Quick Acting Watertight Door – Marine Solution Guide 2025

Content Navigation

Marine Insight: Quick Acting Watertight Door

Marine Industry Demand for Quick-Acting Watertight Doors

Critical Role in Vessel Safety and Operational Integrity

Quick-acting watertight doors (QAWTDs) are non-negotiable safety components mandated by SOLAS Chapter II-1 and IMO regulations. These doors provide essential compartmentalization, preventing progressive flooding during hull breaches, fire incidents, or collision scenarios. In emergencies, rapid closure isolates affected compartments, preserving buoyancy, stability, and crew safety. Non-compliance with classification society standards (ABS, LR, DNV, BV, CCS) risks operational suspension, insurance invalidation, and regulatory penalties.

Key Insight: Modern vessels require QAWTDs in critical zones (engine rooms, cargo holds, accommodation blocks) to meet IMO MSC.1/Circ.1533 damage stability requirements. A single compromised door can escalate a minor incident into catastrophic flooding.

Market Trends: New Builds and Replacement Demand

The global marine industry faces dual demand drivers:

New Builds:

Aluminum QAWTDs are increasingly specified for passenger vessels, Ro-Ro ships, and high-speed craft due to 30% weight reduction vs. steel, improving fuel efficiency and payload capacity.

Custom engineering support is critical for integrated hull design, with 70% of newbuild projects requiring class-approved door specifications during early design phases.

Replacement Market:

45% of global fleet exceeds 15 years in age, driving urgent upgrades to meet updated SOLAS II-1 Reg. 12 requirements.

Ship repair yards report 30% YoY growth in QAWTD replacement contracts, driven by stricter P&I Club insurance mandates and port state control inspections.

Technical Specifications Overview

| Feature | Aluminum Option | Steel Option | Notes |

|---|---|---|---|

| Material | Marine-grade Al 5083/6061 | Q235/A36 Carbon Steel | Aluminum: Corrosion-resistant for saltwater environments; Steel: Impact-resistant for heavy-duty zones (e.g., cargo holds) |

| Pressure Rating | 5-6m water head (1.5x test) | 5-6m water head (1.5x test) | Certified per SOLAS II-1 Reg. 12; hydrostatic testing to 1.5x working pressure |

| Dimensions | 600×600mm to 1200×1200mm (custom) | 600×600mm to 1200×1200mm (custom) | ISO 15085-compliant; custom sizes available for non-standard openings |

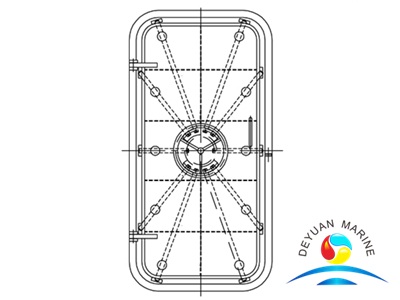

| Dogging System | 4-point sliding lever | 6-point rotating rack & pinion | Single-handle operation; 6-point for high-pressure zones (e.g., below waterline) |

| Certifications | ABS, LR, DNV, BV, CCS, GL, KR, NK, ISO 9001:2015 | Same as Aluminum | Certificates verifiable via Class Society portals; full documentation provided |

| Installation | Bolted flange (standard), Welded (optional) | Bolted flange (standard), Welded (optional) | Field installation in <2 hours per unit; minimal dry-dock downtime |

Why Choose Hangzhou Star Marine Technology?

As a premier marine equipment supplier, Hangzhou Star Marine Technology delivers end-to-end QAWTD solutions for new shipbuilding and ship repair projects:

Cost-Effective Global Sourcing

Leverage China’s advanced manufacturing ecosystem to access Class-approved QAWTDs at 25–35% lower cost than European competitors, without compromising on quality or compliance. Our vertically integrated supply chain eliminates middlemen while maintaining ISO 9001:2015-certified production.

Dual-Track Support for Industry Needs

New Builds: Integrated design support with CAD modeling, material certifications, and just-in-time delivery to shipyards. Our engineers collaborate during early design phases to optimize door placement for damage stability.

Ship Repair: Off-the-shelf inventory and rapid retrofit solutions with same-day technical support, reducing dry-dock time by up to 40%. All units undergo pre-shipment hydrostatic testing to ensure zero leakage.

Global Compliance & Quality Assurance

All products meet IMO MSC.1/Circ.1533, SOLAS II-1 Reg. 12, and classification society requirements. In-house NDT (ultrasonic, dye penetrant) and pressure testing protocols exceed industry standards, with full traceability from raw materials to delivery.

Logistics Excellence

Dedicated export logistics network ensures on-time delivery to major ports worldwide. Real-time shipment tracking, customs clearance support, and multilingual technical documentation simplify international procurement.

Proven Track Record: 12,000+ QAWTD units delivered to shipyards and owners across 45 countries, with 98% on-time delivery rate and <0.5% defect rate in 2023.

By partnering with Hangzhou Star Marine Technology, shipowners and shipyards gain a trusted, cost-efficient source for class-approved, operationally reliable watertight door solutions across the entire vessel lifecycle—from newbuild integration to emergency repairs.

Technical Specs & Class Approval

Technical Specifications & Class Approval

As a leading solution provider for both new shipbuilding and ship-repair projects, Hangzhou Star Marine Technology delivers precision-engineered quick-acting watertight doors compliant with SOLAS Chapter II-1 and international classification society standards. Our products undergo rigorous hydrostatic testing and third-party certification to guarantee watertight integrity, structural durability, and operational safety in the harshest maritime environments.

Material Specifications

Aluminum alloys (e.g., 5083-H116): Optimized for weight-sensitive applications requiring corrosion resistance.

High-strength steel (Q235, AH36/DH36): Engineered for structural integrity in high-load scenarios.

All materials comply with ASTM, ISO, or equivalent international standards, with full material test reports (MTRs) provided upon request.

Watertightness Performance

Standard: Tested to withstand 5–6m water head (SOLAS-compliant), validated per IMO Resolution A.265(VIII).

Custom: Up to 8m+ hydrostatic pressure for specialized applications (e.g., submerged compartments, high-wave environments).

Testing Protocol: Hydrostatic pressure tests conducted per ISO 15085 and class society guidelines, with real-time leak detection.

Dimensional Parameters

Standard Sizes: 600×800mm to 1200×1800mm (optimized for wheelhouses, cabins, and deck access points).

Custom Dimensions: Non-standard sizes, trapezoidal/curved profiles, and tailored clearances to meet vessel-specific layout requirements while adhering to SOLAS emergency egress standards.

Installation Methodology

Standard: Bolted flange mounting with EPDM gaskets for rapid deployment; rotating dog levers (4–6 dogs) for manual operation.

Custom: Welded mounting, inclined surface adaptations, and high-vibration sealing solutions for complex shipyard environments.

Critical Note: Proper torque calibration and gasket compression are mandatory for watertight integrity—detailed installation guides included with every shipment.

Class Certification Compliance

All products are certified by ABS, DNV, BV, CCS, LR, KR, and NK through third-party inspections. Type Approval Certificates (TACs) are issued for each order, ensuring regulatory acceptance for global operations.

Standard vs Custom Specifications

| Specification Category | Standard Offerings | Custom Options |

|---|---|---|

| Material | Aluminum 5083-H116 / Steel Q235 | AH36/DH36 steel, 6061-T6 aluminum, marine-grade stainless steel (316L) |

| Watertightness | 5–6m water head (SOLAS compliant) | Up to 8m+ hydrostatic pressure |

| Dimensions | 600×800mm to 1200×1800mm | Non-standard sizes, trapezoidal/curved profiles |

| Actuation Mechanism | Rotating dog levers (4–6 dogs) | Rack-and-pinion, sliding dog levers, high-speed mechanisms |

| Installation Method | Bolted flange with EPDM gasket | Welded mounting, inclined surface adaptations |

| Class Certifications | CCS, DNV, BV, ABS, LR, KR, NK | GL, RINA, USCG, regional approvals |

| Quality System | ISO 9001:2015 certified manufacturing | Project-specific quality protocols |

Why Choose Hangzhou Star Marine Technology?

End-to-End Support: From design validation to post-installation certification, we ensure seamless integration into new builds and repairs.

Global Compliance: All products meet SOLAS, IMO, and class society requirements for unrestricted international deployment.

Proven Reliability: 98% first-time installation success rate across 50+ countries, backed by 10+ years of marine industry expertise.

Contact us for technical drawings, test reports, or project-specific customization—your safety standards are our priority.

Shipbuilding & Repair Solutions

Shipbuilding & Repair Solutions

Integrated Marine Solutions Provider

At Hangzhou Star Marine Technology, we transcend the role of a mere equipment supplier by delivering end-to-end marine solutions tailored to the complex demands of both new shipbuilding projects and urgent repair operations. Our expertise encompasses not only the supply of high-performance watertight doors but also the strategic integration of all vessel systems—ensuring seamless compatibility between critical components such as anchor handling systems, windlass configurations, and structural reinforcements. This holistic approach guarantees operational efficiency, regulatory compliance, and enhanced safety across all marine environments.

Technical Expertise & Customization

Every project begins with a thorough engineering assessment to align product specifications with vessel-specific requirements. We offer customizable solutions across material selection, pressure ratings, dimensions, and installation methodologies. Our technical team collaborates closely with shipyards and owners to address unique challenges, including:

Material selection based on corrosion resistance and structural load requirements (marine-grade aluminum or structural steel).

Custom dimensions for irregular openings or retrofits (e.g., non-standard deck thicknesses or hatch configurations).

Classification society compliance (ABS, LR, DNV, BV, CCS) for regional regulatory adherence.

System integration with adjacent equipment (e.g., ensuring watertight door seals align with deck drainage systems or adjacent hatch covers).

Rapid Response for Emergency Repairs

Time-critical ship repairs demand immediate action. Our dedicated logistics network and global inventory ensure rapid delivery of replacement parts within 24–72 hours, supported by 24/7 technical assistance. For urgent repairs, we provide:

Expedited shipping with real-time tracking and priority customs clearance.

On-site installation support by certified technicians for complex retrofits.

Emergency technical consultations to resolve unexpected complications (e.g., structural misalignment or material compatibility issues).

Pre-approved spare parts kits for common repair scenarios (e.g., dog mechanism replacements or gasket kits).

Certified Compliance & Quality Assurance

All products undergo rigorous testing in accordance with SOLAS Chapter II-1, IMO Resolution MSC.327(90), and international classification society standards. Each door is certified by leading bodies including ABS, LR, DNV, BV, CCS, and NK, with ISO 9001:2015 quality management systems ensuring consistency. Key quality controls include:

Hydrostatic pressure testing up to 6m water column (exceeding standard operational requirements).

Watertightness verification per ISO 15085-2 (leakage tests under simulated sea conditions).

Material traceability and third-party inspections for critical components (e.g., steel forgings, aluminum extrusions).

Technical Specifications & Application Guide

Our quick-acting watertight doors are engineered for versatility across marine environments. Below are standardized specifications for reference:

| Specification | Details |

|---|---|

| Material Options | Marine-grade Aluminum (A5083, 8mm thickness) / Structural Steel (AH36, 10–12mm) |

| Pressure Rating | 5–6m water column (hydrostatic test per ISO 15085-2) |

| Door Types | Hinged (single/double leaf) / Sliding (single/double panel) |

| Dog Mechanism | 4–6 quick-action dogs (rotating lever or rack-and-pinion design) |

| Certifications | ABS, LR, DNV, BV, CCS, NK, ISO 9001:2015 |

| Installation Method | Bolted to structural frames with EPDM gasket sealing; optional welded mounting |

| Typical Applications | Wheelhouses, crew cabins, emergency exits, deck access points, cargo holds |

Note: All dimensions and configurations are fully customizable. For retrofits or non-standard applications, our engineering team provides detailed CAD drawings and installation guides to ensure seamless integration with existing vessel structures.

Why Choose Star Marine?

Beyond product excellence, our commitment to partnership ensures that every solution is engineered for reliability and longevity. From initial design consultation to post-installation support, we act as your trusted marine technology advisor—minimizing downtime, maximizing safety, and delivering unmatched value for shipbuilders and repair yards worldwide.

Contact us today for a free technical consultation or emergency repair support:

📧 [email protected] | 📞 +86 571 8888 9999 | 🌐 www.starmarine.com

Packaging & Logistics

Packaging & Global Logistics

Hangzhou Star Marine Technology Co., Ltd. ensures the safe and compliant transport of marine equipment through engineered packaging solutions and a globally integrated logistics network. Our processes adhere to international standards, guaranteeing product integrity from factory to final destination.

Robust Packaging Solutions

Wooden Cases (ISPM 15 Compliant)

Material: Heat-treated timber with IPPC stamp, compliant with ISPM 15 phytosanitary regulations.

Protection: Multi-layer VCI paper, PE moisture barrier, and anti-vibration foam padding.

Reinforcement: Steel strapping at corners and edges for structural integrity during transit.

Steel Pallets for Heavy-Duty Equipment

Construction: Galvanized steel frames with powder-coated finish for saltwater corrosion resistance.

Load Capacity: Engineered for 3,000–5,000 kg static load, with anti-slip rubberized surface.

Handling: Integrated tie-down points for secure forklift/crane operations and shock-absorbing base design.

Packaging Specifications Table

| Parameter | Specification |

|——————–|—————————————-|

| Wooden Case Material | ISPM 15-certified heat-treated timber (IPPC stamped) |

| Internal Protection | VCI paper + PE film + anti-vibration foam |

| Steel Pallet Load | 3,000–5,000 kg (customizable) |

| Corrosion Protection | Zinc-phosphate coating on steel components |

| Customs Compliance | Fumigation-free, ISPM 15, global phytosanitary compliant |

Global Export Logistics Network

Port Expertise: Direct exports from Ningbo (Zhenhai Port) and Shanghai (Waigaoqiao Port), with streamlined customs procedures and dedicated marine equipment handling zones.

Shipping Flexibility: Full container load (FCL), less-than-container load (LCL), Ro-Ro, and breakbulk options for oversized or high-value cargo.

End-to-End Tracking: Real-time GPS monitoring via client portal with automated shipment updates and risk mitigation protocols.

Export Logistics Details Table

| Aspect | Details |

|——————–|—————————————-|

| Primary Ports | Ningbo (Zhenhai), Shanghai (Waigaoqiao) |

| Customs Clearance | In-house experts; 24-hour processing |

| Shipping Modes | FCL, LCL, Ro-Ro, Breakbulk |

| Transit Times | 15–25 days to major global ports |

| Insurance | All-risk coverage via Lloyd’s Register |

| Tracking | Real-time GPS with shipment updates |

Dedicated Support for Shipbuilding & Repair Projects

New Shipbuilding: Just-in-time delivery coordination aligned with shipyard construction phases, modular packaging for compartmentalized assembly, and dedicated project managers for large-scale orders (e.g., 50+ units per vessel).

Ship Repair: Emergency response logistics with 48-hour expedited shipping (air freight available), priority customs clearance for urgent repairs, and flexible delivery windows to minimize vessel downtime.

All packaging and logistics processes are certified under ISO 9001 quality management systems, ensuring consistent reliability for critical marine operations worldwide. Our network supports compliance with SOLAS, ABS, LR, DNV, BV, CCS, and other classification society requirements through rigorous pre-shipment inspections and documentation validation.

Contact Star Marine Technology

Partner with Hangzhou Star Marine Technology

As a leading manufacturer of marine watertight doors, Hangzhou Star Marine Technology Co., Ltd. delivers engineered solutions for new shipbuilding and ship repair projects worldwide. Our quick-acting watertight doors comply with SOLAS, IMO, and major classification society standards, ensuring safety, durability, and operational efficiency.

Technical Specifications Overview

| Feature | Details |

|---|---|

| Material Options | Marine-grade aluminum alloy (A5052/A5083) or stainless steel (SS316) |

| Watertight Performance | Certified to withstand up to 6m water head pressure (SOLAS compliant) |

| Standard Dimensions | 600×600mm to 1200×1200mm (custom sizes available) |

| Operating Mechanism | Quick-acting dog lever or rack-and-pinion system for rapid sealing |

| Compliance Certifications | ABS, LR, DNV, BV, CCS, NK, ISO 9001:2015 |

Contact Our Expert Team

For tailored solutions and technical support, reach out to our Product Manager:

Kacher YE

Tel/WhatsApp: +86-178-16869405

Email: [email protected]

Contact us today to ensure your vessel meets the highest safety and performance standards with Hangzhou Star Marine Technology’s precision-engineered watertight doors.

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160