Oily Water Separator – Marine Solution Guide 2025

Content Navigation

Marine Insight: Oily Water Separator

Marine Industry Demand: Oily Water Separator Criticality and Sourcing Advantage

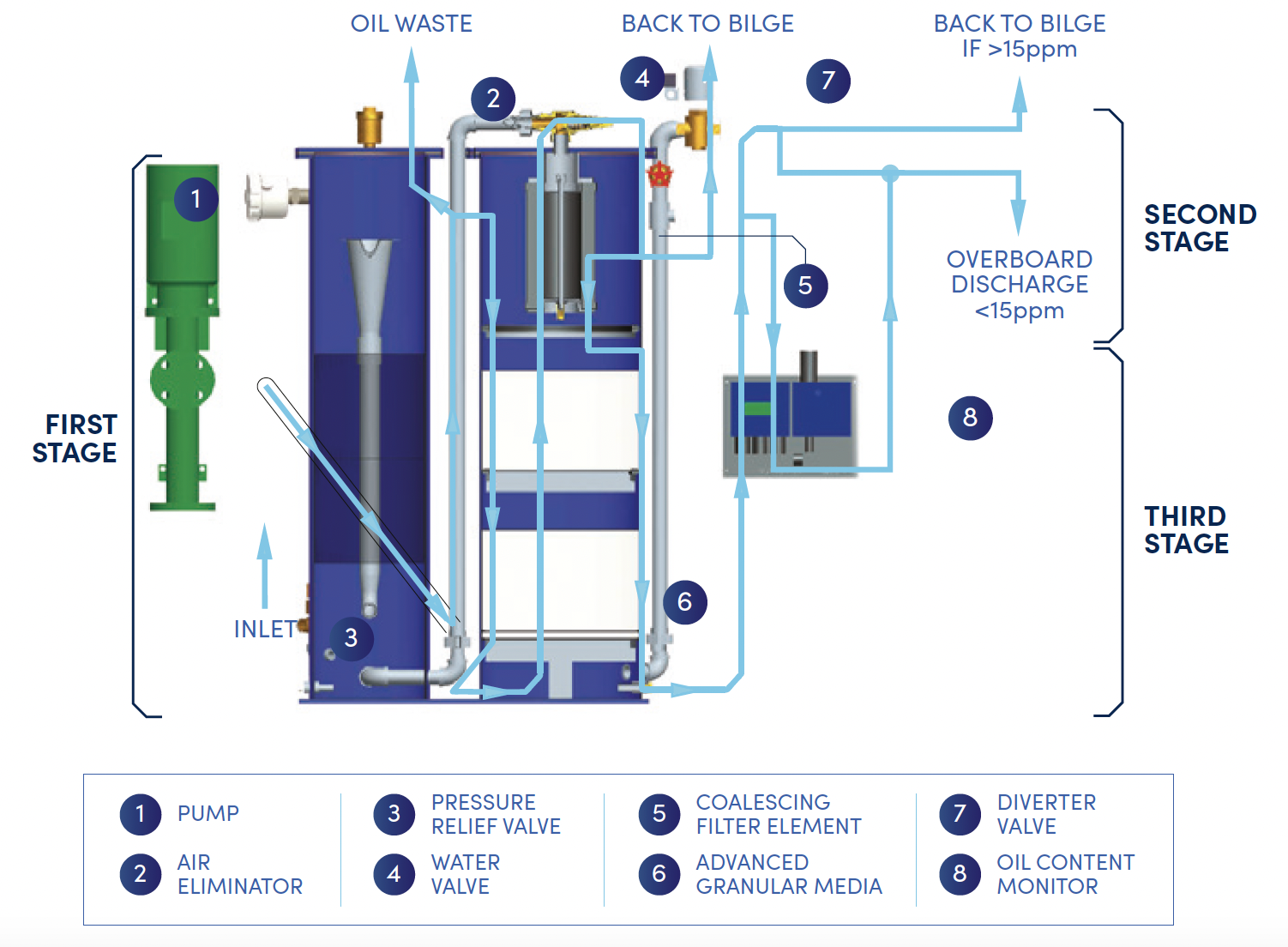

The oily water separator (OWS) represents a fundamental safety and environmental compliance system mandated for all commercial vessels under international maritime law, primarily MARPOL Annex I. Its critical function lies in treating bilge water – a mixture of oil, water, and contaminants accumulated in engine room spaces – before any overboard discharge. Failure to effectively separate oil to concentrations below the stringent 15 parts per million (ppm) threshold poses severe risks. Non-compliant discharges trigger significant environmental damage, leading to heavy fines, vessel detention by Port State Control (PSC), operational delays, and irreparable reputational harm for shipowners. More critically, untreated bilge water accumulation creates hazardous conditions onboard; excessive oil content increases fire risk within confined engine spaces and compromises the vessel’s stability if tank capacities are exceeded. Regulatory scrutiny on OWS performance and monitoring (via Oil Content Meters – OCMs) has intensified globally, making reliable, certified equipment non-negotiable for safe, legal, and uninterrupted vessel operation. The consequences of OWS failure extend beyond immediate penalties, potentially voiding insurance and jeopardizing crew safety through increased fire hazards and environmental incidents.

Sourcing high-performance OWS systems from Hangzhou Star Marine Technology offers shipowners and shipyards a compelling cost-effectiveness proposition without compromising on safety or compliance. Leveraging China’s advanced marine manufacturing ecosystem, Star Marine integrates precision engineering with rigorous quality control processes adhering to IMO MEPC.107(49) standards and major classification society rules (DNV, LR, ABS, CCS, etc.). Our vertically integrated production facilities utilize optimized supply chains for core components like coalescer plates, pumps, and advanced OCM sensors, significantly reducing unit costs compared to European or North American alternatives. Crucially, this cost advantage is achieved while maintaining superior build quality using marine-grade materials such as corrosion-resistant duplex steel and ensuring robust design for harsh marine environments. Star Marine OWS units are engineered for high reliability and minimal maintenance downtime – a key factor in total lifecycle cost savings. Reduced service intervals, readily available spare parts globally, and responsive technical support directly translate to lower operational expenditure and maximized vessel uptime for the operator. We deliver certified compliance and operational resilience at a highly competitive investment point.

The following table outlines key performance and value parameters of Star Marine OWS systems against industry benchmarks:

| Parameter | IMO MEPC.107(49) Requirement | Star Marine Standard Specification | Operational Benefit |

|---|---|---|---|

| Discharge Limit | ≤ 15 ppm oil content | ≤ 10 ppm (Typical Performance) | Enhanced compliance margin, reduced PSC risk |

| Material Construction | Corrosion resistant | Duplex Stainless Steel (Wetted Parts) | Extended service life, reduced maintenance frequency |

| Monitoring System | Certified OCM mandatory | Integrated, Self-Calibrating OCM | Reliable real-time data, simplified certification |

| Operational Mode | Continuous treatment | True Continuous Operation | No bypass needed, consistent performance |

| Certification | Mandatory | DNV, LR, ABS, CCS, RINA, etc. | Global acceptance, seamless flag state approval |

| Service Support | Varies by supplier | Global Network, 24/7 Technical Hub | Minimized downtime, rapid issue resolution |

Choosing Hangzhou Star Marine Technology ensures access to technically superior, fully certified oily water separation technology. Our commitment to engineering excellence within China’s efficient manufacturing framework delivers unmatched value: significant acquisition cost savings combined with the reliability, durability, and global support essential for safeguarding vessel operations, protecting the marine environment, and ensuring continuous compliance in today’s demanding regulatory landscape. This strategic advantage directly contributes to safer voyages and optimized operational economics.

Technical Specs & Approval

The oily water separator (OWS) is a critical component in marine pollution prevention systems, designed to remove oil and suspended solids from bilge water to ensure compliance with international maritime regulations, including MARPOL Annex I. Hangzhou Star Marine Technology Co., Ltd. offers engineered oily water separators tailored for commercial vessels, offshore platforms, and auxiliary marine equipment. These units are built to deliver reliable performance under harsh marine conditions, featuring robust construction, efficient separation technology, and compact design suitable for integration into existing engine room systems.

Each oily water separator is constructed using high-grade materials selected for durability and resistance to corrosion in marine environments. The standard housing is fabricated from carbon steel with anti-corrosion coating, while optional aluminum construction is available for weight-sensitive or high-corrosion-exposure applications. Internal components, including coalescer plates and piping, are made from stainless steel (AISI 316) or engineered polymers to resist degradation from hydrocarbons and saline exposure. The design ensures long service intervals with minimal maintenance, supporting continuous operation at rated capacity.

Watertight integrity is a core design criterion. All housings are pressure-tested and sealed to IP66 standards, ensuring protection against water ingress and dust. Flange connections comply with ISO 7005 standards and are rated for operating pressures up to 10 bar, with elastomer gaskets selected for compatibility with oil and seawater. The system incorporates fail-safe monitoring, including level sensors and automatic shut-off valves, to prevent overfilling and ensure regulatory compliance during operation.

The compact footprint of the oily water separator allows for flexible installation in confined engine room spaces. Units are available in multiple configurations to suit varying vessel sizes and throughput requirements. Dimensions and weights are optimized to facilitate lifting, handling, and retrofitting without structural modifications. All models include integrated lifting lugs and anti-vibration mounting points to meet shock and vibration standards per ISO 13722 and DNVGL-SE-0523.

The following table outlines the technical parameters for standard oily water separator models offered by Hangzhou Star Marine Technology:

| Parameter | Value / Specification |

|---|---|

| Model Range | OWS-0.5, OWS-1.0, OWS-2.0, OWS-3.0 |

| Flow Rate Capacity | 0.5 m³/h, 1.0 m³/h, 2.0 m³/h, 3.0 m³/h |

| Maximum Inlet Oil Content | ≤ 10,000 ppm |

| Outlet Oil Content | ≤ 15 ppm (compliant with MARPOL) |

| Housing Material | Carbon steel (standard), Aluminum (optional) |

| Internal Components Material | AISI 316 Stainless Steel, PTFE, PP |

| Operating Pressure | 0.6 – 1.0 MPa |

| Design Temperature | 0°C to 70°C |

| Electrical Supply | 220 VAC, 50 Hz (custom voltages available) |

| Control System | PLC with touchscreen HMI, alarm logging |

| Enclosure Rating | IP66 |

| Dimensions (L × W × H) | 1,200 × 600 × 1,500 mm (OWS-1.0 typical) |

| Weight (Dry) | 280 kg (OWS-1.0, steel), 190 kg (aluminum) |

| Approval Standards | IMO MEPC.107(49), DNV, ABS, CCS, BV |

All units are supplied with full documentation, including material test certificates, pressure test reports, and type approval certifications. Custom configurations are available upon request to meet specific vessel integration or regulatory requirements.

Shipbuilding Solutions

Hangzhou Star Marine Technology: Oily Water Separator Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive, compliant oily water separator (OWS) systems tailored for global shipyards and repair facilities. As specialists in marine outfittings within the Shipbuilding & Repair Solutions sector, we provide engineered solutions from initial specification through installation support and lifecycle maintenance, ensuring seamless integration and regulatory adherence for new construction and critical retrofits. Our focus is on minimizing vessel downtime through rapid technical response and certified equipment supply.

Our technical integration expertise ensures OWS systems meet stringent international mandates, primarily IMO MEPC.107(49) and MARPOL Annex I requirements, alongside specific flag state and port state control standards such as USCG Type Approval. We partner with leading global OWS manufacturers, enabling us to offer a range of skid-mounted and modular units optimized for space-constrained engine rooms across diverse vessel types, from large tankers and container ships to offshore support vessels and ferries. Critical to new build projects, our engineering team collaborates directly with naval architects and shipyard superintendents to verify system compatibility with vessel piping, electrical interfaces, and automation requirements, preventing costly delays during sea trials. For repair scenarios, our rapid assessment protocol identifies root causes of separator failure or non-compliance, allowing immediate dispatch of certified technicians or pre-configured spare parts kits.

The following table outlines representative OWS models within our standard export portfolio, highlighting key technical parameters essential for project specification:

| Model Series | Treatment Capacity (m³/h) | Discharge Standard Compliance | Key Certifications | Typical Vessel Applications |

|---|---|---|---|---|

| HMS Compact | 0.5 – 5.0 | ≤ 15 ppm | IMO MEPC.107(49), RINA, DNV | Tugs, Workboats, Small Ferries |

| HMS Standard | 5.0 – 25.0 | ≤ 15 ppm | IMO MEPC.107(49), ABS, LR, USCG | Coastal Cargo, Offshore Supply Vessels |

| HMS High-Flow | 25.0 – 50.0+ | ≤ 15 ppm | IMO MEPC.107(49), ClassNK, BV, USCG | Tankers, Large Container Ships |

Expedited support is fundamental to our repair service commitment. We maintain strategic spare parts hubs in Shanghai, Singapore, and Rotterdam, enabling 72-hour delivery for critical components like coalescer plates, 15ppm monitors, and control system modules worldwide. Our 24/7 technical hotline connects shipyards directly with marine engineers fluent in English and Mandarin, providing remote diagnostics and troubleshooting guidance to resolve operational issues before physical intervention is required. This proactive approach significantly reduces dry-docking periods during scheduled repairs or emergency breakdowns.

Hangzhou Star Marine Technology ensures your oily water management system is not merely compliant but operationally robust. By combining certified equipment sourcing, application-specific engineering, and an unrivaled global response network, we deliver turnkey OWS solutions that safeguard your vessel’s operational schedule and environmental compliance. Contact our Export Management team for immediate technical specifications or project support.

Packaging & Logistics

Packaging & Logistics for Oily Water Separator Exports

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all oily water separators are packaged to meet international maritime shipping standards, preserving equipment integrity during transit and complying with global phytosanitary regulations. Our packaging protocols are designed to protect sensitive marine components from environmental exposure, mechanical shock, and handling damage throughout the export journey from China to global destinations.

All oily water separator units are secured within custom-engineered wooden export cases constructed from high-grade plywood or solid timber, treated and certified in accordance with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This international regulation mandates that all wood packaging material used in international trade must be heat-treated or fumigated to prevent the spread of invasive pests. Each wooden case is stamped with the official ISPM 15 mark, confirming compliance with these requirements. The cases are internally lined with moisture-resistant barrier materials and include anti-vibration padding to safeguard control panels, sensors, and filtration modules during long-haul shipping.

For heavier models or skid-mounted oily water separator systems, we utilize reinforced steel pallets with lifting provisions compatible with forklifts and shipboard cranes. These steel pallets are hot-dip galvanized to resist corrosion during sea transport and are designed to meet ISO container loading standards. Equipment is securely bolted or strapped to the pallets, minimizing movement during vessel roll and pitch conditions. All external fasteners are tightened to specified torque values, and protective caps are installed on pipe flanges and electrical conduits to prevent contamination or damage.

Our standard export point is via the major container ports of Ningbo and Shanghai, both of which are among the world’s busiest and most efficient maritime hubs. These ports offer direct liner services to North America, Europe, the Middle East, Africa, and Southeast Asia, ensuring timely delivery and seamless customs clearance. Prior to shipment, all packages undergo final inspection and documentation verification, including packing lists, certificates of origin, and compliance documentation.

We coordinate logistics through certified freight forwarders experienced in marine equipment shipments, offering both FOB and CIF terms depending on customer requirements. Container types vary based on order size—20-foot or 40-foot dry containers for standard units, with open-top or flat-rack containers used for oversized assemblies.

The following table summarizes our standard packaging configurations:

| Packaging Type | Dimensions (L×W×H) | Max Load Capacity | ISPM 15 Certified | Suitable For |

|---|---|---|---|---|

| Wooden Export Case | Custom | Up to 2,500 kg | Yes | Standard OWS units, control panels |

| Reinforced Steel Pallet | 1,200×1,000 mm | Up to 5,000 kg | N/A (Metal) | Skid-mounted systems, large OWS |

| Plywood Crate | Custom | Up to 3,000 kg | Yes | Multi-component installations |

All packaging solutions are designed to ensure compliance, durability, and ease of handling at destination ports. Hangzhou Star Marine Technology maintains strict quality control throughout the packaging process to uphold our reputation for reliable, professional marine equipment exports.

Contact Star Marine

Contact Star Marine for Expert Oily Water Separator Solutions

Navigating international maritime environmental regulations demands precision-engineered oily water separator systems that guarantee compliance with MARPOL Annex I and IMO Resolution MEPC.107(49). At Hangzhou Star Marine Technology Co. Ltd., we specialize in designing, manufacturing, and exporting certified marine outfittings that exceed global discharge standards. Our oily water separators integrate advanced coalescing technology, automated monitoring, and robust construction to ensure zero tolerance for oil content in bilge water—critical for vessel operations in Emission Control Areas (ECAs) and sensitive waterways. As your dedicated export partner, we streamline the complexities of international certification, customs clearance, and installation support, ensuring seamless integration into newbuilds or retrofits across container vessels, tankers, and offshore platforms.

Partnering with Star Marine means accessing engineering expertise rooted in 15+ years of SOLAS and flag state authority compliance. Our systems undergo rigorous factory acceptance testing (FAT) per ISO 10088:2019 protocols, with documentation tailored to your vessel’s classification society requirements (DNV, ABS, LR, etc.). Whether addressing stringent U.S. Coast Guard Type Approval or EU Marine Equipment Directive (MED) certification, our export team manages end-to-end logistics, including INCOTERMS 2020 alignment and pre-shipment inspection coordination. We recognize that delays in pollution control equipment deployment risk operational penalties; thus, we prioritize rapid response cycles for technical queries, spare parts provisioning, and on-site commissioning support.

For immediate technical consultation or export documentation, contact our Product Manager specializing in oily water separation systems:

| Contact Detail | Information | Response Timeframe |

|---|---|---|

| Primary Contact | Kacher YE | Within 4 business hours |

| Role | Product Manager, Marine Outfittings | |

| Direct Email | [email protected] | |

| Technical Support | [email protected] | 24 hours |

| Global Hotline | +86-571-88XXXXXX (Hangzhou HQ) | 8:00–17:00 CST |

| After-Hours Emergency | [email protected] | 24/7 for critical cases |

Kacher YE leads our technical export division with in-depth knowledge of oily water separator performance under diverse operational conditions—from Arctic voyages to tropical ballast operations. He will guide you through system selection based on your vessel’s bilge capacity, pump specifications, and regulatory jurisdiction, providing 3D installation drawings and lifecycle cost analysis. Star Marine’s export portfolio includes separators rated for 0.5–50 m³/h flow rates, with integrated 15 ppm monitors and alarm systems compliant with MEPC.107(49) amendments. All units ship with full test reports, CE/MED certificates, and multilingual operation manuals.

Initiate your project with confidence by emailing Kacher YE directly. Include your vessel particulars, target delivery timeline, and classification society requirements to receive a customized technical dossier and commercial proposal within 72 hours. For urgent compliance upgrades or audit preparations, reference “OILY WATER EMERGENCY” in your subject line to trigger priority handling. Hangzhou Star Marine Technology stands ready to safeguard your vessel’s environmental integrity while optimizing operational efficiency—because in maritime sustainability, precision isn’t optional; it’s imperative. Trust our engineering rigor to keep your operations seaworthy and audit-ready worldwide.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160