Portable Marine Generator – Marine Solution Guide 2025

Content Navigation

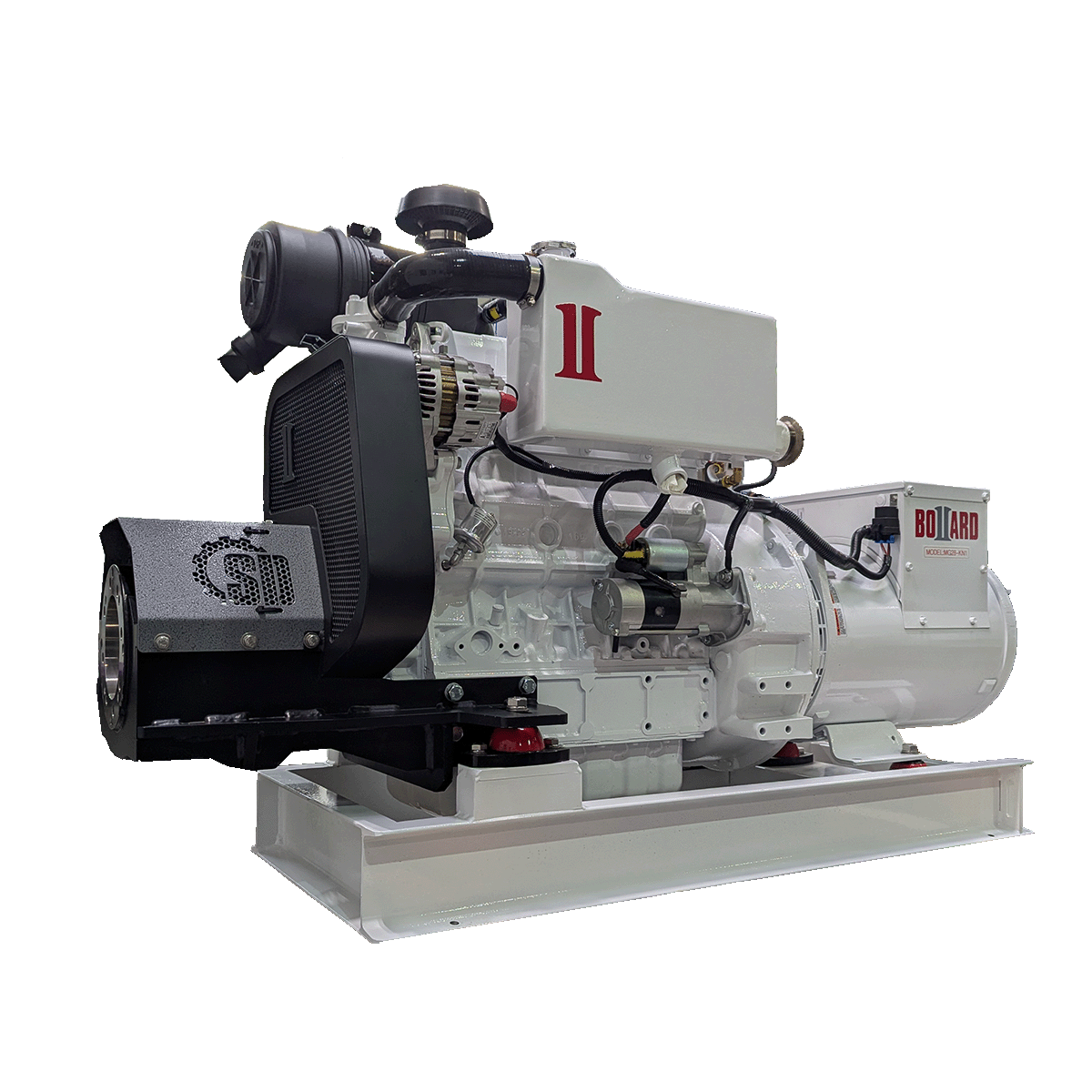

Marine Insight: Portable Marine Generator

The portable marine generator plays a critical role in ensuring vessel safety and operational continuity across a wide range of maritime applications. As an essential component within the marine outfittings category, this equipment provides reliable backup or primary electrical power in situations where the main propulsion generator is offline, during maintenance, or when auxiliary power is required for onboard systems. Its importance is particularly evident in emergency scenarios such as blackouts, fire suppression system activation, or navigation system failure, where uninterrupted power supply can mean the difference between a controlled response and a catastrophic incident. Portable marine generators are also indispensable during harbor layovers, dry-docking, or when support vessels need to deliver power to larger ships without running their main engines, reducing fuel consumption and emissions.

Modern maritime regulations, including those set by the International Maritime Organization (IMO) and classification societies such as ABS, DNV, and CCS, emphasize the need for redundant power systems to maintain critical functions like communication, lighting, bilge pumping, and bridge instrumentation. A portable marine generator fulfills this requirement with flexibility and scalability, especially on smaller commercial vessels, fishing boats, yachts, and offshore support units where space and weight are limiting factors. These generators are engineered to withstand harsh marine environments, featuring corrosion-resistant enclosures, vibration dampening mounts, and weatherproofing to ensure performance under extreme conditions.

Sourcing portable marine generators from Hangzhou Star Marine Technology Co., Ltd. offers significant cost advantages without compromising on quality or compliance. Based in China, Star Marine leverages advanced manufacturing capabilities, economies of scale, and streamlined supply chain logistics to deliver high-performance marine equipment at competitive export prices. Our generators are built to meet international marine standards, including ISO 8528, IEC 60034, and MARPOL Annex VI, ensuring global regulatory acceptance. Additionally, our in-house engineering team customizes output capacity, fuel type (diesel or gasoline), noise reduction features, and mounting configurations to meet specific client requirements.

The following table outlines key technical and economic advantages of Star Marine’s portable marine generators compared to average market alternatives:

| Feature | Star Marine Portable Generator | Industry Average |

|---|---|---|

| Power Output Range | 5–30 kVA | 5–25 kVA |

| Fuel Efficiency (g/kWh) | ≤ 210 | ≥ 240 |

| Noise Level (dB at 7m) | ≤ 72 | 75–80 |

| Weight (kg, 10 kVA model) | 135 | 150–165 |

| Compliance Standards | IMO, DNV, CCS, ISO, IEC | Varies by supplier |

| Average Lead Time (weeks) | 4–6 | 8–12 |

| FOB Price (10 kVA, USD) | $2,100 | $2,600–$3,000 |

By combining technical reliability, regulatory compliance, and cost-effective pricing, Hangzhou Star Marine Technology establishes itself as a strategic partner for global buyers seeking dependable marine power solutions. Our commitment to quality assurance and after-sales support further enhances long-term value, making our portable marine generators a preferred choice in the international maritime market.

Technical Specs & Approval

Technical Specifications: Portable Marine Generator Series

Hangzhou Star Marine Technology Co., Ltd. designs its portable marine generators to meet the rigorous demands of offshore and coastal operations. Engineered for continuous operation in high-salinity, high-humidity environments, these units prioritize corrosion resistance, structural integrity, and safety compliance. All models undergo stringent salt spray testing per ISO 9227 and vibration analysis per ISO 16750-3 to ensure reliability under dynamic maritime conditions. Critical components are sealed against salt ingress, and electrical systems incorporate marine-grade insulation rated for 150°C operational temperatures.

Material selection is fundamental to longevity in marine applications. The generator housing utilizes marine-grade aluminum alloy 5083 for optimal strength-to-weight ratio and exceptional corrosion resistance, eliminating the risk of galvanic corrosion when mounted near steel structures. Structural brackets and mounting points are fabricated from ASTM A36 carbon steel, treated with a dual-layer protective coating: zinc-rich primer (75μm) followed by epoxy-polyurethane topcoat (100μm), exceeding IMO MSC/Circ.1120 standards for anti-corrosion performance. Fuel tanks are constructed from 3mm-thick 316L stainless steel, passivated and electropolished to prevent microbial-induced corrosion in stored diesel.

Watertight integrity is non-negotiable for marine power systems. Each generator achieves IP66 ingress protection rating, validated through 15-minute exposure to powerful water jets (12.5mm nozzle, 100L/min at 100kPa) from any direction. Critical junction boxes and control panels feature NEMA 4X-rated gaskets with silicone compression seals, maintaining pressure differentials up to 5kPa. All cable penetrations utilize Marelon® non-metallic glands to prevent moisture tracking while accommodating thermal expansion. The design eliminates standing water traps through seamless welded joints and strategic drainage channels, ensuring operability after submersion in waves up to 1m depth for 30 minutes (per IEC 60529 Annex B).

The following table details key dimensional and performance parameters for standard configurations:

| Parameter | Model SMG-2.5kW | Model SMG-5.0kW | Model SMG-10kW |

|---|---|---|---|

| Housing Material | Marine Aluminum Alloy 5083 | Marine Aluminum Alloy 5083 | Marine Aluminum Alloy 5083 |

| Structural Frame | ASTM A36 Steel (Dual-Coated) | ASTM A36 Steel (Dual-Coated) | ASTM A36 Steel (Dual-Coated) |

| IP Rating | IP66 | IP66 | IP66 |

| Overall Dimensions (L×W×H) | 580×420×450 mm | 720×520×550 mm | 950×680×650 mm |

| Operational Weight | 68 kg | 125 kg | 210 kg |

| Continuous Output | 2.5 kVA | 5.0 kVA | 10.0 kVA |

| Fuel Tank Capacity | 12 L | 25 L | 45 L |

All units comply with SOLAS Chapter II-1 regulations for emergency power systems and carry DNV-GL Type Approval certification. Dimensional tolerances are held to ±1.5mm to ensure compatibility with standard ISO container lashing points and vessel deck fixtures. The compact footprint facilitates deployment on lifeboats, offshore platforms, and auxiliary vessel decks without compromising maintenance access. Hangzhou Star’s engineering team provides certified dimensional drawings (ISO 128-24 compliant) for integration validation prior to shipment, ensuring seamless installation within client-specific marine outfittings frameworks. This precision guarantees operational readiness across global maritime zones, from tropical ports to Arctic supply routes.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine outfittings solutions tailored to the demanding requirements of modern shipbuilding and repair operations. As a trusted provider in the maritime industry, we specialize in portable marine generators that serve as reliable power sources during vessel construction, maintenance, and emergency scenarios. Our engineered systems ensure uninterrupted operations, safety compliance, and operational efficiency across diverse marine environments.

Our portable marine generators are designed to meet international marine standards, including ISO 8528, IMO Tier II emissions compliance, and classification society approvals such as CCS, ABS, and DNV. These units provide temporary or auxiliary power during critical phases of shipbuilding—such as outfitting, commissioning, and sea trials—where permanent onboard power may not yet be available. In repair and dry-dock settings, our generators eliminate downtime by maintaining essential electrical loads, supporting lighting, welding, HVAC, and control systems without reliance on shore power or main engines.

Star Marine’s approach integrates engineering excellence with rapid deployment capability. We understand that time is critical in both new construction and repair cycles. Our team offers fast-response technical support, with standard units available for immediate dispatch and custom configurations delivered within compressed timelines. Our generators are built with marine-grade corrosion-resistant materials, compact sound-attenuated enclosures, and fuel-efficient diesel engines, ensuring durability and low maintenance in harsh maritime conditions.

To support shipyards and repair facilities globally, we provide full project lifecycle services—from initial technical consultation and load analysis to installation supervision and after-sales support. Our engineering team collaborates directly with naval architects and project managers to ensure seamless integration with vessel power architecture. Remote monitoring options and digital service platforms further enhance uptime and predictive maintenance planning.

The following table outlines key specifications of our standard portable marine generator series:

| Model | Power Output (kVA) | Engine Type | Fuel Type | Sound Level (dBA @ 1m) | Dimensions (L×W×H, mm) | Weight (kg) | Certification |

|---|---|---|---|---|---|---|---|

| PMG-50 | 50 | Diesel, 4-stroke | Diesel | 78 | 1800×800×1400 | 850 | CCS, ABS |

| PMG-100 | 100 | Diesel, 4-stroke | Diesel | 80 | 2400×1000×1500 | 1400 | CCS, DNV, ABS |

| PMG-150 | 150 | Diesel, 6-cylinder | Diesel | 82 | 2800×1100×1600 | 1950 | CCS, DNV, LR |

| PMG-200 | 200 | Diesel, 6-cylinder | Diesel | 83 | 3200×1200×1700 | 2400 | CCS, ABS, GL |

Each unit is subjected to rigorous factory acceptance testing, including load bank trials and vibration analysis, ensuring performance reliability before delivery. With a focus on operational continuity and client satisfaction, Hangzhou Star Marine Technology stands as a strategic partner for shipbuilders and repair yards seeking agile, high-performance power solutions. Our commitment to innovation, quality, and fast turnaround makes us a preferred supplier in the global marine outfittings market.

Packaging & Logistics

Packaging & Logistics for Portable Marine Generators

Proper packaging and logistics execution are critical for ensuring the safe transit of portable marine generators, which are exposed to harsh maritime environments during shipment. At Hangzhou Star Marine Technology, we implement industry-standard protocols to protect equipment integrity, comply with international regulations, and streamline global delivery. Our packaging methodology prioritizes structural resilience, moisture resistance, and adherence to phytosanitary requirements, specifically tailored for the demanding conditions of sea freight.

All portable marine generators are secured within custom-engineered wooden export crates compliant with ISPM 15 (International Standards for Phytosanitary Measures No. 15). These crates utilize heat-treated (HT) plywood, certified to a minimum core thickness of 18 mm, eliminating the risk of pest infestation without chemical fumigation. Each crate features internal bracing, anti-vibration padding, and sealed moisture barriers to safeguard sensitive electrical components against humidity, salt air, and impact during ocean transit. The ISPM 15 stamp, permanently branded on each crate face, guarantees regulatory acceptance across all major global ports, including the EU, USA, and Australia, avoiding customs delays or rejections.

Generators are mounted on galvanized steel pallets designed for heavy-duty marine logistics. These pallets incorporate reinforced stringers, non-slip surfaces, and integrated lashing points compatible with container securing systems. The palletized units ensure stability during crane lifts, straddle carrier handling, and multi-tier container stacking. Steel pallets also prevent deformation under load, resist corrosion from deck washdowns, and facilitate seamless transfer via forklifts at origin and destination ports.

Export operations are centralized through China’s premier maritime hubs: Ningbo-Zhoushan Port (world’s busiest container port) and Shanghai Port (Yangshan Deep-Water Terminal). Both facilities offer direct mainline vessel services to all key global trade lanes, with dedicated cold chain and hazardous cargo zones if required. Our Ningbo/Shanghai logistics partners manage end-to-end processes, including customs clearance, terminal handling, and real-time container tracking. Standard lead time from factory to vessel loading is 3–5 business days, leveraging Hangzhou’s proximity to these ports via the Hangzhou Bay Bridge corridor.

The following table details critical packaging specifications for our standard portable marine generator models:

| Parameter | Value | Compliance Standard |

|---|---|---|

| Crate Material | 18 mm Heat-Treated Plywood | ISPM 15 HT Certified |

| Pallet Dimensions | 1200 mm × 1000 mm × 150 mm | ISO 6780 |

| Max Gross Weight | 1,800 kg per palletized unit | SOLAS VGM Category II |

| Moisture Barrier | 200-micron PE Film + Silica Gel | ASTM D4276 |

| Lashing Points | 4 x M12 Steel Rings (SWL 2,500 kg) | ISO 1161 |

Documentation accuracy is non-negotiable. We provide ISPM 15 certificates, detailed packing lists with net/gross weights, and VGM (Verified Gross Mass) submissions 24 hours prior to container gating. All shipments include waterproof documentation pouches affixed externally to crates, containing operation manuals and warranty cards. Our Ningbo/Shanghai freight forwarders coordinate with carriers like COSCO and Maersk to ensure container slots align with production schedules, minimizing port demurrage risks. This integrated approach guarantees generators arrive operational, fully compliant, and ready for immediate deployment upon delivery to the vessel or end client.

Contact Star Marine

For marine operators, shipbuilders, and offshore support teams seeking reliable, high-performance portable power solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in marine outfittings. Our portable marine generators are engineered to meet the rigorous demands of maritime environments, combining compact design with industrial-grade durability and compliance with international marine standards such as ISO 8846, IMO, and CE. Whether for auxiliary power during vessel maintenance, emergency backup on offshore platforms, or temporary energy needs in remote port locations, our generators deliver consistent, clean power under challenging conditions.

At the heart of our product development is a commitment to innovation, safety, and customer-specific adaptation. Each portable marine generator is built with corrosion-resistant materials, marine-grade sound attenuation enclosures, and fuel systems optimized for extended runtime and low emissions. We offer models powered by leading engine platforms including Yanmar, Kubota, and Volvo Penta, ensuring global serviceability and spare parts availability. Our engineering team integrates advanced voltage regulation, digital control panels, and optional remote monitoring systems to support seamless integration into existing marine electrical networks.

To ensure your project receives the optimal configuration, we encourage direct engagement with our Product Manager, Kacher YE. With over 12 years of experience in marine power systems and export operations, Mr. Ye specializes in translating operational requirements into technically sound, cost-effective solutions. He leads technical consultations, custom design reviews, and export logistics coordination, ensuring full compliance with destination country regulations and shipping protocols.

We invite global distributors, shipyards, and marine equipment integrators to contact Mr. Kacher YE for detailed technical specifications, pricing, and project support. Whether you are evaluating a single unit for onboard use or planning a large-scale deployment across a fleet, our team provides end-to-end assistance—from initial inquiry to after-sales service.

Below is an overview of our standard portable marine generator series:

| Model | Output (kVA) | Engine Type | Fuel Type | Noise Level (dBA @ 7m) | Dimensions (L×W×H, mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| SMG-5P | 5.0 | Yanmar 3TNV | Diesel | 72 | 950×550×720 | 185 |

| SMG-8P | 8.0 | Kubota V2203 | Diesel | 74 | 1120×620×780 | 240 |

| SMG-12P | 12.0 | Volvo Penta TAD520 | Diesel | 76 | 1350×700×850 | 320 |

| SMG-18P | 18.0 | Yanmar 4TNV | Diesel | 78 | 1500×780×920 | 410 |

All units are manufactured under ISO 9001-certified processes and undergo 100% load testing prior to shipment. Custom configurations—including weatherproof canopies, dual-fuel capability, and 50/60 Hz switchable output—are available upon request.

For technical inquiries, project quotations, or export documentation support, please contact Product Manager Kacher YE directly at [email protected]. We respond to all inquiries within 4 business hours and provide multilingual support in English, Spanish, and Arabic. Partner with Hangzhou Star Marine Technology for precision-engineered portable power that meets the demands of modern maritime operations.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160