Mooring Rope – Marine Solution Guide 2025

Content Navigation

Marine Insight: Mooring Rope

Marine Industry Demand: Mooring Rope – Safety Imperative and Strategic Sourcing Advantage

Mooring ropes represent a fundamental, non-negotiable component within the global maritime infrastructure, directly impacting vessel and port safety during critical berthing, mooring, and cargo operations. Their primary function extends far beyond simple tethering; they are engineered energy absorption systems designed to withstand immense dynamic loads generated by wind, currents, wave action, and vessel movement. Failure of mooring lines under operational stress can lead to catastrophic consequences, including vessel breakaway, collisions with docks or other vessels, structural damage to port facilities, environmental spills, and significant personnel injury or fatality. Consequently, international maritime regulations, classification society rules (such as those from DNV, ABS, LR), and port state control regimes mandate the use of certified mooring equipment meeting stringent performance standards. Modern synthetic fiber ropes, particularly High Modulus Polyethylene (HMPE) and high-tenacity polyester, have largely superseded traditional materials due to their superior strength-to-weight ratio, reduced elongation under load (critical for precise vessel positioning), enhanced durability, and resistance to rot, mildew, and many chemicals. Selecting ropes that consistently meet or exceed ISO 20438:2017 and OCIMF MEG4 specifications is not merely a compliance issue but a core operational safety requirement for any vessel operator or terminal.

Sourcing high-performance mooring ropes from Hangzhou Star Marine Technology offers a compelling strategic and economic advantage without compromising on the paramount requirement of safety. Our vertically integrated manufacturing facility in Hangzhou leverages significant economies of scale in the production of advanced synthetic fibers and finished rope assemblies. This scale, combined with optimized domestic supply chains for raw materials within China’s robust polymer industry, allows us to achieve substantial cost efficiencies. Crucially, these efficiencies are realized while maintaining rigorous adherence to international quality management systems; Star Marine holds ISO 9001:2015 certification, and all mooring ropes undergo comprehensive in-house testing per recognized standards before shipment. We eliminate unnecessary intermediary markups inherent in complex global supply chains, providing direct factory-to-vessel or terminal pricing. Furthermore, our deep technical expertise in marine rope engineering ensures that cost-effectiveness does not equate to reduced performance. We utilize premium-grade HMPE and polyester fibers, precision braiding techniques, and advanced termination methods (spliced eyes, shackles) to deliver ropes with documented performance characteristics that meet or exceed global safety benchmarks. This combination of certified quality, reliable supply, and optimized manufacturing costs translates directly into a superior total cost of ownership for our clients.

The following table highlights key performance characteristics of standard mooring rope types offered by Star Marine, demonstrating the balance of safety attributes and value:

| Material Type | Min. Breaking Strength (kN) | Elongation at Break (%) | Avg. Service Life (Years) | Key Safety Advantage |

|---|---|---|---|---|

| HMPE (8-Strand) | 1,200 – 3,500 | 2.5 – 3.5 | 5 – 8+ | Exceptional strength/weight; Low stretch |

| Polyester (8-Strand) | 800 – 2,800 | 18 – 22 | 7 – 10+ | High fatigue resistance; UV stability |

| Polypropylene (3-Strand) | 400 – 1,500 | 25 – 30 | 2 – 4 | Cost-effective; Good floatation |

Hangzhou Star Marine Technology delivers mooring solutions where uncompromising safety standards converge with demonstrable cost leadership. By choosing Star Marine, operators invest in certified, high-reliability equipment that safeguards assets and personnel while optimizing procurement expenditure within the demanding global maritime environment. Our commitment to quality and value ensures your mooring system remains a robust asset, not a liability.

Technical Specs & Approval

Mooring ropes are critical components in marine operations, ensuring secure vessel docking, offshore mooring, and safe load handling under dynamic environmental conditions. At Hangzhou Star Marine Technology Co., Ltd., our mooring ropes are engineered to meet stringent international maritime standards, offering high tensile strength, durability, and resistance to environmental degradation. Designed for use in both commercial shipping and offshore applications, these ropes are constructed using advanced materials such as aluminum-coated steel and galvanized steel, selected for their optimal balance of strength, corrosion resistance, and service life in marine environments.

One of the key technical considerations in mooring rope performance is material composition. Aluminum-coated steel wire provides enhanced resistance to saltwater corrosion while maintaining high breaking strength, making it ideal for long-term offshore deployments. Galvanized steel variants offer a cost-effective solution with reliable performance in coastal and estuarine conditions. Both materials are precision-laid in multi-strand configurations to ensure flexibility, fatigue resistance, and uniform load distribution under tension.

Watertightness is achieved through specialized construction techniques, including compact stranding and optional polymer impregnation or sheathing. These features minimize water ingress into the rope core, reducing internal corrosion and extending operational life. Additionally, the outer layer may incorporate a protective polymeric jacket to enhance abrasion resistance and reduce wear during winching and fairlead contact.

Dimensional accuracy is maintained across all production batches to ensure compatibility with standard winches, bollards, and mooring hardware. Our mooring ropes are available in nominal diameters ranging from 16 mm to 60 mm, with lengths customizable between 350 meters and 500 meters depending on vessel class and mooring requirements. Each rope is manufactured under ISO 2415 and EN 13414 compliance, with full traceability and individual certification for breaking load, elongation, and construction integrity.

Below is a summary of the technical parameters for standard mooring rope configurations offered by Hangzhou Star Marine Technology:

| Parameter | Specification |

|---|---|

| Material | Aluminum-coated steel, Galvanized steel |

| Nominal Diameter | 16 mm – 60 mm (in increments of 2 mm) |

| Standard Length | 350 m – 500 m (custom lengths available) |

| Construction | 6×36 FC or 6×37 IWRC (Independent Wire Rope Core) |

| Minimum Breaking Load | 180 kN – 2,800 kN (depending on diameter) |

| Elongation at Rated Load | ≤ 2.5% (elastic + structural elongation) |

| Watertight Features | Compacted strands, optional polymer impregnation |

| Corrosion Protection | Aluminum coating (Zn-Al alloy), hot-dip galvanizing |

| Compliance Standards | ISO 2415, EN 13414, DNVGL Type Approval available |

| Operating Temperature | -40°C to +100°C |

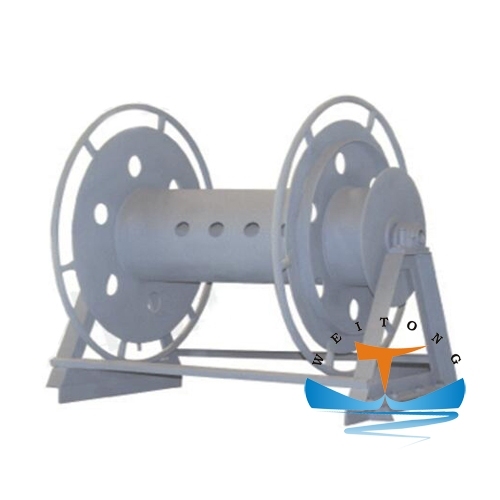

| Packaging | Reel-mounted, moisture-resistant wrapping |

All mooring ropes undergo rigorous quality control, including tensile testing, non-destructive examination, and visual inspection per AQL Level II. Hangzhou Star Marine Technology ensures that every product shipped meets the operational demands of modern maritime environments, providing reliability, safety, and long-term value to global clients.

Shipbuilding Solutions

Hangzhou Star Marine Technology: Complete Mooring Rope Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered mooring rope solutions meeting the stringent demands of global shipyards and repair facilities. As a specialized marine outfitter within the Shipbuilding & Repair Solutions sector, we provide certified, high-performance synthetic fiber ropes essential for vessel safety during berthing, mooring, and offshore operations. Our focus is on eliminating project delays through rapid response, technical expertise, and seamless integration into new construction or critical repair workflows. We understand that downtime equates to significant financial loss; therefore, our export process is optimized for speed without compromising on quality or compliance.

Our core product range includes premium polyester and polypropylene mooring lines, manufactured to exacting international standards. Each rope undergoes rigorous testing to ensure consistent breaking strength, fatigue resistance, and longevity under harsh marine conditions. Critical certifications including ISO 20438, DNVGL-ST-N001, ABS, LR, and BV are standard, guaranteeing acceptance by major classification societies and port authorities worldwide. The table below outlines key specifications for our most common shipyard solutions:

| Rope Type | Construction | Typical Diameter Range (mm) | Min. Breaking Load (kN) | Key Certifications | Primary Application |

|---|---|---|---|---|---|

| Polyester Double Braid | 100% Polyester | 40 – 120 | 1,200 – 12,500 | DNV, ABS, LR, ISO 20438 | Ocean-going Vessels, Tankers |

| Polypropylene 3-Strand | 100% Polypropylene | 30 – 90 | 600 – 5,800 | BV, GL, ISO 20438 | Tugs, Barges, Short Sea Vessels |

| HMPE (Spectra/Dyneema) | 100% HMPE | 28 – 80 | 1,800 – 8,200 | DNV, ABS, LR | Offshore Support, High-Performance |

Implementation for new builds is streamlined through early engagement with shipyard procurement and design teams. We provide detailed technical submittals, load calculation support, and coordinate delivery schedules precisely with the vessel’s outfitting phase, ensuring ropes arrive ready for immediate deployment. For repair and retrofit projects, our global logistics network enables expedited shipping of standard or custom lengths. Our 24/7 technical support team assists yards in selecting replacement ropes matching original specifications or upgrading to higher-performance materials, minimizing vessel turnaround time in dry dock.

Star Marine’s export strength lies in our integrated approach. We manage all documentation – including certificates of origin, material test reports, and multilingual labels – adhering strictly to INCOTERMS 2020 (primarily FOB Shanghai/Ningbo or EXW). Dedicated export managers facilitate clear communication, handle customs complexities, and provide real-time shipment tracking. This end-to-end responsibility, from initial inquiry to on-board delivery, ensures shipyards receive not just a product, but a reliable, certified component of their operational safety system. Partner with Hangzhou Star Marine Technology for mooring solutions that uphold maritime safety standards while accelerating your build or repair schedule.

Packaging & Logistics

Packaging & Logistics for Mooring Rope Exports

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all mooring rope shipments are packaged to meet international maritime transport standards, preserving product integrity and compliance throughout global logistics chains. As a critical component of marine outfittings, mooring ropes are subjected to rigorous handling, variable climatic conditions, and extended transit times. To mitigate risks associated with moisture, mechanical damage, and regulatory non-compliance, we utilize two primary packaging systems: ISPM 15 certified wooden cases and reinforced steel pallets. These methods are selected based on rope diameter, length, quantity, and destination-specific import regulations.

Wooden cases used for mooring rope packaging are constructed from heat-treated, kiln-dried hardwood and comply fully with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This certification ensures that all wooden packaging materials are free from pests and pathogens, a requirement enforced by customs authorities in over 180 countries, including the United States, Australia, and members of the European Union. Each wooden case is stamped with the official IPPC (International Plant Protection Convention) mark, verifying compliance. The interior of the case is lined with moisture-resistant polyethylene film to prevent hygroscopic absorption, which is particularly important for synthetic fiber ropes such as polyester and polypropylene. The rope is coiled or spooled under controlled tension to avoid kinking and secured within the case using internal bracing.

For heavier-duty applications or bulk shipments, we employ steel pallets with welded reinforcement and anti-corrosion coating. These pallets provide superior load stability during containerized shipping and are ideal for high-tensile ropes used in offshore and deep-sea mooring operations. The ropes are typically bundled in multiple layers, separated by protective spacers, and wrapped with UV-resistant shrink film. Steel pallets are especially recommended for shipments to tropical or high-humidity regions where wooden packaging may degrade or attract regulatory scrutiny.

All export shipments originate from the major Chinese ports of Ningbo and Shanghai, both of which offer direct maritime links to key global trade routes. Our logistics partners ensure timely container loading, accurate documentation, and adherence to shipping line requirements. Standard export packaging includes detailed labeling with product specifications, batch numbers, and handling instructions in accordance with IMDG and SOLAS guidelines where applicable.

The following table outlines the standard packaging configurations based on mooring rope specifications:

| Rope Diameter (mm) | Packaging Type | Max Load per Unit | Dimensions (L×W×H) | Compliance Standard |

|---|---|---|---|---|

| 12 – 28 | ISPM 15 Wooden Case | 1,500 kg | 120×80×80 cm | ISPM 15, IPPC Marked |

| 29 – 48 | Steel Pallet | 3,000 kg | 120×100×150 cm | ISO 1496-2, Anti-Corrosion Coated |

| 49 – 64 | Steel Pallet (Heavy Duty) | 5,000 kg | 140×120×180 cm | ISO 1496-2, Welded Frame |

Our packaging and logistics strategy ensures that every mooring rope arrives at its destination in optimal condition, ready for immediate deployment in demanding marine environments.

Contact Star Marine

Contact Star Marine for Premium Mooring Rope Solutions

Hangzhou Star Marine Technology Co. Ltd. stands as your trusted partner for mission-critical marine outfittings, specializing in high-performance mooring ropes engineered for global maritime operations. Our ISO 9001-certified manufacturing processes and rigorous adherence to OCIMF guidelines ensure every product meets the uncompromising safety and durability standards demanded by modern shipping, offshore energy, and port infrastructure sectors. As international trade volumes grow and vessel sizes increase, selecting mooring systems that guarantee operational integrity under extreme environmental stress is not merely advantageous—it is imperative for risk mitigation and regulatory compliance.

Our mooring rope portfolio leverages advanced polymer science and decades of maritime application expertise. Below is a summary of key technical capabilities defining our export-ready solutions:

| Specification | Performance Standard | Application Relevance |

|---|---|---|

| Material Composition | High-modulus polyester, HMPE, or aramid | Optimized for UV resistance, fatigue life, and minimal elongation |

| Breaking Strength Range | 50 to 3,000+ kN | Scales from coastal vessels to VLCCs and offshore platforms |

| Certification | ISO 10545, OCIMF Mooring Equipment Guidelines, DNV Type Approval | Ensures global regulatory acceptance and insurance compliance |

| Customization | Diameter (12mm–120mm), splice types, color coding | Tailored to vessel specifications and port authority requirements |

| Service Life | 5–10 years (depending on usage cycles) | Reduces total cost of ownership through extended operational reliability |

These specifications reflect our commitment to engineering resilience where failure is not an option. Whether your operation requires dynamic positioning support for deepwater rigs or secure berthing in high-tidal-range ports, Hangzhou Star Marine Technology delivers ropes that withstand cyclic loading, abrasion, and corrosive marine environments without compromising safety margins.

Initiate a technical consultation with Kacher YE, our dedicated Product Manager for Mooring Systems, to address your specific operational challenges. Kacher brings 12 years of field experience in global marine outfittings export, specializing in translating complex vessel requirements into certified, turnkey mooring solutions. He will guide you through material selection, load analysis, and compliance documentation tailored to your fleet’s operational profile and regional regulatory frameworks.

Do not compromise on the lifeline securing your assets. Contact Kacher YE directly via email at [email protected] to request:

A detailed technical dossier with test certificates for your target vessel class

Customized load capacity calculations based on your berthing environment

Logistics support for time-sensitive global shipments under INCOTERMS® 2020

Hangzhou Star Marine Technology operates from Hangzhou, China, with export coordination hubs in Rotterdam and Singapore, ensuring seamless documentation, customs clearance, and just-in-time delivery to ports worldwide. Our team understands that delays in mooring equipment procurement directly impact vessel turnaround times and operational revenue. By engaging with Kacher, you gain a strategic partner committed to safeguarding your operations through precision-engineered marine outfittings.

Act now to secure mooring systems that perform when it matters most. Email Kacher YE today to schedule a technical review and receive a project-specific quotation within 24 business hours. Your vessels deserve the reliability only Hangzhou Star Marine Technology can deliver.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160