Star Marine China leverages advanced manufacturing infrastructure, deep metallurgical expertise, and rigorous quality management systems certified to ISO 9001 and ISO 15089 to deliver valves that exceed international standards. Our vertically integrated production process, utilizing premium marine-grade materials (ASTM A216 WCB, CF8M, duplex stainless steels) and precision CNC machining, ensures consistent dimensional accuracy and performance. Crucially, every valve undergoes 100% shell and seat pressure testing per API 598, with optional helium leak testing for critical applications, providing documented assurance of safety compliance. This eliminates the hidden costs associated with field failures, warranty claims, and regulatory non-conformance common with uncertified suppliers.

The following table illustrates key valve types, their critical safety functions, and Star Marine’s value proposition:

| Valve Type | Critical Safety Application | Star Marine Value Advantage |

|---|---|---|

| Gate Valves | Main seawater inlet/outlet, ballast systems | Enhanced corrosion resistance via optimized material selection; reduced maintenance intervals due to precision lapped seats |

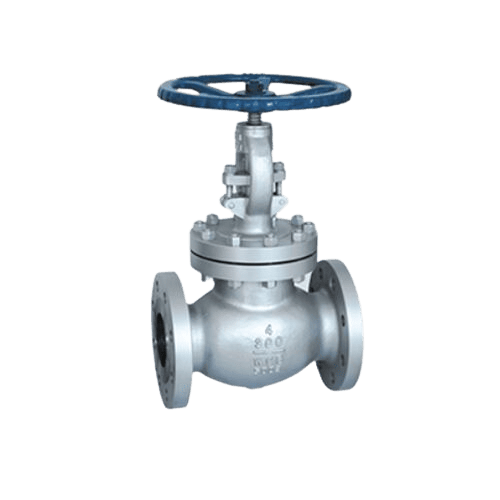

| Globe Valves | Fuel oil transfer, high-pressure cooling lines | Superior throttling control; minimized internal leakage per ISO 5208 Class VI; extended service life in abrasive media |

| Ball Valves | Emergency shutdown (ESD), firemain isolation | Zero leakage guarantee; robust stem design preventing blowout; rapid actuation reliability |

| Check Valves | Preventing backflow in bilge/pump systems | Precise cracking pressure calibration; anti-slam design eliminating water hammer damage |

| Butterfly Valves | Large diameter seawater circulation systems | Lightweight yet high-pressure integrity; optimized disc design for minimal cavitation |

Sourcing from Hangzhou Star Marine Technology delivers significant cost-effectiveness without compromising safety. Our operational efficiency within China’s robust maritime supply chain, combined with economies of scale from dedicated valve production lines, allows competitive pricing while maintaining uncompromised quality. We provide comprehensive technical support, rapid global logistics, and direct accountability—eliminating layers of intermediaries that inflate costs and complicate traceability. For vessel operators and builders, Star Marine offers the optimal balance: certified safety performance meeting the highest maritime standards, delivered with the economic efficiency essential for modern shipyard competitiveness. Investing in Star Marine valves is an investment in assured vessel safety and operational continuity.

Technical Specs & Approval

Marine valves are critical components in shipboard piping systems, ensuring controlled flow, isolation, and safety across various onboard applications such as ballast, cooling, fuel transfer, and firefighting systems. At Hangzhou Star Marine Technology Co., Ltd., our marine valves are engineered to meet the rigorous demands of maritime environments, combining durable materials, precise manufacturing, and compliance with international standards. Our product range includes valves constructed from high-grade bronze and cast steel, selected based on application requirements, fluid type, and operating conditions. Bronze valves are ideal for seawater and low-temperature applications due to their excellent corrosion resistance and machinability, while cast steel valves are preferred for high-temperature and high-pressure services, offering superior strength and reliability.

Our valves are rated across a pressure range from PN6 to PN40, enabling deployment in both low-pressure auxiliary lines and high-pressure main systems. The PN6 rating suits applications with minimal pressure stress, such as freshwater circulation, whereas PN40-rated valves are designed for critical systems involving steam, heavy fuel oil, or high-pressure hydraulic lines. All valves undergo stringent pressure testing, including shell and seat leakage tests, in accordance with international protocols to ensure integrity under operational loads.

Compliance with recognized standards is a cornerstone of our manufacturing philosophy. Our marine valves conform to JIS (Japanese Industrial Standards) and DIN (Deutsches Institut für Normung) specifications, ensuring interchangeability, dimensional accuracy, and global acceptance. JIS-compliant valves are widely used in Asian shipyards and vessels operating in regional trade, while DIN-standard valves meet the dimensional and performance expectations of European and international fleets. Each valve is marked with material grade, pressure rating, standard designation, and serial traceability for quality assurance and regulatory compliance.

All products are manufactured under ISO 9001-certified quality management systems and are supplied with material test certificates (MTCs), inspection reports, and, upon request, third-party certification from classification societies such as CCS, ABS, DNV, LR, and NK. Surface treatments include anti-corrosive coatings and passivation where applicable, enhancing longevity in saline and humid environments. Installation-friendly designs with standard flanged or threaded ends ensure ease of integration into existing and new marine piping systems.

The following table outlines the key technical parameters of our marine valve series:

| Parameter | Bronze Valves | Cast Steel Valves | Applicable Standards | Pressure Rating (PN) |

|---|---|---|---|---|

| Body Material | ASTM B62 Bronze | ASTM A216 WCB Cast Steel | JIS F 7405, JIS F 7406 | PN6, PN10, PN16, PN25, PN40 |

| Disc Material | Bronze or Stainless Steel | Stainless Steel | DIN 3352, DIN 85005 | |

| Stem Material | AISI 410 Stainless Steel | AISI 410 Stainless Steel | ||

| Seat Material | NBR, EPDM, PTFE | PTFE, Metal-seated options | ||

| Test Pressure (Shell) | 1.5 x PN | 1.5 x PN | ISO 5208 | |

| Test Pressure (Seat) | 1.1 x PN | 1.1 x PN | ||

| Operating Temperature | -20°C to +120°C | -29°C to +425°C | ||

| End Connections | Flanged (JIS 10K, 16K, 20K), Threaded | Flanged (DIN PN10-PN40) | JIS, DIN, ISO |

Hangzhou Star Marine Technology ensures every valve is performance-validated and documented, supporting safe, efficient, and compliant marine operations worldwide.

Shipbuilding Solutions

Comprehensive Marine Valve Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co. Ltd. delivers engineered marine valve solutions tailored to the stringent demands of new vessel construction and critical repair operations. Our integrated approach ensures seamless integration into shipbuilding workflows while providing rapid-response support for dry-docking and emergency repairs, minimizing vessel downtime. With ISO 9001:2015 certification and approvals from DNV-GL, ABS, LR, and CCS, our valves comply with SOLAS Chapter II-1 regulations and ISO 5208 leakage standards, guaranteeing operational safety and regulatory adherence across global fleets.

For new construction projects, Star Marine collaborates with naval architects and shipyards during the design phase to optimize valve selection, material specifications, and system integration. We supply certified valves for critical systems including ballast, fuel transfer, cooling, and firefighting, ensuring compatibility with propulsion and auxiliary machinery. Our engineering team provides 3D modeling support and material test reports (MTRs) to accelerate approval cycles, reducing lead times without compromising on quality. Strategic partnerships with global logistics providers enable just-in-time delivery to shipyards in China, Southeast Asia, and Europe, aligning precisely with construction milestones.

In repair and retrofit scenarios, our 24/7 technical support and extensive inventory network ensure urgent valve requirements are met within 72 hours. A dedicated repair coordination team interfaces directly with ship captains and class surveyors to verify specifications, expedite documentation, and dispatch replacement units pre-certified for immediate installation. This capability is critical during unscheduled dry-docking, where vessel idle costs can exceed $50,000 USD per day. Our Shanghai hub maintains 30,000+ valves in stock, covering legacy and modern designs, while our reverse-engineering service replicates obsolete components to original OEM tolerances.

The following table summarizes key valve types and their applications in shipbuilding and repair contexts:

| Valve Type | Pressure Rating | Materials | Primary Applications | Repair Advantage |

|---|---|---|---|---|

| ASTM A216 WCB Gate | Class 150-600 | Carbon Steel, SS Trim | Ballast, Bilge Systems | Interchangeable stems for field servicing |

| Forged Globe | Class 800 | SS316, Duplex 2205 | Fuel Oil Transfer, Steam Lines | Modular seat replacement kits |

| Trunnion Ball | Class 600 | SS316, Inconel 625 | Cargo Handling, Chemical Tanks | Zero-emission stem packing systems |

| Swing Check | Class 300 | Cast Iron, Ductile Iron | Cooling Water Circuits | Bolted cover design for rapid inspection |

Star Marine’s export management system streamlines customs clearance through pre-validated documentation packages, including Form A for preferential tariffs and CMR consignment notes for EU shipments. All valves undergo factory acceptance testing per MSS SP-61, with digital test records accessible via our client portal. By unifying engineering expertise, regulatory compliance, and agile logistics, we transform valve procurement from a supply chain challenge into a strategic asset for shipbuilders and repair yards worldwide. Partner with Hangzhou Star Marine Technology to ensure your vessel systems operate with uncompromised reliability and minimal operational disruption.

Packaging & Logistics

Packaging & Logistics for Marine Valves – Hangzhou Star Marine Technology Co., Ltd.

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all marine valves are packaged to meet international shipping standards and safeguard product integrity during global transit. Our packaging protocols are designed to comply with maritime transport regulations, environmental conditions, and customs requirements, particularly for sensitive industrial components such as marine valves. We utilize two primary packaging systems: ISPM 15 certified wooden cases and reinforced steel pallets, selected based on valve type, size, weight, and destination.

All wooden packaging materials used in our export operations are treated and certified in accordance with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This globally recognized standard ensures that wooden crates and cases are heat-treated or fumigated to eliminate pests and prevent the spread of invasive species through international trade. Each wooden case is marked with the official ISPM 15 stamp, guaranteeing compliance with phytosanitary regulations in all major markets, including the United States, European Union, Australia, and Japan. These cases are constructed from durable, kiln-dried plywood or solid wood, with internal cushioning using anti-corrosive VCI (Vapor Corrosion Inhibitor) paper and foam inserts to protect valve surfaces, flanges, and actuation components from mechanical shock and moisture exposure.

For heavier or large-diameter valves, such as gate, globe, and butterfly valves exceeding 50 kg, we employ robust steel pallets. These pallets are engineered for high load-bearing capacity and secured with welded frames and corner protectors. Valves are fastened using industrial-grade straps or bolts, ensuring zero displacement during handling and ocean freight. Steel pallets are particularly recommended for containerized shipments where stacking strength and stability are critical. They are also ideal for just-in-time delivery scenarios at shipyards or offshore facilities due to their reusability and compatibility with forklift and crane operations.

All packaged units are labeled with essential shipping information, including product identification, gross weight, handling instructions (e.g., “This Side Up”, “Do Not Invert”), and our company branding. Hazardous material labels are applied only when applicable (e.g., for valves with residual testing fluids).

Our primary export hubs are the major container ports of Ningbo and Shanghai, both offering direct shipping lines to global destinations with reliable transit times and advanced cargo tracking systems. We coordinate with certified freight forwarders to ensure seamless customs clearance, accurate documentation (including packing lists, certificates of origin, and phytosanitary certificates), and real-time shipment monitoring.

The following table outlines our standard packaging configurations based on valve specifications:

| Valve Type | Weight Range (kg) | Packaging Method | Crating Standard | Export Port |

|---|---|---|---|---|

| Ball Valves | 1 – 25 | Wooden Case | ISPM 15 Certified | Ningbo / Shanghai |

| Butterfly Valves | 10 – 60 | Wooden Case or Steel Pallet | ISPM 15 / Steel Frame | Ningbo / Shanghai |

| Gate & Globe Valves | 20 – 200 | Steel Pallet with Frame | Reinforced Steel | Ningbo / Shanghai |

| Check Valves | 5 – 80 | Wooden Case | ISPM 15 Certified | Ningbo / Shanghai |

We remain committed to delivering marine valves in optimal condition, ensuring compliance, safety, and efficiency throughout the global supply chain.

Contact Star Marine

Contact Star Marine for Your Critical Valve Solutions

Hangzhou Star Marine Technology Co. Ltd. stands at the forefront of marine valve engineering, delivering precision-crafted solutions that meet the rigorous demands of global maritime operations. Our valves undergo stringent ISO 9001-certified manufacturing processes and comply with DNV-GL, ABS, LR, and CCS standards, ensuring reliability in ballast, fuel transfer, bilge, and seawater systems. For vessels navigating complex regulatory landscapes or requiring mission-critical component integrity, our engineering team provides tailored valve solutions engineered for corrosion resistance, pressure stability, and extended service life in harsh marine environments.

Technical specifications define procurement decisions in marine valve selection. The table below summarizes core parameters for our flagship product lines, reflecting our commitment to dimensional accuracy and operational safety:

| Parameter | Globe Stop Valves | Butterfly Valves | Ball Valves | Check Valves |

|---|---|---|---|---|

| Size Range | DN15–DN600 | DN50–DN1200 | DN10–DN300 | DN25–DN500 |

| Pressure Rating | PN16–PN420 | PN10–PN100 | PN16–PN420 | PN16–PN250 |

| Temperature Range | -20°C to 200°C | -10°C to 120°C | -40°C to 200°C | -20°C to 150°C |

| Body Material | ASTM A216 WCB | Ductile Iron | ASTM A105 | ASTM A216 WCB |

| Seat Material | SS316 | EPDM/NBR | PTFE | SS304 |

| Certifications | DNV-GL, CCS, LR | DNV-GL, ABS, KR | DNV-GL, BV, RINA | DNV-GL, NK, IRS |

Engaging directly with our Product Management team eliminates procurement delays and technical misalignment. Kacher YE, our dedicated Product Manager for Marine Valves, possesses 12 years of specialized experience in valve system integration for tankers, offshore platforms, and container vessels. His expertise spans material selection for sulfuric acid resistance in exhaust gas cleaning systems, cryogenic valve adaptations for LNG carriers, and compliance verification against IMO MSC.428(98) ballast water management requirements. When you contact Kacher, you gain a technical partner who translates operational challenges into engineered valve specifications—ensuring seamless retrofitting or newbuild compatibility.

Do not navigate complex valve procurement without expert guidance. Submit your project requirements, vessel specifications, and classification society mandates directly to Kacher YE. He will initiate a confidential technical review within 4 business hours, provide CAD-compatible dimensional drawings, and coordinate factory acceptance testing schedules at our Hangzhou facility. For urgent dry-dock replacements, our Ningbo and Shanghai port warehouses maintain 24/7 inventory access for valves up to DN300.

Act now to secure precision-engineered valve solutions:

Contact Kacher YE via email at [email protected]. Include your vessel’s IMO number, required valve quantities, and applicable classification society rules. Specify operational parameters such as media type (e.g., heavy fuel oil, seawater, ballast water), pressure differentials, and ambient conditions. Our team operates on GMT+8 but accommodates global time zones for technical consultations. All inquiries receive a formal quotation with lead time analysis, material test reports, and 3D model attachments within 24 hours. Trust Hangzhou Star Marine Technology—where engineering excellence meets maritime reliability. Your vessel’s performance depends on every component; ensure yours meets uncompromising standards.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160