Rubber Cable – Marine Solution Guide 2025

Content Navigation

Marine Insight: Rubber Cable

Marine Industry Demand for Rubber Cables: Ensuring Vessel Safety and Operational Reliability

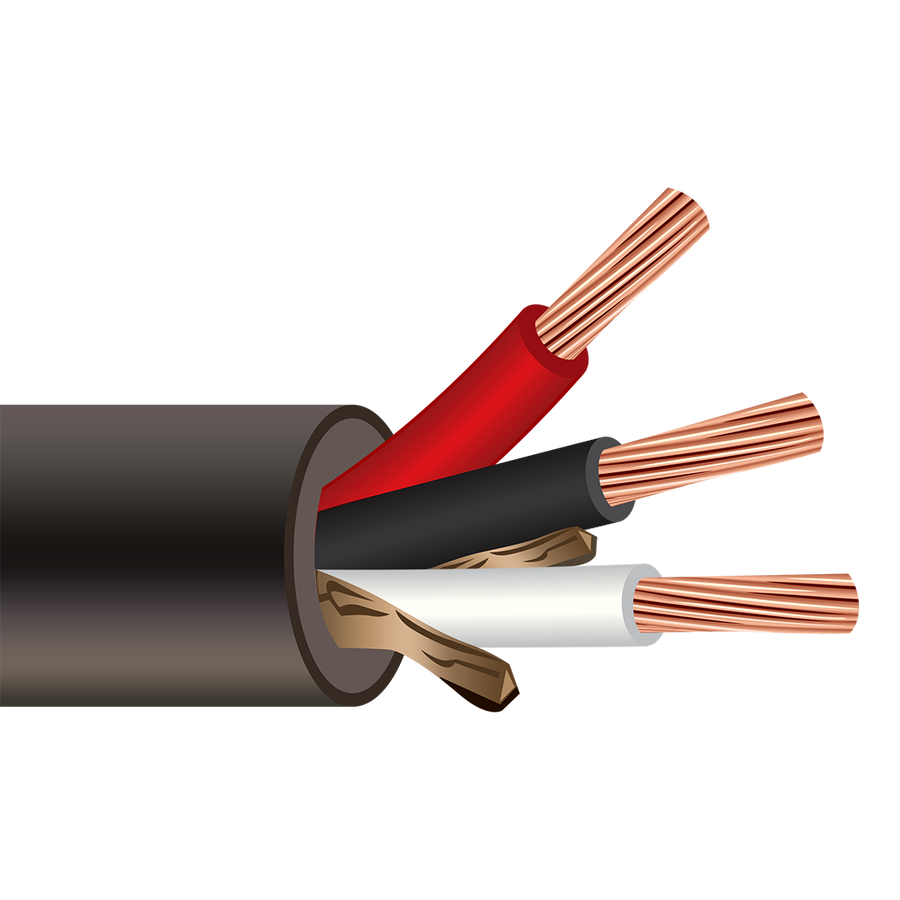

Rubber cables are a critical component in marine electrical systems, playing a pivotal role in ensuring the safety, reliability, and operational efficiency of vessels. These cables are specifically engineered to withstand the harsh conditions encountered in marine environments, including exposure to saltwater, extreme temperatures, vibration, and mechanical stress. Unlike standard PVC-insulated cables, rubber cables offer superior flexibility, UV resistance, and flame retardancy, making them ideal for use in engine rooms, navigation systems, lighting circuits, and deck machinery. Their ability to maintain electrical integrity under dynamic conditions directly contributes to the prevention of electrical failures, short circuits, and potential fire hazards—key concerns in maritime safety protocols.

The International Maritime Organization (IMO) and classification societies such as Lloyd’s Register, DNV, and ABS mandate the use of cables that meet stringent performance standards, particularly in fire safety and smoke emission. Rubber cables, especially those made from Ethylene Propylene Diene Monomer (EPDM) or Silicone Rubber, comply with these requirements by offering low smoke zero halogen (LSZH) properties and high resistance to oil and chemicals. This compliance is not merely regulatory—it is a fundamental aspect of crew safety and vessel survivability in emergency scenarios.

In commercial shipping, offshore platforms, and naval operations, uninterrupted power transmission is essential. Rubber cables ensure consistent performance even in confined or moving spaces due to their high flexibility and abrasion resistance. Their durability reduces maintenance frequency and replacement costs, contributing to lower lifecycle expenses for shipowners and operators. Given the increasing focus on energy efficiency and system integration in modern vessels, the selection of high-performance cabling is no longer a peripheral concern but a core element of marine system design.

Why Source Rubber Cables from Hangzhou Star Marine Technology Co., Ltd.?

Hangzhou Star Marine Technology Co., Ltd. provides a cost-effective and technically reliable solution for global marine outfitters and shipbuilders seeking high-quality rubber cables. Based in China, the company leverages advanced manufacturing capabilities, strict quality control systems, and economies of scale to deliver products that meet international standards at competitive prices. All rubber cables produced by Star Marine are certified to IEC 60092, IMO FTP Code, and other relevant marine specifications, ensuring seamless integration into global vessel construction and repair projects.

The following table outlines key performance characteristics of Star Marine’s standard rubber cable offerings:

| Parameter | Specification |

|---|---|

| Conductor Material | Tinned copper, stranded |

| Insulation Material | EPDM or Silicone Rubber |

| Voltage Rating | 0.6/1 kV |

| Temperature Range | -40°C to +90°C |

| Flame Resistance | IEC 60332-1-2, IEC 60332-3 (Category A) |

| Smoke Emission | IEC 61034 (Low Smoke Zero Halogen) |

| Oil Resistance | Compliant with IEC 60811-404 |

| Certification Standards | DNV-GL, ABS, LR, CCS, BV, RINA |

By sourcing rubber cables from Hangzhou Star Marine Technology, international clients gain access to technically compliant, durable, and competitively priced marine electrical solutions, backed by responsive export logistics and technical support. This strategic advantage supports timely project execution and long-term operational safety at sea.

Technical Specs & Approval

Technical Specifications: Marine Rubber Cables

Hangzhou Star Marine Technology Co. Ltd. manufactures premium rubber cables engineered for demanding marine and offshore environments. Our cables comply with IEC 60092-350/351/353 standards and SOLAS regulations, ensuring operational safety, longevity, and regulatory adherence. Constructed with high-purity copper conductors and advanced rubber compounds, these cables deliver exceptional flexibility, oil resistance, and flame retardancy. Critical applications include shipboard power distribution, deck machinery, and subsea equipment where dynamic movement and exposure to seawater, chemicals, and extreme temperatures are routine. All products undergo rigorous factory acceptance testing, including cold bend verification at -25°C and flame propagation trials per IEC 60332-3.

Key technical parameters are detailed in the table below. Conductor stranding adheres to Class 5 flexibility standards (IEC 60228), while the seamless extruded sheath integrates halogen-free, low-smoke (HFFR) rubber for enhanced safety in confined vessel spaces. Armor options—galvanized steel wire (GSWA) or aluminum wire (AWA)—provide mechanical protection and tensile strength for拖曳 or subsea deployment. Watertight integrity is validated through 10,000-cycle flexing tests submerged at 3 meters depth, maintaining IP68 rating (IEC 60529) without degradation. Dimensional tolerances strictly follow IEC 60092-354, with outer diameter deviations controlled within ±0.1 mm for precise conduit compatibility.

| Parameter | Specification | Standard/Notes |

|---|---|---|

| Conductor Material | Annealed Copper (OFC), Class 5 Stranding | IEC 60228; Min. 100% IACS conductivity |

| Insulation Material | EPR (Ethylene Propylene Rubber) | Oil/Acid/Alkali resistant; -40°C to +90°C |

| Sheath Material | HFFR Rubber (Halogen-Free) | Flame retardant; Low smoke density (IEC 61034) |

| Voltage Rating | 0.6/1 kV (U₀/U) | Max. 1.2 kV DC for testing |

| Armor Type | Optional GSWA or AWA | Galvanized Steel/Aluminum Wire; 28-32 wires/mm² |

| Water Resistance | IP68 (10,000 cycles at 3m depth) | IEC 60529; No leakage after 24h submersion |

| Outer Diameter Tolerance | ±0.1 mm (for diameters ≤50 mm) | IEC 60092-354; Measured at 20°C |

| Packing | Wooden Drums (ID 600-1200 mm); Max. 5 km/drum | Marked with Lot No., Length, Compliance Labels |

Watertightness is achieved through triple-layer construction: conductor stranding with rubber bedding, extruded insulation, and a seamless outer sheath. Armor layers (where specified) are helically applied with overlapping tape to prevent water ingress under pressure. Dimensional consistency is maintained via laser-guided extrusion, ensuring minimal ovality (<3%) and roundness for reliable gland sealing. Cables are supplied in continuous lengths per ISO 2807, with custom cutting tolerances of ±0.5%. All batches include traceable mill certificates verifying material composition and test results.

Hangzhou Star Marine Technology prioritizes export compliance through dual certification (DNV-GL and CCS) and pre-shipment inspections per INCOTERMS 2020. Our rubber cables are optimized for global maritime operations, balancing mechanical robustness with installation efficiency. Technical documentation, including 3.1 material test reports and SOLAS compliance statements, accompanies every shipment to streamline customs clearance and vessel integration. For project-specific requirements, our engineering team provides customized cross-sectional designs and salt-spray validation data.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine outfittings solutions tailored to the demanding requirements of shipbuilding and repair operations worldwide. As a trusted supplier in the maritime industry, we specialize in high-performance rubber cables engineered for durability, flexibility, and resistance to harsh marine environments. Our technical expertise and streamlined logistics ensure that shipyards and repair facilities receive the right products on time, minimizing downtime and supporting efficient project execution.

Rubber cables are critical components in marine electrical systems, providing reliable power transmission across decks, engine rooms, cranes, winches, and shore power connections. At Star Marine, we supply a full range of rubber-insulated and sheathed cables compliant with international standards such as IEC 60092, ICEA, and IEEE 45. These cables are designed to withstand oil, water, UV exposure, extreme temperatures, and continuous flexing—making them ideal for both new vessel construction and retrofitting during dry-dock repairs.

Our approach integrates technical consultation, product selection, and rapid delivery to meet tight shipbuilding schedules. With an in-depth understanding of marine electrical systems, our engineering team collaborates directly with naval architects, shipbuilders, and classification societies to ensure compatibility and regulatory compliance. Whether supplying cables for propulsion systems, lighting circuits, or deck machinery, we provide customized solutions that align with project specifications and operational demands.

For repair and maintenance projects, fast response is essential. Star Marine maintains strategic inventory levels of standard and high-demand rubber cable types at our Hangzhou facility, enabling same-day dispatch for urgent orders. Our global logistics network supports air and sea freight options, ensuring timely delivery to major shipyards across Asia, the Middle East, Europe, and the Americas.

The following table outlines key rubber cable types we supply for marine applications:

| Cable Type | Application | Standard | Conductor Size Range | Key Features |

|---|---|---|---|---|

| YH/YHF | Shipboard Power Distribution | IEC 60092-304 | 1.5 – 300 mm² | Oil-resistant, flexible, flame-retardant |

| NHXCH | Emergency Circuits, Safety Systems | IEC 60092-304 | 1.5 – 240 mm² | Fire-resistant, low smoke halogen-free |

| YGHR | Mobile Equipment, Cranes | ICEA T-27-547 | 6 – 185 mm² | Heavy-duty, abrasion-resistant, weatherproof |

| U1000R2R2S | Shore Connection Cables | HD 22.11 | 25 – 400 mm² | High mechanical strength, UV and ozone resistant |

All cables undergo rigorous quality control, including voltage withstand testing, insulation resistance checks, and environmental aging tests. Certifications from CCS, DNV, LR, ABS, and BV are available upon request.

Star Marine is committed to being a responsive, technically proficient partner in marine outfittings. By combining high-quality rubber cables with engineering support and rapid delivery, we empower shipbuilders and repair yards to maintain productivity, ensure safety, and meet project deadlines with confidence.

Packaging & Logistics

Packaging & Logistics for Marine Rubber Cables

Proper packaging and logistics execution are critical for ensuring marine rubber cables arrive at destination ports in operational condition, meeting stringent maritime environmental and handling demands. At Hangzhou Star Marine Technology, we implement internationally compliant packaging protocols designed to withstand ocean transit stresses, including vibration, humidity, salt exposure, and multi-modal handling. All shipments originate from our primary export hubs at Ningbo-Zhoushan Port (world’s busiest container port) and Shanghai Port, leveraging optimized maritime routes and customs clearance efficiency.

Wooden Crate Specifications

Heavy-duty marine rubber cables (typically reels ≥500 kg) are secured within ISPM 15 certified wooden crates. These crates utilize heat-treated (HT) softwood, free from bark and pests, with mandatory ISPM 15 branding on all wooden components. Internal bracing prevents reel movement, while moisture-resistant polyethylene wrapping and silica gel desiccants mitigate humidity ingress. Crates feature integrated lifting points for safe port crane operations and are palletized for forklift handling. This method ensures structural integrity during stacking up to 3 tiers in container holds or on deck storage.

Steel Pallet Solutions

For lighter cable reels (≤500 kg) or cut-to-length coils, we deploy reusable galvanized steel pallets. These pallets feature welded cross-beams, non-slip surfaces, and corner protectors to prevent cable deformation. Steel pallets eliminate phytosanitary risks associated with wood, streamlining customs processes in ISPM 15-restricted regions. Each pallet is secured with steel strapping and weatherproof stretch film, with individual reels labeled per IMO marking standards. Steel pallets are stackable to 4 tiers in dry containers, maximizing cargo space utilization.

The following table details key packaging parameters for standard cable configurations:

| Packaging Type | Max Reel Weight | External Dimensions (L×W×H) | Stack Height | Container Fit (40ft HC) | ISPM 15 Required |

|---|---|---|---|---|---|

| Wooden Crate | 3,000 kg | 1,800×1,500×1,600 mm | 3 tiers | 8 crates | Yes |

| Steel Pallet | 500 kg | 1,200×1,000×1,400 mm | 4 tiers | 24 pallets | No |

All shipments undergo pre-shipment verification per ISO 11607 standards, with load distribution calculations provided to carriers. Ningbo and Shanghai port operations utilize our certified logistics partners for seamless yard-to-vessel coordination, adhering to CIC (Container Inspection Clause) guidelines. Documentation includes ISPM 15 certificates for wooden packaging, non-wood declarations for steel pallets, and detailed stowage plans. We coordinate with vessel operators to ensure cables are segregated from corrosive or temperature-sensitive cargo, with humidity-controlled containers deployed for extended voyages. This integrated approach guarantees compliance with SOLAS cargo securing requirements while minimizing transit damage risks for global marine outfitters.

Contact Star Marine

For marine outfittings that demand reliability, durability, and compliance with international maritime standards, Hangzhou Star Marine Technology Co., Ltd. stands at the forefront of innovation and quality. As a trusted manufacturer and exporter specializing in marine-grade rubber cables, we understand the rigorous demands of marine environments—where moisture, salt exposure, mechanical stress, and fluctuating temperatures can compromise inferior materials. Our rubber cables are engineered to exceed these challenges, delivering uninterrupted performance across a wide range of maritime applications, including vessel power distribution, deck machinery, lighting systems, and onboard auxiliary equipment.

At Hangzhou Star Marine Technology, we manufacture rubber cables using high-purity, oil-resistant synthetic rubber compounds that ensure superior flexibility, abrasion resistance, and long-term insulation integrity. Each cable undergoes stringent quality control procedures in alignment with IEC 60092 standards, guaranteeing compliance with classification societies such as CCS, ABS, DNV, LR, and BV. Our production facility integrates advanced extrusion and vulcanization technologies, enabling us to deliver cables in various conductor configurations, voltage ratings, and shielding options tailored to customer specifications.

We recognize that every marine project has unique requirements. Whether you are outfitting a newbuild vessel, retrofitting an existing fleet, or sourcing cables for offshore platforms, our engineering team works closely with clients to provide customized solutions. From determining the optimal cross-sectional area and stranding configuration to selecting flame-retardant or low-smoke zero-halogen (LSZH) sheathing, we ensure technical precision and regulatory compliance at every stage.

To streamline your procurement process and ensure timely delivery, we maintain extensive inventory levels and offer flexible packaging and labeling options for international shipping. Our export logistics network supports seamless delivery to major maritime hubs worldwide, backed by comprehensive documentation including certificates of origin, test reports, and marine product certifications.

Partnering with Hangzhou Star Marine Technology means gaining access to not only premium marine cables but also expert technical support and responsive customer service. We are committed to building long-term relationships based on trust, performance, and mutual success in the global maritime industry.

For technical inquiries, custom quotations, or product specifications, please contact our Product Manager, Kacher YE, directly at [email protected]. We respond to all inquiries within 24 hours during business days and are available for virtual consultations to discuss your project requirements in detail.

Below is an overview of our standard rubber cable specifications for reference:

| Parameter | Specification |

|---|---|

| Standard | IEC 60092-351 / IEC 60092-353 |

| Conductor Material | Tinned copper, Class 5 stranded |

| Insulation Material | EPR or SIR (Ethylene Propylene Rubber / Silicone Rubber) |

| Sheath Material | Chloroprene rubber (CR) or CSM |

| Voltage Rating | 300/500 V, 450/750 V, 0.6/1 kV |

| Temperature Range | -25°C to +90°C (operational) |

| Flame Resistance | IEC 60332-1-2 (Single cable) |

| Smoke Density | IEC 61034-2 (Low smoke versions available) |

| Oil Resistance | Yes, per IEC 60811-404 |

Contact Kacher YE today to ensure your marine cabling solution meets the highest standards of safety, efficiency, and performance.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160